Auxiliary fixture for silk-screen printing and working method

A technology of screen printing and auxiliary fixtures, which is applied to screen printing machines, printing machines, printing machines, etc., can solve problems affecting fabric quality, difficult positioning, offset, etc., and achieve the effect of accelerating the solidification speed and the solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings. In this process, in order to ensure the clarity and convenience of the description, we may exaggerate the width of the lines or the size of the constituent elements in the diagram.

[0038] In addition, the following terms are defined based on the functions in the present invention, and may be different according to the user's or operator's intention or practice. Therefore, these terms are defined based on the entire content of this specification.

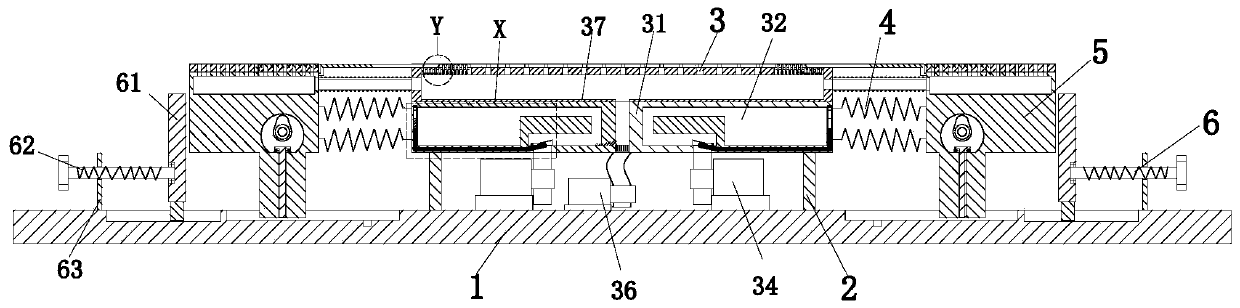

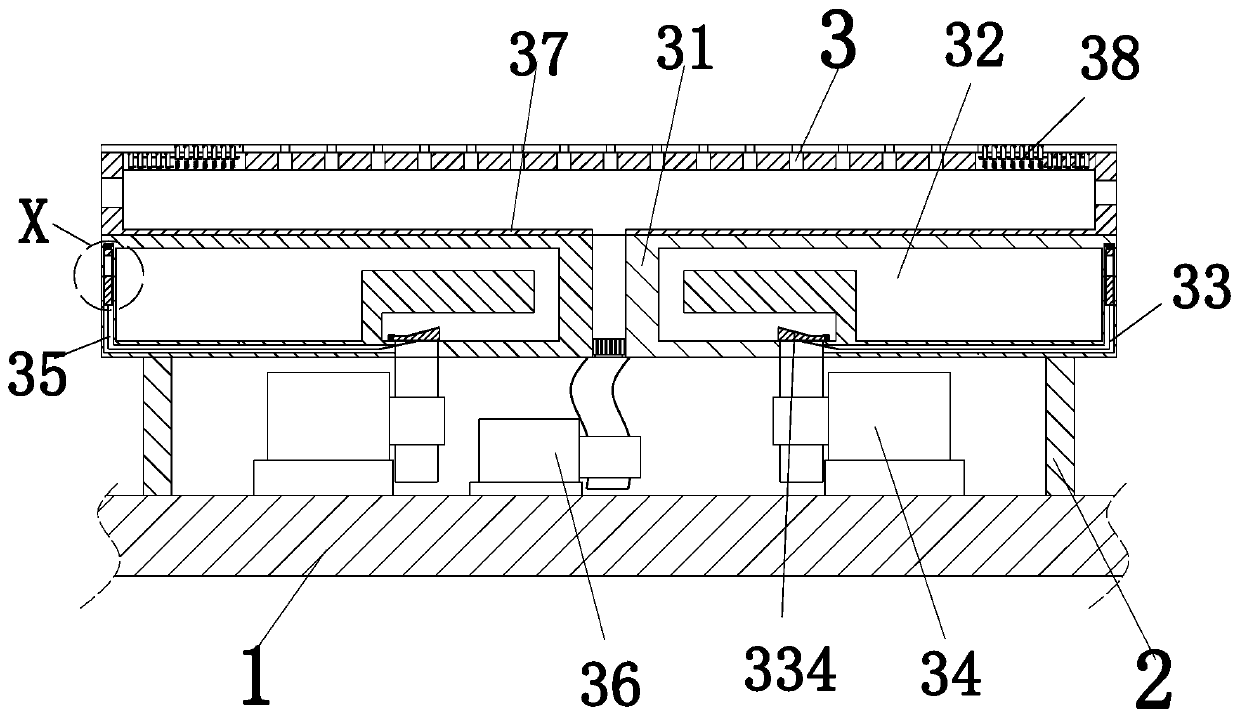

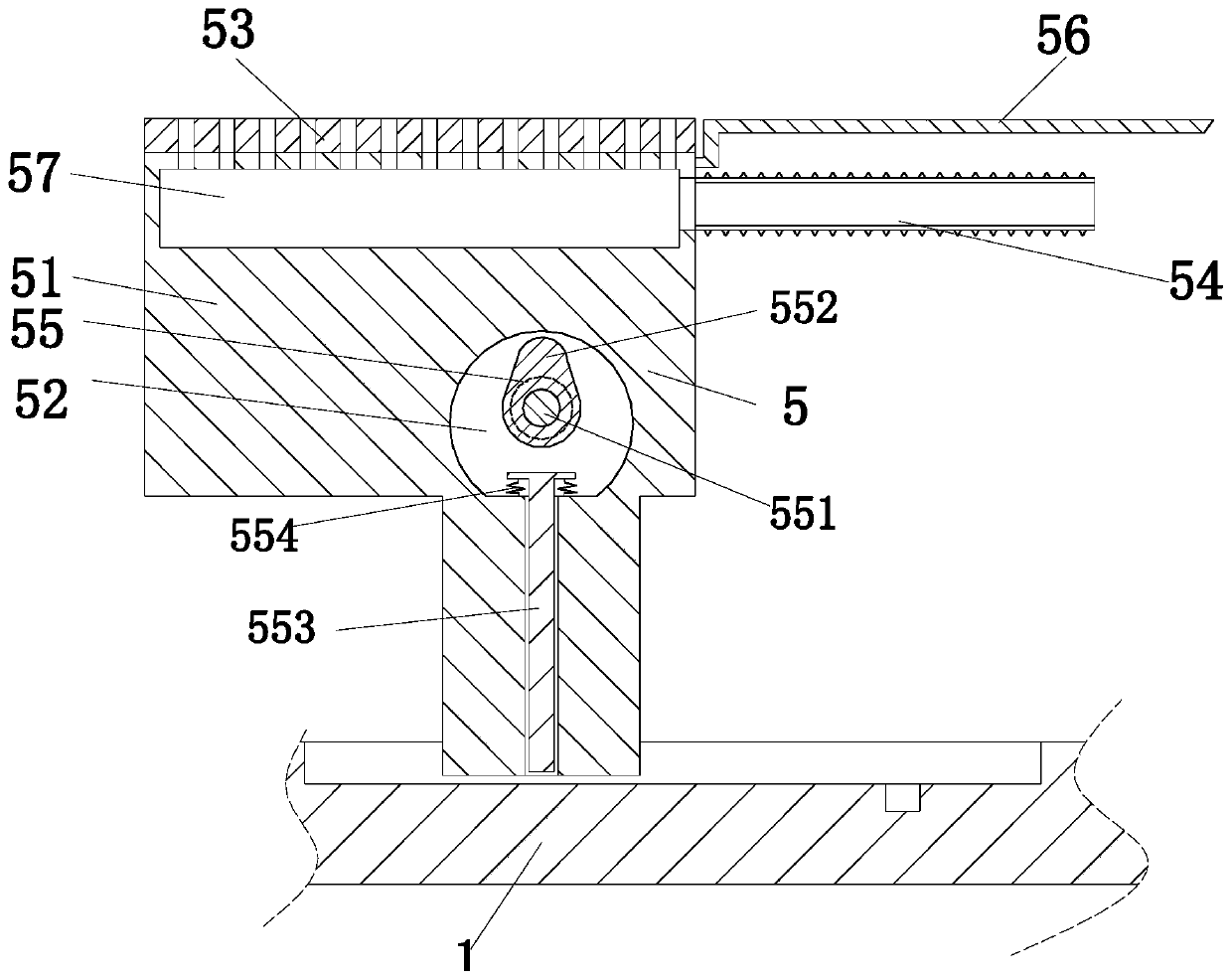

[0039] Such as Figure 1 to Figure 6 As shown, an auxiliary fixture for screen printing includes a base plate 1, a support rod 2, an intermediate placement device 3, a return spring 4, two sticking devices 5 and two blocking frames 6, and the middle part of the base plate 1 is supported by The rod 2 is connected with the middle placing device 3, and the left and right ends of the middle placing device 3 are connected with the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com