MBR flat membrane element

A flat membrane and element technology, applied in the field of MBR flat membrane elements, can solve the problems of water not easy to flow freely, poor mechanical stability, easy damage, etc., and achieve the effects of increasing water flux, reducing weight, and reducing preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

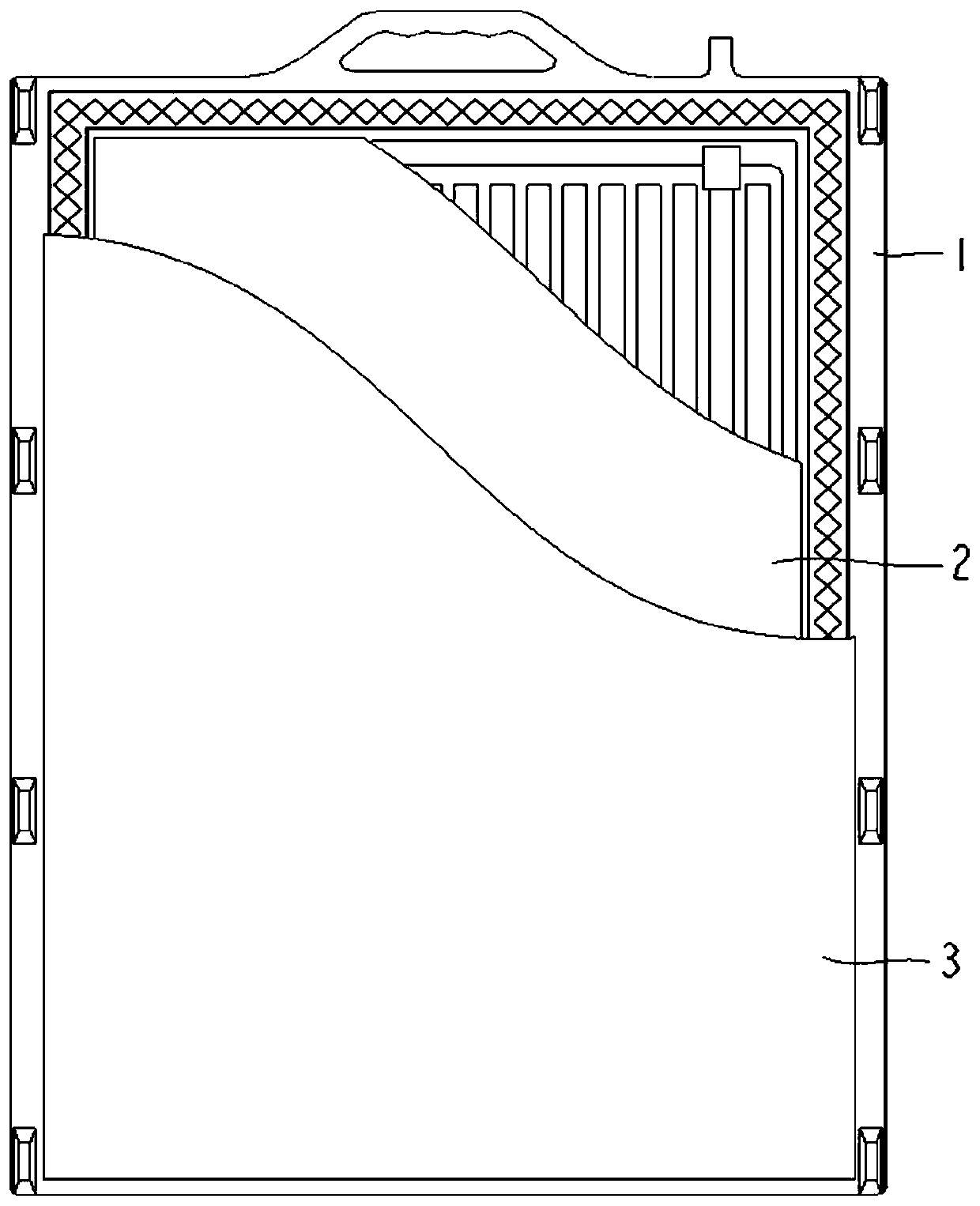

[0026] A kind of MBR flat membrane element, as attached figure 1 As shown, including support plate 1, guide cloth 2, filter membrane 3, guide cloth 2 is spot-welded on both sides of support plate 1; filter membrane 3 is on the outer surface of guide cloth 2 on both sides, filter membrane The sheet 3 is welded on the outer frame of the support plate 1 and forms a sealing structure of the inner membrane cavity with the two sides of the support plate 1 .

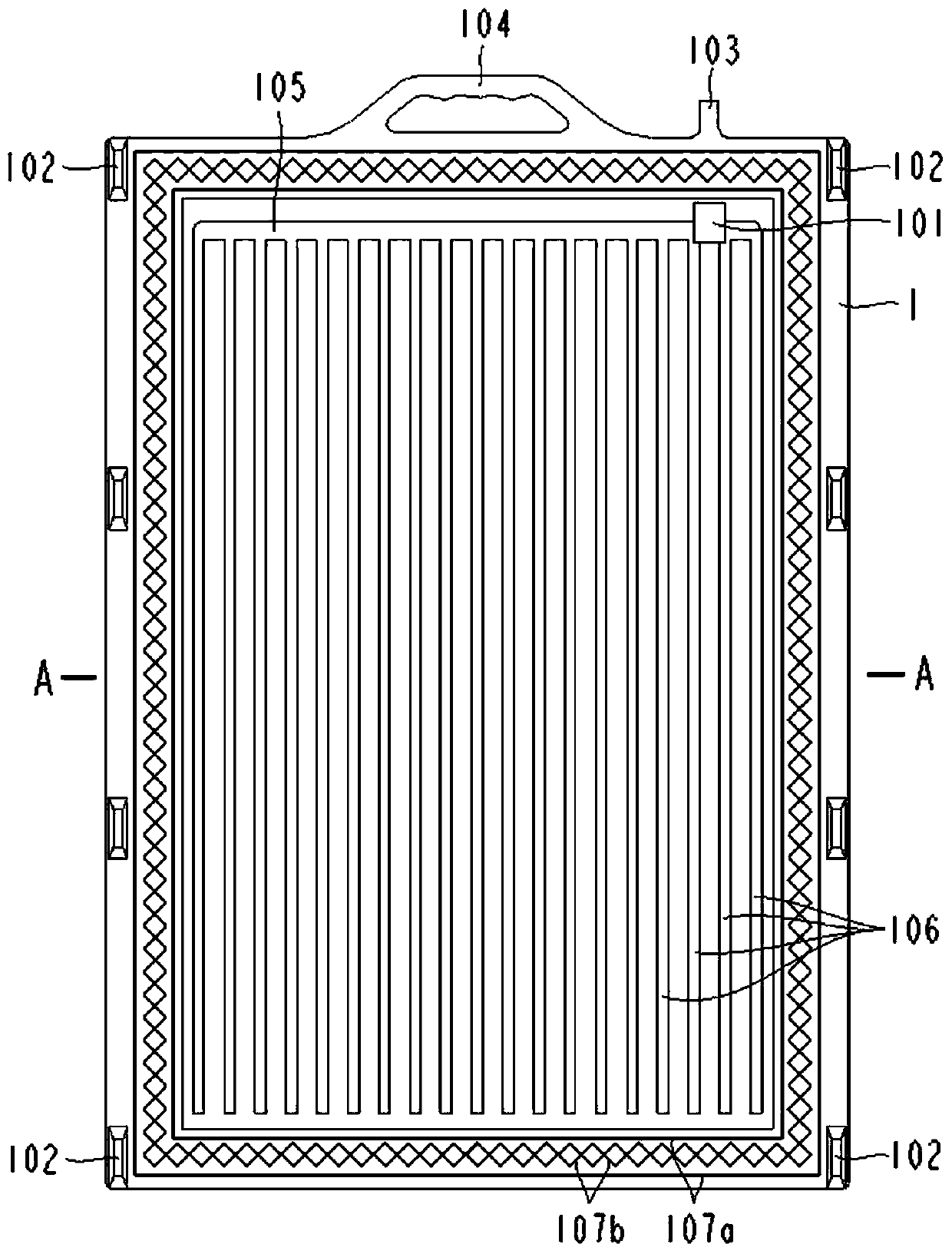

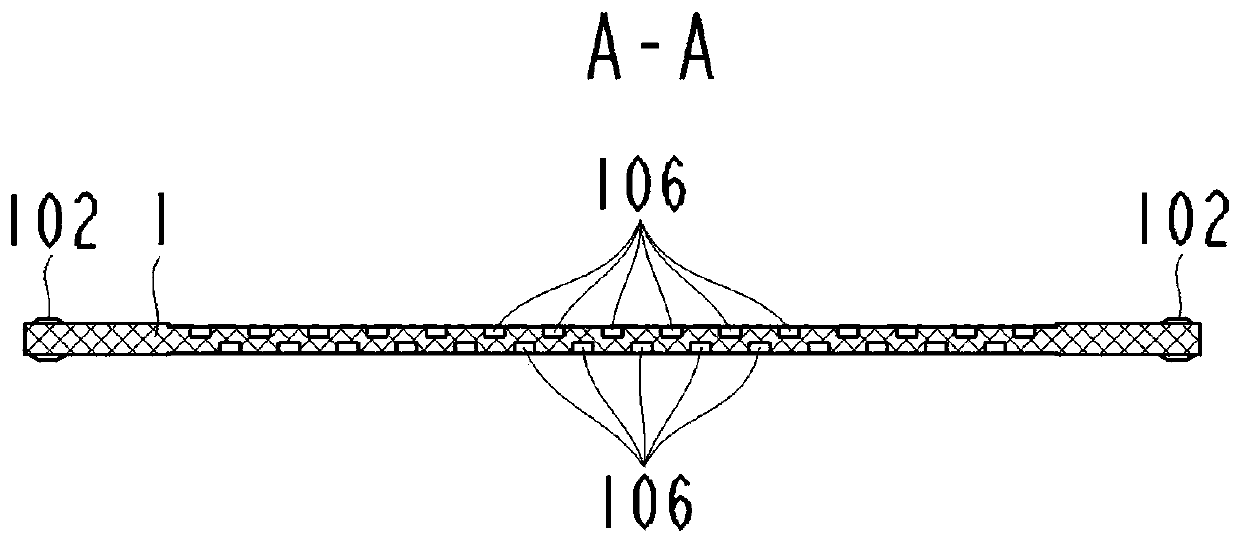

[0027] as attached figure 2 , attached image 3 As shown, the top of the support plate 1 is provided with a water production port 103 that communicates with the inner membrane cavity; the upper part of the support plate 1 side is provided with a liquid pool groove 101 near the water production port 103; Eight bosses 102 are arranged on the edge of the frame; a handle 104 is arranged in the middle of the bottom of the support plate 1; guide grooves 106 are formed on both sides of the support plate 1, and guide grooves 106 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com