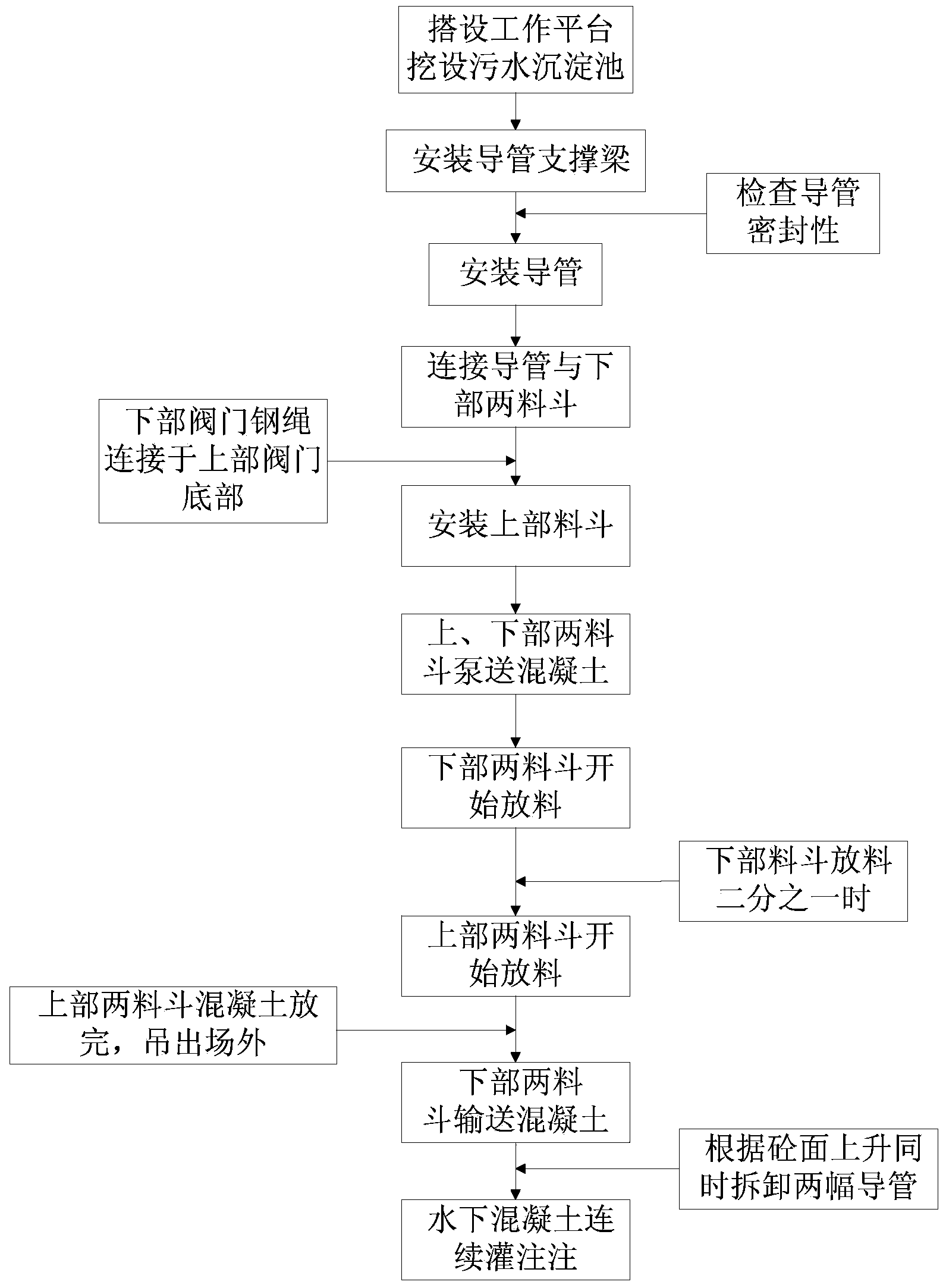

Underground concrete pouring construction technology based on double guide tubes and four hoppers

A technology of underwater concrete and construction technology, applied in the direction of infrastructure engineering, construction, etc., to achieve the effect of solving quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

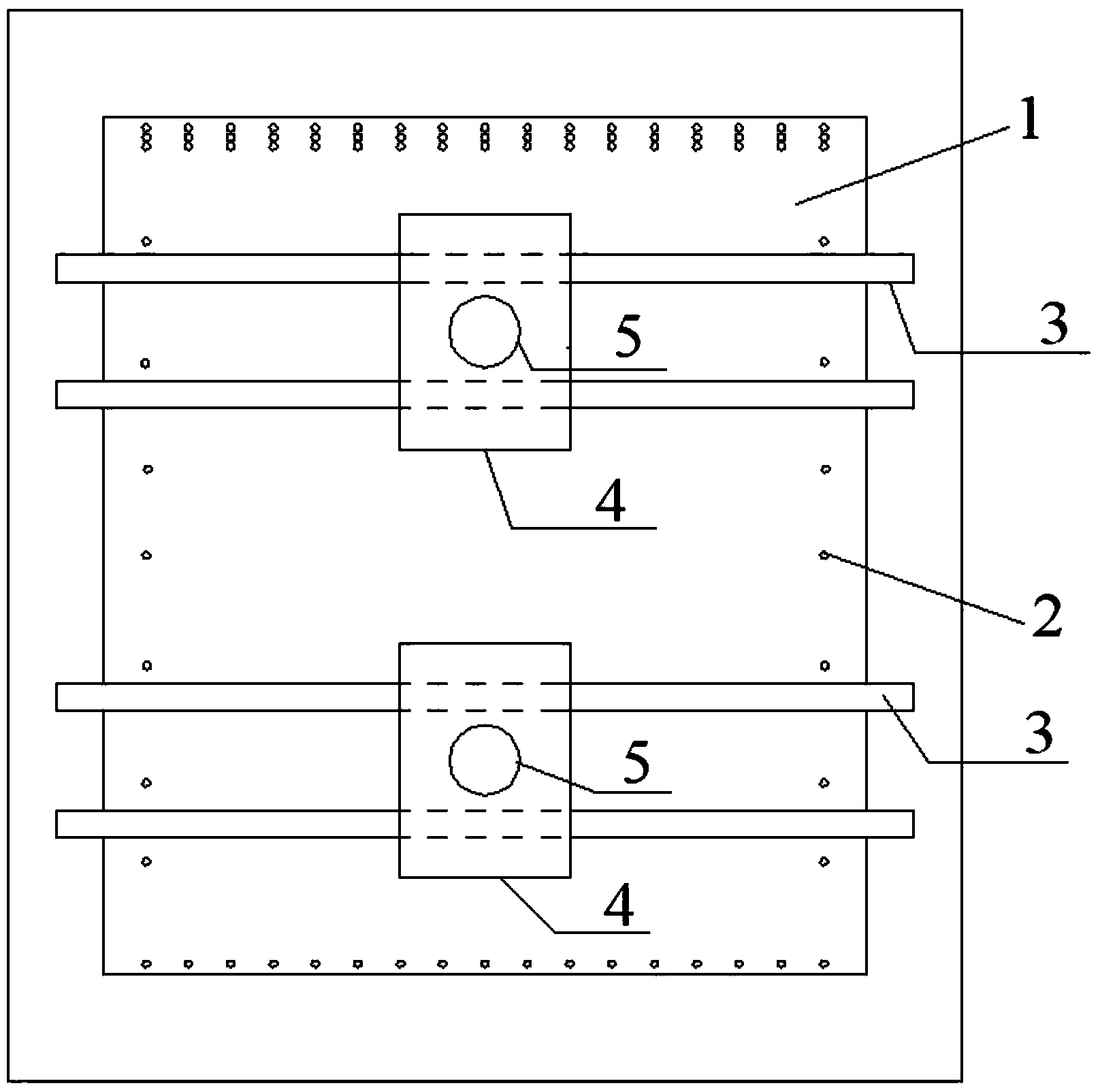

Method used

Image

Examples

specific Embodiment

[0056]The "anti-slide pile project in the west area of Yanneng Huachangping Project in Fuxian County, Shaanxi Province" was constructed in August 2012, and a total of 7 slope anti-slide piles in the first phase and 16 trench mouths in the second phase were poured using "double conduits and four hoppers". The anti-slide piles have a cross-section of 3m×4m, the buried depth of the lower part of the pile is 16m-32m, and the deepest water in the hole is 20m, which successfully overcomes the difficulty of underwater injection of large-section square piles. The pouring of all underwater piles was completed at the end of June 2013. After testing, the pile body structure is complete, and the integrity category is Class I piles.

[0057] List of construction technology applications

[0058]

[0059] To sum up, the construction process of "double conduits and four hoppers" greatly improves the construction progress, saves more than 60 days of construction period, completes the stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com