Casting-curing insensitive high-explosion-heat explosive and preparation method thereof

A solidified and insensitive technology, which is applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive composition, etc., can solve the problems of weak research on aluminum-containing casting PBX, achieve good viability, improve casting quality, The effect of high workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

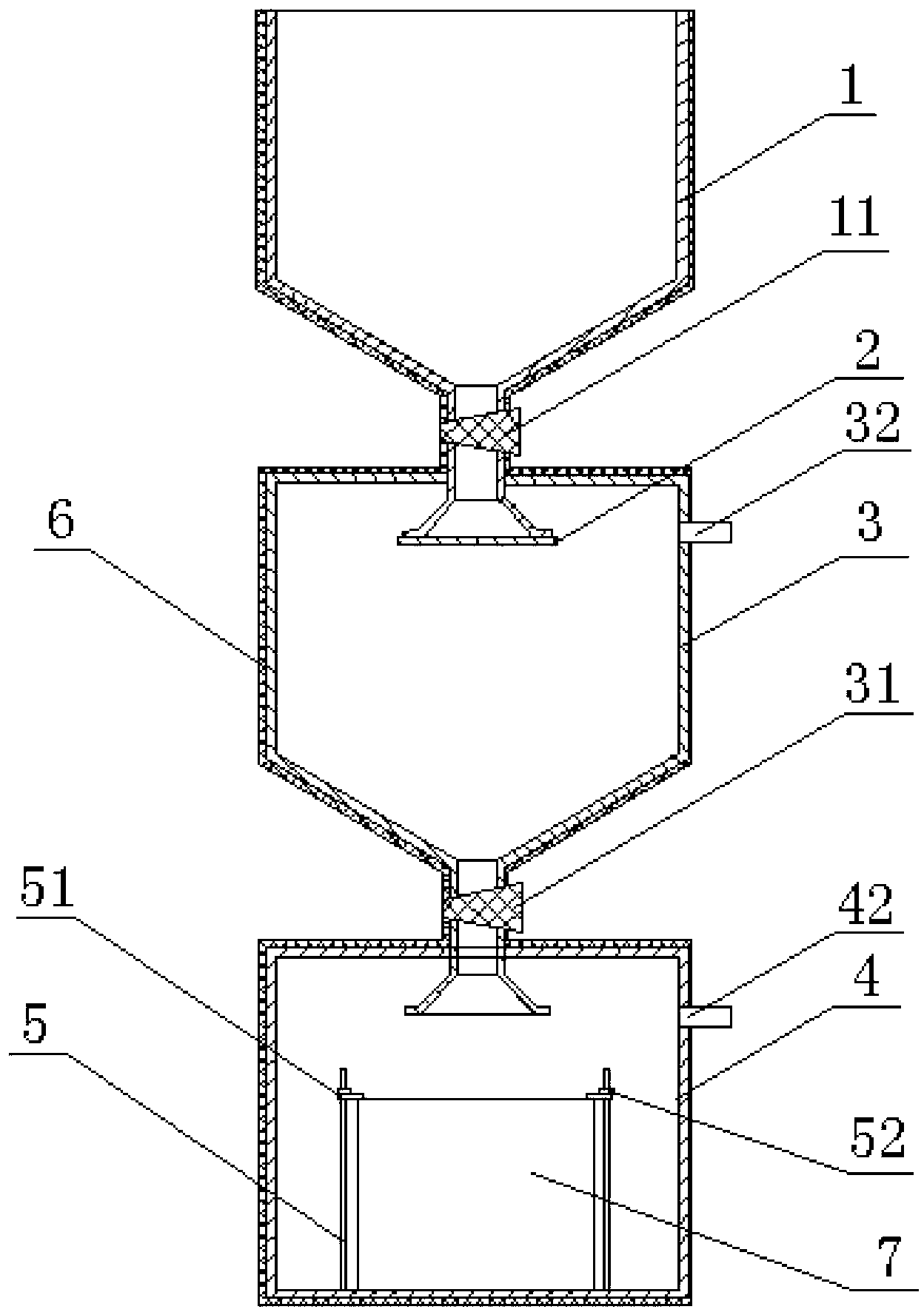

Method used

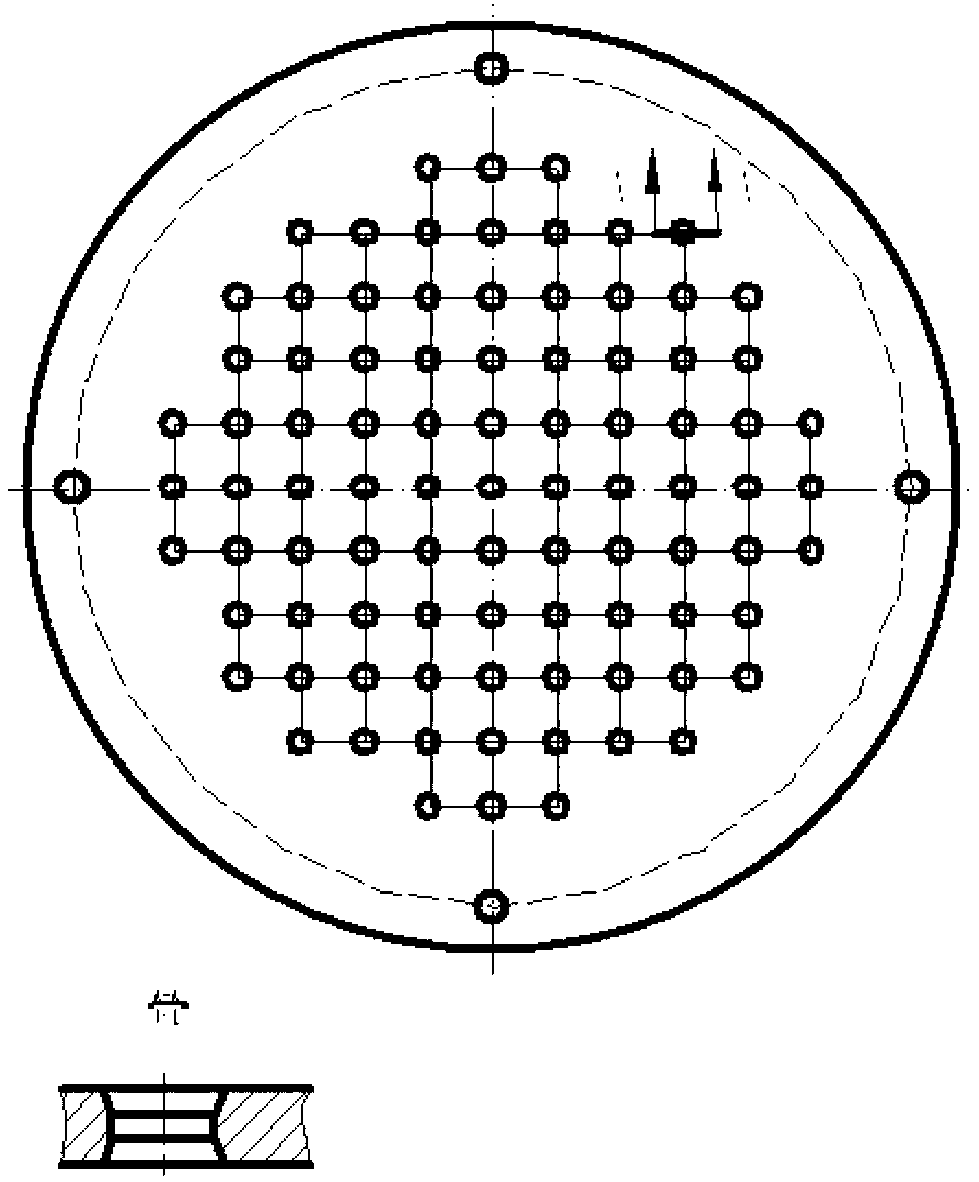

Image

Examples

Embodiment 1

[0034] A cast solidified insensitive high-explosive thermal explosive, the formula of which consists of: RDX: 65 parts, Al: 21.5 parts, HTPB: 7 parts, WAX: 2.85 parts, DOS: 3.11 parts, TDI: 0.54 parts.

[0035] The coarse and fine particle gradation adopted by RDX is as follows: coarse particles with a particle size ranging from 0.250 mm to 0.420 mm account for 61.5% of the mass of RDX, fine particles with a particle size of ≤0.05 mm account for 38.5% of the mass of RDX, and the particle size of the fine particles is ≤0.05 The particle content of mm is not less than 97% of the amount of fine particles; the particle size of fuel aluminum powder ranges from 0.005mm to 0.05mm.

[0036] The preparation method of the pouring solidification type insensitive high-explosive thermal explosive mainly comprises the following steps:

[0037] (1) Ingredients: Quantitatively weigh each component in the formula and set aside;

[0038] (2) Mix materials by feeding in batches and kneading: th...

Embodiment 2

[0060] A cast solidified insensitive high-explosive thermal explosive, the formula of which consists of: RDX: 65 parts, Al: 21.5 parts, HTPB: 7 parts, WAX: 2.85 parts, DOS: 3.11 parts, TDI: 0.54 parts.

[0061] The coarse and fine particle gradation adopted by RDX is as follows: coarse particles with a particle size range of 0.250 mm to 0.420 mm account for 64.6% of the mass of RDX, fine particles with a particle size of ≤0.05 mm account for 35.4% of the mass of RDX, and the particle size of the fine particles is ≤0.05 The particle content of mm is not less than 97% of the amount of fine particles; the particle size of fuel aluminum powder ranges from 0.005mm to 0.05mm.

[0062] The preparation method and the vacuum pouring device used are the same as in Example 1.

Embodiment 3

[0064] A cast solidified insensitive high-explosive thermal explosive, the formulation of which consists of: RDX: 65 parts, Al: 21.5 parts, HTPB: 6.85 parts, WAX: 3 parts, DOS: 3 parts, TDI: 0.65 parts.

[0065] The coarse and fine particle gradation adopted by RDX is as follows: coarse particles with a particle size range of 0.250 mm to 0.420 mm account for 64.6% of the mass of RDX, fine particles with a particle size of ≤0.05 mm account for 35.4% of the mass of RDX, and the particle size of the fine particles is ≤0.05 The particle content of mm is not less than 97% of the amount of fine particles; the particle size of fuel aluminum powder ranges from 0.005mm to 0.05mm.

[0066] The preparation method and the vacuum pouring device used are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com