Method for delivering faster a short coffee extract from capsule

A coffee extraction and capsule technology, which is used in the field of distributing small cups of coffee extracts from capsules quickly, can solve the problems of poor aroma distribution, low coffee solids concentration, etc., to reduce flow time, reduce pressure loss, Improving the effect of quality attributes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0080] Example 1. Grinding Technique

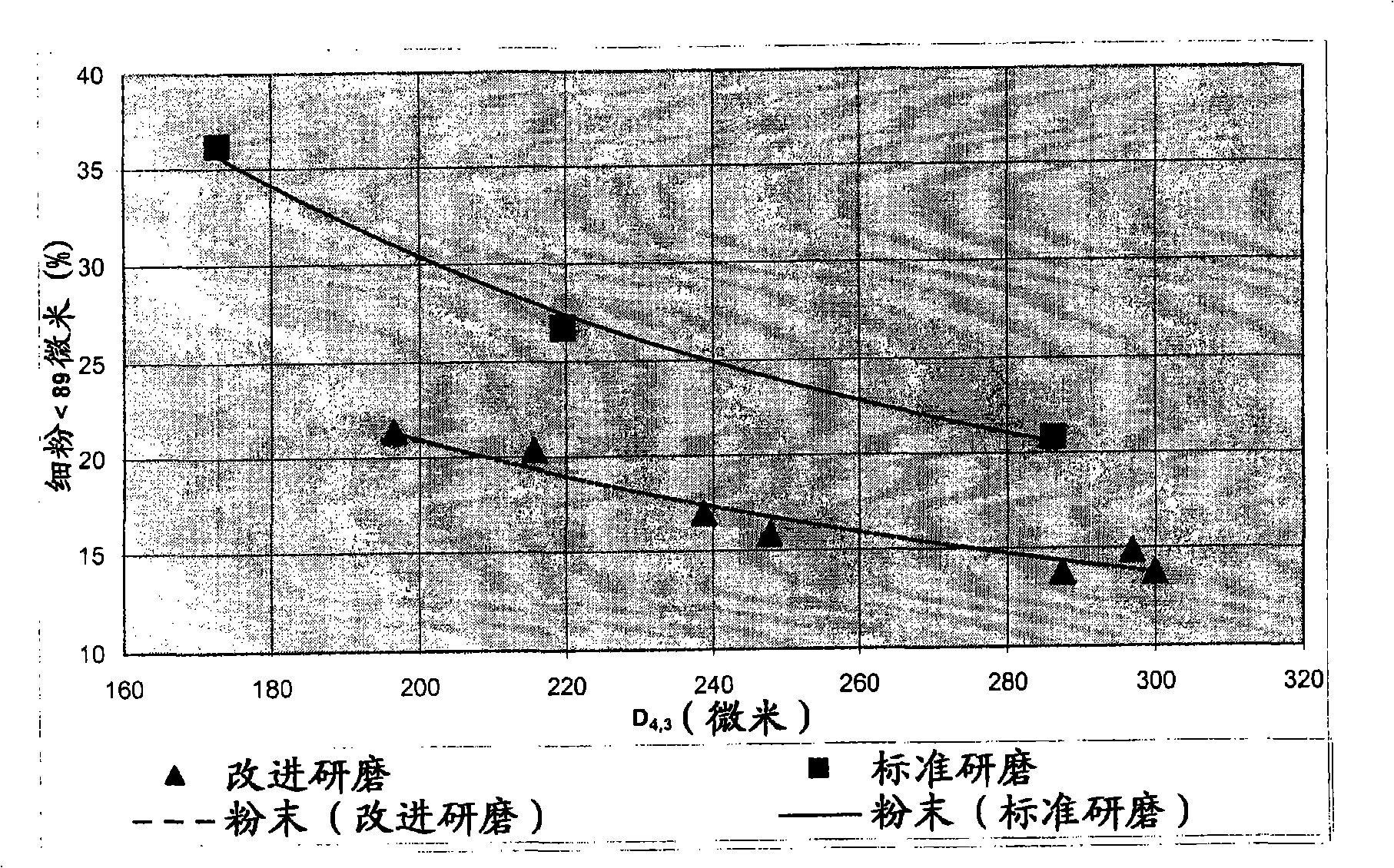

[0081] figure 1 The curves in show the average diameter D when considering different grinding techniques 4,3 The relationship between the percentage of fine powder.

[0082] The curve "Standard Grind" was obtained by grinding coffee beans at different average particle sizes using a standard grinding technique utilizing only axial corrugated rollers.

[0083] The curve "improved grind" was obtained by grinding coffee beans at different average particle sizes using a grinding technique utilizing 10 corrugated rollers on five first stages and two Six levels of smooth rollers.

[0084] As shown in the lower curve for improved grinding, the fines level can be reduced to values of approximately 21% for an average particle size of 199 microns, to values of approximately 19% for an average particle size of approximately 240 microns, and to values of approximately 19% for an average particle size of 299 microns The average particle siz...

example 2

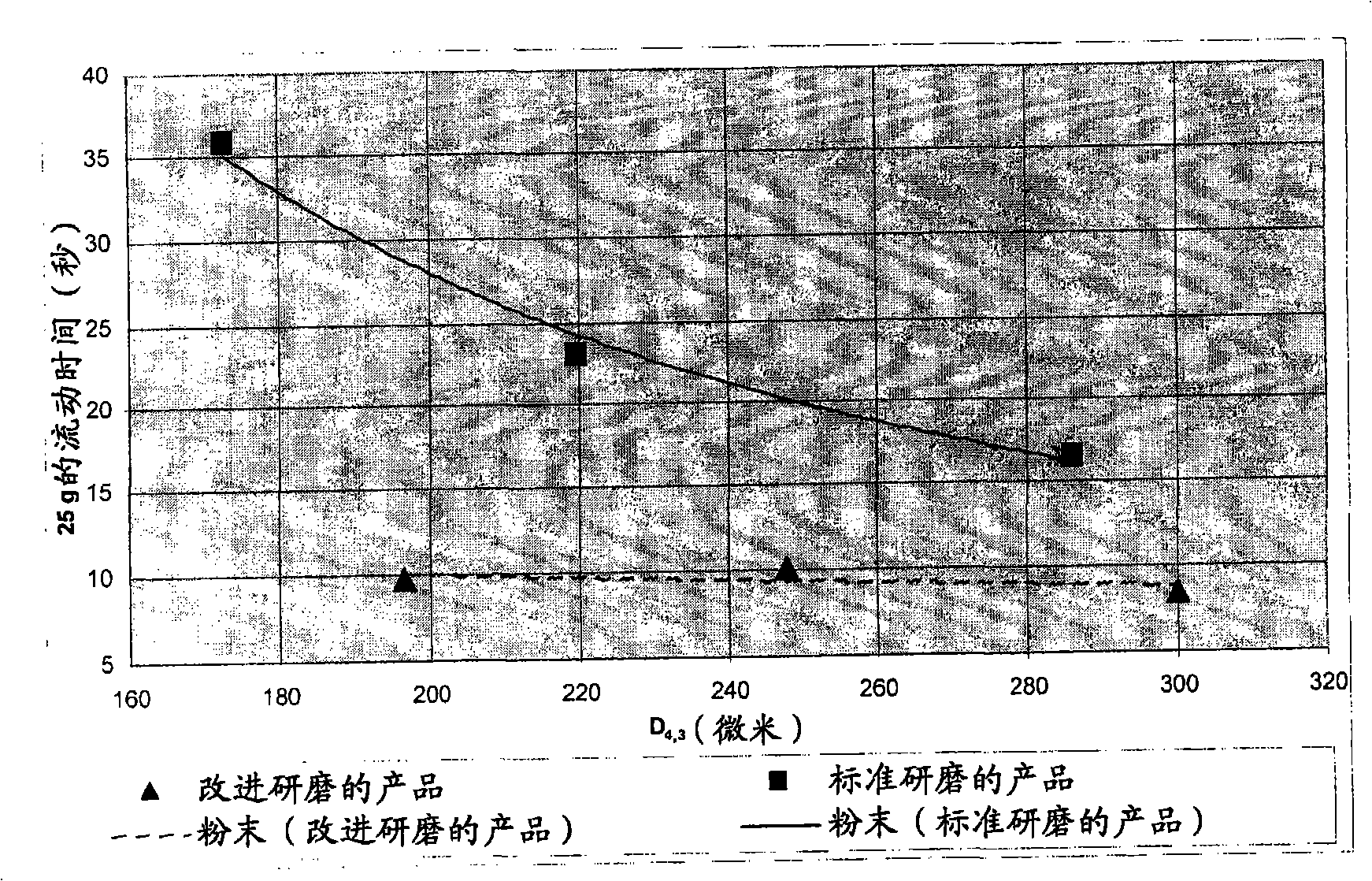

[0085] Example 2. Effect of particle size determination (average particle size / fines) on flow time:

[0086] figure 2 The curve of shows that, for the mixture with the reduced particle size obtained by the improved grinding and the standard mixture obtained by the standard grinding, the average particle size (D 4,3 ) on the flow time through the capsule. Surprisingly, in the range of 200-300 microns, the flow time was approximately constant (approximately 10 seconds) for ground coffee with less fines, as opposed to standard coffee blends with conventional fines content. In general, the flow time of the coffee extract can be greatly reduced for coffee blends with reduced levels of fines.

example 3

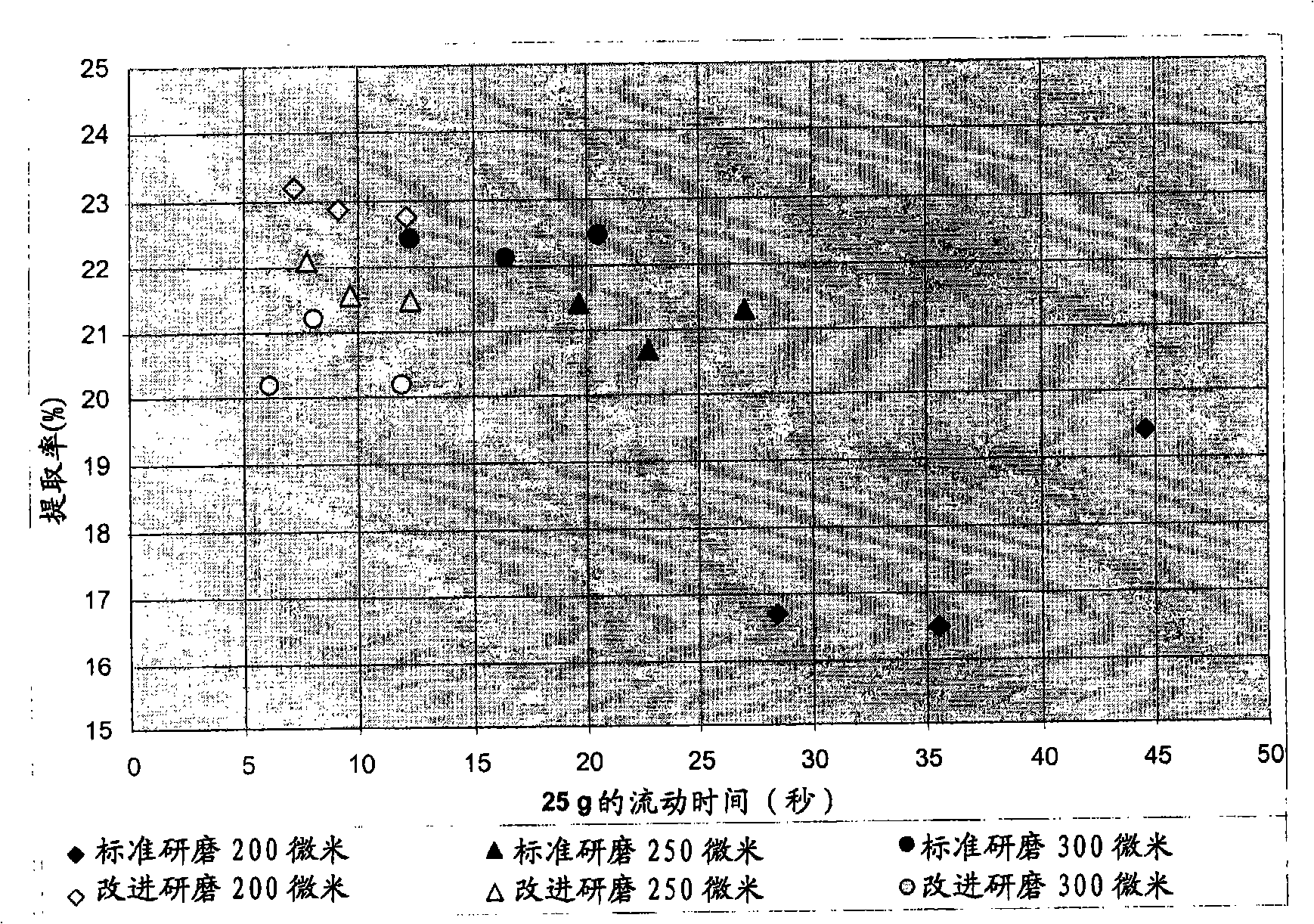

[0087] Example 3. Effect of flow time on extraction rate:

[0088] image 3 The curves in the figure show that, for three different average particle sizes of 200, 250 and 300 microns respectively, the delivery time of 25 grams of coffee extract using the capsules of the invention containing (improved) ground coffee with reduced fines content Effect of flow time on extraction rate. For the same average particle size, the capsules of the invention were compared with capsules containing ground coffee with a conventional fines content ("standard"). The extraction yield of the resulting coffee extract was calculated according to the procedure illustrated in Example 9. Surprisingly, the results showed that the improved blend with reduced fines levels provided much less flow time compared to the standard blend, while the extraction rate remained within the desired range. All mixtures of the invention in the 200-300 micron range had a flow time well below 15 seconds for dispensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com