Ethylene and oxygen mixing method

A technology of oxygen and ethylene, which is applied in the field of ethylene and oxygen mixing in the ethylene oxide/ethylene glycol process, can solve the problems such as the unsatisfactory mixing effect of ethylene and oxygen, and achieve enhanced ability to adapt to changes in operating load and good technical effects , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

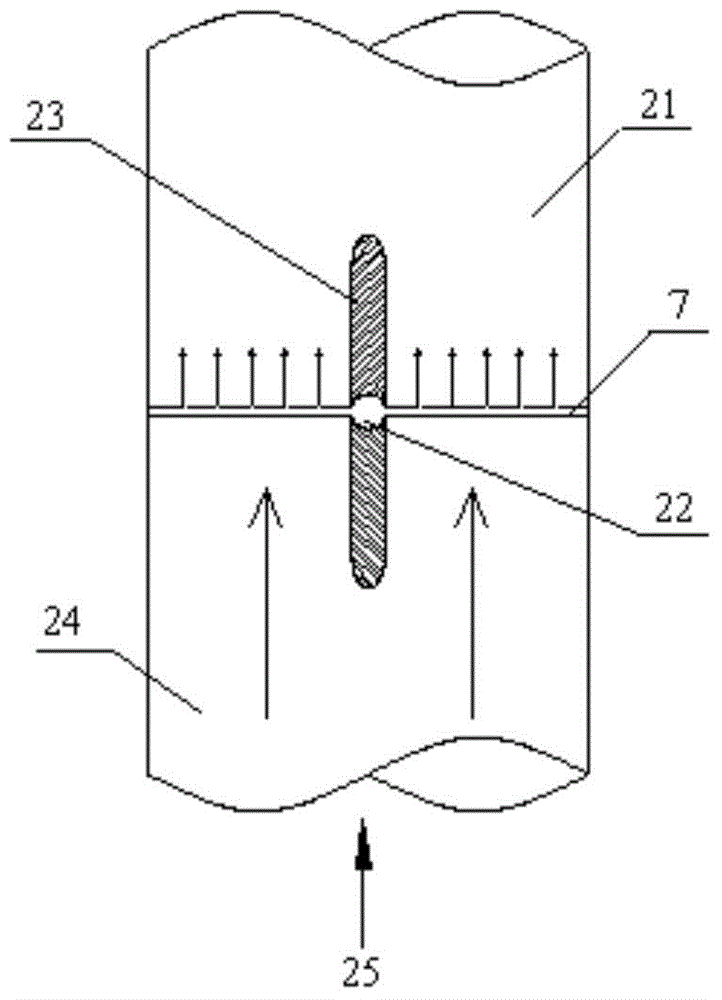

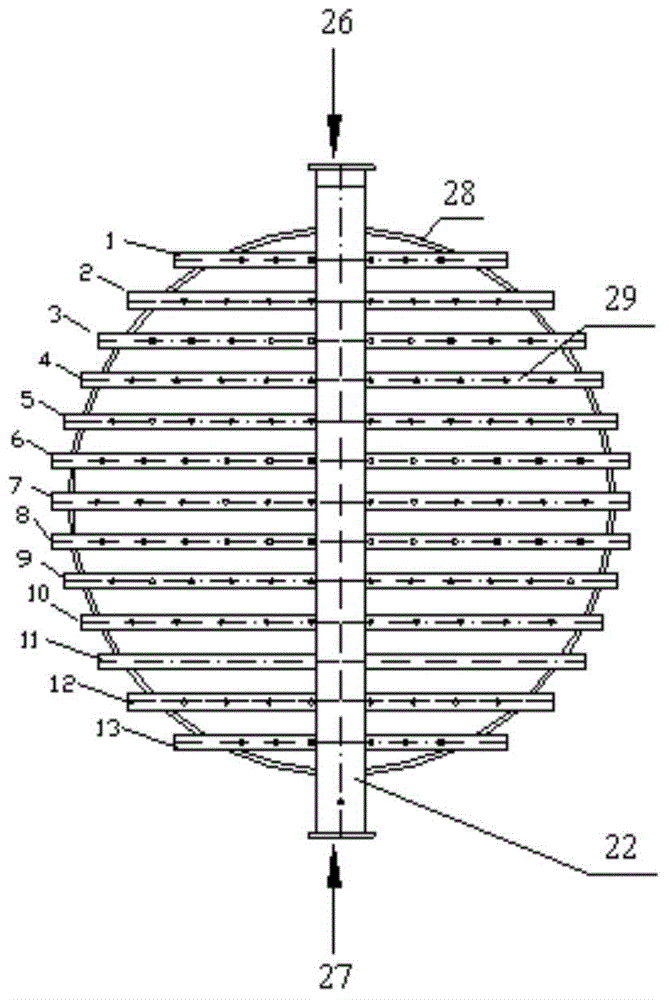

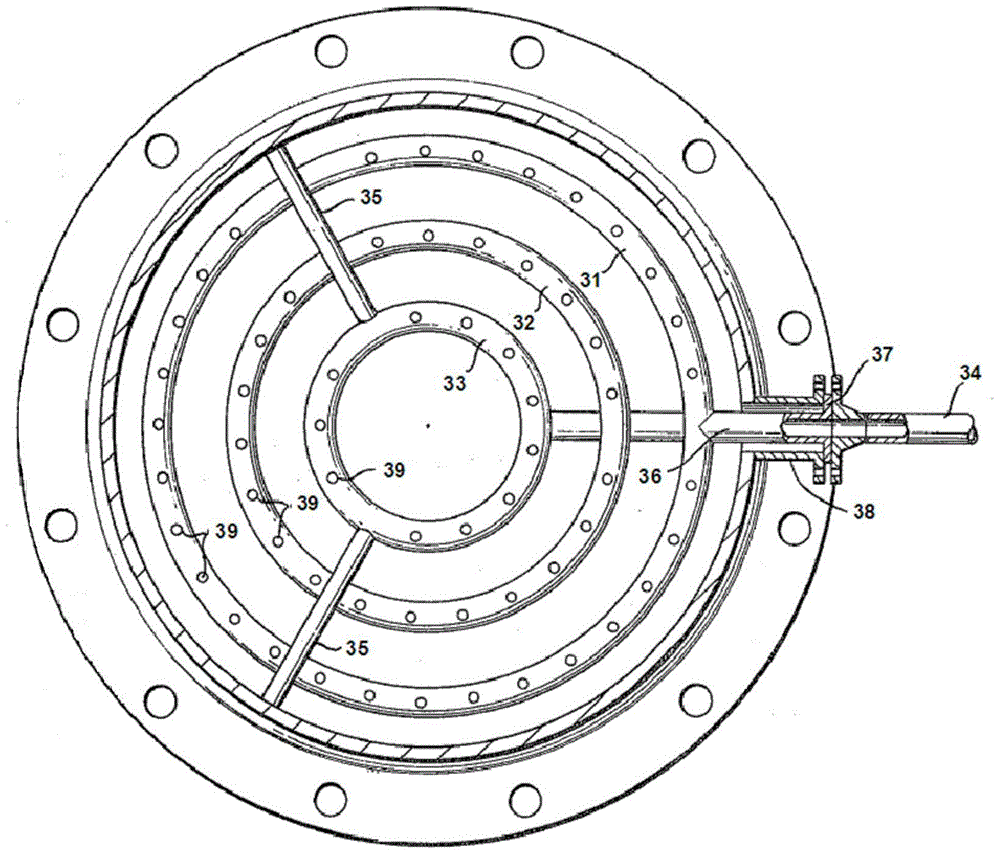

[0030] use figure 1 and figure 2 For the central main pipe oxygen mixer shown, the structural parameters of the oxygen mixer are as follows:

[0031] Main channel inner diameter: 1100mm

[0032] Inner diameter of central main pipe: 100mm

[0033] Number of branch pipes: 13

[0034] Branch pipe inner diameter: 32mm

[0035] Branch spacing: 88.4mm

[0036] Small hole inner diameter: 7mm

[0037] Hole spacing: 90mm

[0038] Number of small holes: 128

[0039] Select the central branch pipe 7 (the number of small holes is 8), and compare the back pressure deviation of each small hole (that is, the deviation between the small hole back pressure and the average value of the back pressure), and investigate the mixing effect of the central main pipe mixer.

[0040] The intake volume is as follows:

[0041] Oxygen flow: 3314kg / hr

[0042] Oxygen temperature: 25°C

[0043] Oxygen pressure: 2647.8KPa G

[0044] Oxygen density: 36kg / m 3

[0045] Oxygen viscosity: 0.021cp

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com