Automatic assembling pressure-closing device for touch screen and control method thereof

A technology of lamination equipment and automatic assembly, applied in metal processing equipment, manufacturing tools, metal processing and other directions, can solve the problems of high production capacity requirements of production personnel, uneven gap between the touch screen and the shell, and low production efficiency of manual operation. , to achieve stable product quality control, eliminate the influence of high fluidity and proficiency, and improve production stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

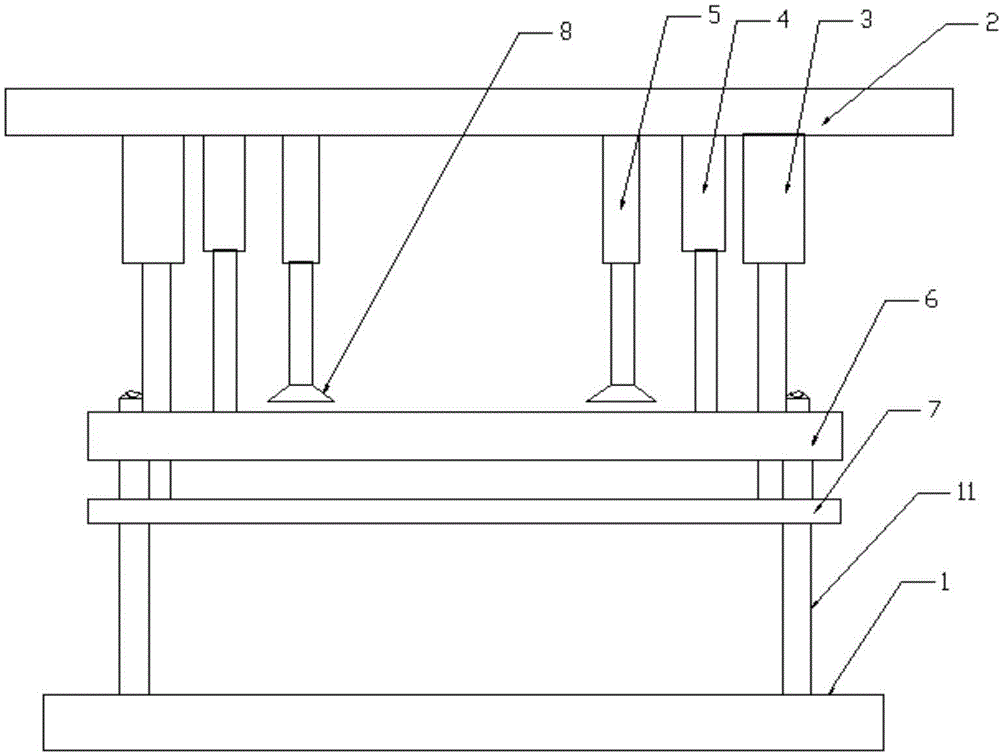

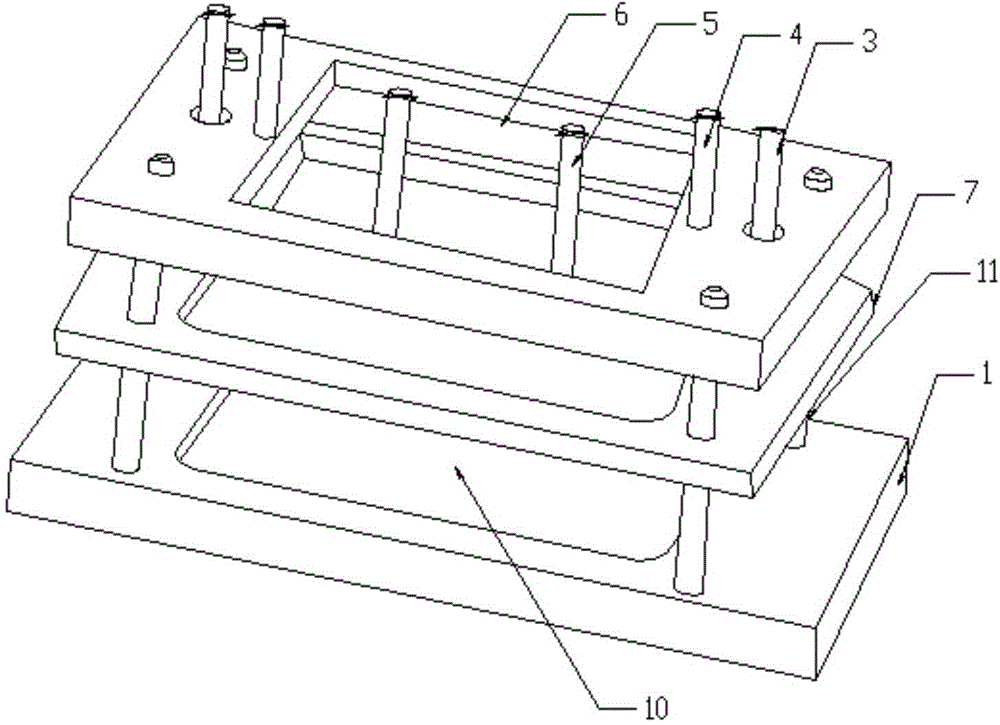

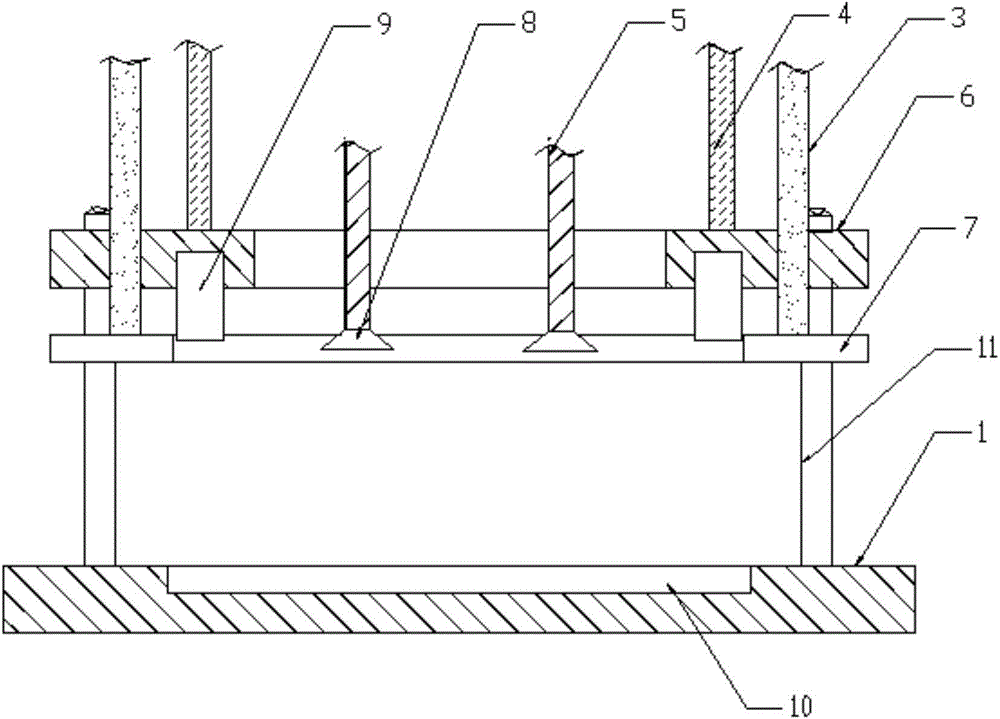

[0030] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] See attached figure 1 - attached image 3 , a touch screen automatic assembly and pressing equipment, including a base 1 and a cantilever 2 above the base 1, the base 1 is used to place the back cover of the product to be assembled, and the cantilever 2 is equipped with a first driving mechanism 3, a second Two driving mechanisms 4 and the third driving mechanism 5, the lower end of the first driving mechanism 3 is connected with a pressing plate 6, and the second driving mechanism 4 passes through the pressing plate 6 and is connected with the gap control plate 7, the gap control The plate 7 is used to place the gap control sheet between the back cover of the product to be assembled and the touch screen, the third drive mechanism 5 is connected to the suction cup 8, and the suction cup 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com