Baffle pipe and core-cooling device for an injection mold

A cooling device and injection mold technology, applied in the field of injection mold core cooling devices, can solve the problems of reduced cooling efficiency of cooling water, uneven temperature of the lower core 30, etc., to improve cooling efficiency, shorten the take-out cycle, and improve heat exchange rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

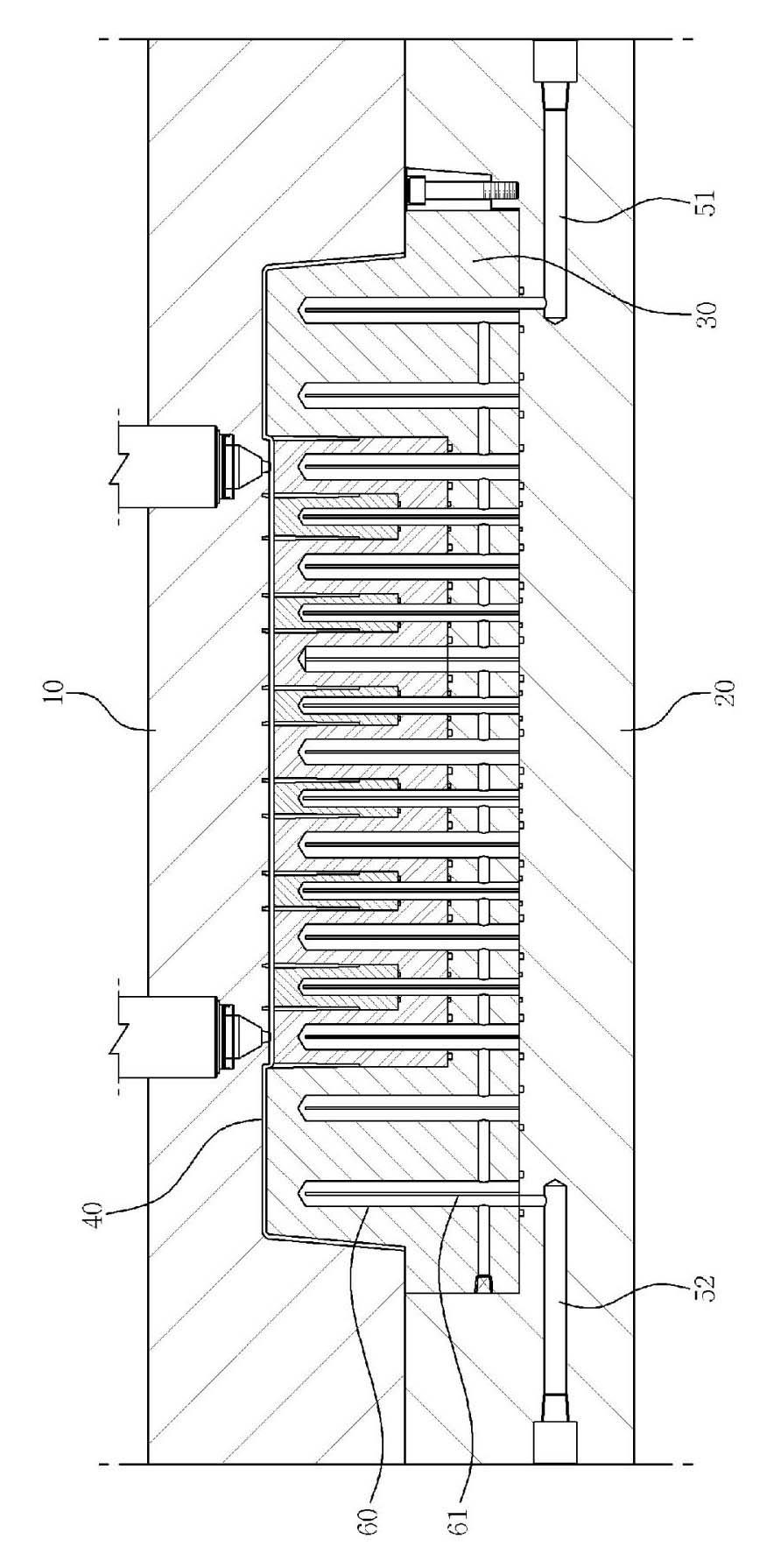

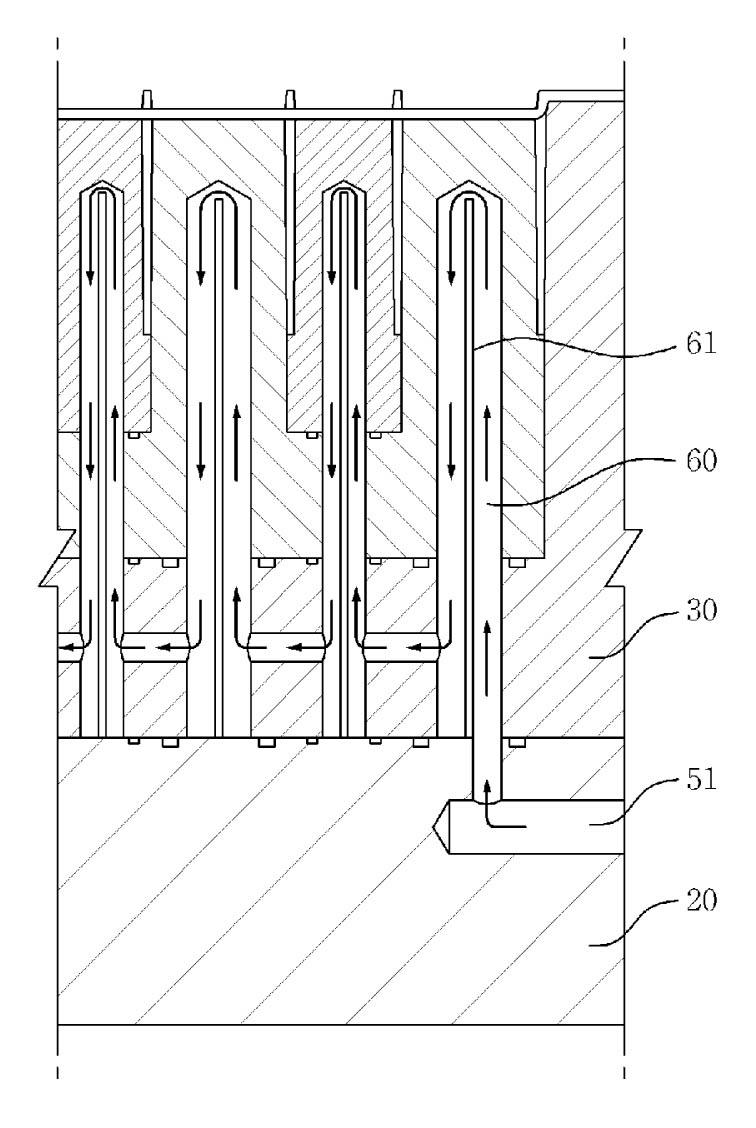

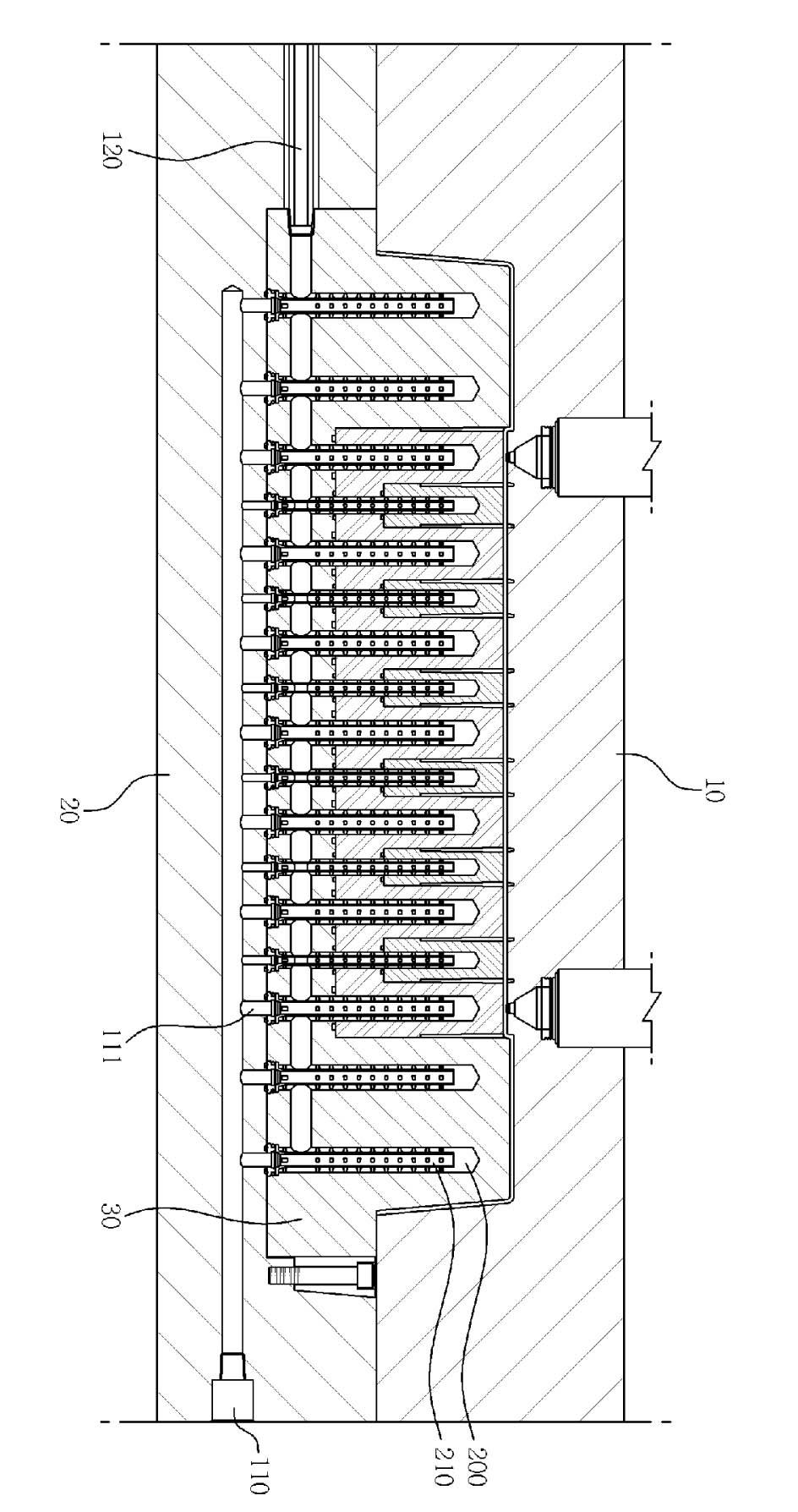

[0049] like Figure 3 to Figure 6 As shown, the present invention is applicable to an injection mold core cooling device composed of the following parts: the basic cooling water pipe, located on the lower circular plate 20, is composed of a cooling water inlet 110 and a cooling water discharge port 120; the core cooling water pipe 200 , which communicate with the inlet 110 and the outlet 120 of the above-mentioned basic cooling water pipe, and are arranged to ensure circulation along the inner side of the lower core 30 .

[0050] According to the present invention, the baffle tubes 210 are combined with the core cooling water pipes 200 , and the cooling water inlets 110 of the basic cooling water pipes are connected to the lower ends of the baffle tubes 210 . In addition, the cooling water outlet 120 of the basic cooling water pipe is connected to the lower part of the core cooling water pipe 200 on one side.

[0051] Although the above-mentioned baffle tube 210 can be made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com