Method for preparing high-fluidity silica mortar

A high fluidity, silica mortar technology, applied in the application field of civil engineering materials, can solve the problems of inducing human diseases, carcinogenesis, and visibility reduction, etc., and achieve the effect of simple process and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

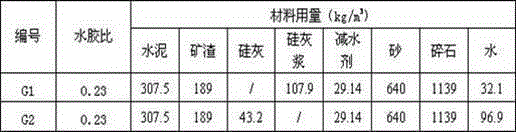

Embodiment 1

[0016] A preparation method for high fluidity silica mortar, comprising steps:

[0017] 1) Ingredients, the raw materials include 40% silica fume and 59.976% water by mass percentage, and sodium hexametaphosphate is used in this embodiment. As a dispersant, its mass is 0.06% of the mass of silica fume, that is, 0.024% of the mass of silica mortar;

[0018] 2) Put the prepared silica fume and dispersant in the silica mortar mixer;

[0019] 3) Slowly stir for 4-6 minutes while adding water to the mixer to prepare a silica mortar with a solid content of 40%.

Embodiment 2

[0021] A preparation method for high fluidity silica mortar, comprising steps:

[0022] 1) Ingredients, raw materials include 50% silica fume and 49.60% water by mass percentage, sodium hexametaphosphate is used in this embodiment. As a dispersant, its mass is 0.8% of the mass of silica fume, that is, 0.4% of the mass of silica mortar;

[0023] 2) Put the prepared silica fume and dispersant in the silica mortar mixer;

[0024] 3) Slowly stir for 4-6 minutes while adding water to the mixer to prepare a silica mortar with a solid content of 50%.

Embodiment 3

[0026] A preparation method for high fluidity silica mortar, comprising steps:

[0027] 1) Ingredients, the raw materials include 60% silica fume and 39.50% water by mass percentage, and sodium hexametaphosphate is used in this embodiment. As a dispersant, its mass is 0.83% of the mass of silica fume, that is, 0.5% of the mass of silica mortar;

[0028] 2) Put the prepared silica fume and dispersant in the silica mortar mixer;

[0029] 3) Add water to the mixer and stir slowly for 4-6 minutes to prepare a silica mortar with a solid content of 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com