Foaming method

A foaming mold and injection foaming technology, which is applied in the foaming field, can solve the problems of slow foam flow and poor thermal insulation performance of the foamed layer, and achieve the effects of improving production efficiency, good thermal insulation effect, and fine and uniform cell diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

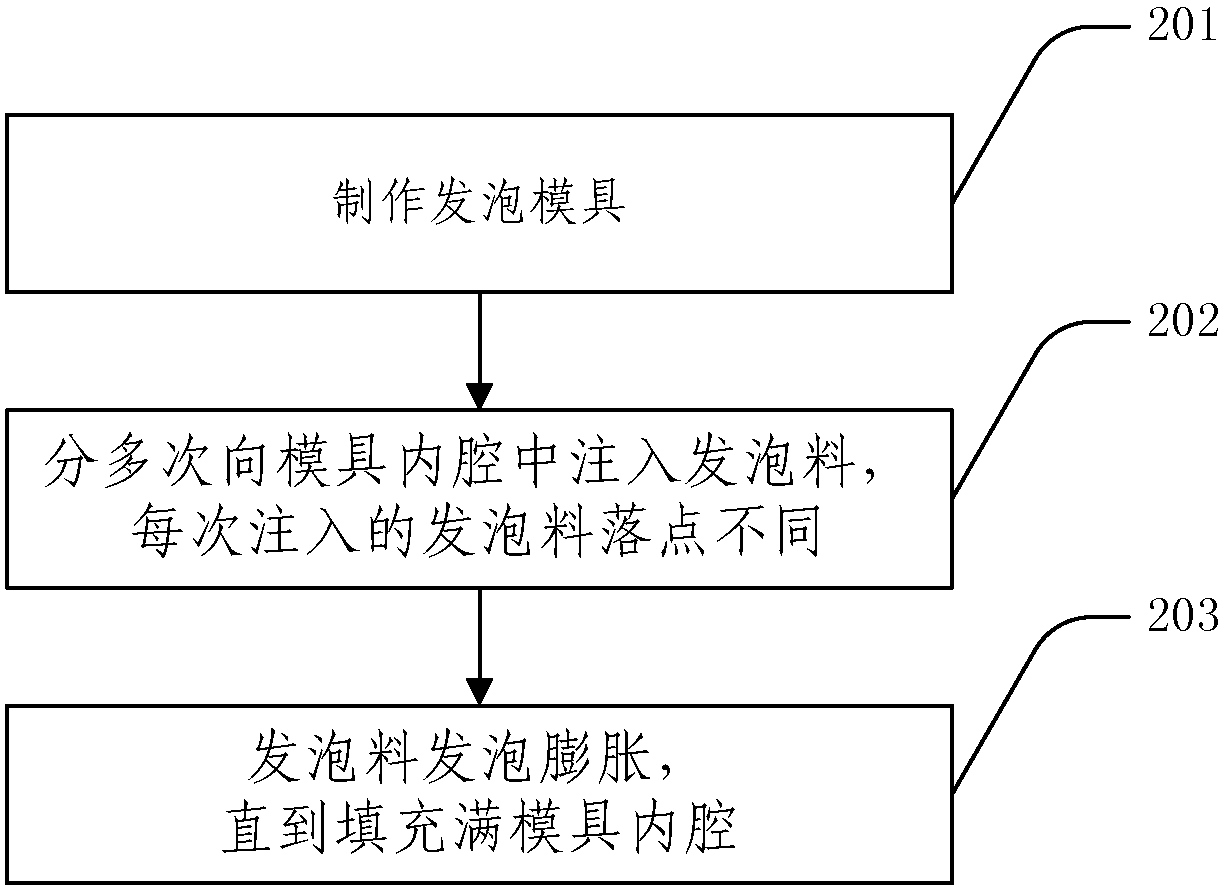

[0029] Such as figure 2 Shown, foaming method of the present invention comprises the following steps:

[0030] Step 201: making a foaming mold;

[0031] Step 202: Inject the foaming material into the inner cavity of the mold several times, and each injection of the foaming material has a different falling point;

[0032] Step 203: The foaming material expands until it fills the inner cavity of the mold.

[0033] Among them, the following methods can be used to inject the foaming material into the inner cavity of the mold in multiple times:

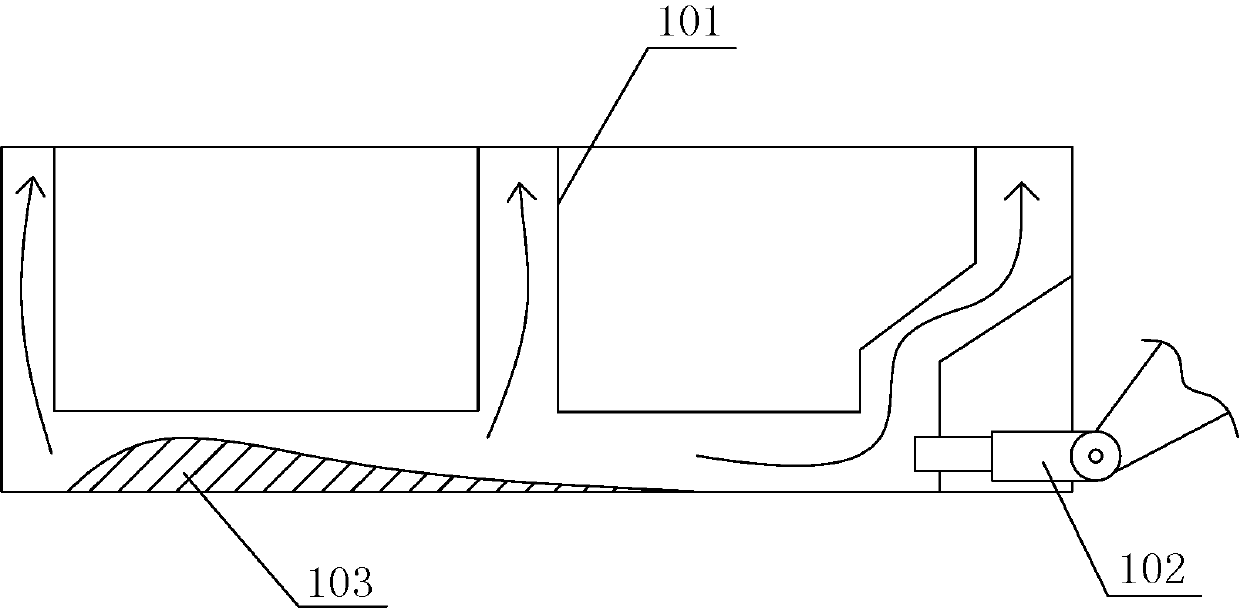

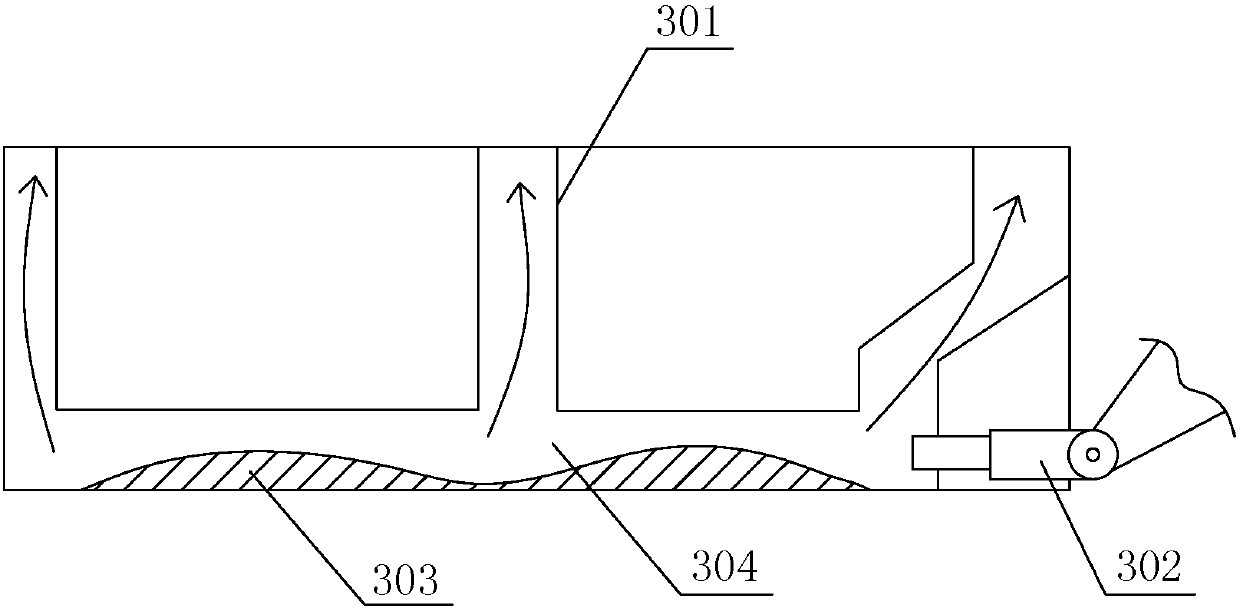

[0034] Such as image 3 As shown, the frequency conversion gun head 302 is used to inject the foaming material 303 into the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com