Patents

Literature

65results about How to "Avoid meltdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat Energy Recapture And Recycle And Its New Applications

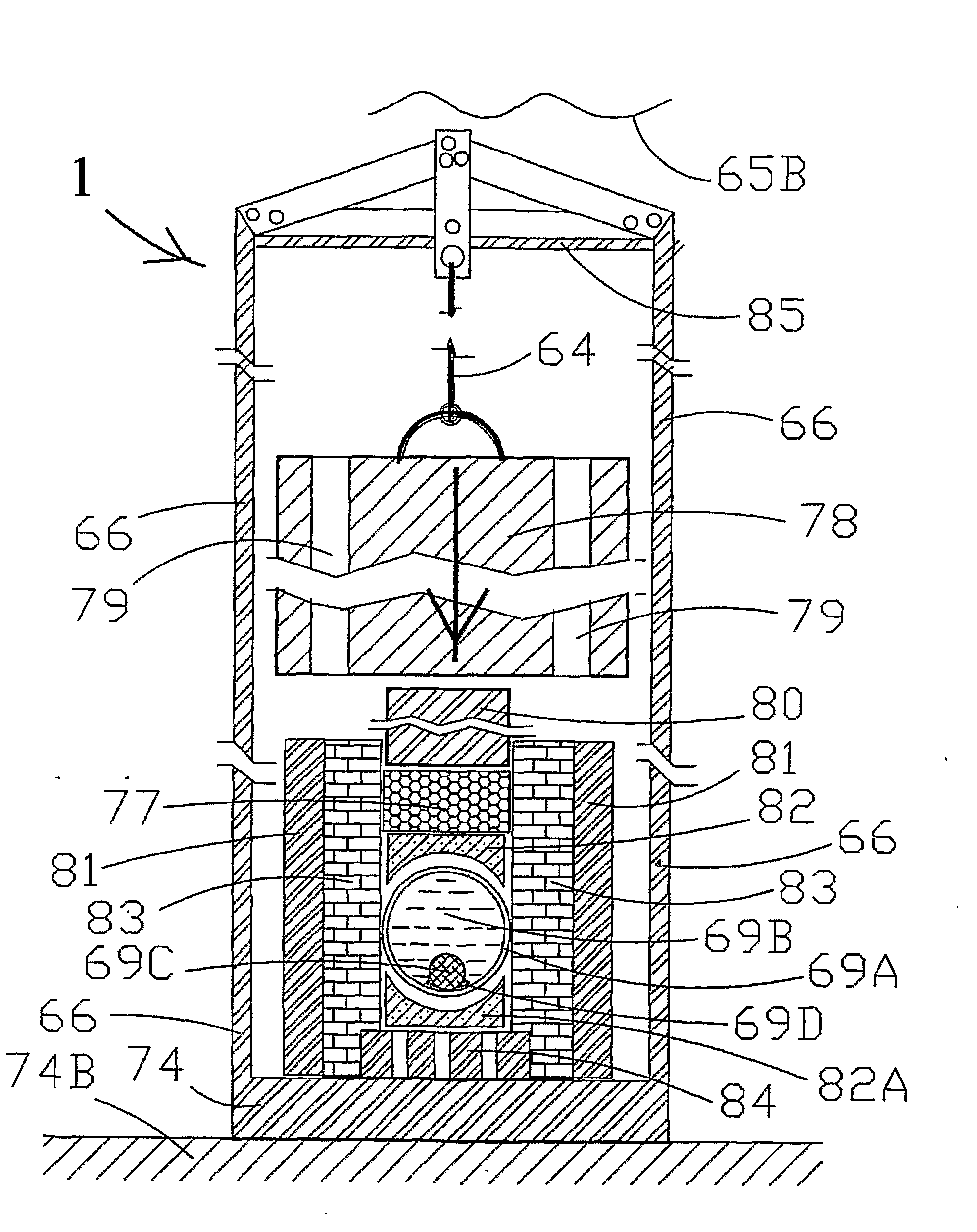

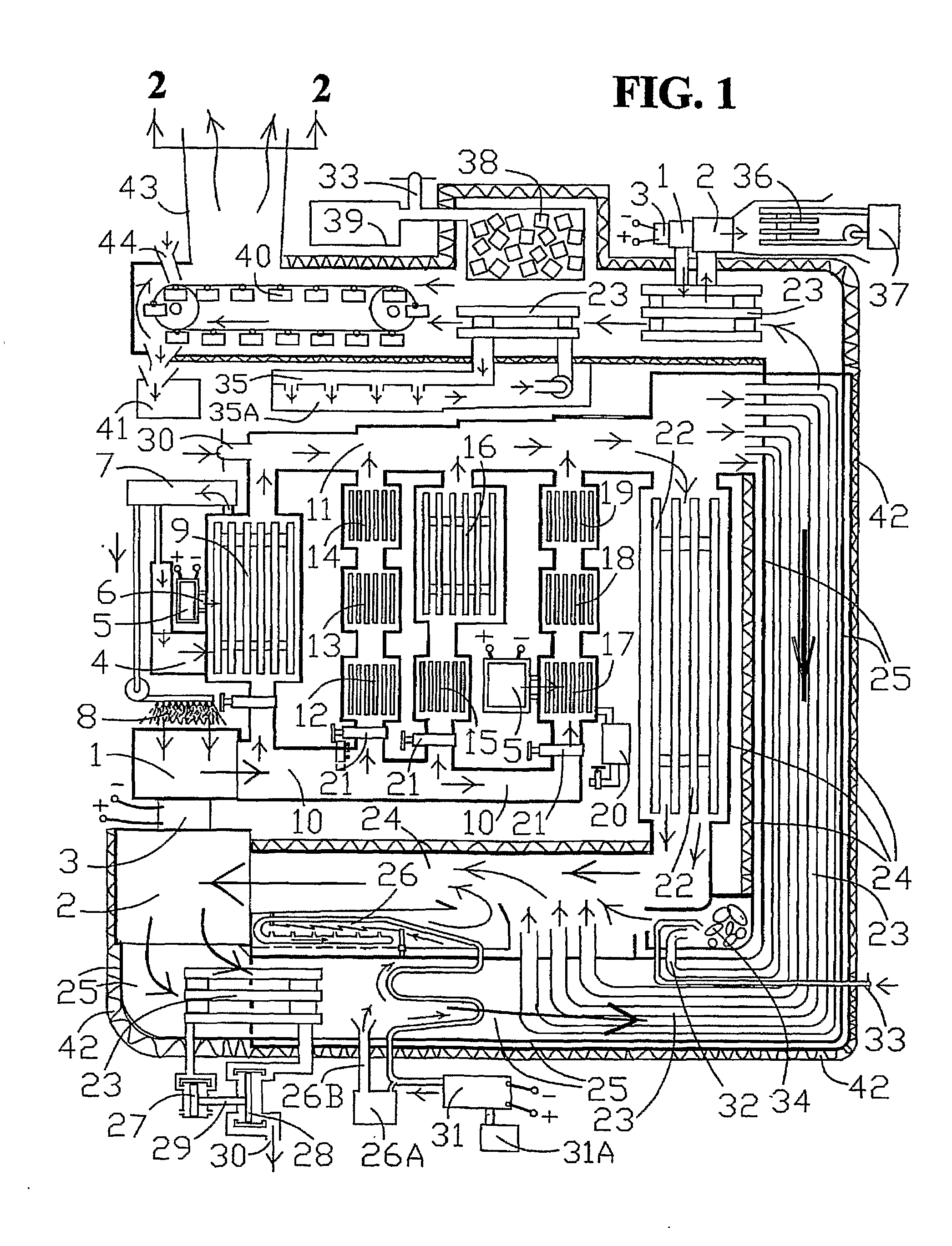

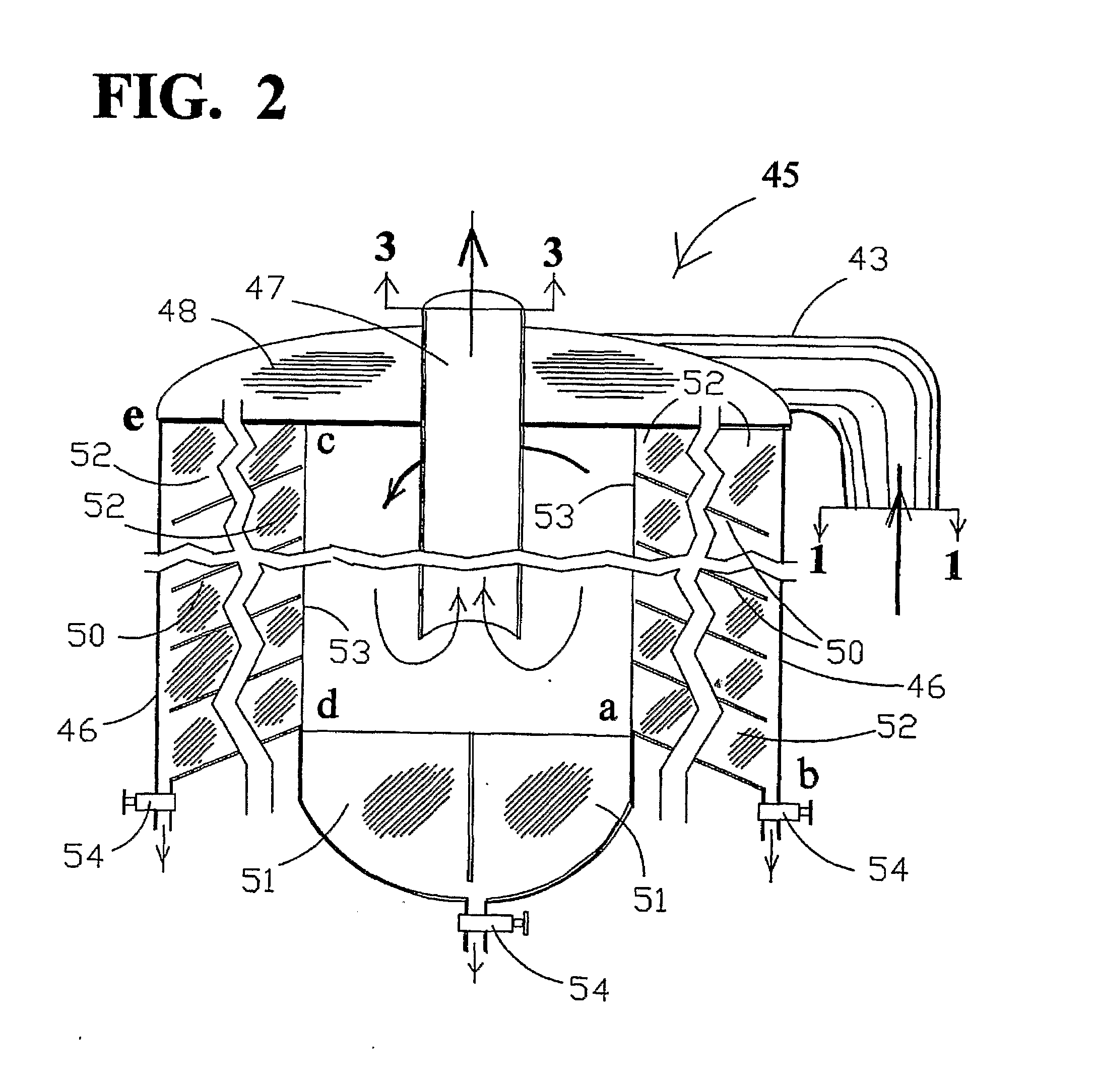

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

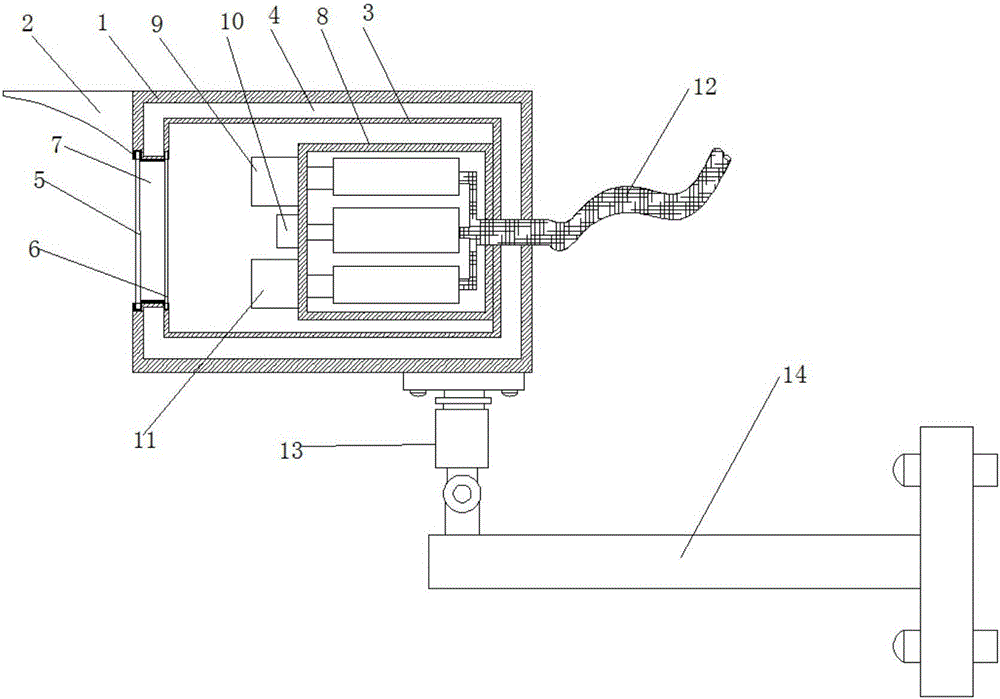

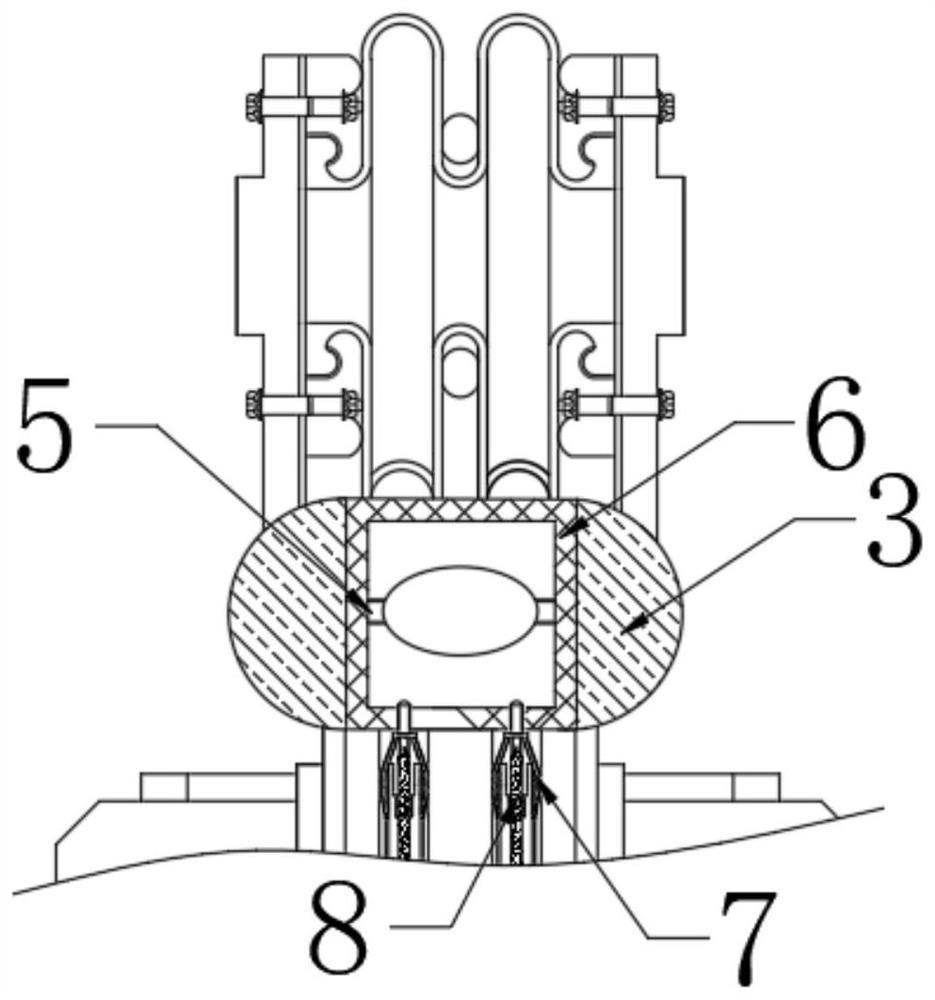

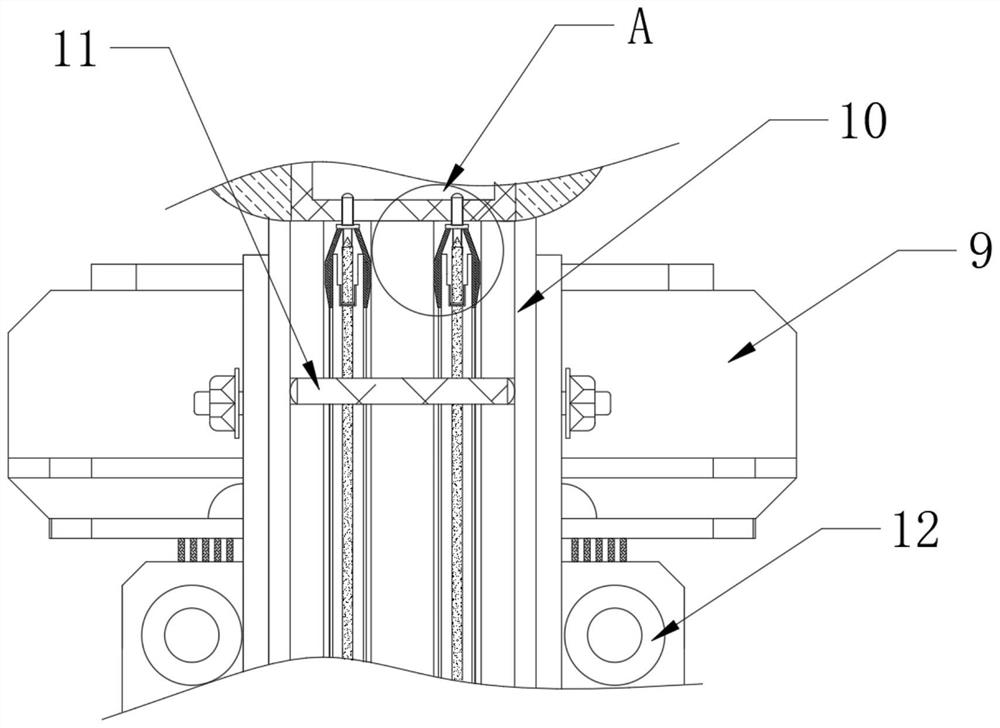

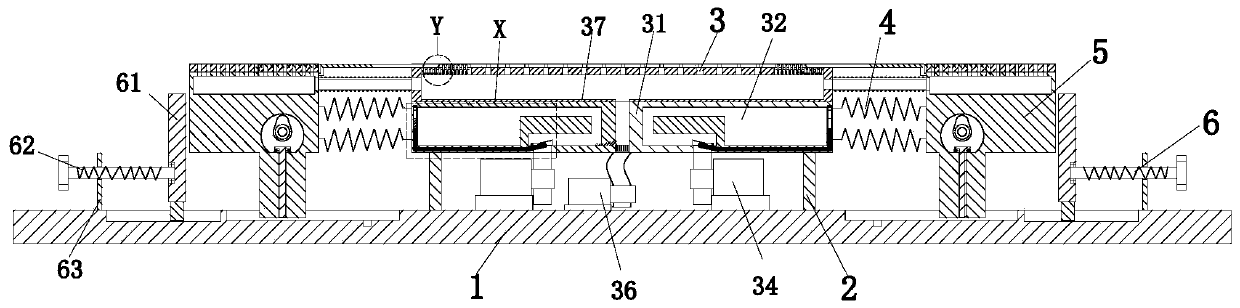

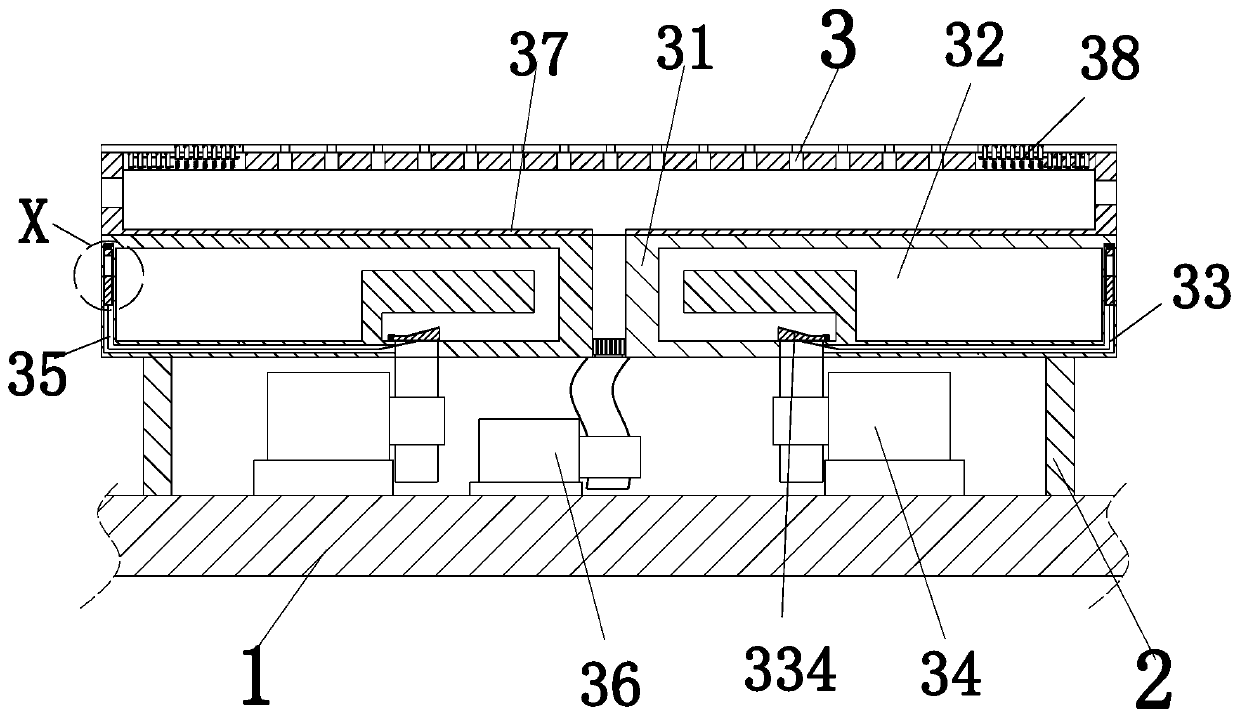

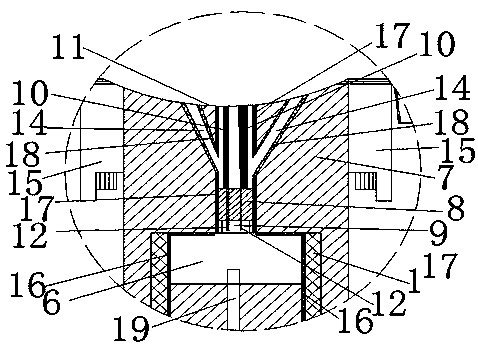

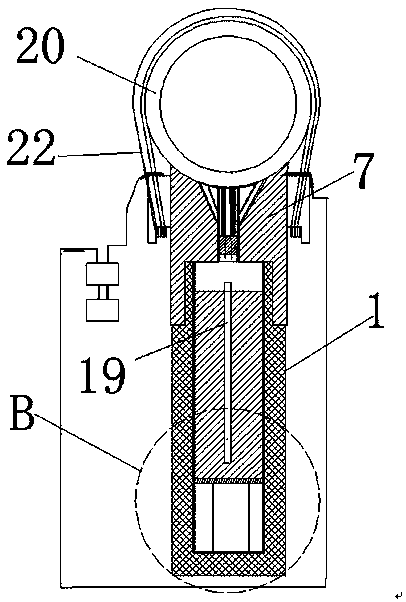

Explosion-proofing infrared UV flame detector

InactiveCN105931418AAvoid burnsSlow temperature conductionFire alarm radiation actuationEngineeringElectronic component

The invention discloses an explosion-proofing infrared UV flame detector including an explosion-proofing outer casing, one side of the explosion-proofing outer casing is provided with a shield plate, the inside of the explosion-proofing outer casing is provided with an explosion-proofing inner casing, a first vacuum layer is formed between the explosion-proofing outer casing and the explosion-proofing inner casing, one side, closing to the shield plate, of the explosion-proofing outer casing is provided with a piece of explosion-proofing outer glass, and one side, closing to the explosion-proofing outer glass, of the explosion-proofing inner casing is provided with a piece of explosion-proofing inner glass. The first vacuum layer is formed between the explosion-proofing outer casing and the explosion-proofing inner casing, a second vacuum layer is formed between the explosion-proofing outer glass and the explosion-proofing inner glass, the vacuum layers reduce the effect of heat transfer to make the temperature conduction of the inside and the outside of the sensor slow, thereby preventing internal electronic components from being melted, and reducing the internal blasting probability, and moreover, the detector main body is provided with an infrared flame detector, a UV flame detector, and a high-definition pick-up head, so that the scene of fire can be maximally detected.

Owner:ANHUI SHENGLONG ELECTRIC

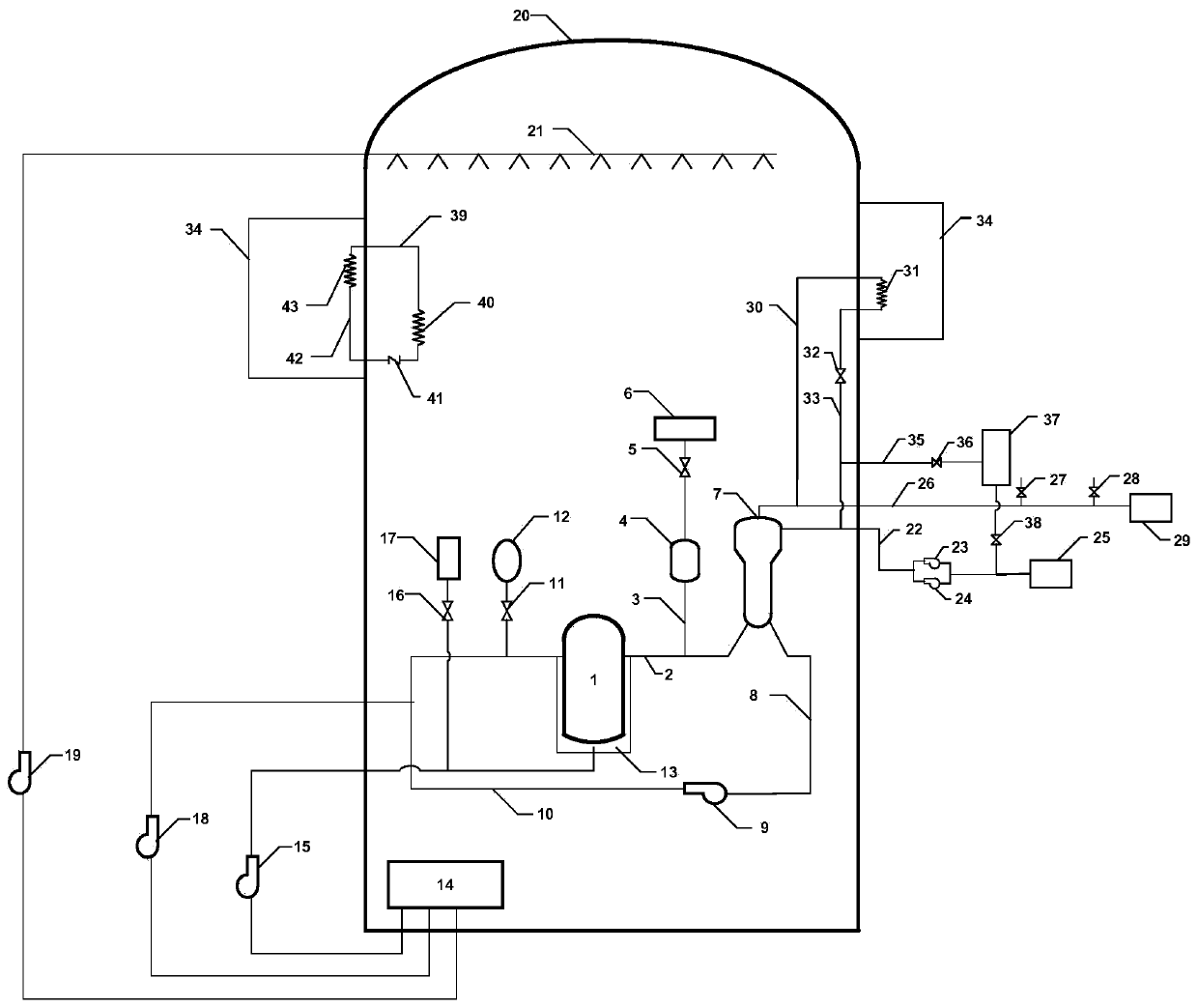

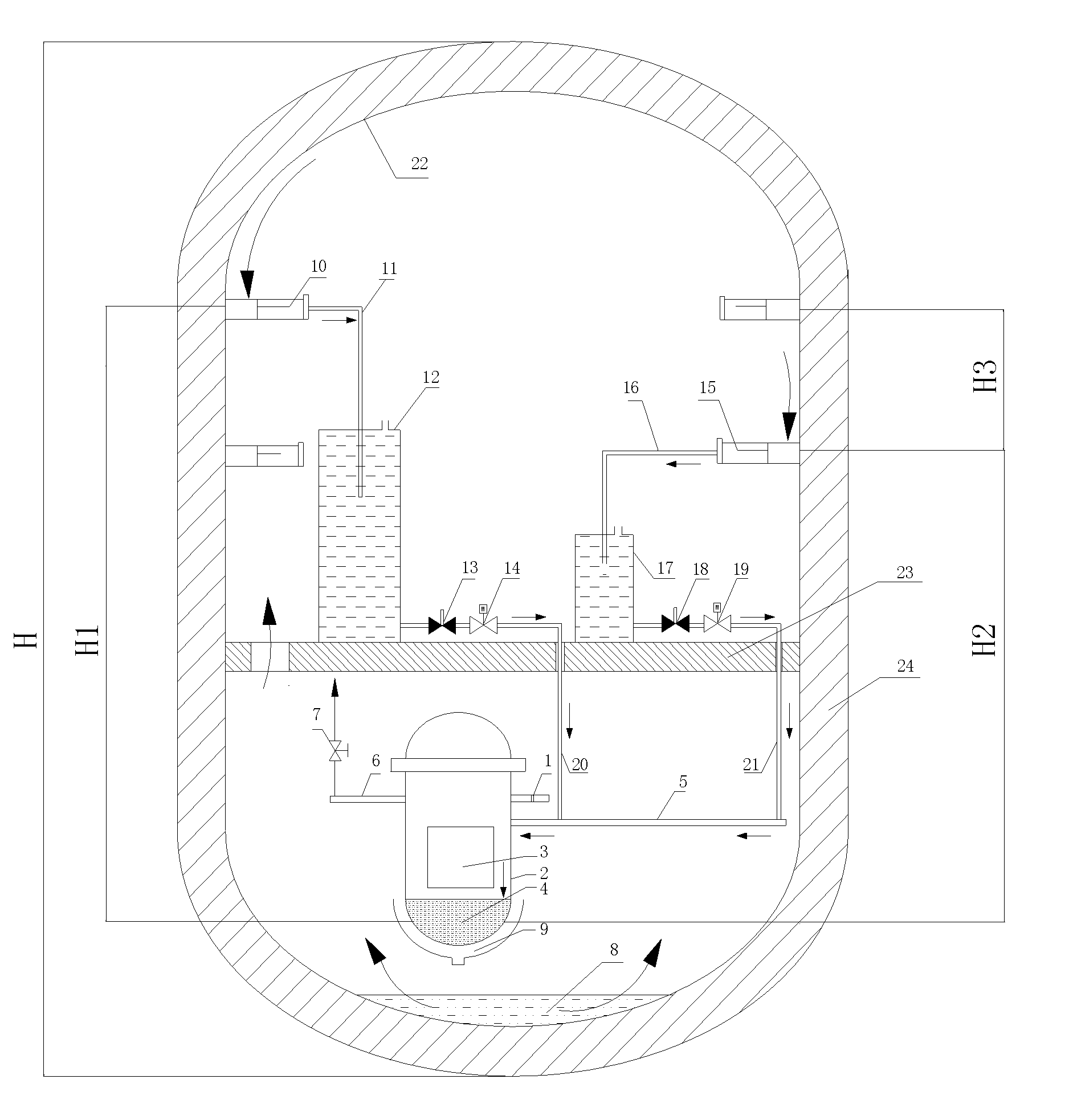

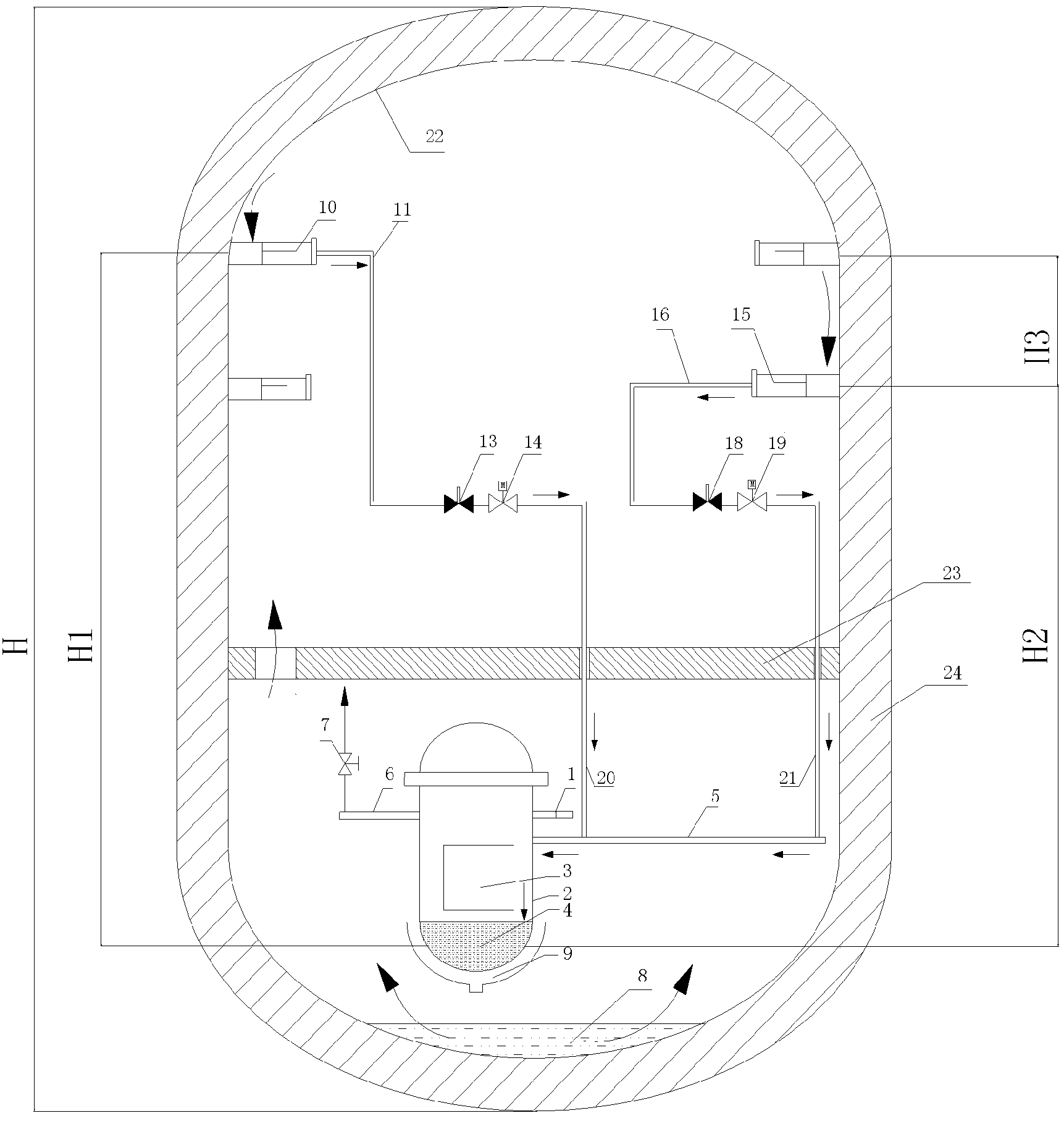

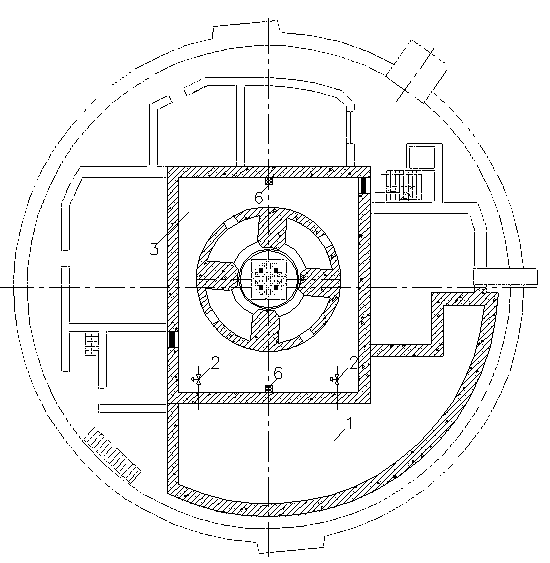

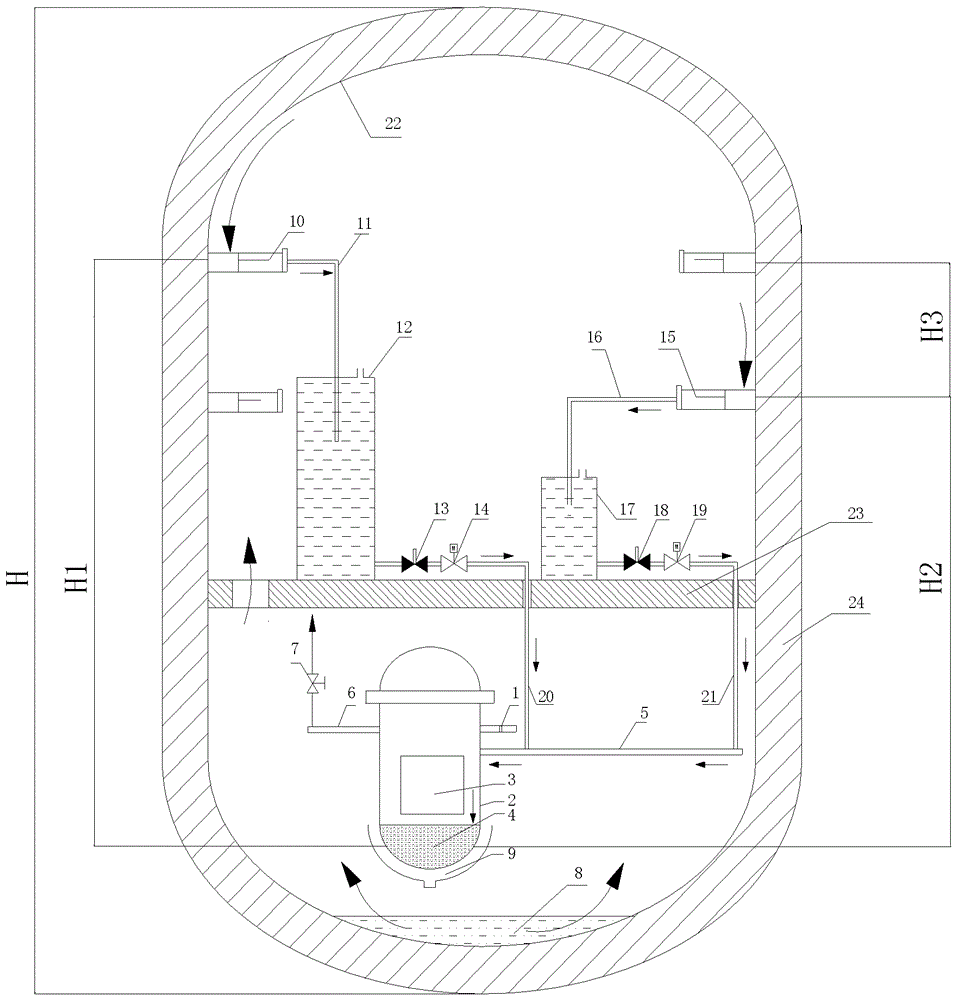

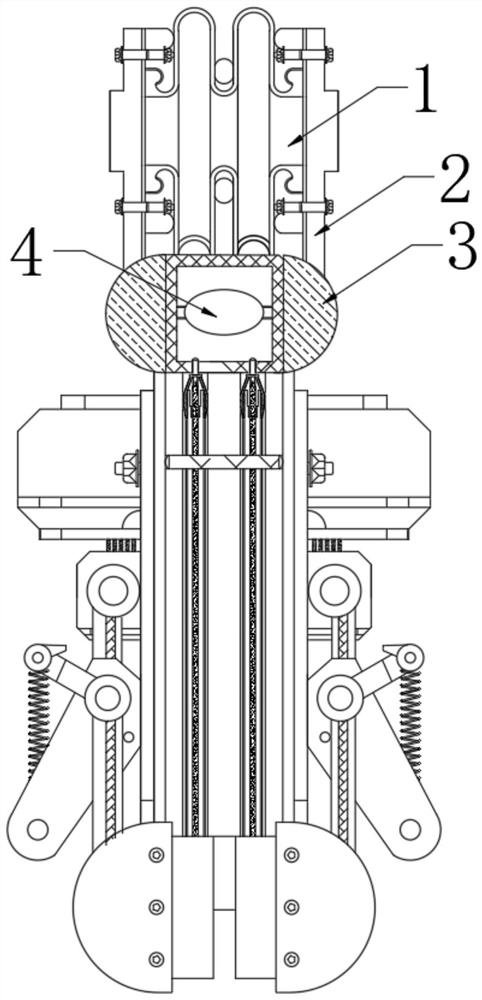

Active and passive combined safety system and method for nuclear power plant

ActiveCN111128414AIncrease diversityIncrease multiplicityNuclear energy generationCooling arrangementNuclear plantPressurized water reactor

The invention relates to the technical field of nuclear power. The invention particularly discloses an active and passive combined overall safety system and method for a pressurized water reactor nuclear power plant. The system comprises a safety injection system consisting of an active safety injection system and a passive safety injection system, a reactor cavity water injection system consisting of an active reactor cavity water injection system and a passive reactor cavity water injection system, a containment heat removal system consisting of an active containment spraying system and a passive containment heat removal system, and a steam generator secondary side heat removal system consisting of an auxiliary water supply system, a steam turbine bypass discharge system and a secondaryside passive residual heat removal system. According to the invention, the passive safety system is used as the supplement of the active safety system; the passive technology is fully utilized, the depth defense level and requirements of the nuclear power plant are comprehensively considered, depth defense is enhanced, energy removal under predicted operation events, design benchmark working conditions and design expansion working conditions (including serious accidents) possibly occurring in the nuclear power plant is better coped with, and the safety of the nuclear power plant is greatly improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

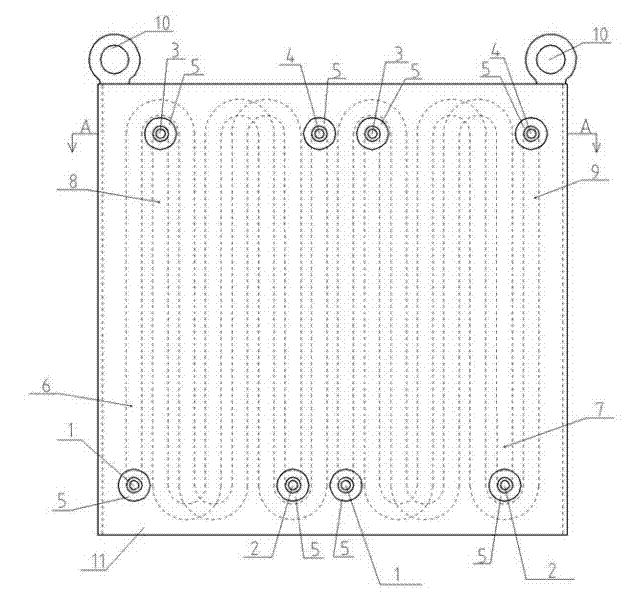

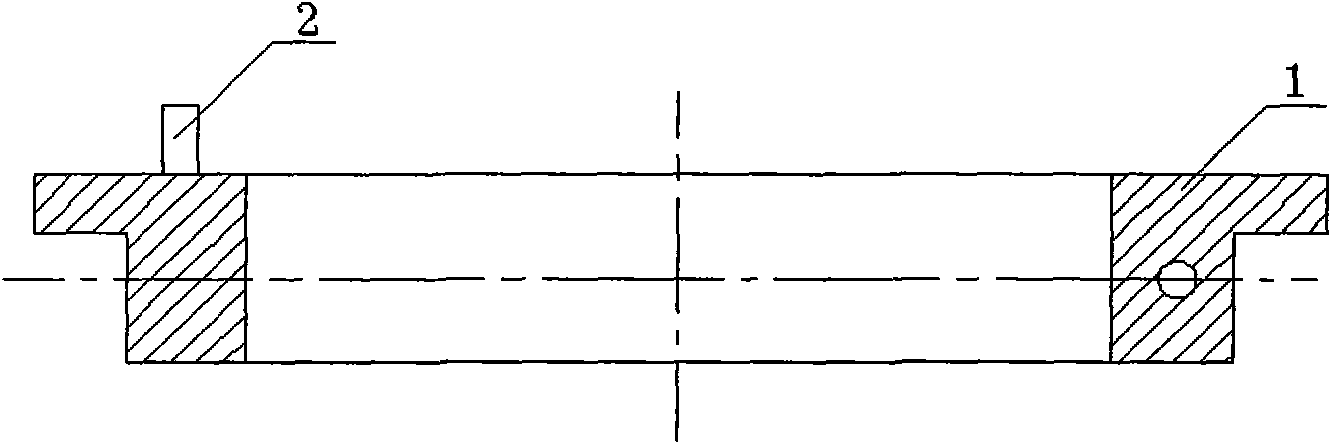

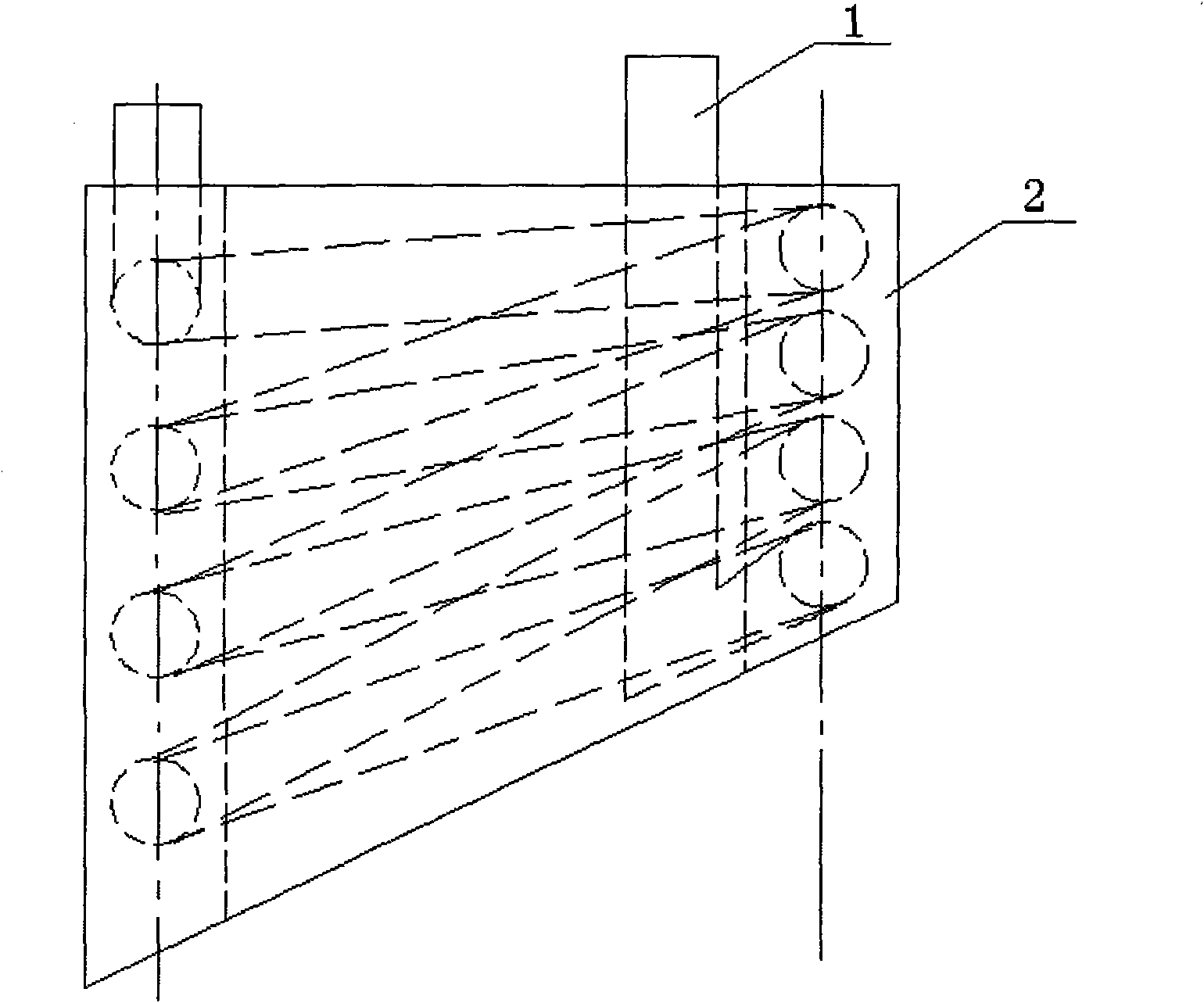

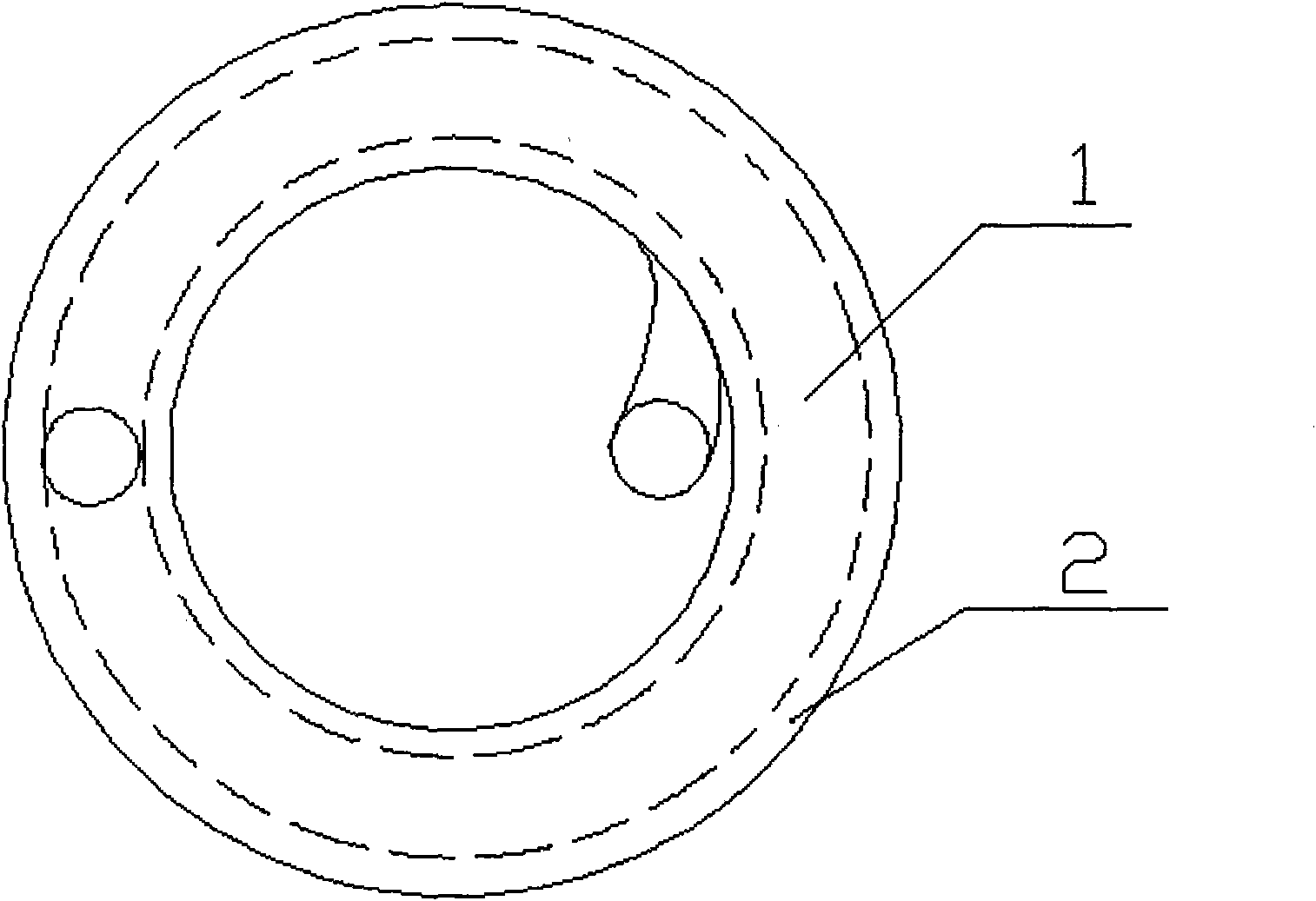

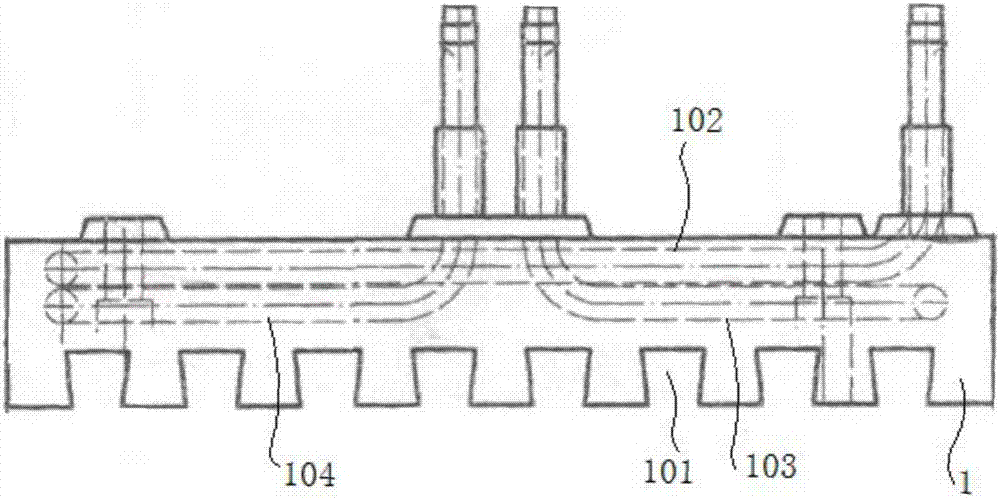

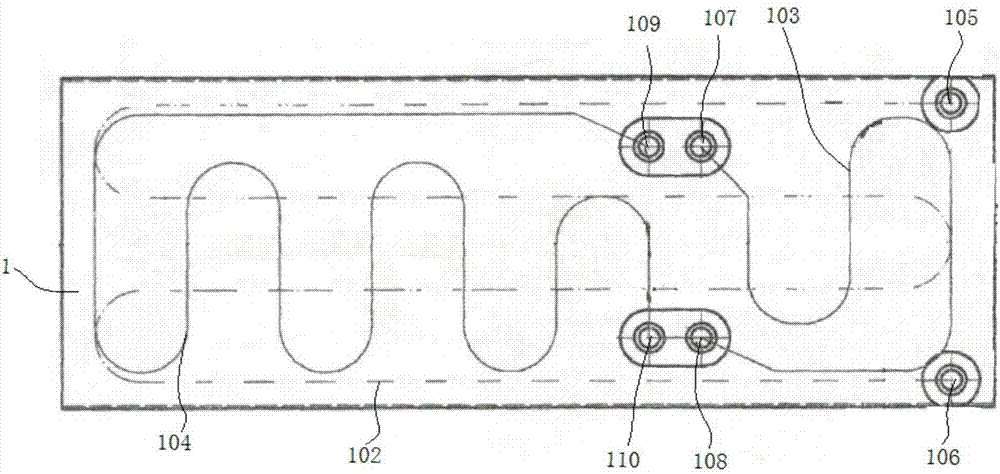

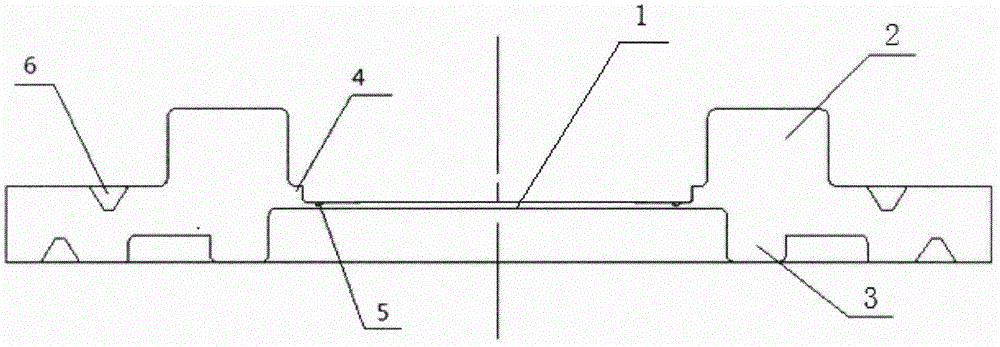

Cast copper water jacket embedded with double-layer pure copper pipes and manufacturing method thereof

The invention relates to a cast copper water jacket embedded with double-layer pure copper pipes for cooling large nickel-iron electric furnace bodies, and a manufacturing method thereof. The water jacket comprises four double-layer misplaced cooling pipelines which are installed in an arc wall body, wherein the water inlet duct and water outlet duct of each cooling pipeline are positioned on theouter arc surface of the arc wall body; the outlet heads of each water inlet duct and each water outlet duct are provided with duct protecting bosses capable of preventing the root of each duct from being cut by a furnace shell because of expansion caused by heat and contraction caused by cold; and an installation hole is formed on the upper end surface of the arc wall body. In the invention, by adopting the technical scheme, the manufactured cast copper water jacket embedded with double-layer pure copper pipes has the advantages of good cooling performance, good thermal shock resistance, good leak resistance, high utilization rate of effective working volume of equipment, low manufacturing cost and long service life, thereby laying a foundation for a process of producing nickel iron by directly smelting laterite in a nickel-iron electric furnace.

Owner:江西余越科技有限公司

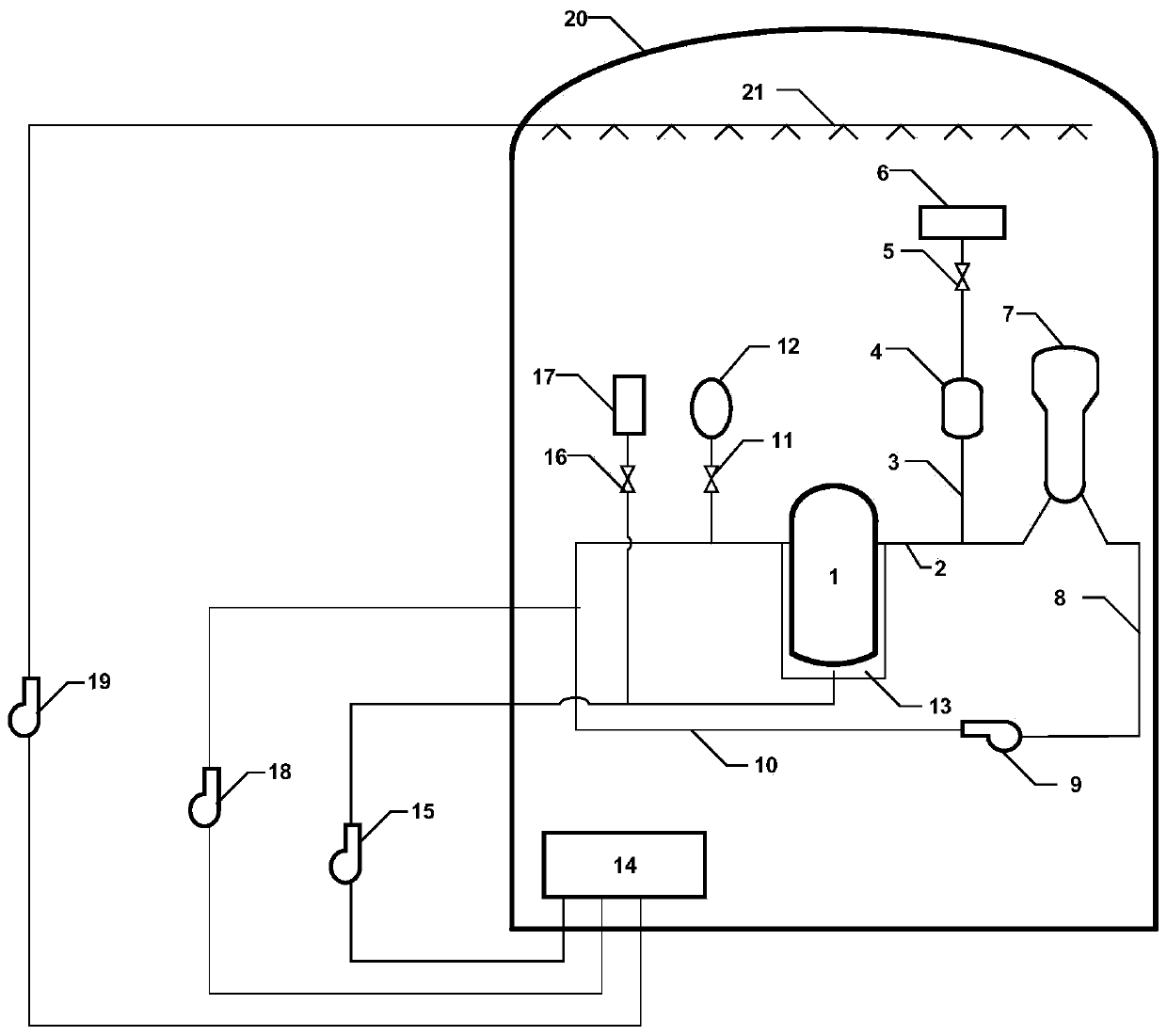

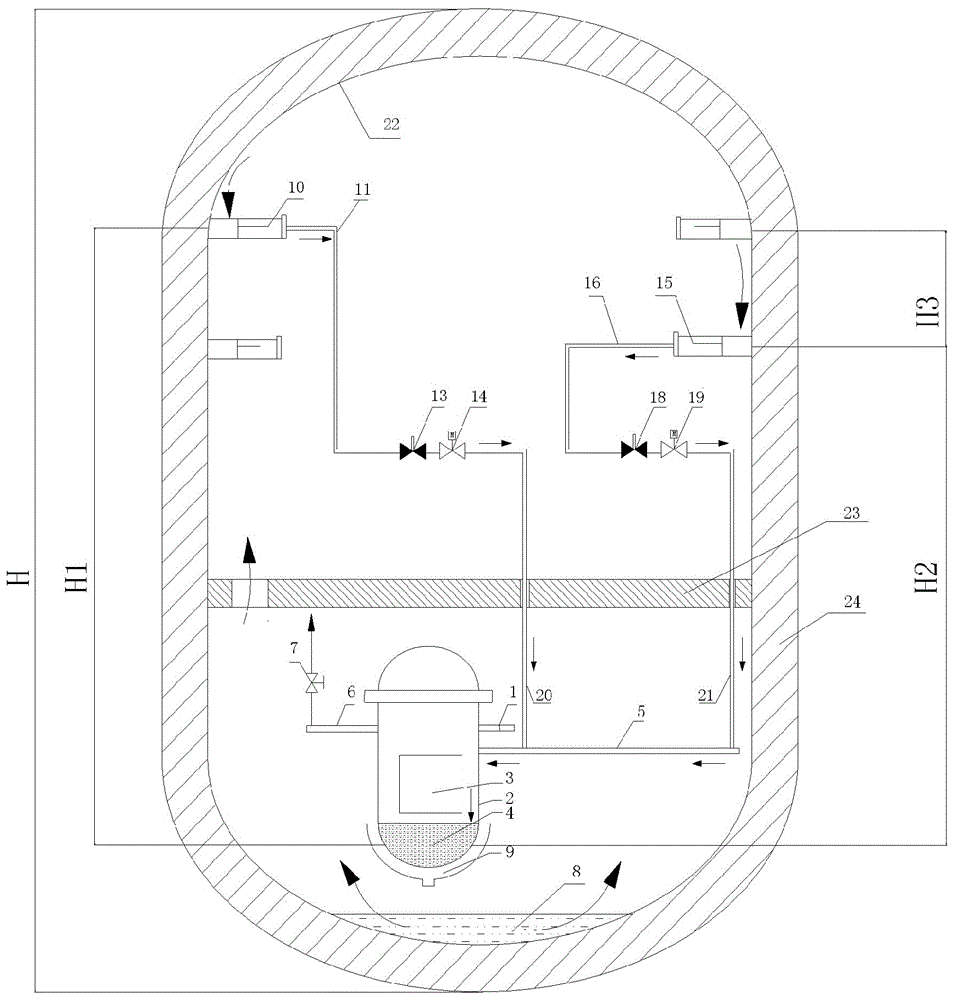

Passive containment shell condensed water injection system

ActiveCN104167229AEnsure safetyReduce the temperatureNuclear energy generationCooling arrangementNuclear powerNuclear engineering

The invention relates to a passive containment shell condensed water injection system. The system comprises a first water collecting device; a first condensed water injection pipeline, which is connected to the first water collecting device and a pressure container direct injection pipeline; and a first valve mechanism, which is arranged on the first condensed water injection pipeline and is capable of starting the condensed water injection and controlling the condensed water injection flow after receiving a severe accident signal. The first water collecting device comprises a first water collecting groove, which is arranged along the circumferential direction of the internal wall of a containment shell. The first water collecting groove is arranged above the reactor core, and the standard distance between the first water collecting groove and the reactor core is 40% to 75% of the total height of the containment shell. When a severe accident happens, the system can utilize the pressure due to the height difference between the water collecting groove and the reactor core to completely inject the condensed water into the reactor core to ensure the safety of the reactor. Moreover, the system also can collect the condensed water from the internal wall of the containment shell and directly injects the collected condensed water into the reactor core to cool the melts in the reactor core. The system has the advantages of simple structure, high reliability, and suitability for various kinds of nuclear power stations.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

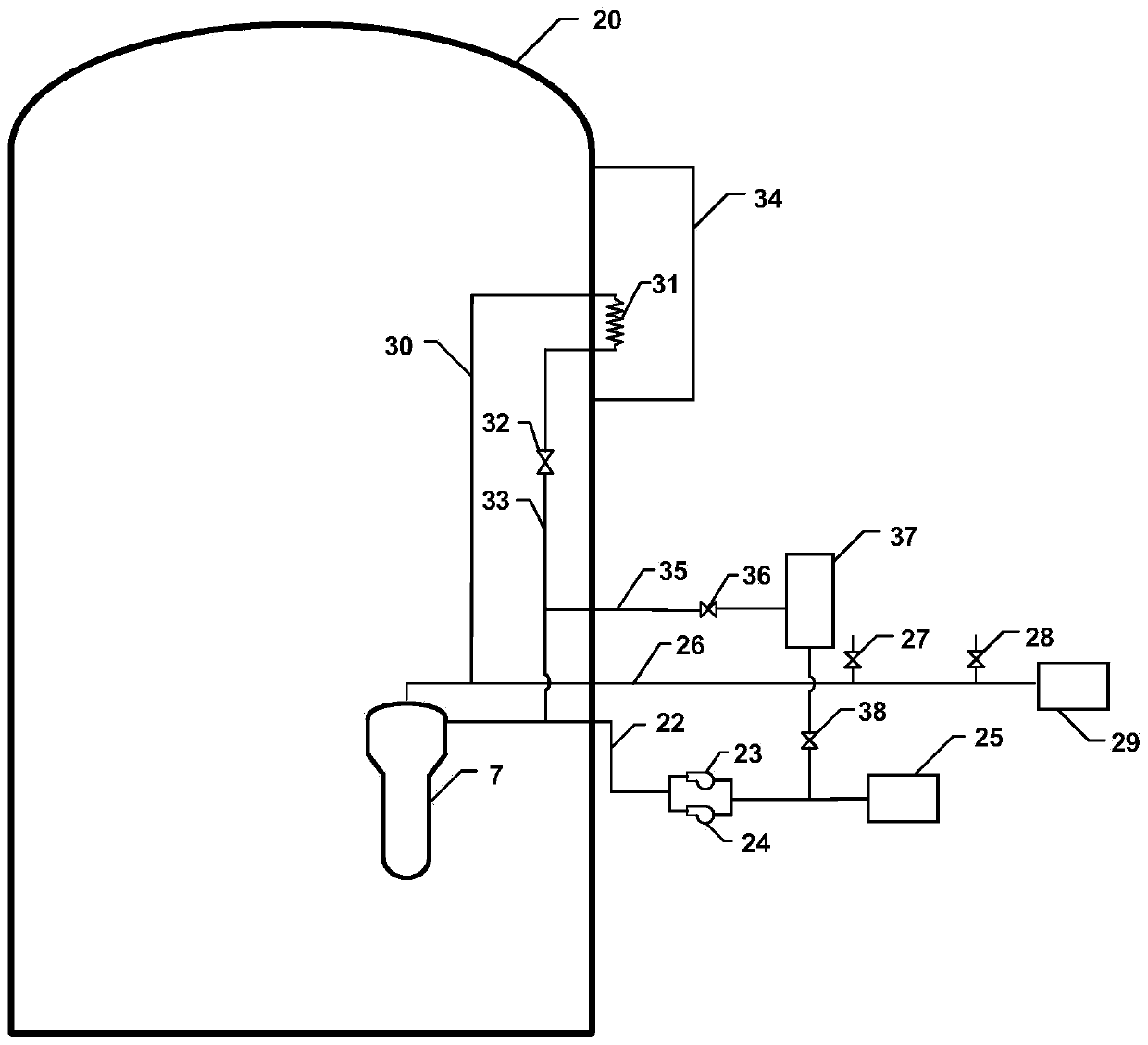

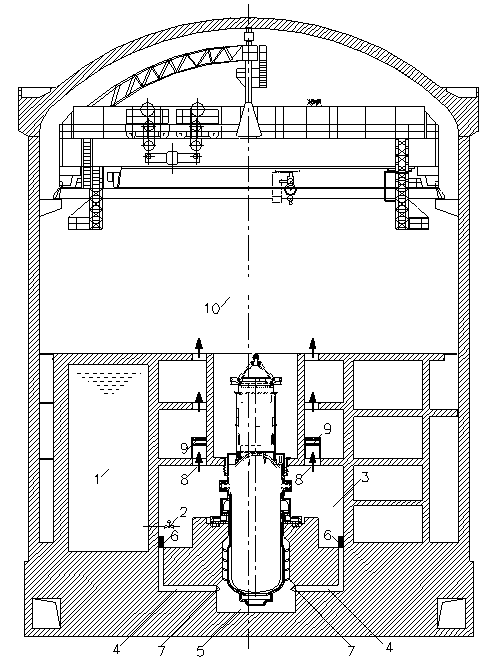

Integral reactor passive reactor cavity runner system and application method thereof

ActiveCN103390436ARelieve pressureReduce hydrogen concentrationNuclear energy generationEmergency protection arrangementsReactor pressure vesselPressure vessel

The invention discloses an integral reactor passive reactor cavity runner system and an application method thereof. The integral reactor passive reactor cavity runner system comprises a reactor cavity and a reactor pit as well as an annular main shield wall positioned between the reactor cavity and the reactor pit, wherein the reactor pit is formed below the main shield wall, and the reactor cavity is positioned above the main shield wall; the reactor cavity and the reactor pit are communicated through an L-type runner; one end, close to a reactor pit, of the runner is provided with a wind shield, and the top of the reactor cavity is provided with two gas releasing holes. The integral reactor passive reactor cavity runner system and the application method thereof provided by the invention have the advantages that a passive reactor cavity runner structure can submerge the reactor cavity and the reactor pit of an integral reactor in a passive manner, cool a reactor pressure vessel, maintain the integrity of the reactor pressure vessel, prevent the reactor pressure vessel from being melted out through a reactor core melt, provide the injection flow for cooling a reactor core of the reactor for a long time, and prevent risks of the overpressure and hydrogen gathering explosive of the reactor cavity of the integral reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Casting method of electric furnace water cooling cast steel furnace cover

InactiveCN101634524AGuaranteed micro-fusionImprove mechanical propertiesFurnace componentsProcess efficiency improvementAlloyMolten steel

The invention relates to a casting method of electric furnace water cooling cast steel furnace cover, which adopts a cast steel material to cast a base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the base body, casting the middle part of the cooling water pipe into the base body and leading the two ends thereof to extend from the base body; leading the casting model to be horizontal when in modeling, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoids air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the electric furnace water cooling cast steel furnace cover, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the mechanical performance of the electric furnace water cooling cast steel furnace cover.

Owner:江苏联兴成套设备制造有限公司

Casting method of cast steel rotary furnace flue

ActiveCN101634521AGuaranteed micro-fusionImprove cooling effectFurnace cooling arrangementsProcess efficiency improvementAlloyMolten steel

The invention relates to a casting method of a cast steel rotary furnace flue, which adopts a cast steel to cast a base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the base body; leading the casting model to be horizontal in the modeling process, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoids air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the rotary furnace flue, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the mechanical performance of the cast steel rotary furnace flue.

Owner:江苏联兴成套设备制造有限公司

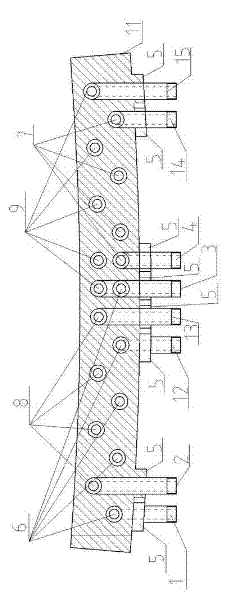

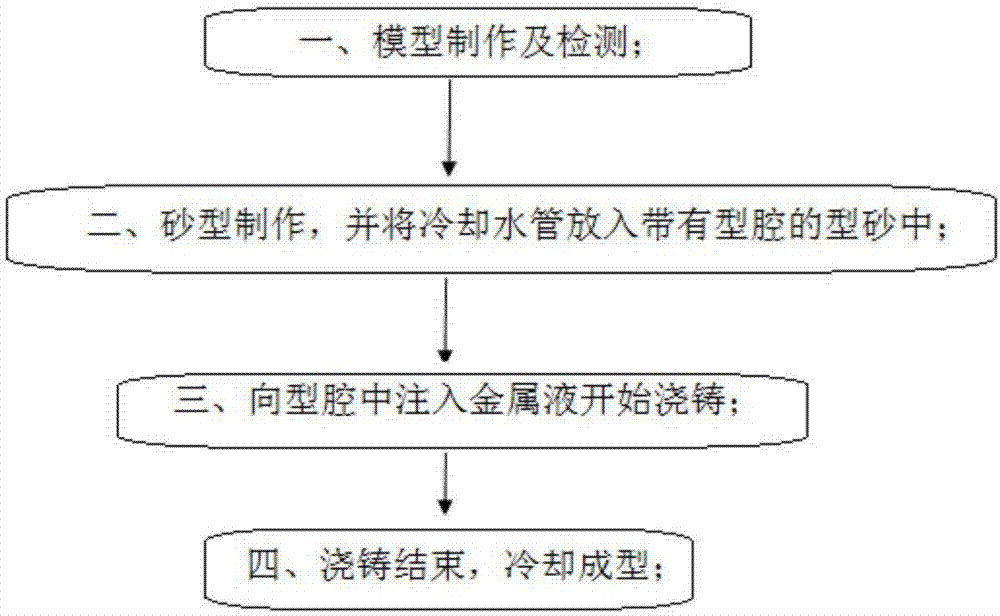

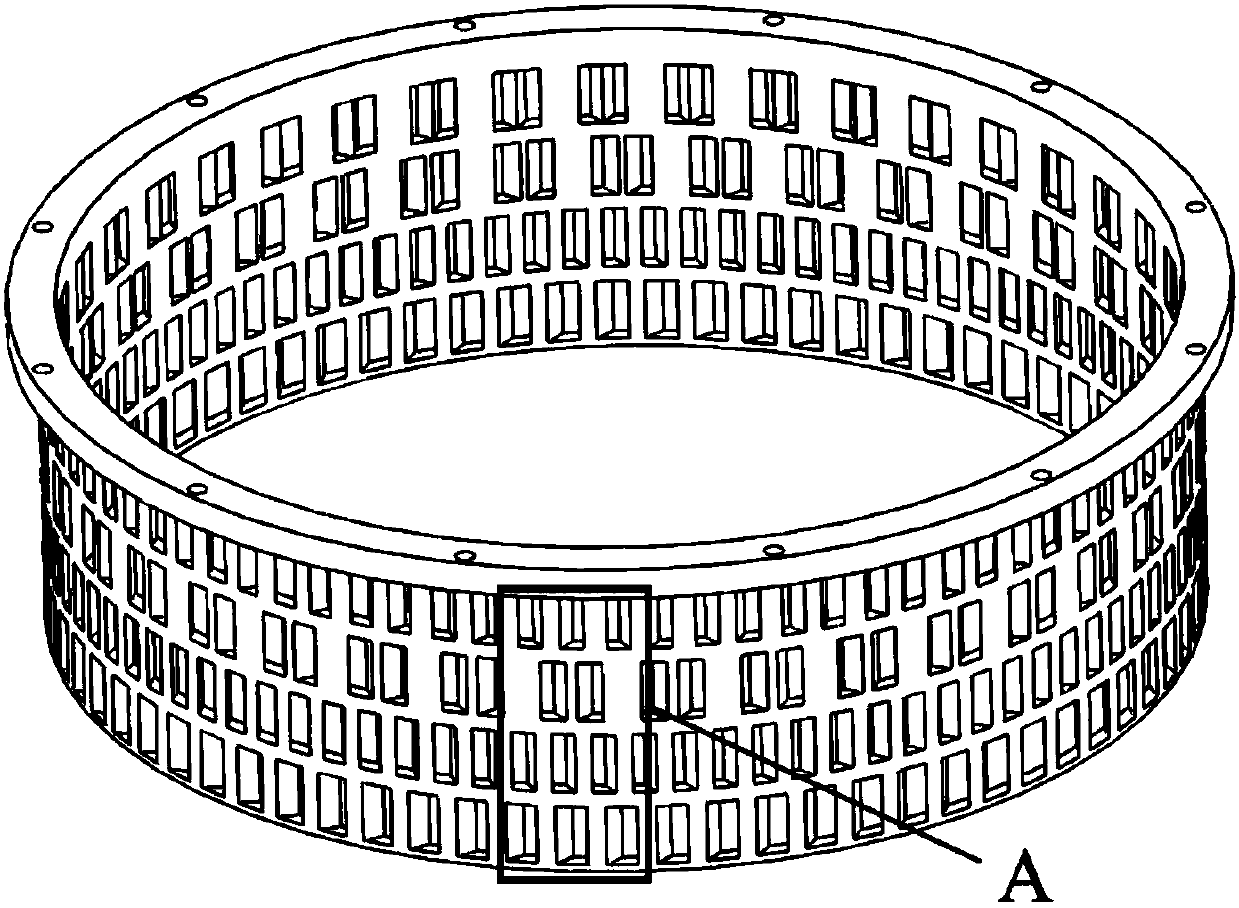

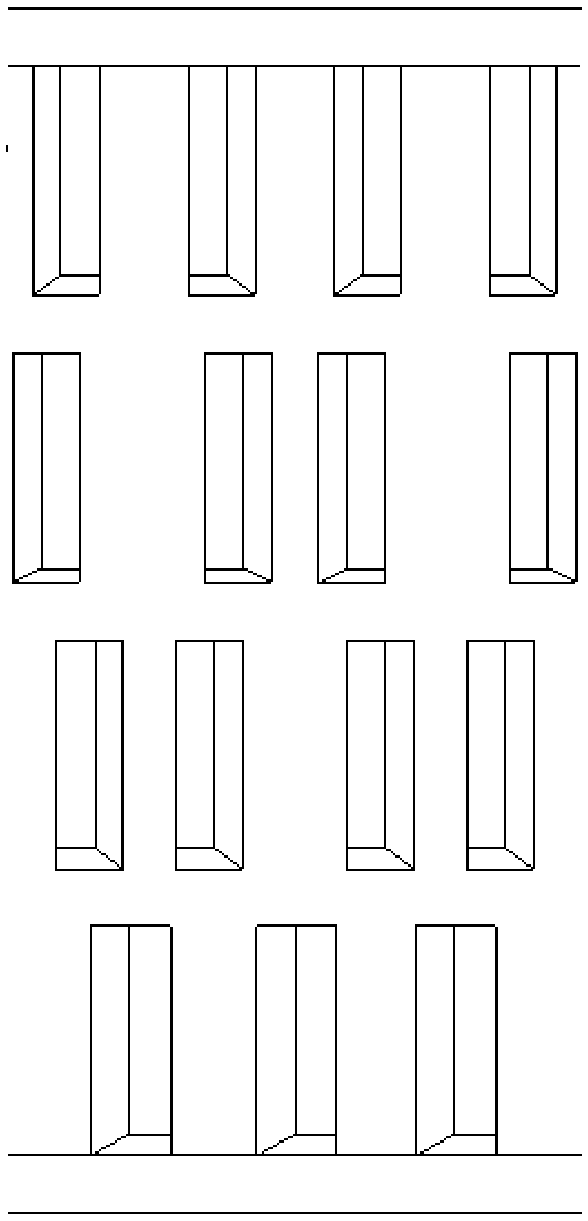

Multilayer cooling blast-furnace cooling stave and processing technology thereof

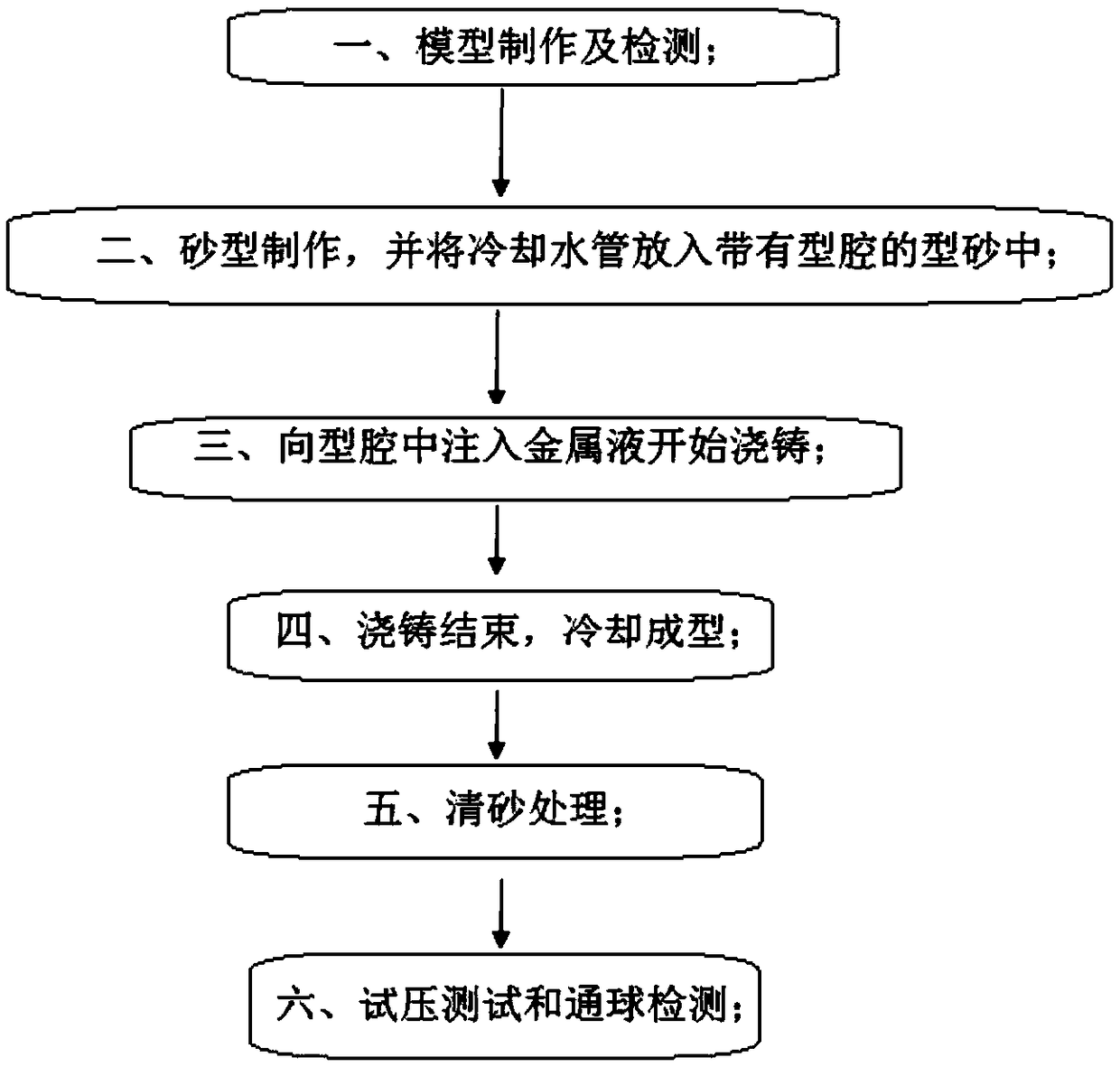

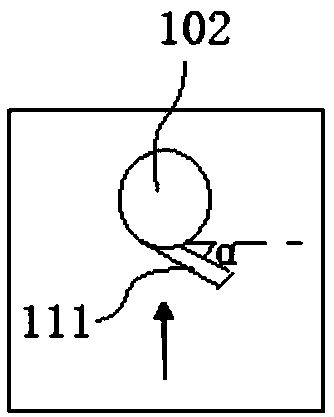

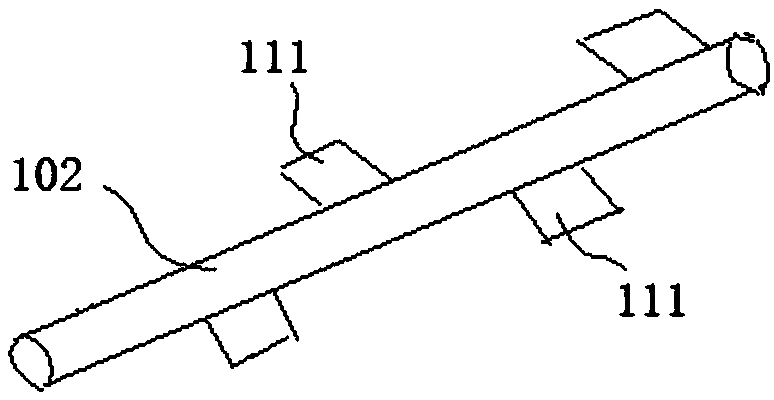

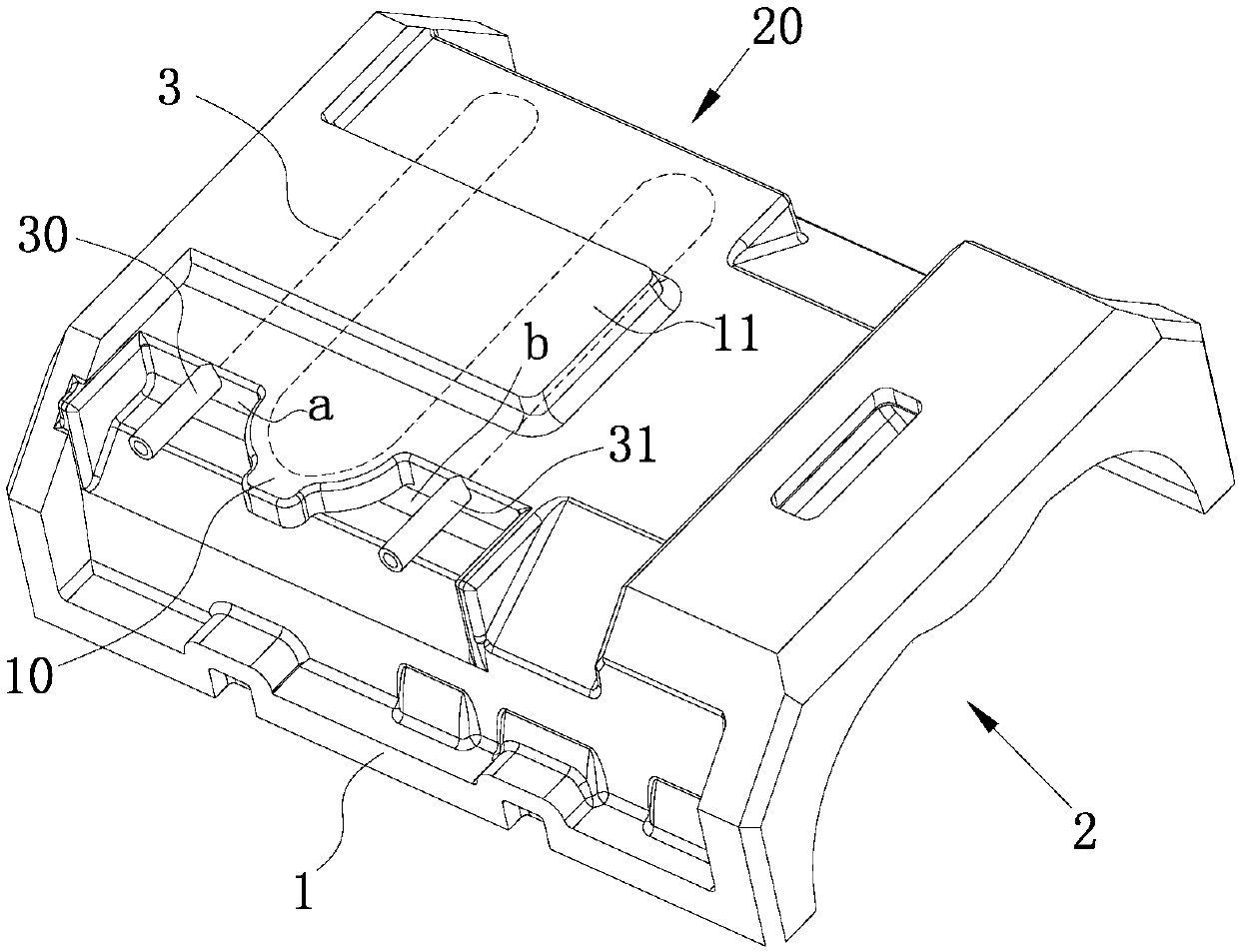

ActiveCN107083462AImprove cooling effectFully meltedFoundry mouldsCooling devicesCooling effectMolten steel

The invention discloses a multilayer cooling blast-furnace cooling stave and a processing technology thereof, and belongs to the field of cooling staves. The processing technology comprises the following steps that 1, a cooling stave wood pattern is produced; 2, a sand mold is produced and cooling water pipes are arranged, wherein the cooling stave wood pattern is put into a sand box, sand molding is compacted, the cooling stave wood pattern is taken out and a mold cavity is formed, and the cooling water pipes are distributed in the mold cavity; each cooling water pipe comprises a first cooling water pipe, a second cooling water pipe and a third cooling water pipe; 3,molten steel is poured into the mold cavity and casting is started; 4, cooling molding is conducted after casting. The processing technology can overcome the shortage that over smelting of the cooling water pipes occurs in the cooling stave easily, multilayer cooling pipes are paved in the cooling stave to strengthen the cooling effect, the machining process is controlled strictly, over smelting of the cooling water pipes is avoided effectively, and the technical effects of smelting but not melt and seamless fusion can be achieved.

Owner:MAANSHAN RUNTONG HEAVY IND TECH CO LTD

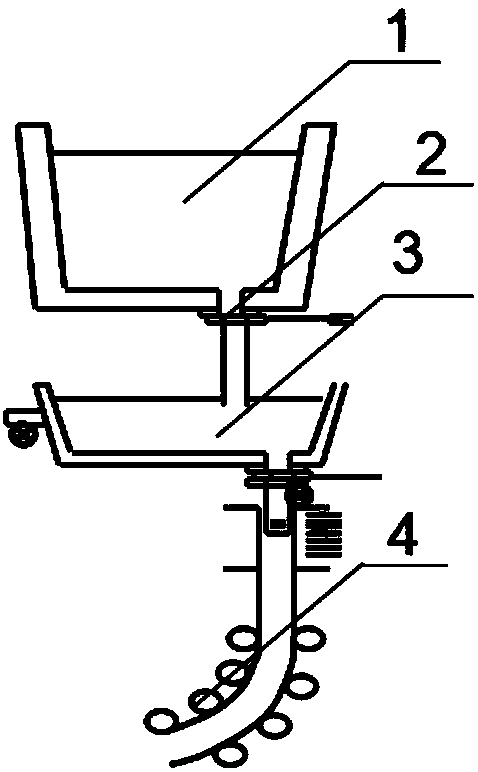

Passive containment condensate injection system

ActiveCN104167229BEnsure safetyReduce the temperatureNuclear energy generationCooling arrangementLine tubingNuclear power

The invention relates to a passive containment shell condensed water injection system. The system comprises a first water collecting device; a first condensed water injection pipeline, which is connected to the first water collecting device and a pressure container direct injection pipeline; and a first valve mechanism, which is arranged on the first condensed water injection pipeline and is capable of starting the condensed water injection and controlling the condensed water injection flow after receiving a severe accident signal. The first water collecting device comprises a first water collecting groove, which is arranged along the circumferential direction of the internal wall of a containment shell. The first water collecting groove is arranged above the reactor core, and the standard distance between the first water collecting groove and the reactor core is 40% to 75% of the total height of the containment shell. When a severe accident happens, the system can utilize the pressure due to the height difference between the water collecting groove and the reactor core to completely inject the condensed water into the reactor core to ensure the safety of the reactor. Moreover, the system also can collect the condensed water from the internal wall of the containment shell and directly injects the collected condensed water into the reactor core to cool the melts in the reactor core. The system has the advantages of simple structure, high reliability, and suitability for various kinds of nuclear power stations.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

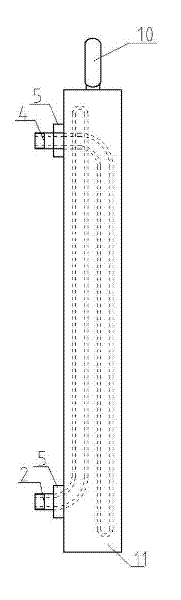

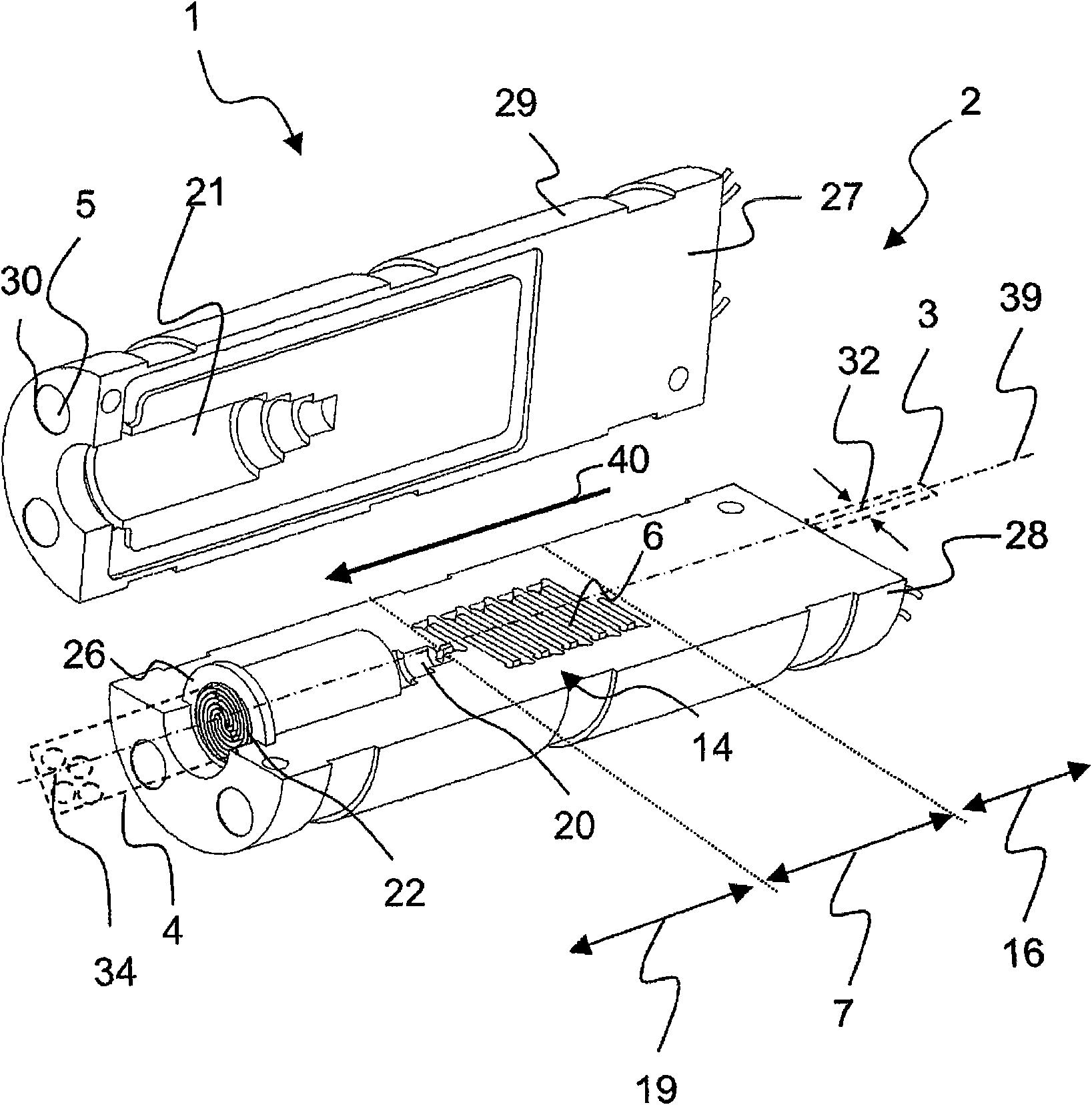

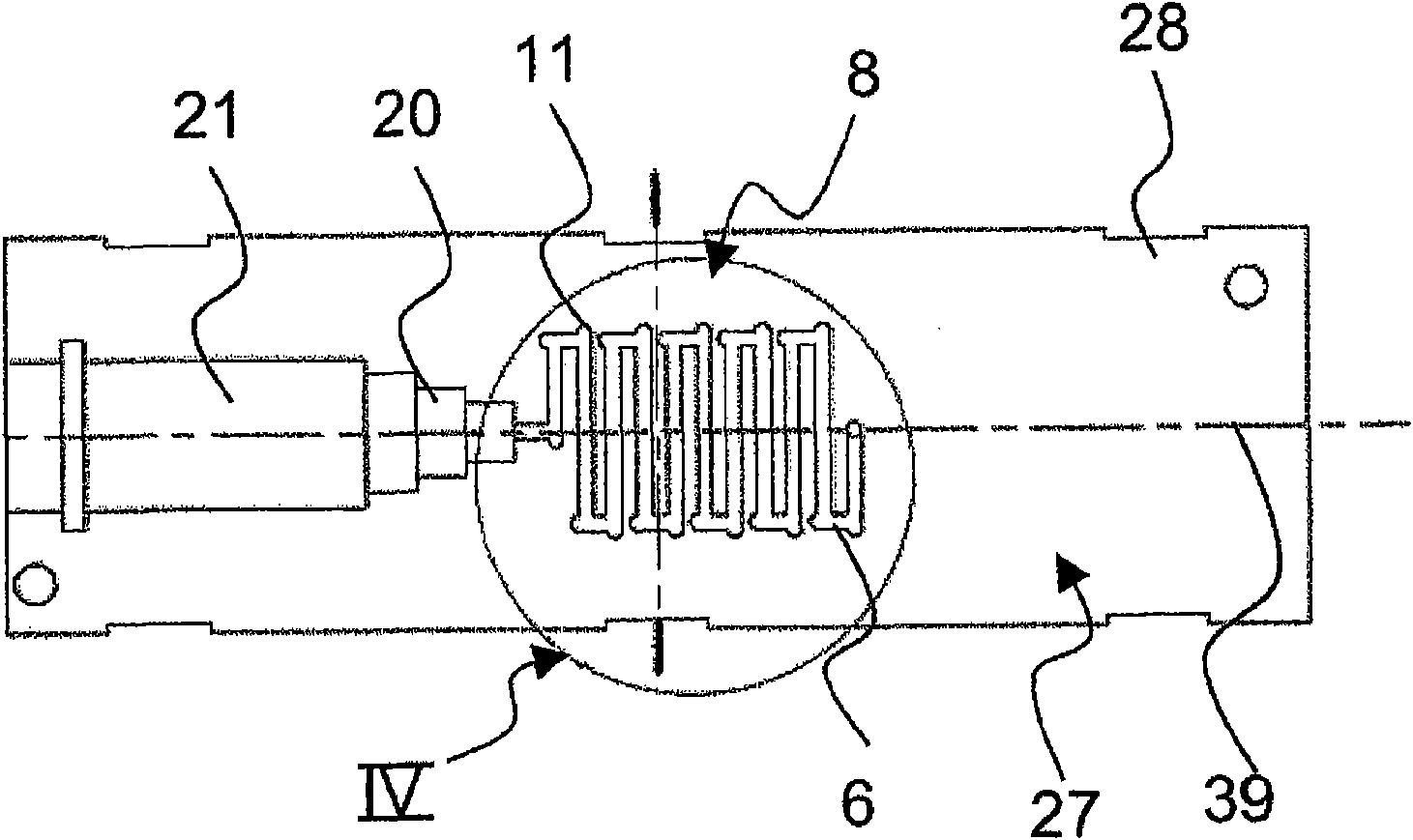

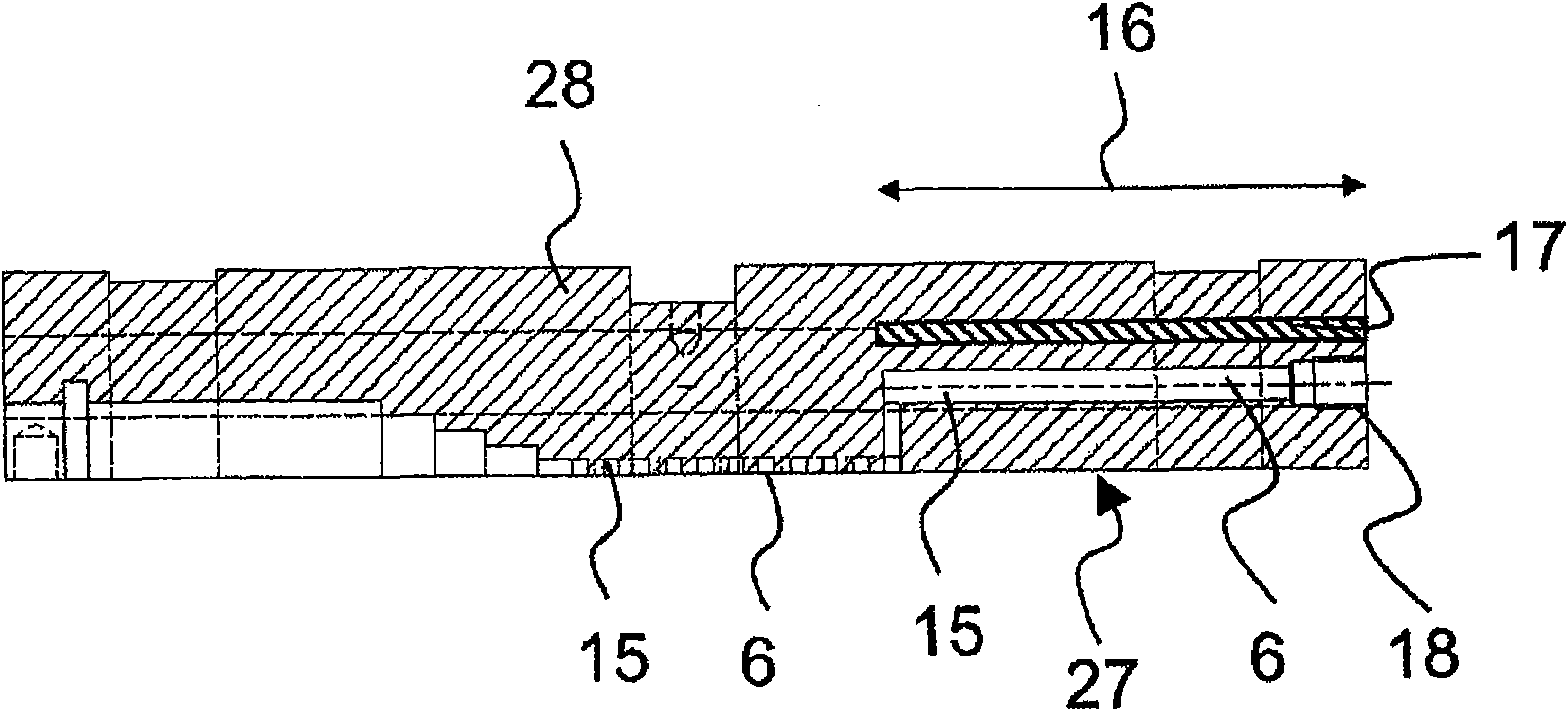

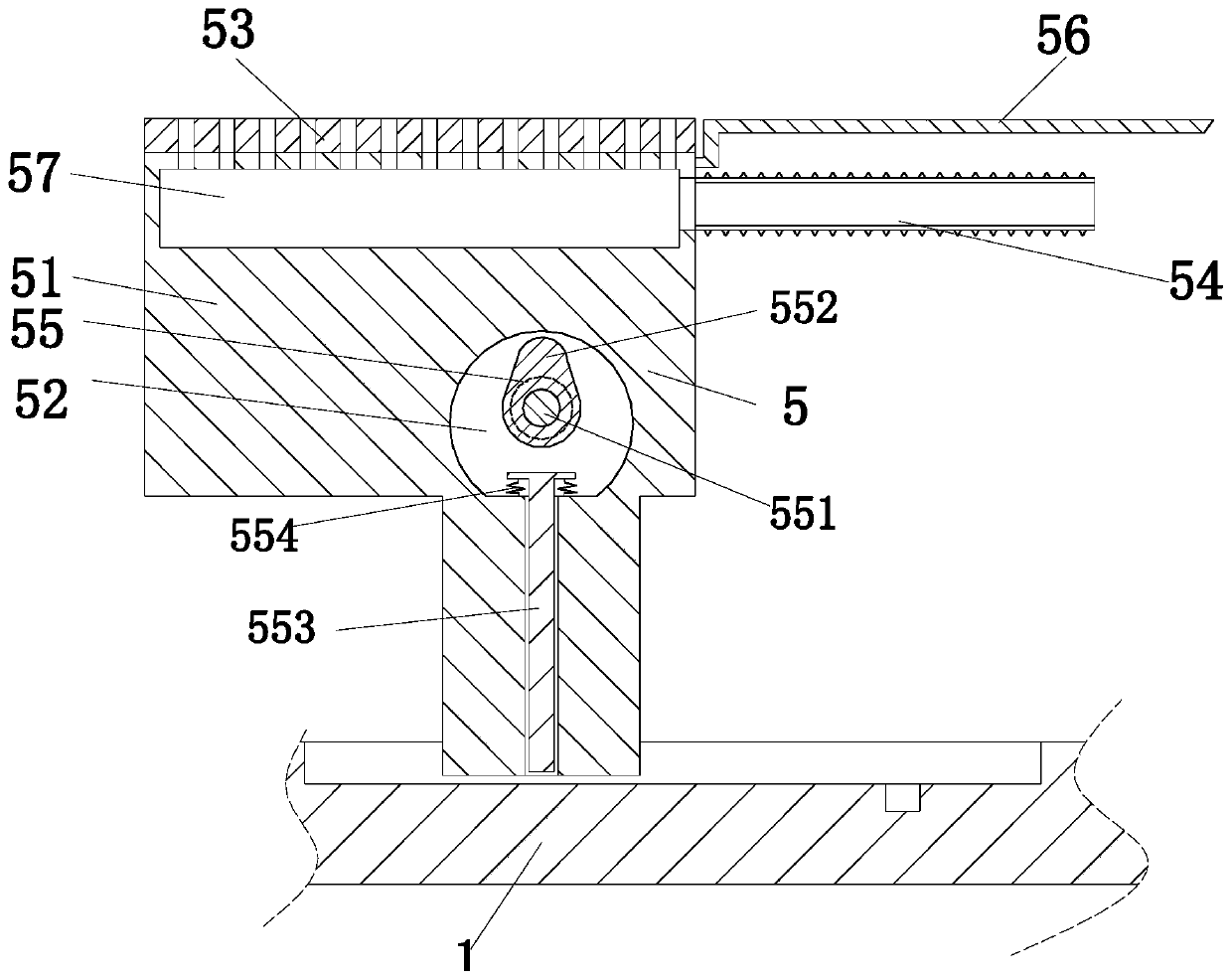

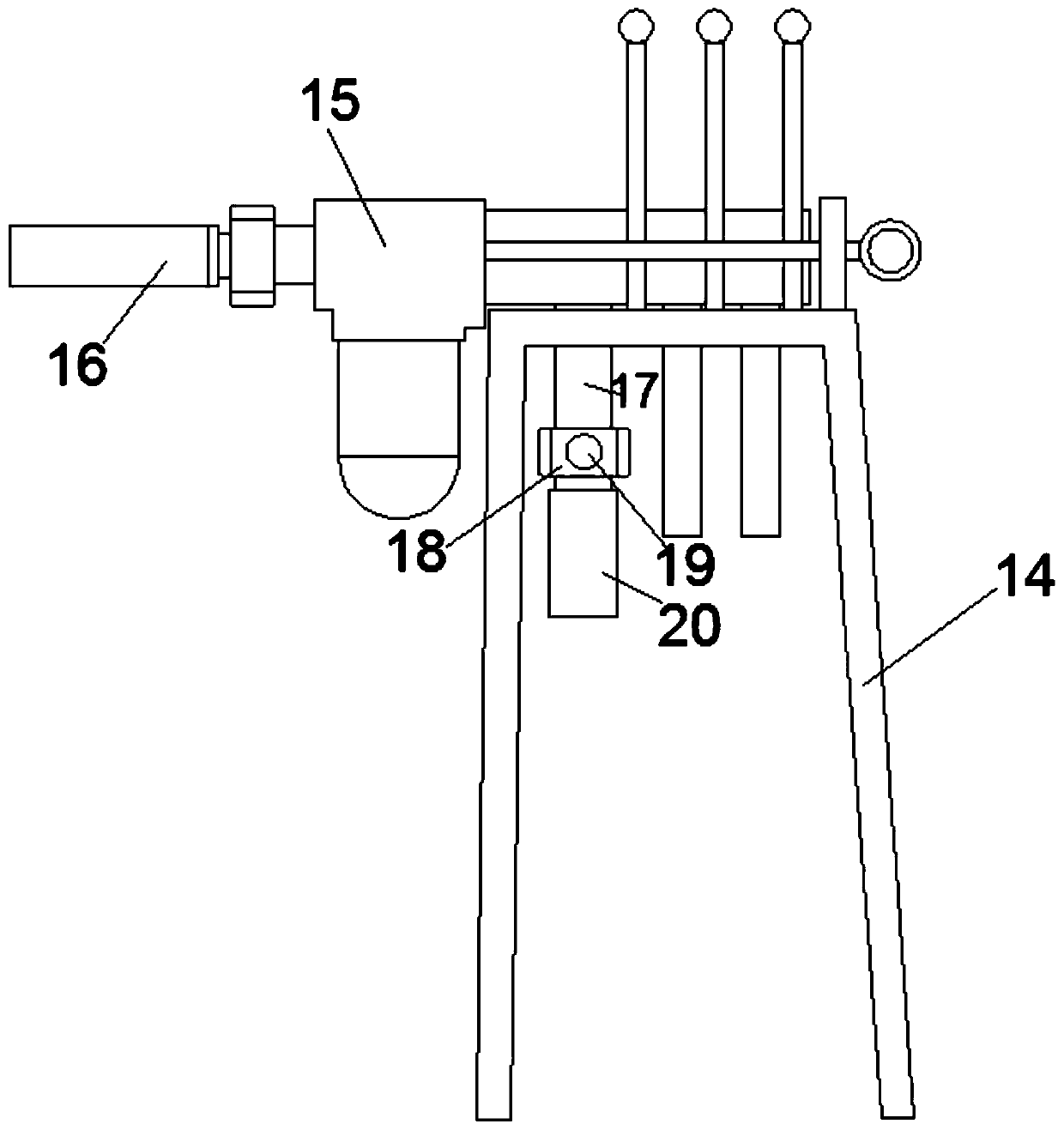

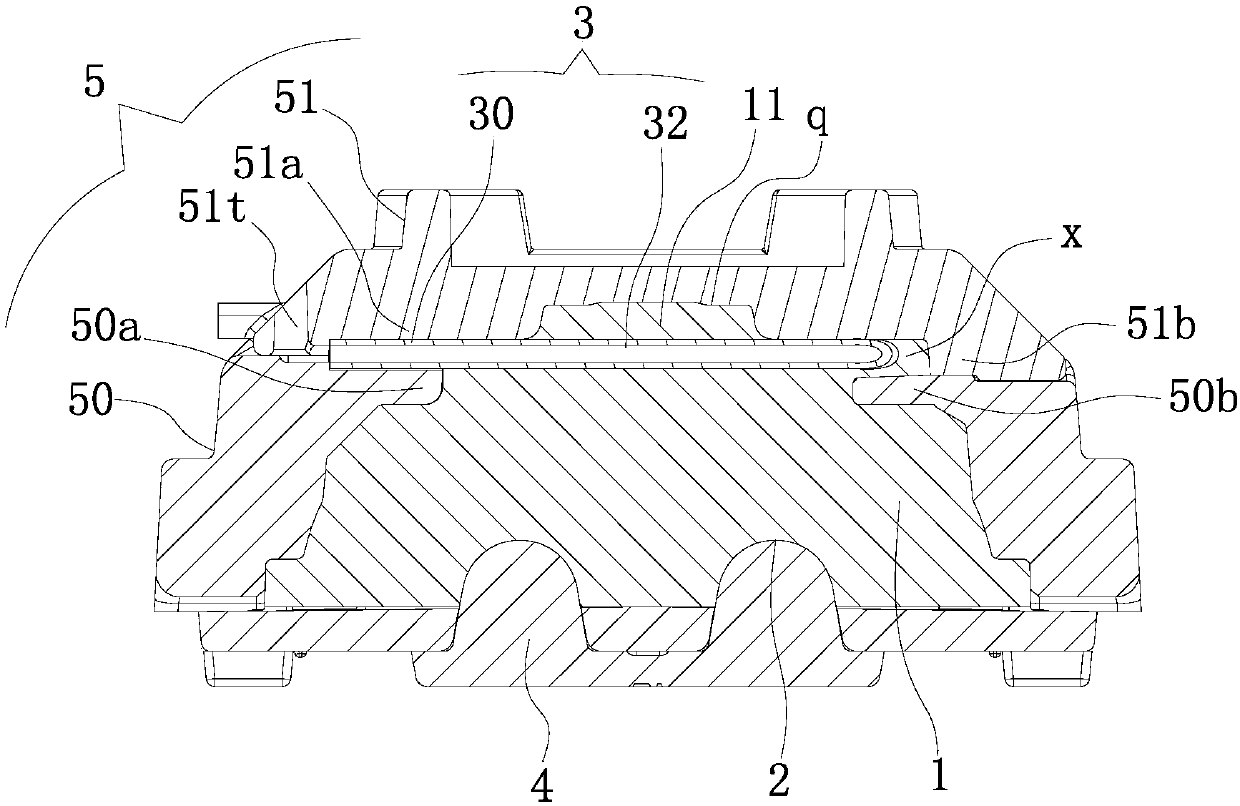

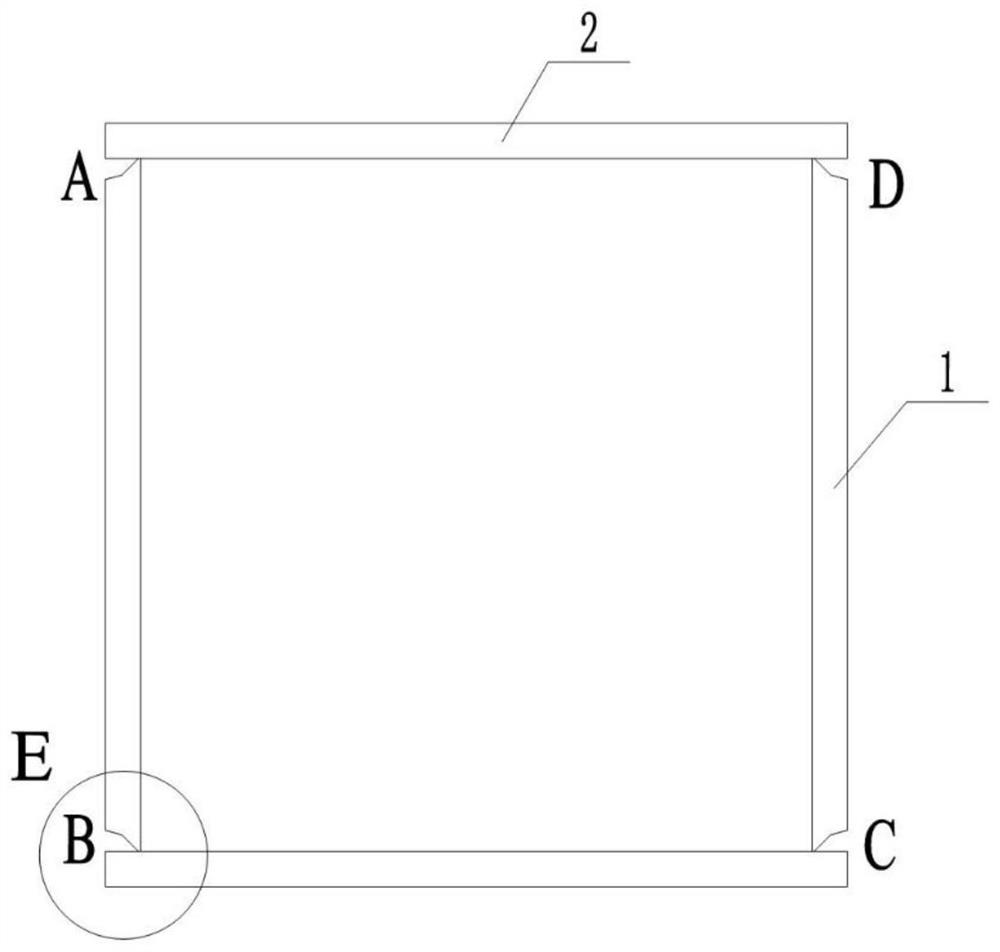

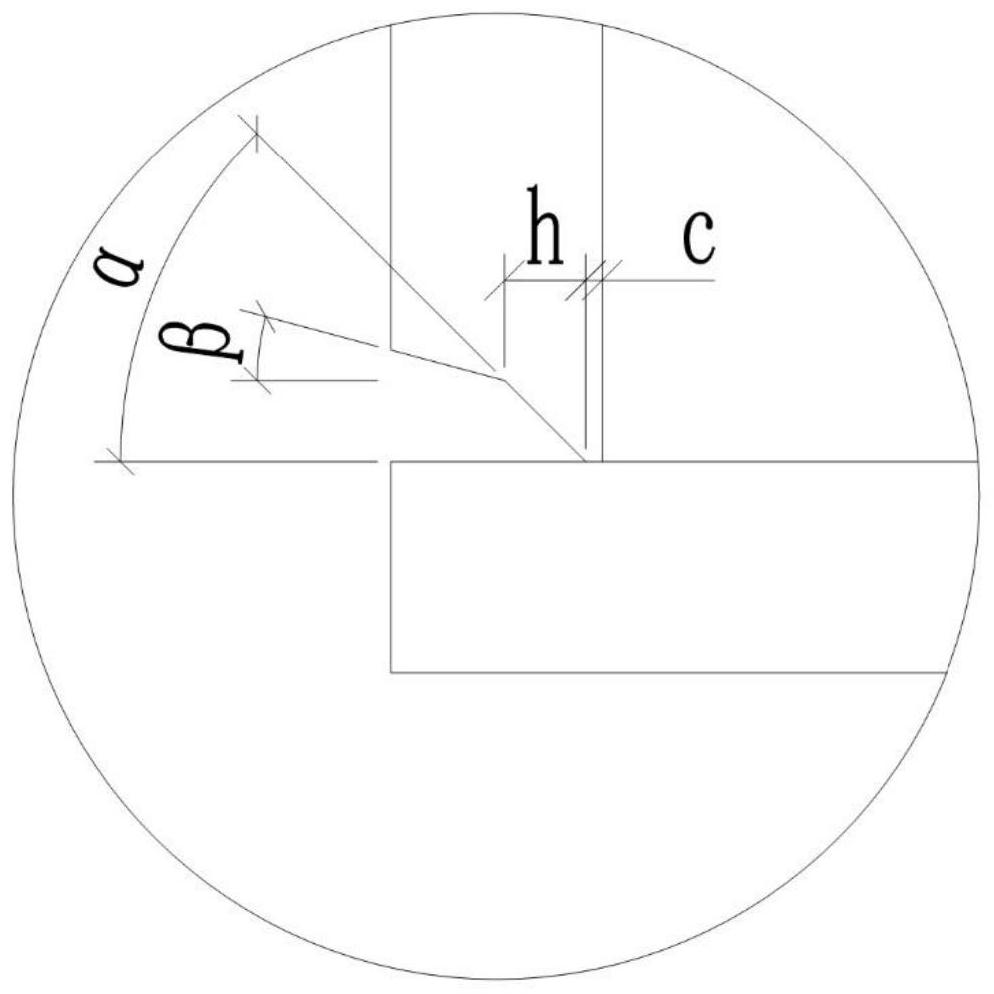

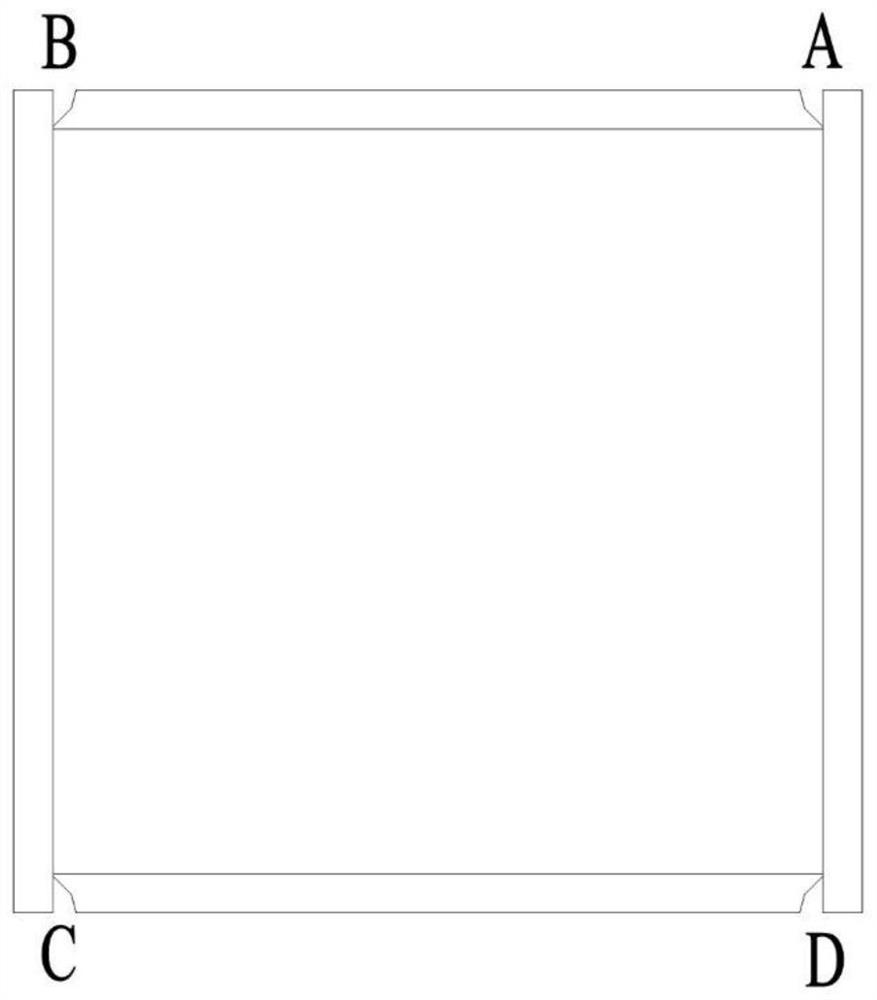

Evaporator for mobile anhydrous ammonia production, and method for manufacturing such an evaporator

InactiveCN101678242AAvoid meltdownExhaust apparatusSilencing apparatusHeat conductingAmmonia production

Disclosed is an evaporator (1) for ammonia to be used in mobile emission systems. Said evaporator (1) comprises a base (2) encompassing at least one supply pipe (3) and at least one discharge pipe (4). At least one heating element (5) and at least one duct (6) for connecting the supply pipe (3) to the discharge pipe (4) are arranged within the base (2). The at least one heating element (5) is in heat-conducting contact with an evaporation section (7) of the at least one duct (6), while the at least one duct (6) has a serpentine shape (8) in said evaporation section (7).

Owner:EMITEC EMISSIONSTECHNIK

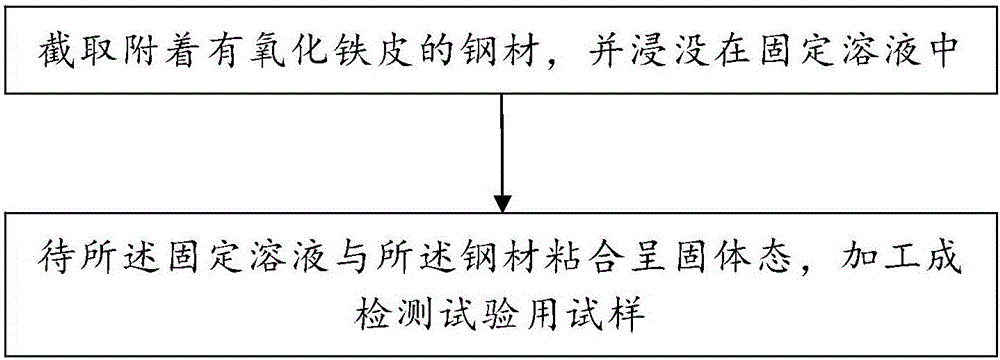

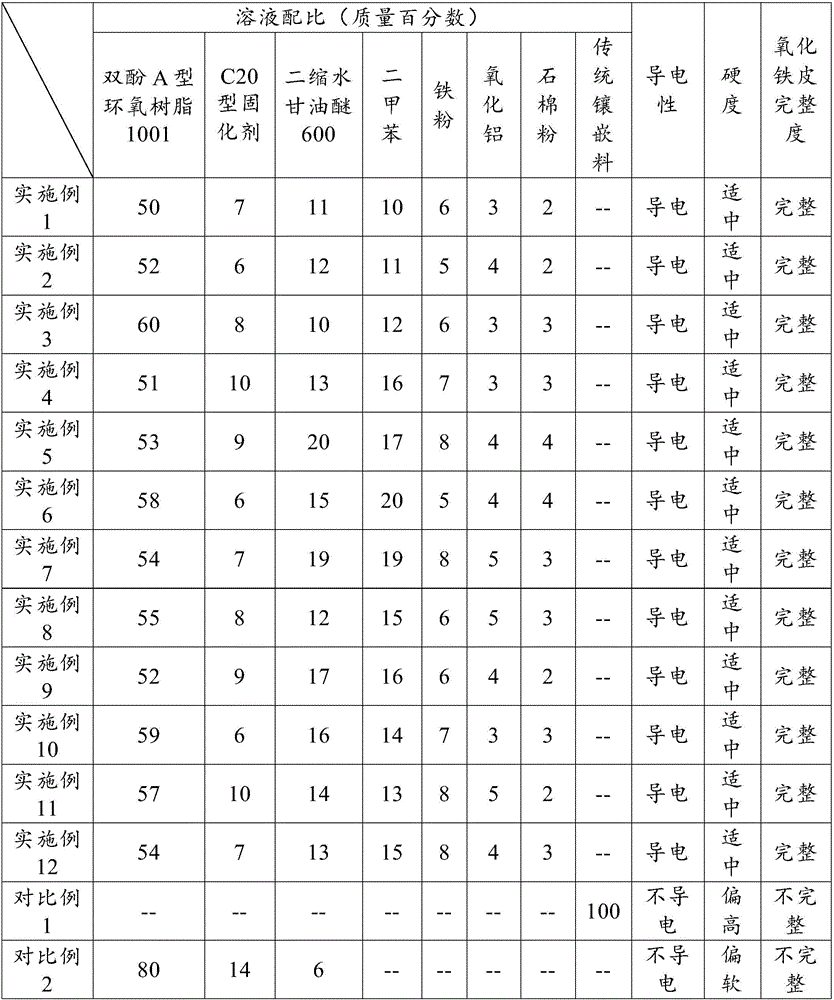

Iron oxide scale sample preparation method and detection method

InactiveCN105928760AImprove reliabilityEasy to operatePreparing sample for investigationSpatial organizationMaterials science

The invention belongs to the technical field of steel making, and discloses an iron oxide scale sample preparation method. The method comprises the steps that steel attached with an iron oxide scale is cut out and immersed in a fixation solution; when the fixation solution bonds with the steel to be in a solid state, a sample for detection experiments is machined, wherein the fixation solution is prepared from bisphenol A type epoxy resin, a C20 type curing agent, diglycidyl ether and aluminum oxide, and the input of the C20 type curing agent is 10%-20% by mass of bisphenol A type epoxy resin. According to the iron oxide scale sample preparation method, a spatial organization structure of the iron oxide scale can be completely preserved, and the reliability of experimental detection is greatly improved.

Owner:武汉钢铁有限公司

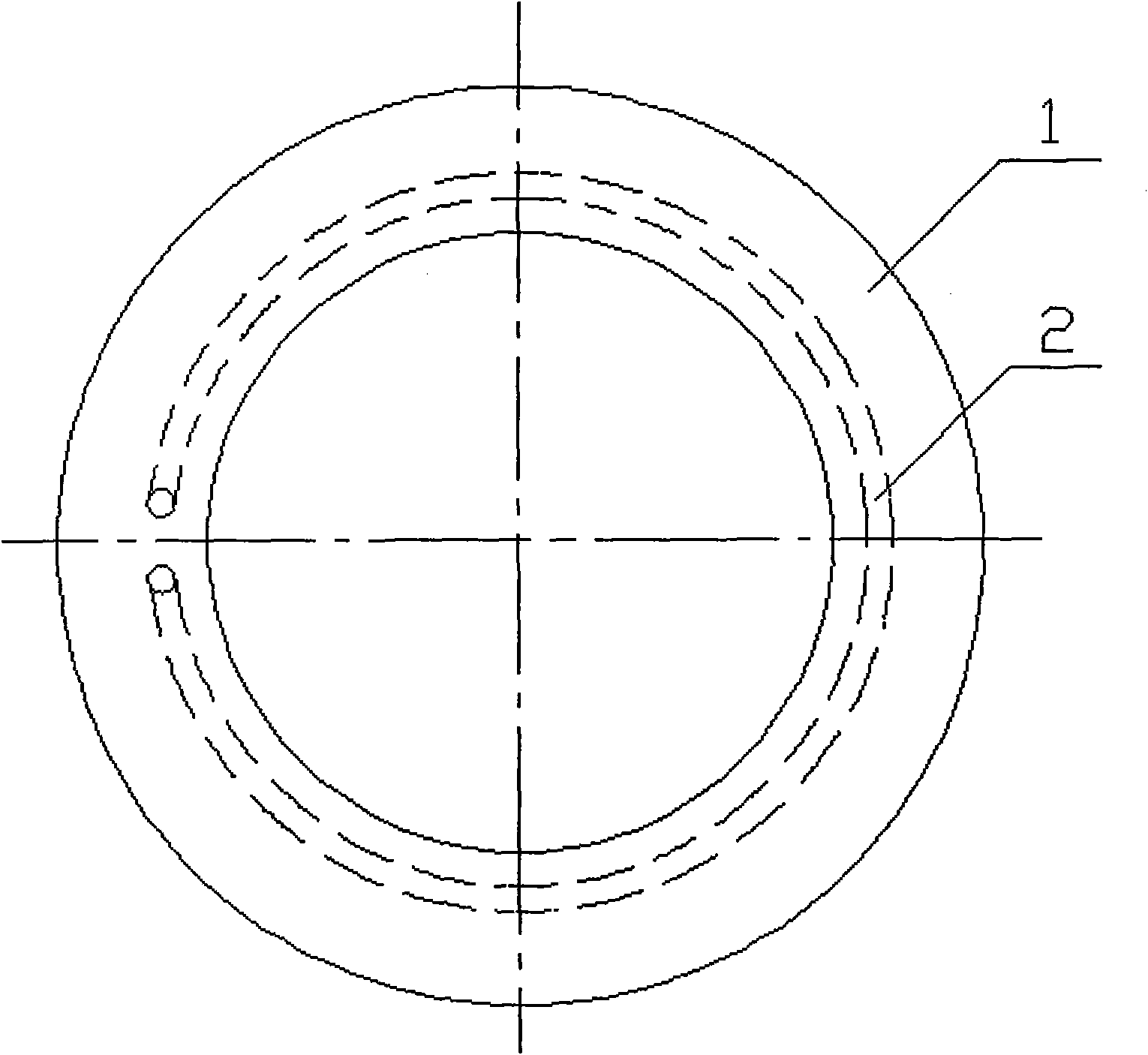

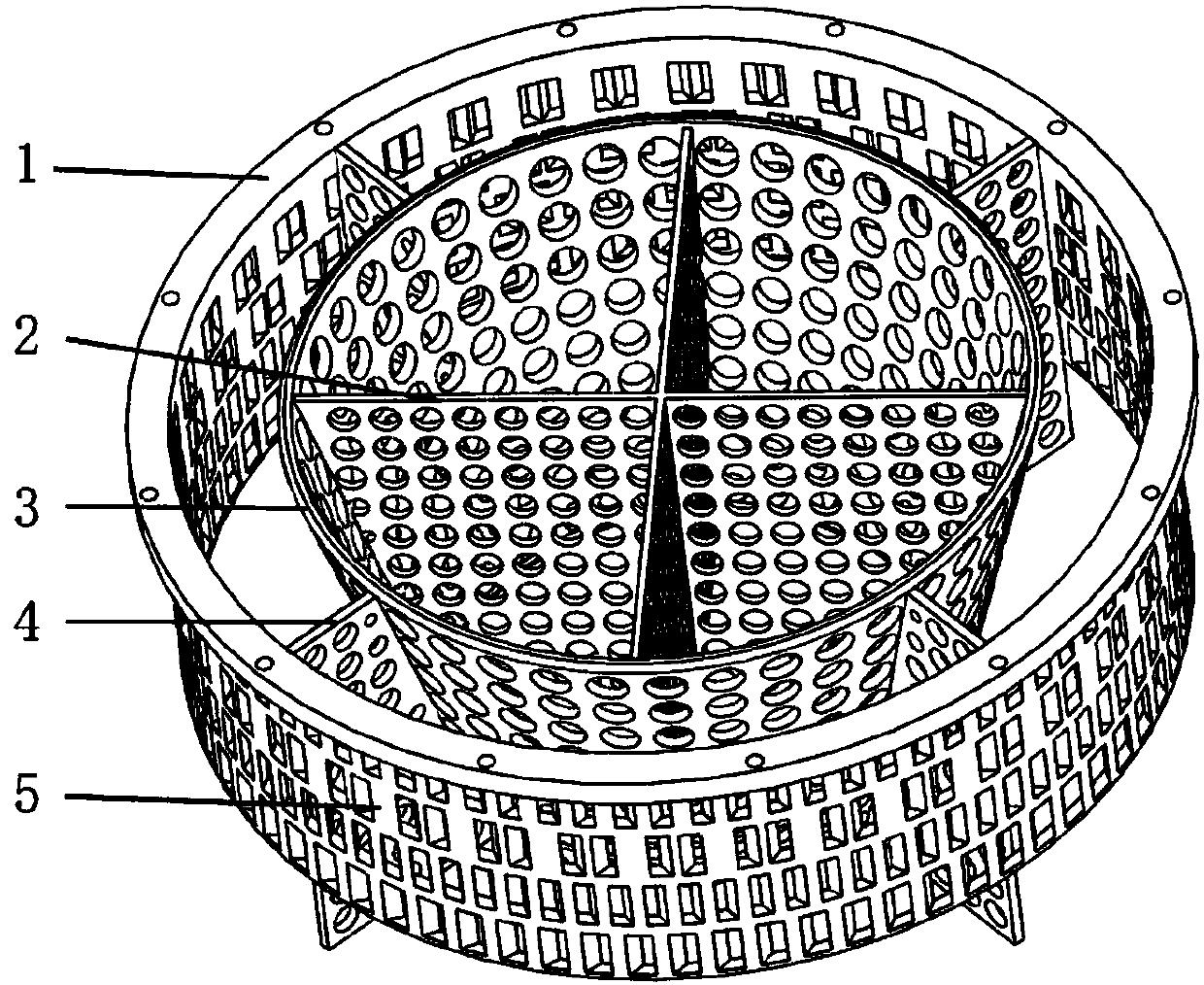

Pressurized water nuclear reactor nested component

PendingCN107658031ASimple structureEasy to replaceNuclear energy generationCooling arrangementUltrasound attenuationNuclear reactor

A pressurized water nuclear reactor nested component comprises an inner-layer flow distributing barrel, an outer-layer flow distributing barrel and at least three outer-layer flow distributing plates.Multiple water flowing holes are formed in the wall of each of the inner-layer flow distributing barrel and the outer-layer flow distributing barrel, an outer flange connected with a reactor core lower supporting plate is arranged at the upper end of the outer-layer flow distributing barrel, and multiple water flowing holes are formed in the surface of each plate; the inner-layer flow distributing barrel is put in an inner cavity of the outer-layer flow distributing barrel, central lines of the inner-layer flow distributing barrel and the outer-layer flow distributing barrel are coincident, the outer-layer flow distributing plates are in dispersed arrangement in an annular space surrounded by the outer wall of the inner-layer flow distributing barrel and the inner wall of the outer-layerflow distributing barrel, and two side faces of each outer-layer flow distributing plate are fixedly connected with the outer wall of the inner-layer flow distributing barrel and the inner wall of theouter-layer flow distributing barrel. The nested component is used for coolant flow distributing, attenuation of coolant flow at the edge of a reactor core inlet can be reduced, displacement and disturbance of a coolant in a lower cavity are prevented, vortex is suppressed, and quantity of metal obtained by melting is increased.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Battery protection equipment for preventing charging head of new energy automobile from being fused

InactiveCN113036713AAvoid feverPrevent the situationEmergency protective arrangements for automatic disconnectionCold airRubber material

The invention relates to the technical field of whole vehicle manufacturing of new energy vehicles, and discloses battery protection equipment for preventing a charging head of a new energy vehicle from being fused. The exterior of a main body is fixedly connected with an air spring. According to the battery protection equipment for preventing the charging head of the new energy automobile from being fused, due to the fact that a rubber block cannot provide enough bearing force for the load of an air spring, the air spring expands to extrude a rubber block, the rubber block extrudes a mounting frame to synchronously move towards the middle, and cold air in a telescopic bag is extruded out; the gas enters a thermometer through a central tube and moves downwards under the power-off action of a power-off strip; the left end and the right end of the power-off strip are a positive electrode and a negative electrode respectively, the power-off strip is made of a rubber material, and electric quantity is guided out; and the gas finally enters a metal part, and the cooled gas in the metal part is stored and detected, so the situation that a gun head is heated and fused due to the fact that equipment cannot be cooled in time due to high temperature is prevented.

Owner:广州创开科技有限公司

Method for preventing punchthrough of slag ladles during containing washing slag of converter

InactiveCN104561435AReduce the temperatureStrong adhesionManufacturing convertersLiquid slagSteel casting

The invention discloses a method for preventing punchthrough of slag ladles during containing washing slag of a converter. The method comprises the following steps: during normal smelting of 3-6 furnace steel before the converter prepares to wash out, containing liquid slag of the converter by the converter by virtue of slag ladles of a steel casting according to a normal process; pouring out the liquid slag in the slag ladles, and leaving 3-6 empty slag ladles with slag films; when the washing slag is poured out by the converter, containing the liquid slag of the converter by virtue of the slag ladles with converter slag films; and after containing the liquid slag of the converter, processing the washing slag of the converter according to a normal slag treatment process.

Owner:XINJIANG BAYI IRON & STEEL

Preparation method of radiator containing complex variable cross-section hole channel

PendingCN113857462ASimplify the manufacturing processIncrease profitGearingCylindersHigh volume manufacturingManufactured material

The invention discloses a preparation method of a radiator containing a complex variable cross-section hole channel, and belongs to the technical field of manufacturing of electronic component radiators. According to the method, alloy used by the radiator is used as a raw material, a complex variable-cross-section pipe is prepared in advance, the shape and size of each part in the complex variable-cross-section pipe are the same as those of each part in a hole of the complex variable-cross-section hole channel in the radiator, and then the complex variable-cross-section pipe is placed into a casting mold to be positioned and fixed; and after poured alloy liquid is solidified, the complex variable-cross-section pipe and the alloy are tightly combined, an integrated casting is formed, and the radiator containing the complex variable-cross-section hole channel is obtained. Compared with a traditional preparation method of the radiator containing the complex variable cross-section hole channel, the method is simple in preparation process, short in production period, high in material utilization rate and low in production cost, and the prepared radiator is high in hole channel size precision and mechanical property, good in heat dissipation effect, long in service life, suitable for mass production and high in application and popularization value.

Owner:UNIV OF SCI & TECH BEIJING

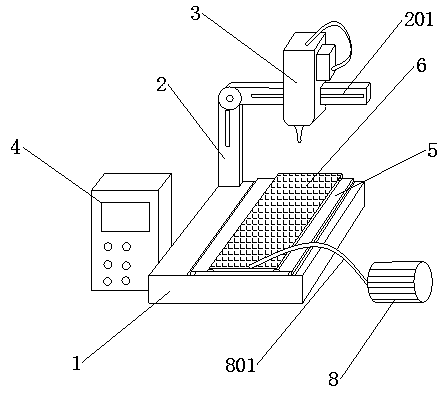

Stable operation pad for electronic circuit board soldering

InactiveCN109996396AExtended service lifeSolve the burrsPrinted circuit assemblingMetal working apparatusSolderingElectronic circuit

The invention discloses a stable operation pad for electronic circuit board soldering. The stable operation pad comprises a device body and a mechanical arm, wherein the mechanical arm is arranged above the device body, one end of the mechanical arm is connected with the device body in a transmission manner, a welding head track is arranged above the mechanical arm, the welding head track is embedded in the mechanical arm, a slide track is arranged above the device body, the slide track is fixedly connected on the device body, a blower is arranged at the right of the device body, and the blower is fixedly connected on the device body. The stable operation pad for electronic circuit board soldering is provided with a thermal insulating layer that is tightly attached to the operation pad, ametal net is arranged below the thermal insulating layer, the meal net is tightly attached to the thermal insulating layer that is made of a high temperature resisting material, so that high temperature due to welding is prevented from melting the workbench, and the workbench is further protected.

Owner:GUILIN SHIHUAN WASTE GAS TREATMENT EQUIP

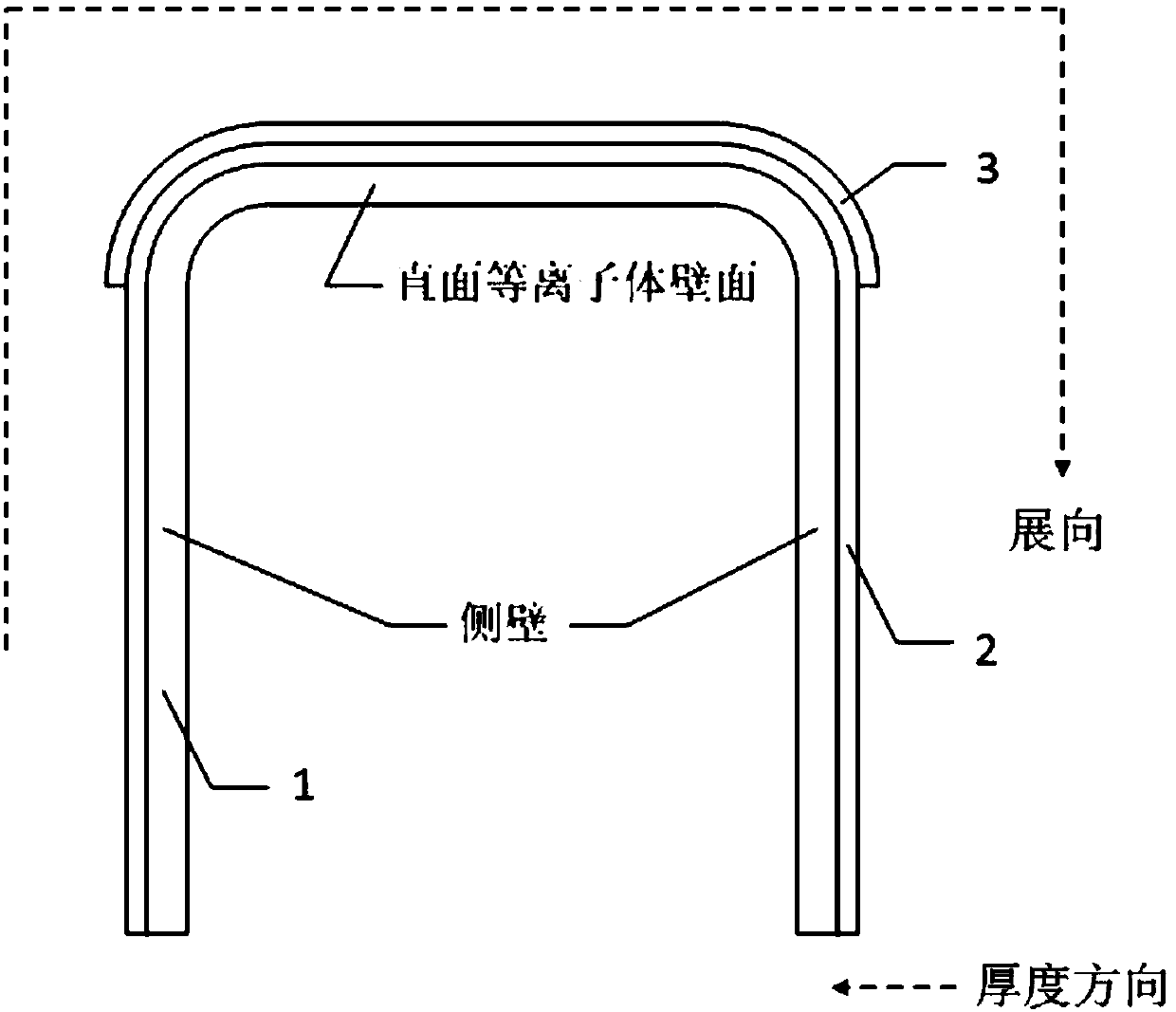

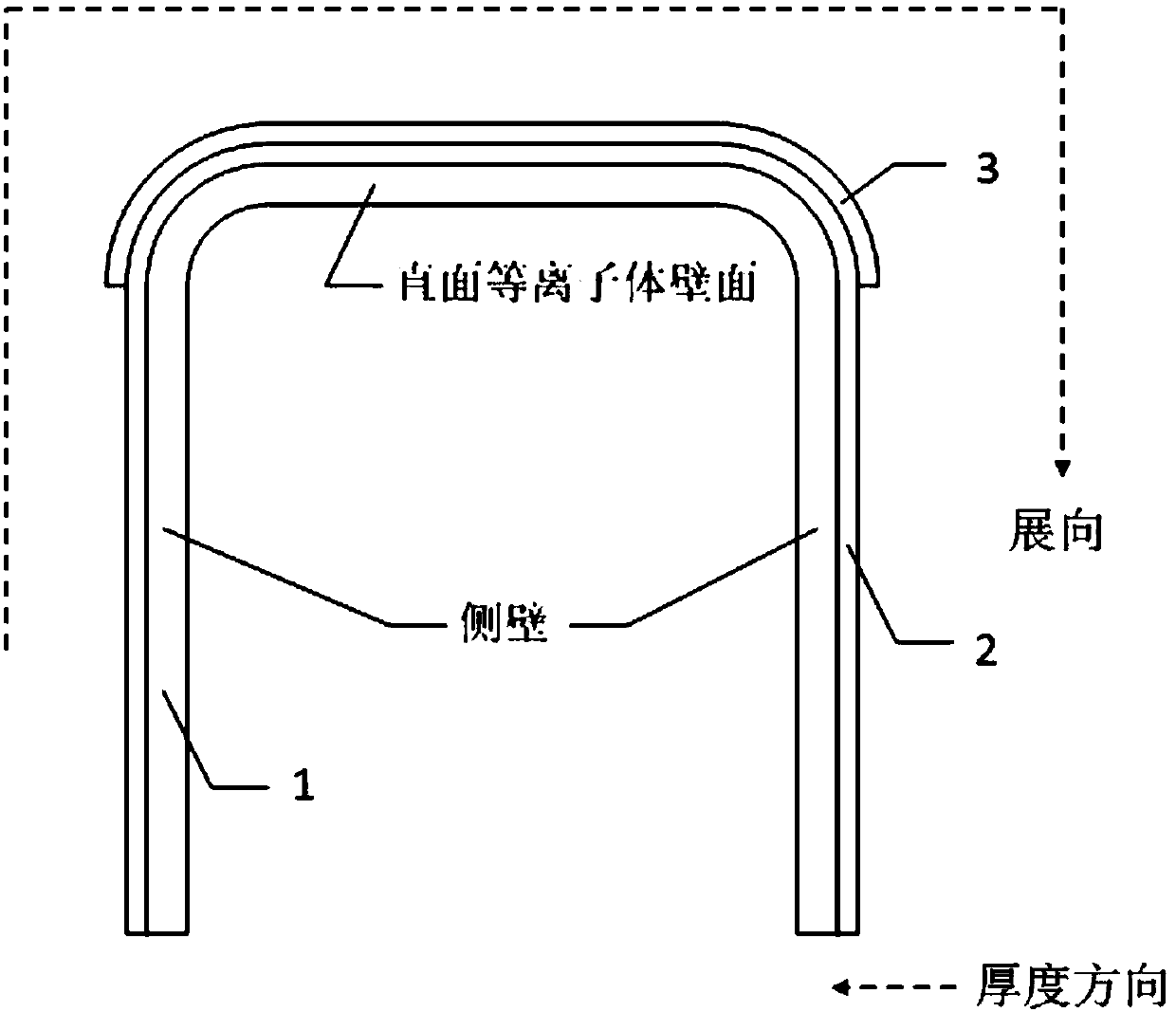

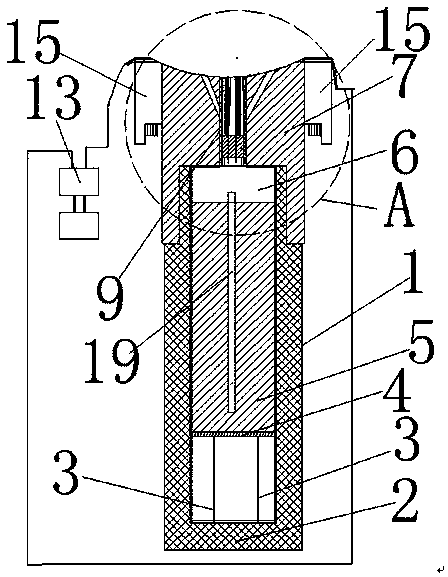

Nuclear fusion first wall capable of preventing temperature of part directly facing plasma from being too high

InactiveCN109961856AAvoid meltdownUniform wall temperature distributionNuclear energy generationThermonuclear fusion reactorPhysicsThermal conductivity

The invention discloses a nuclear fusion first wall capable of preventing temperature of a part directly facing plasma from being too high, and belongs to the technical field of nuclear fusion devices. The outer wall surface of the fusion first wall is covered by a material layer with a thermal conductivity coefficient in the spread horizontal plane direction higher than a thermal conductivity coefficient in the thickness direction; and the outer surface of the material layer is further provided with a uniform protective layer on the wall surface directly-facing the plasma. According to the nuclear fusion first wall provided by the invention, the material layer with the thermal conductivity coefficient in the spread horizontal plane direction higher than the thermal conductivity coefficient in the thickness direction is arranged between the outer wall and the protective layer of the nuclear fusion first wall, so that transfer of heat from the wall surface, directly facing the plasma, of the first wall to the side surface can be realized, the wall temperature distribution of the first wall is uniform, the first wall is prevented from being molten due to too-high local temperature, and at the same time the structural thermal stress of the first wall can be reduced; and the nuclear fusion first wall is applied to a nuclear fusion reaction device.

Owner:HARBIN INST OF TECH

Covering agent for preventing tundish from being melted and damaged and application

The invention provides a covering agent for preventing a tundish from being melted and damaged, and the covering agent comprises a premelting material and an adsorbate. The premelting material comprises, by weight, 50-65% of CaO, 20-31% of Al2O3, 10-18% of MgO, 7.5-12.5% of SiO2, 2.5-3% of C; the melting point is 1300-1450 DEG C; and the mass ratio of the premelting material to the adsorbate is 5-6:1-2. The covering agent for preventing the tundish from being melted and damaged, provided by the invention, can be widely applied to the production process in continuous casting steel, reduces casting abnormality and has the characteristic of stable continuous casting. The covering agent for preventing the tundish from being melted and damaged can effectively prevent the tundish coating from being melted and damaged. Before the technical scheme of the invention is adopted, the depth of the melting and damage of the tundish can reach 20 mm-30 mm; and the depth is basically within 2 mm afterthe implementation of the technical scheme, and the problem of the melting and damage is basically solved.

Owner:BAOSHAN IRON & STEEL CO LTD

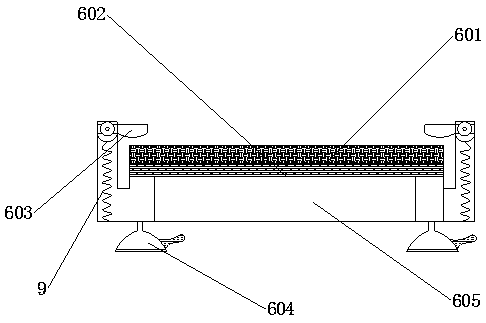

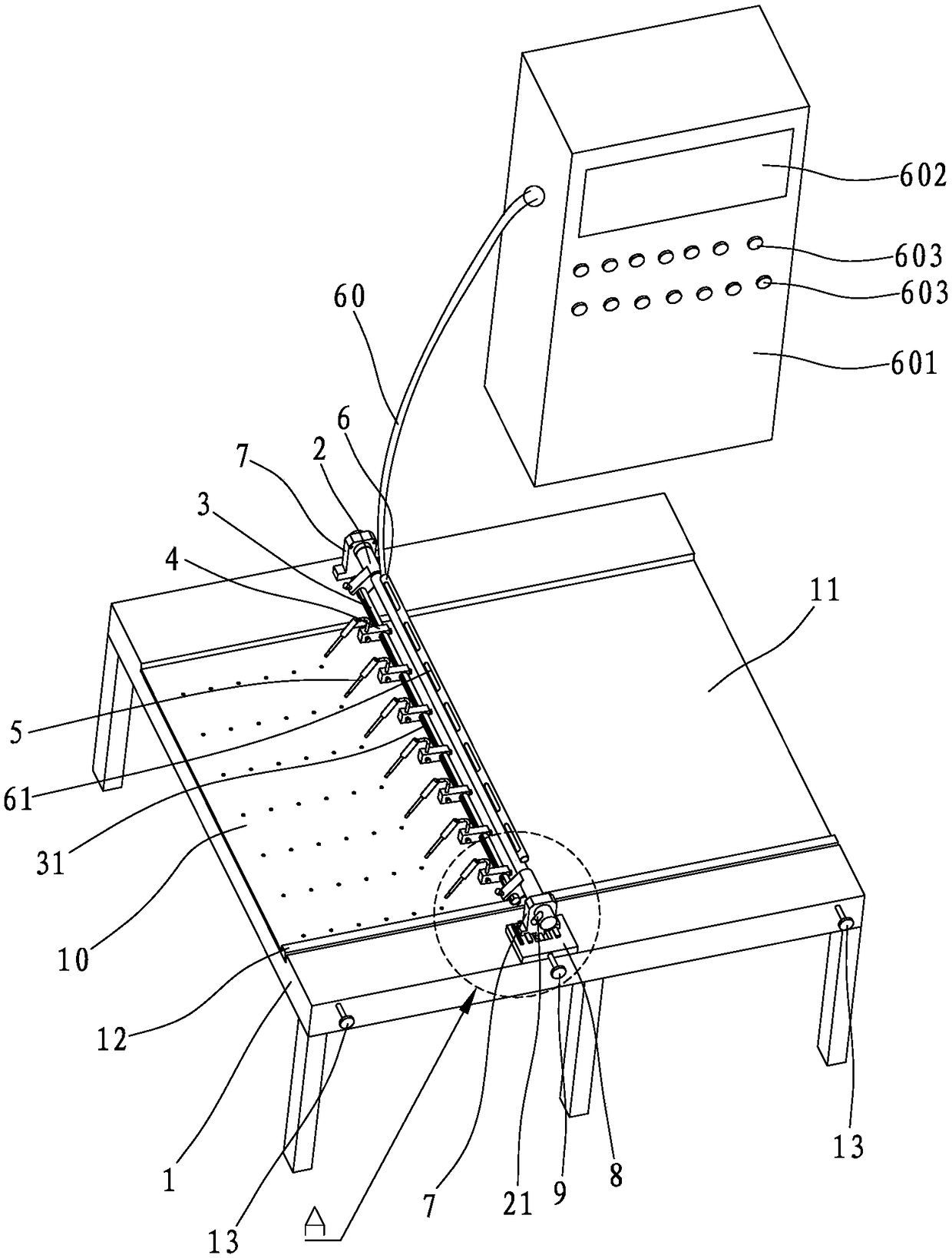

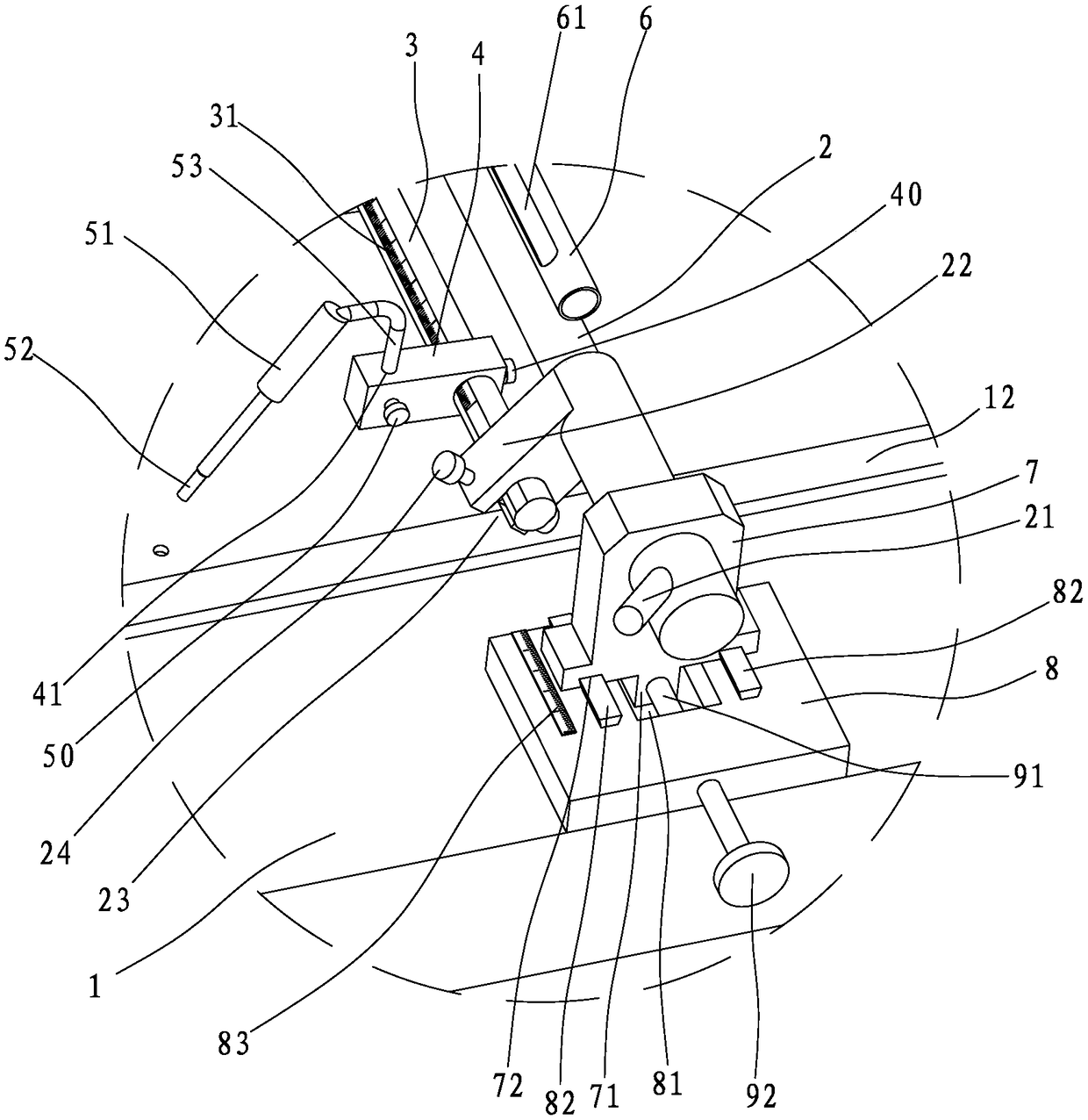

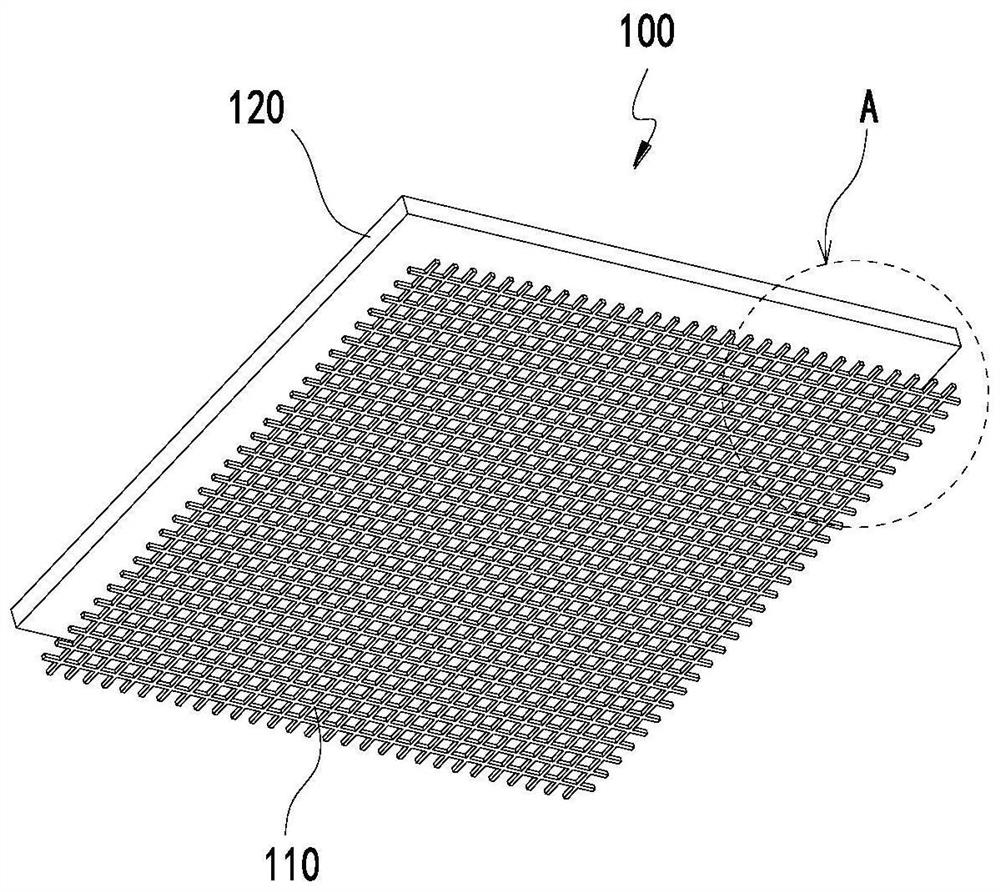

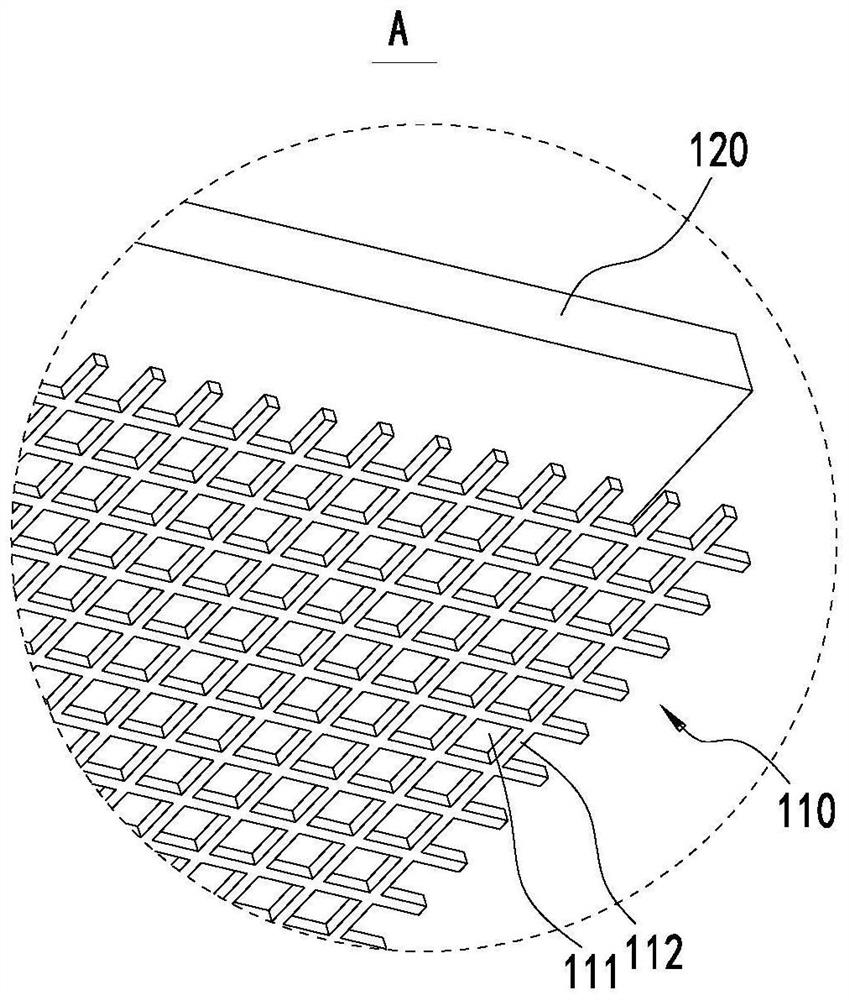

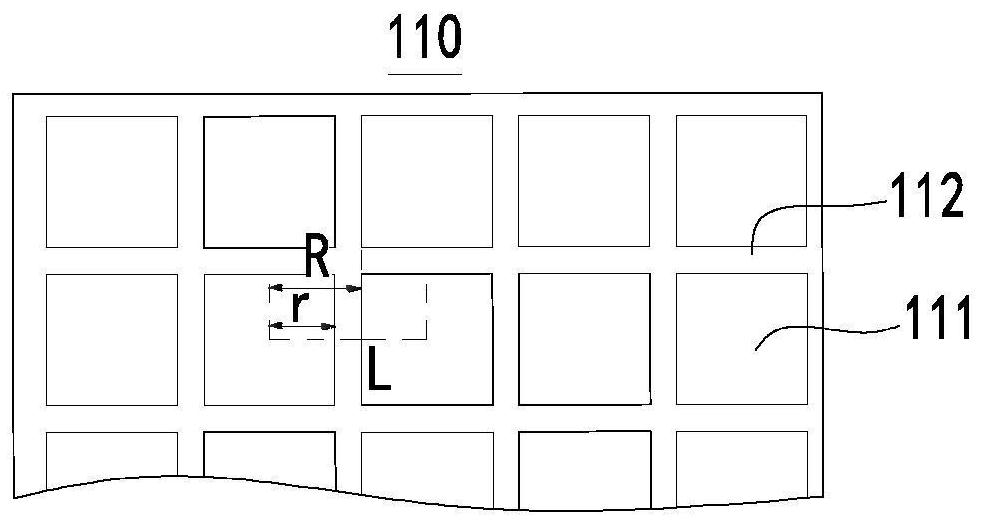

Auxiliary fixture for silk-screen printing and working method

ActiveCN110588147AProlong clotting timeAvoid meltdownScreen printersScreen printingElectrical and Electronics engineering

The invention relates to an auxiliary fixture for silk-screen printing and a working method. The auxiliary fixture comprises a base plate, a support rod, a middle placing device, return springs, two bonding devices and two stop frames; the middle part of the base plate is connected with the middle placing device through the support rod; the left and right ends of the middle placing device are connected with the two bonding devices through the return springs; the bonding devices are connected with the base plate through a sliding fit mode; and the two stop frames are arranged at the left and right ends of the base plate. The auxiliary fixture can solve such difficulties as difficult positioning of printing objects before silk-screen printing of textures due to softer texture materials, failed pattern printing caused by possible corrugation or deviation condition of the textures during printing and easy influence on the quality of the textures due to the ink dispersion phenomenon causedby delayed drying of ink after printing on surfaces due to higher permeability of the textures.

Owner:淮北新骏电子科技有限公司

Combustion type steel component oriented cutting device

ActiveCN109623136AFull combustion reactionAvoid meltdownAlumino-thermic welding apparatusElectricityPunching

The invention discloses a combustion type steel component oriented cutting device. A bottom support sleeve, a top plate with a circular cross section, a cutting agent layer and an igniting agent layerare arranged in a charging barrel in sequence from bottom to top; a fixing device for fixing a top cover on objects to be punched is arranged on the radial peripheral surface of the top cover; a cylindrical through hole is formed in the center of the top cover; a cylindrical insulation plug is mounted in the through hole; the insulation plug is vertically provided with a top sleeve; two ignitionelectrodes are mounted in the center of the insulation plug, and are connected with electric ignition devices; and the top cover is provided with multiple punching holes. The cutting device is high inenergy density, high in combustion temperature, high in cutting speed and suitable for quick emergency hot cutting and underwater cutting of various steel structural parts under the conditions without electricity, gas and equipment in the fields or battlegrounds.

Owner:ARMY ENG UNIV OF PLA

Rubber plate cutting structure

The invention discloses a rubber plate cutting structure which comprises a worktable. A recessed flow channel is arranged on the worktable, a rubber plate can longitudinally move in the flow channel,a beam stretching over the flow channel is arranged on the worktable, a mounting rod is arranged on the beam, a plurality of mounting blocks capable of sliding and rotating on the mounting rod sleevethe mounting rod, first scale marks for axial sliding reference of the mounting blocks are arranged on the mounting rod, first locking screws for fixing the mounting blocks onto the mounting rod are arranged on the mounting blocks, electric heating cutting rods capable of cutting the rubber plate to form holes are arranged on the mounting blocks, a storage pipe for storing a cable is arranged on the beam and parallel to the beam, a plurality of leading-out holes for leading out the cable to be in circuit connection with the electric heating cutting rods are formed in the storage pipe, a left support and a right support for supporting the beam are arranged on two sides of the worktable, a wrench is arranged on the beam and pulls the beam to rotate, the electric heating cutting rods are driven to cut the rubber plate, and operation is facilitated.

Owner:广东邦达实业有限公司

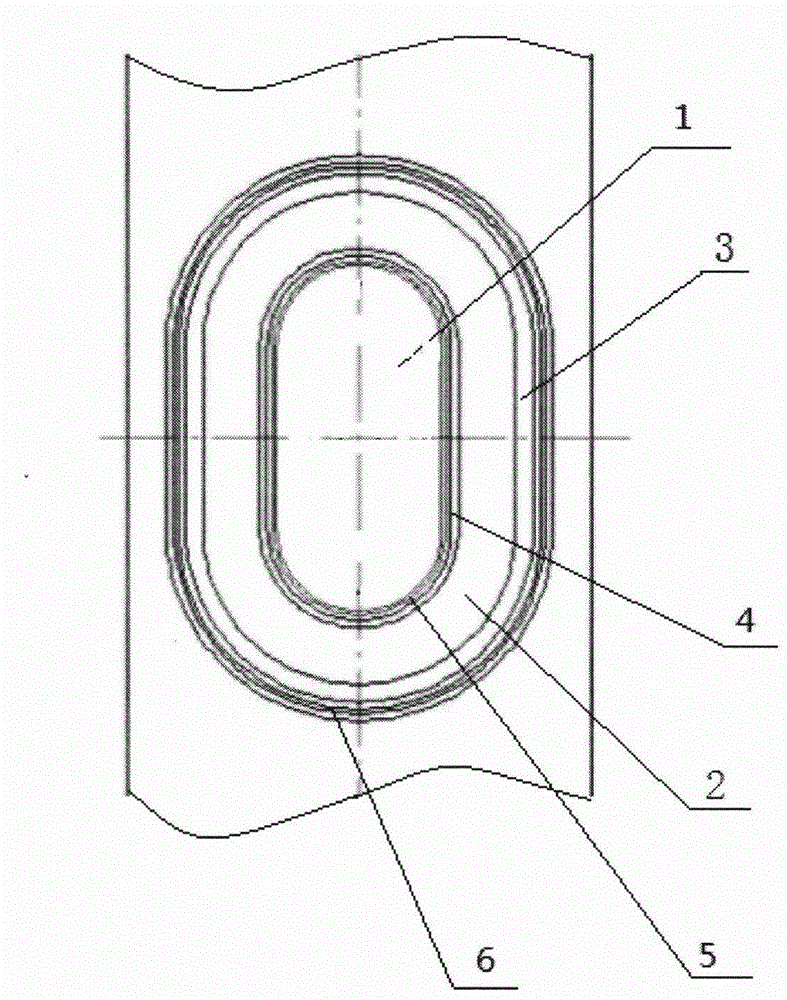

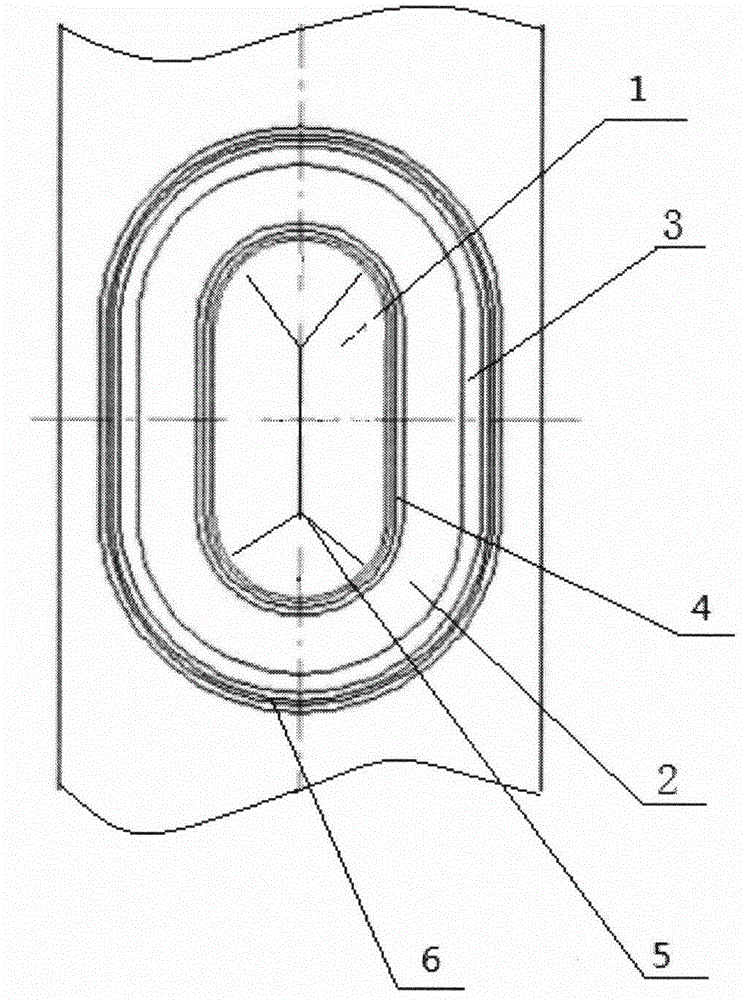

Integrally-formed explosion-proof membrane used on top cover of automobile lithium battery, and preparation method for explosion-proof membrane

ActiveCN106129301AAvoid meltdownAvoid security issuesCell component detailsEngineeringLithium battery

The invention discloses an integrally-formed explosion-proof membrane used on a top cover of an automobile lithium battery, and a preparation method for the explosion-proof membrane. The explosion-proof membrane is characterized in that the overall explosion-proof membrane and the top cover of the lithium battery are manufactured and formed concurrently; the explosion-proof membrane is oval; an oval enclosure wall is arranged around the explosion-proof membrane; a protruding small enclosure wall is arranged on the lower surface, close to the lower surface of the inner edge, of the enclosure wall; a transitional small lug boss is arranged on the inner side of the enclosure wall; a pressing rib explosion-proof groove is formed in the oval part on the edge of the small lug boss; and trapezoid grooves are formed in the upper and lower surfaces, which are connected with the top cover of the lithium battery, outside the oval enclosure wall respectively. The explosion-proof membrane has the advantages that the explosion-proof membrane and the top cover of the lithium battery are manufactured and formed concurrently, so that a step of welding is omitted; and therefore, the safety problem of the product caused by melt-through of the explosion-proof membrane, or insecure welding and the like can be avoided consequently.

Owner:NINGBO ZHENYU TECH

Atomizing dust removal and noise reduction system for down-the-hole drill and construction method

PendingCN111364931AGuaranteed stabilityImprove air quality in the working environmentEarth drilling toolsFlushingDust controlStructural engineering

The invention discloses an atomizing dust removal and noise reduction system for a down-the-hole drill and a construction method. The atomizing dust removal and noise reduction system involves a control component and a speed reducer, wherein a high-pressure air pipe is arranged on the control component, the high-pressure air pipe comprises an air outlet pipeline, a water supply pip is arranged onthe pipe wall of the air outlet pipeline in a communicating mode, the water supply pipe is used for supplying water to the air outlet pipeline, the air outlet pipeline is connected with a dust removalair inlet pipeline in the speed reducer, one end of a drill rod is connected to the power output end of the speed reducer, an impactor is connected to the other end of the drill rod, a drill bit is arranged on the impactor, the dust removal air inlet pipeline of the speed reducer communicates with the drill rod and an inner cavity of the impactor, and a dust removal hole of the drill bit is further connected to the inner cavity of the impactor in a communicating mode. According to the atomizing dust removal and noise reduction system, atomized water is conveyed and the effects of dust removaland noise reduction are achieved by connecting an existing high-speed air pipeline and a simple and easy water supply pipe, and the dust removal and noise reduction system has the advantages that theconstruction cost is reduced, the construction difficulty is simple, and the operation is easy.

Owner:中国葛洲坝集团第三工程有限公司

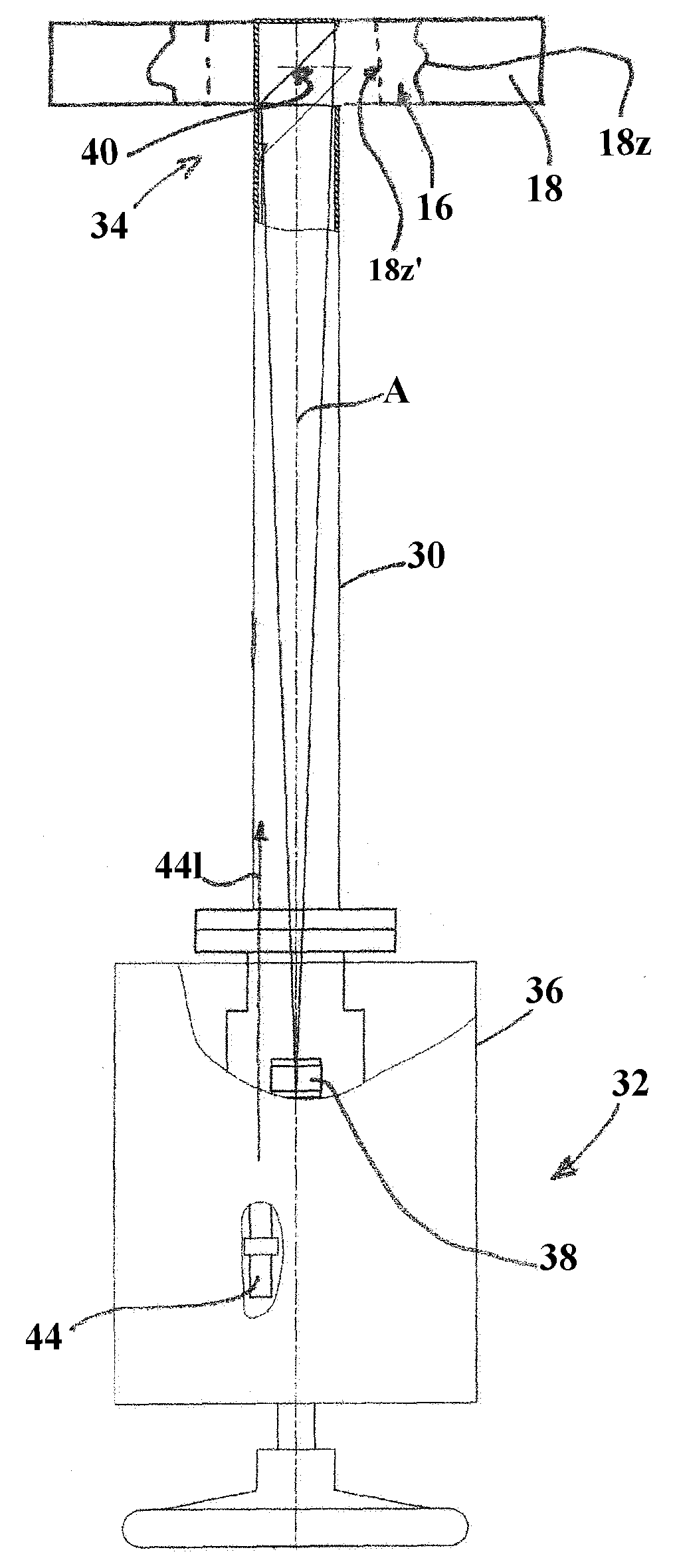

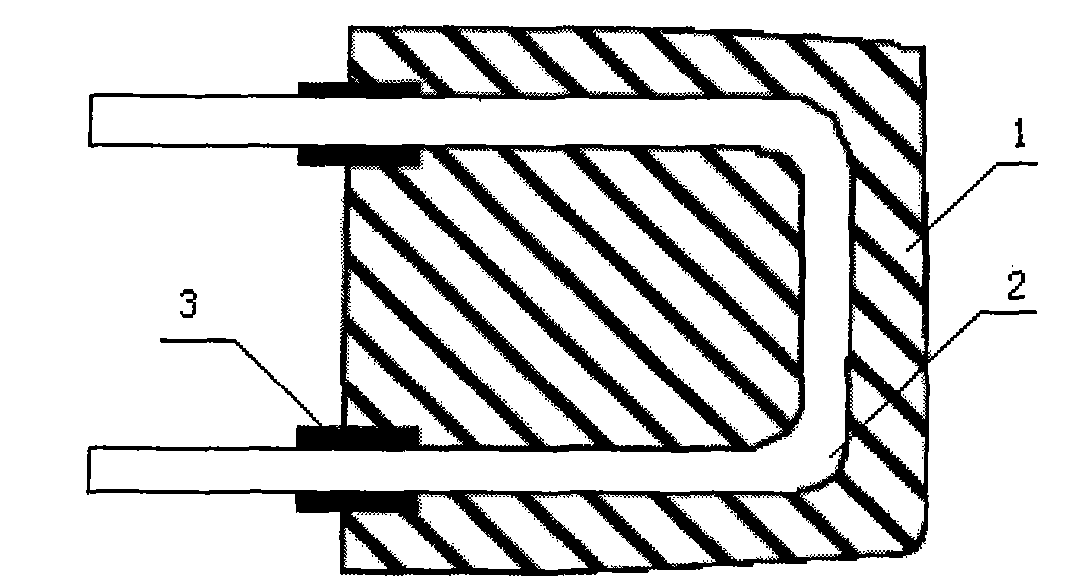

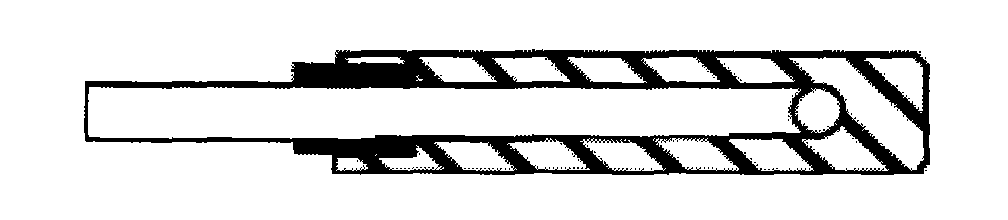

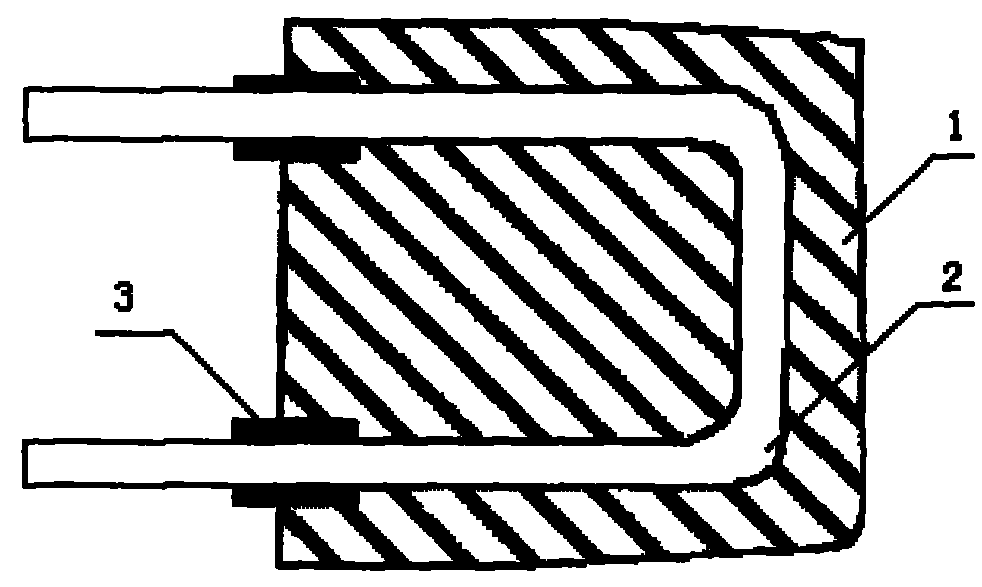

Apparatus for detecting and measuring cylindrical surfaces on fireproof ceramic components in metallurigal applications

InactiveCN103348216AAvoid meltdownUsing optical meansTelevision systemsMaterials scienceFocal length

The apparatus has a cylindrical measuring pipe (30) formed in a peripheral portion that lies opposite to a reflection surface (40), so that a camera (38) detects a part of a cylindrical upper surface (18z) of an adjacent refractory ceramic component (18) with focal length between an objective and a reflection surface. The part of the upper surface runs along a radial distance, and is detected by the camera. A distance measuring unit (44) is arranged in the pipe at a distance between points or surface sections on the part of the upper surface at a reference point.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

Casting method of cast steel cooling plate

InactiveCN101634520BImprove mechanical propertiesExtend your lifeFurnace cooling arrangementsElectric furnaceAlloyMolten steel

The invention relates to a casting method of a cast steel cooling plate, which adopts a cast steel material to cast a cooling plate base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model, sheathing a pipe sleeve on the coolingwater pipe and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the cooling plate base body, and casting the middle part of the cooling water pipe into the cooling plate base body; leading the casting model to be horizontal in the modeling process, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoid air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the cooling plate, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the cooling effectand the mechanical performance of the cast steel cooling plate.

Owner:江苏联兴成套设备制造有限公司

A cooling wall and its processing method

ActiveCN107254559BImprove cooling effectImprove protectionFoundry mouldsCooling devicesCooling effectMachining process

The invention discloses a cooling stave and a machining method thereof, and belongs to the field of cooling staves. The machining method includes the following steps of 1, production of a wood pattern of the cooling stave; 2, production of a sand mould and distribution of a cooling water pipe, specifically, putting the wood pattern of the cooling stave into a sand box, compacting the pattern of the sand mould, taking the wood pattern of the cooling stave out to form a cavity, and distributing the cooling water pipe in the cavity; the cooling water pipe comprises a first cooling water pipe, a second cooling water pipe and a third cooling water pipe; 3, injecting liquid steel into the cavity and starting casting; and 4, conducting cooling and forming after casting. According to the cooling stave and the machining method thereof, the defect that a cooling stave is prone to happening melt-through of cooling water pipes is overcome, by laying multiple layers of cooling water pipes in the cooling stave, the cooling effect is improved, and by strictly controlling the machining process, melt-through of the cooling water pipes can be effectively prevented so as to achieve the technical effects of fused while not molten and seamless fusion.

Owner:MAANSHAN RUNTONG HEAVY IND TECH CO LTD

Welding method for corner weld joint of Q690qD bridge steel box type rod piece

PendingCN114700595AAvoid meltdownQuality assuranceWelding accessoriesFillet weldStructural engineering

The invention discloses a Q690qD bridge steel box type rod piece corner weld joint welding method which comprises the steps that grooves are symmetrically machined in the two long sides of a web, the grooves are single-side double-V-shaped grooves with truncated edges, and the truncated edges of the single-side double-V-shaped grooves are 2-6 mm thick; the angle of the upper V-shaped groove is 10-15 degrees; the angle of the lower V-shaped groove is 45-55 degrees; the depth of the lower V-shaped groove is 15 to 28 mm; the cover plate and the web plate are assembled into a box type rod piece, positioned welding is conducted in the groove, and the cover plate and the web plate are connected together; the formed box type rod piece is turned over rightwards by 90 degrees, and two edge and corner weld joints on one side of the box type rod piece are welded; and the formed box type rod piece is turned over rightwards by 180 degrees, and then two corner angle welding seams on the other side of the box type rod piece are welded. According to the method, the manufacturing problems in the aspects of assembling, welding and the like of the box type rod piece are solved, the welding quality is guaranteed, and welding deformation is controlled.

Owner:中铁宝桥(扬州)有限公司 +1

Protective components, covers and cases

ActiveCN110875443BEffective interceptionAvoid meltdownSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsParticulatesProtection layer

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com