Sludge primary treatment equipment

A preliminary treatment and equipment technology, applied in sludge treatment, water/sludge/sewage treatment, chemical/physical processes, etc., can solve the problem of uneven mixing of sludge, great harm of sludge to urban rivers, and insufficient design of mixing components Reasonable and other issues, to achieve the effect of good stirring effect and large stirring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

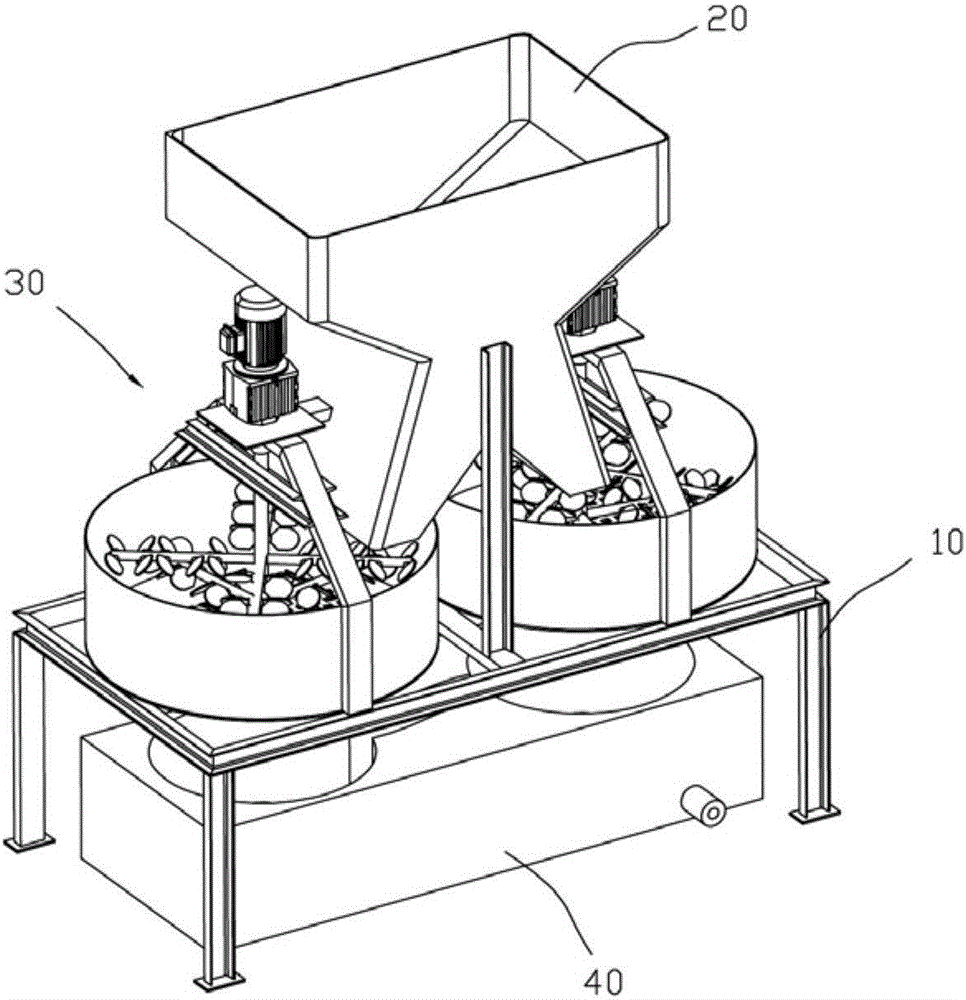

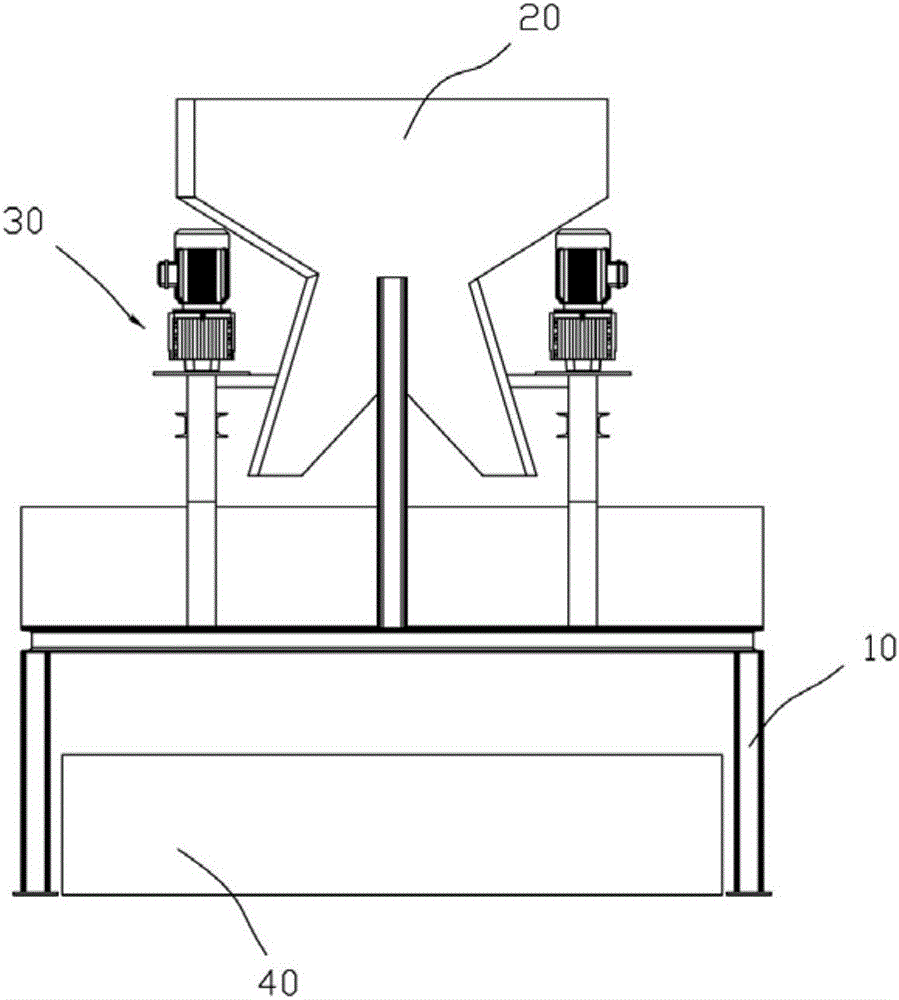

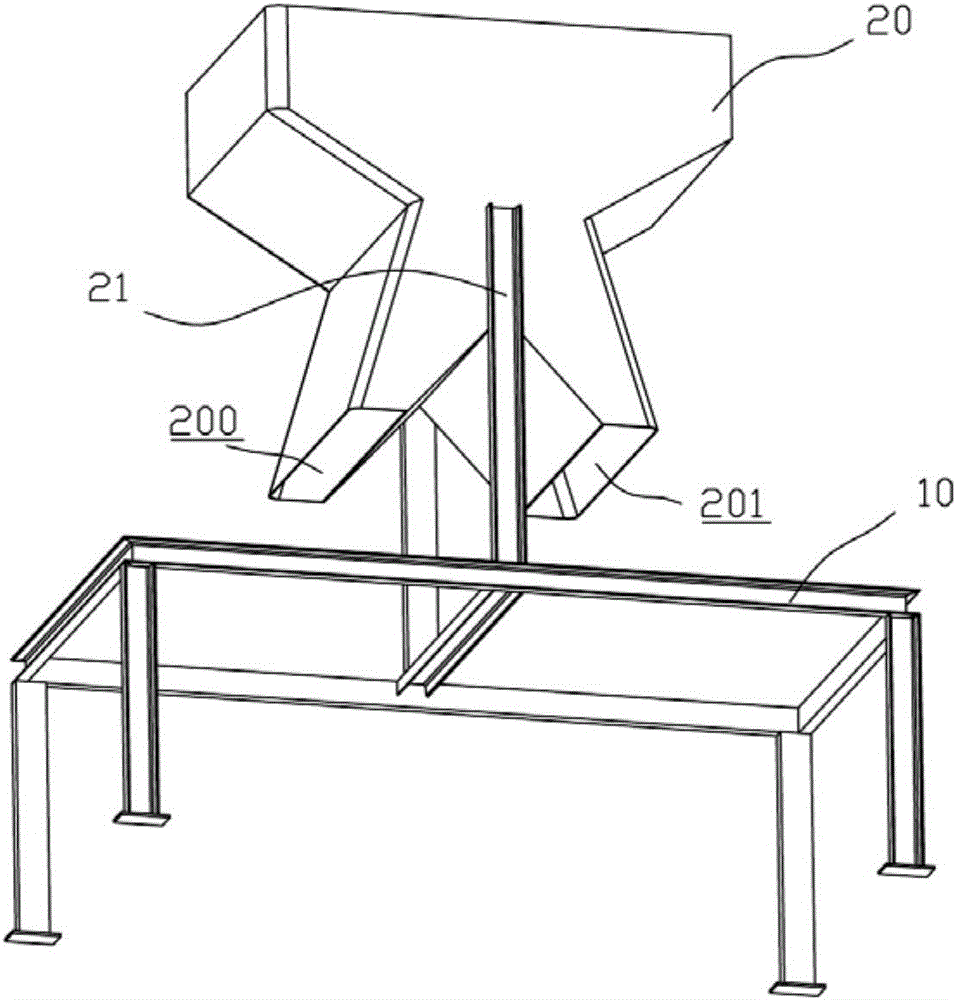

[0025] Such as Figure 1 to Figure 6 As shown, a preliminary treatment equipment for sludge includes a support 10, a material distribution box 20 is arranged above the support 10, and the material distribution box 20 is installed on the support 10 through a material distribution box fixing plate 21; The bottom of the material distribution box 20 is provided with a first discharge port 200 and a second discharge port 201, and the bottom of the first discharge port 200 and the second discharge port 201 is provided with a stirring assembly 30, and the stirring assembly 30 includes a blade assembly 34 and a mixing bucket 35, and a collection box 40 is arranged below the mixing bucket 35.

[0026] Such as Figure 5 As shown, the blade assembly 34 includes a blade fixing rod 340 and a blade 341 , several blades 341 are evenly distributed on the blade fixing rod 340 , and the blade 341 and the blade fixing rod 340 have upper and lower layers.

[0027] Such as Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com