Enhanced permeable medium

A diversion medium and enhanced technology, applied in textiles and papermaking, layered products, knitting, etc., can solve the problems of three-dimensional fabrics that are not suitable for the manufacture and processing of thin composite products, and achieve the purpose of overcoming wasteful shortcomings, improving uniformity, The effect of overcoming poor adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

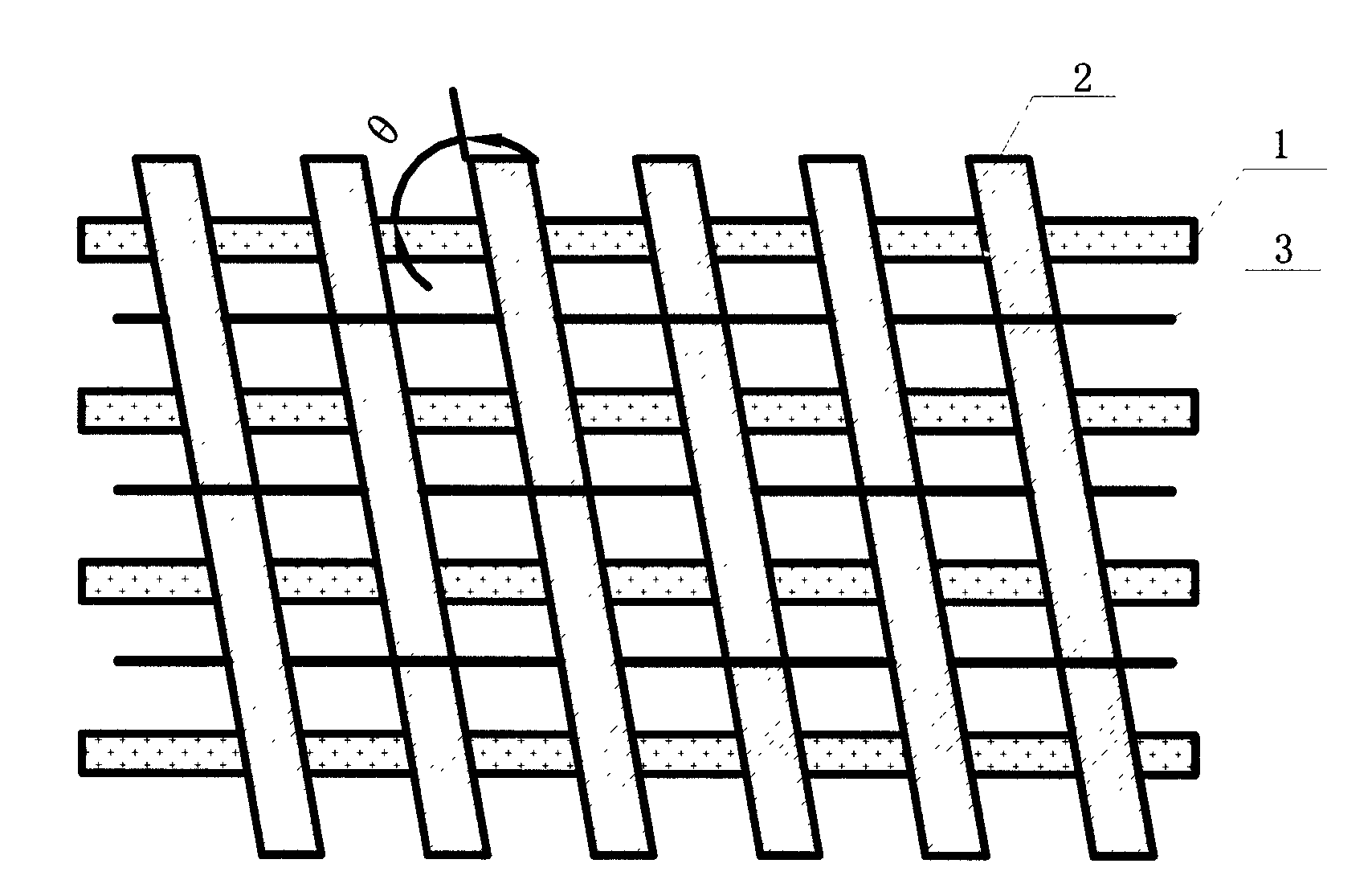

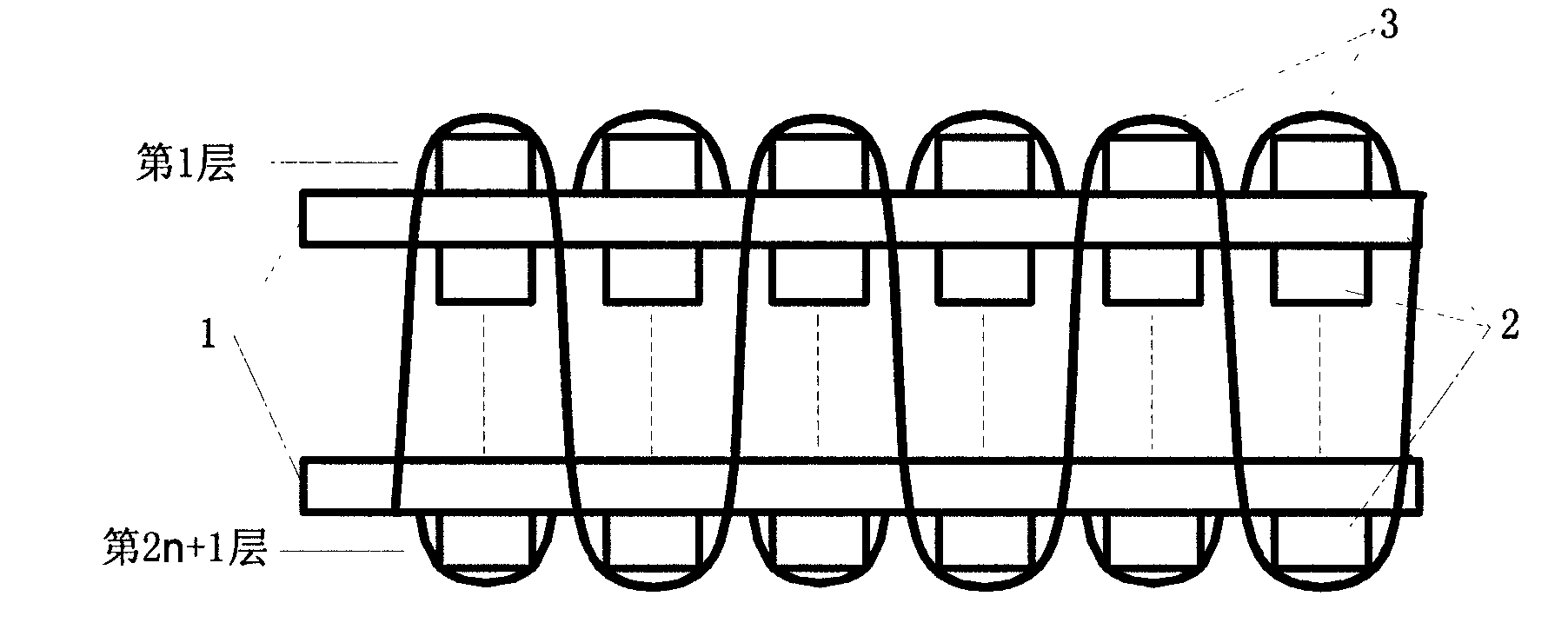

[0035] 1200tex alkali-resistant untwisted glass fiber roving and KEVLAR 49 aramid fiber yarn treated with a starch-based sizing agent and a silane coupling agent mixed sizing agent, mixed at a weight ratio of 1:1, bundled into a 0.2mm thick, 3mm wide Fiber bundles are used as yarn bundles for even layers; T-1000 glass fiber reinforced alumina fiber yarn and T300 (6K) carbon fiber yarn treated with starch-based sizing agent are mixed at a weight ratio of 2:1, and the thickness of the bundle is 0.4mm , The yarn bundle with a width of 1.5mm is used as the yarn bundle for odd layers; the yarn bundle obtained by 0.02mm×0.05mm is used as the yarn bundle for weaving by gathering the high modulus PBO fiber yarn of 1090dtex treated with a silane coupling agent.

[0036] Lay each layer of yarn bundles with the distance between odd and even layers of yarn bundles being 3mm, among which, there are 3 layers of odd layers and 2 layers of even layers, the angle between odd and even layers of ...

Embodiment 2

[0039]1000tex alkali-free untwisted glass fiber roving and T300 (3K) carbon fiber yarn treated with starch-based sizing agent mixed with sizing agent were mixed at a weight ratio of 2:1, and bundled into a fiber bundle with a thickness of 0.05mm and a width of 0.1mm as the first Yarn bundles for one layer; iron-chromium-aluminum alloy fiber yarns with a diameter of 12 μm and a core number of 1700 f and KEVLAR 49 aramid fiber yarns treated with a silane coupling agent, mixed at a weight ratio of 1:2, and bundled so that the thickness and width are both The yarn bundle of 0.1mm is used as the yarn bundle for the second layer; the KEVLAR 49 aramid fiber yarn treated with the silane coupling agent is bundled into a yarn bundle with a thickness of 0.08mm and a width of 0.1mm as the yarn bundle for the third layer; 45 polyester fiber yarns and 150D nylon fiber yarns treated with a silane coupling agent were mixed in a weight ratio of 1:1, and bundled to obtain a yarn bundle of 0.01 m...

Embodiment 3

[0043] Use 2000tex E-glass fiber yarn treated with starch-based sizing agent mixed with sizing agent, bundled into fiber yarn bundles with a thickness of 0.5mm and a width of 3mm as yarn bundles for even layers; KEVLAR 49 aramid fiber treated with a silane coupling agent The fiber yarn and the 400D nylon fiber yarn are mixed in a weight ratio of 3:1, and the yarn bundles with a thickness of 1 mm and a width of 3 mm are used as yarn bundles for odd layers; 0.1 mm× A yarn bundle of 0.5 mm was used as a yarn bundle for weaving.

[0044] The yarn bundles of the odd and even layers are placed at a distance of 5mm. Among them, 2 layers of the odd layer are used as the upper and lower layers, and 1 layer of the even layer is used as the center layer. The angle between the yarn bundles of the odd and even layers is 70°. The odd-numbered yarn bundles are flushed separately, and the yarn bundles for weaving are stitched along the direction parallel to the even-numbered yarn bundles to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com