Casting method of electric furnace water cooling cast steel furnace cover

A steel casting and water-cooling technology, which is applied in the casting field of high-temperature metallurgical furnaces and electric furnace water-cooled cast steel furnace covers. Wear and inner surface oxidation problems, improve cooling effect, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

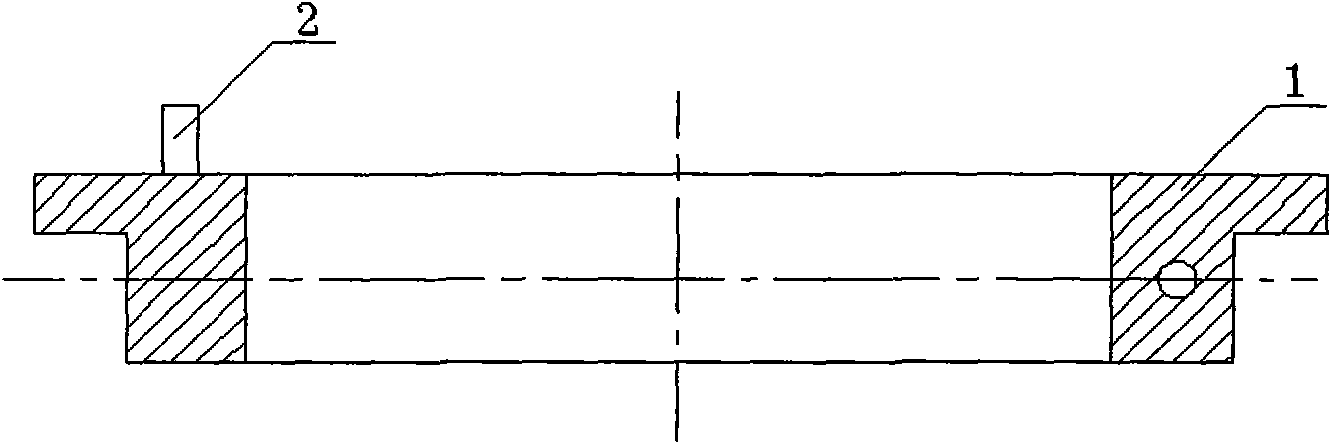

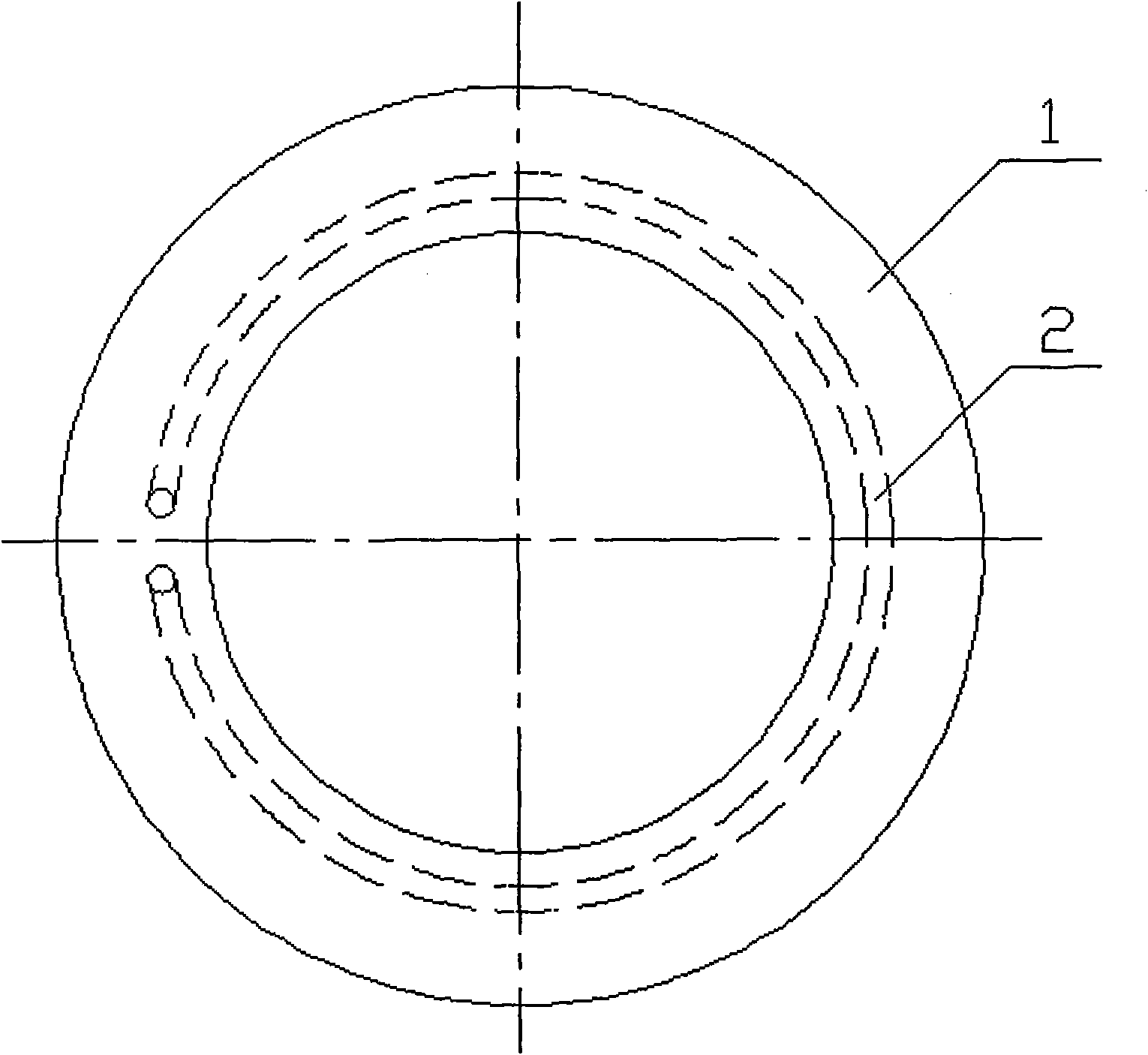

[0031] figure 1 It is a central sectional view of the electric furnace water-cooled cast steel furnace cover of the present invention; figure 2 It is the top view of the electric furnace water-cooled cast steel furnace cover of the present invention.

[0032] In the casting method of the electric furnace water-cooled cast steel furnace cover of the present invention, the material of the cooling water pipe is selected as cast steel, and the cast steel material is used to cast the matrix at the same time, and the specific pouring steps are:

[0033](1) The molten steel is smelted in an intermediate frequency induction furnace (3 tons of bulk density). At the end of the molten steel smelting, the slagging agent is added twice to make it evenly cover the surface of the molten steel. The total consumption of the slagging agent is added at a rate of 1kg / ton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com