Patents

Literature

41results about How to "Reduced heat transfer capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

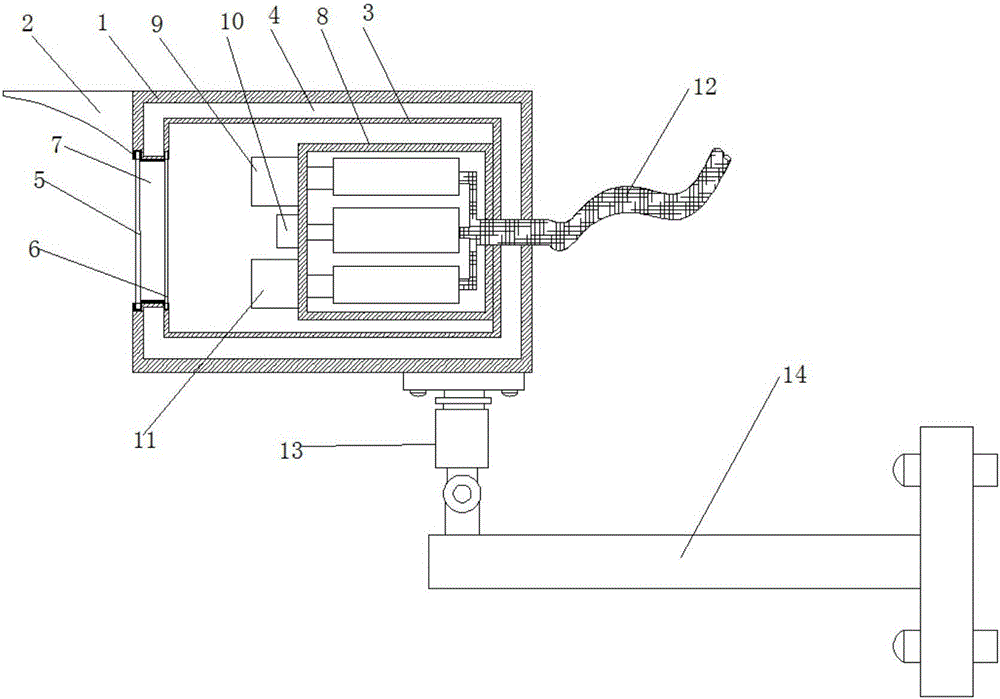

Explosion-proofing infrared UV flame detector

InactiveCN105931418AAvoid burnsSlow temperature conductionFire alarm radiation actuationEngineeringElectronic component

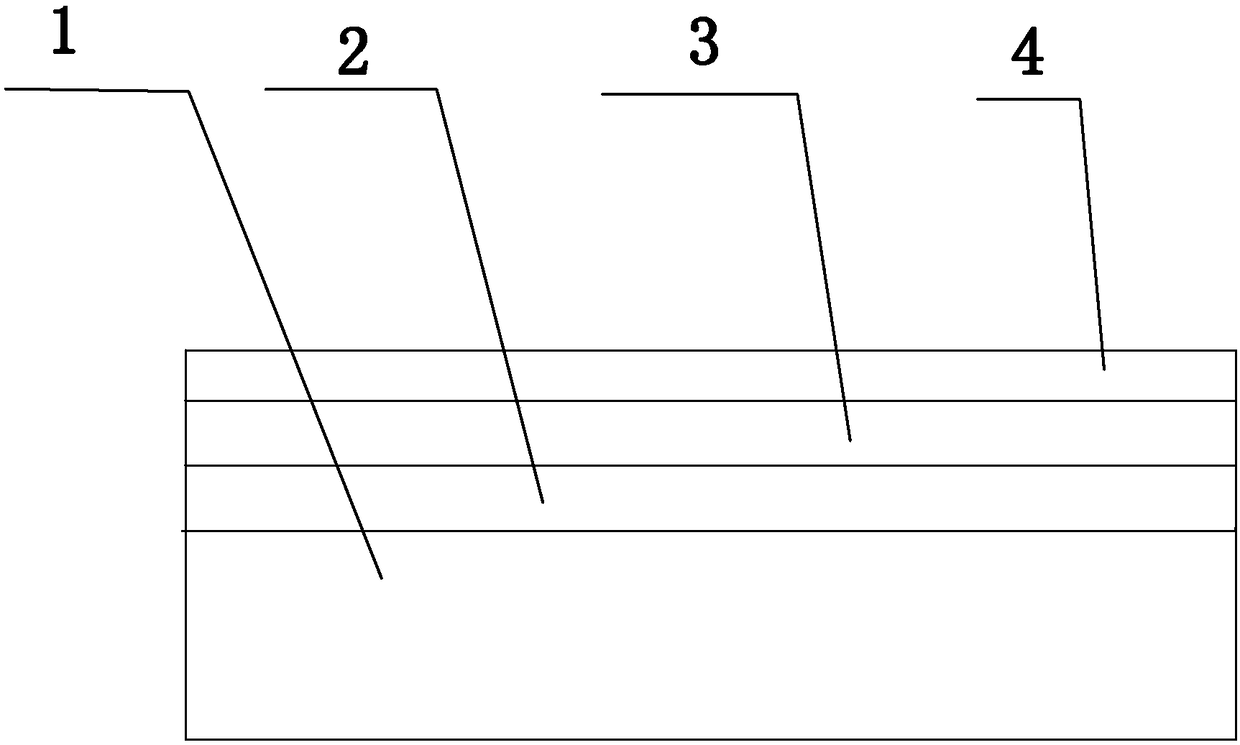

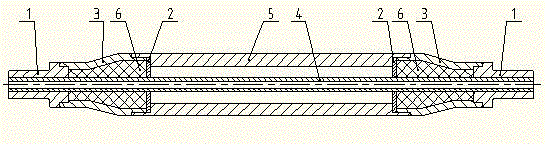

The invention discloses an explosion-proofing infrared UV flame detector including an explosion-proofing outer casing, one side of the explosion-proofing outer casing is provided with a shield plate, the inside of the explosion-proofing outer casing is provided with an explosion-proofing inner casing, a first vacuum layer is formed between the explosion-proofing outer casing and the explosion-proofing inner casing, one side, closing to the shield plate, of the explosion-proofing outer casing is provided with a piece of explosion-proofing outer glass, and one side, closing to the explosion-proofing outer glass, of the explosion-proofing inner casing is provided with a piece of explosion-proofing inner glass. The first vacuum layer is formed between the explosion-proofing outer casing and the explosion-proofing inner casing, a second vacuum layer is formed between the explosion-proofing outer glass and the explosion-proofing inner glass, the vacuum layers reduce the effect of heat transfer to make the temperature conduction of the inside and the outside of the sensor slow, thereby preventing internal electronic components from being melted, and reducing the internal blasting probability, and moreover, the detector main body is provided with an infrared flame detector, a UV flame detector, and a high-definition pick-up head, so that the scene of fire can be maximally detected.

Owner:ANHUI SHENGLONG ELECTRIC

Montmorillonite-based nano composite heat insulation coating

The invention provides a montmorillonite-based nano composite heat insulation coating and belongs to the technical field of heat insulation materials used in equipment or buildings. The coating comprises the following components in percentage by mass: 5 to 30 percent of montmorillonite, 15 to 30 percent of vinyl acetate / acrylic emulsion or styrene-acrylic emulsion, 30 to 50 percent of water, 5 to 10 percent of nano calcium carbonate, 2 to 6 percent of nano zinc oxide, 2 to 6 percent of nano titanium oxide, 0.01 to 0.1 percent of film-forming auxiliary, 0.1 to 2 percent of antifoaming agent, 0.1 to 2 percent of wetting dispersant, 0.5 to 2 percent of antifreezing agent and 0.1 to 2 percent of leveling agent. A method for preparing the coating comprises the following steps of: under the condition of low-speed stirring, stirring the water, the montmorillonite, the wetting dispersant and a half of the antifoaming agent at a high speed for 1 to 2 hours; adding the nano calcium carbonate, the nano zinc oxide and the nano titanium oxide into the mixture with stirring; stirring at a high speed for 3 hours; under the condition of low-speed stirring, slowly adding the emulsion dropwise and consequently adding the rest antifoaming agent, the film-forming auxiliary, the antifreezing agent and the leveling agent into the mixture; stirring for 3 to 4 hours at a low speed; and finally canning to obtain the finished product of the coating. The montmorillonite-based nano composite heat insulation coating has the advantages of good energy saving effect, stable performance, safe use and convenient application.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of waterproof heat-insulating glass coating

InactiveCN108165158ALow water absorptionHigh reactivityPolyurea/polyurethane coatingsReflecting/signal paintsPolymer scienceAntimony tin oxide

The invention discloses a preparation method of a waterproof heat-insulating glass coating, and belongs to the technical field of coating preparation. According to the preparation method provided by the invention, a modified self-made polyurethane emulsion is used as a matrix, a self-made nano antimony tin oxide dispersion liquid and modified mixed powder are used as modifying reinforcing agents,and a coupling agent, a defoaming agent and a thickening agent are supplemented to prepare the water-proof heat-insulating glass coating. Firstly, a silane coupling agent KH-550 is used to modify polyurethane resin, so that the water absorption of the glass coating is gradually reduced; and then an effect of reducing light transmission and heat transfer is achieved through the nano antimony tin oxide under the action of deionized water, dispersion substances and absolute ethyl alcohol. According to the preparation method, mixed powder formed by mixing and grinding hollow glass beads, calcium carbonate and silica fume is sequentially added, wherein the hollow glass beads have a hollow structure and have excellent heat-insulating performance, and in addition, the calcium carbonate and the submicron-grade silica fume fine particles have excellent penetrability, so that the adhesive strength and the water resistance can be enhanced, and the preparation method has a wide application prospect.

Owner:谢新昇

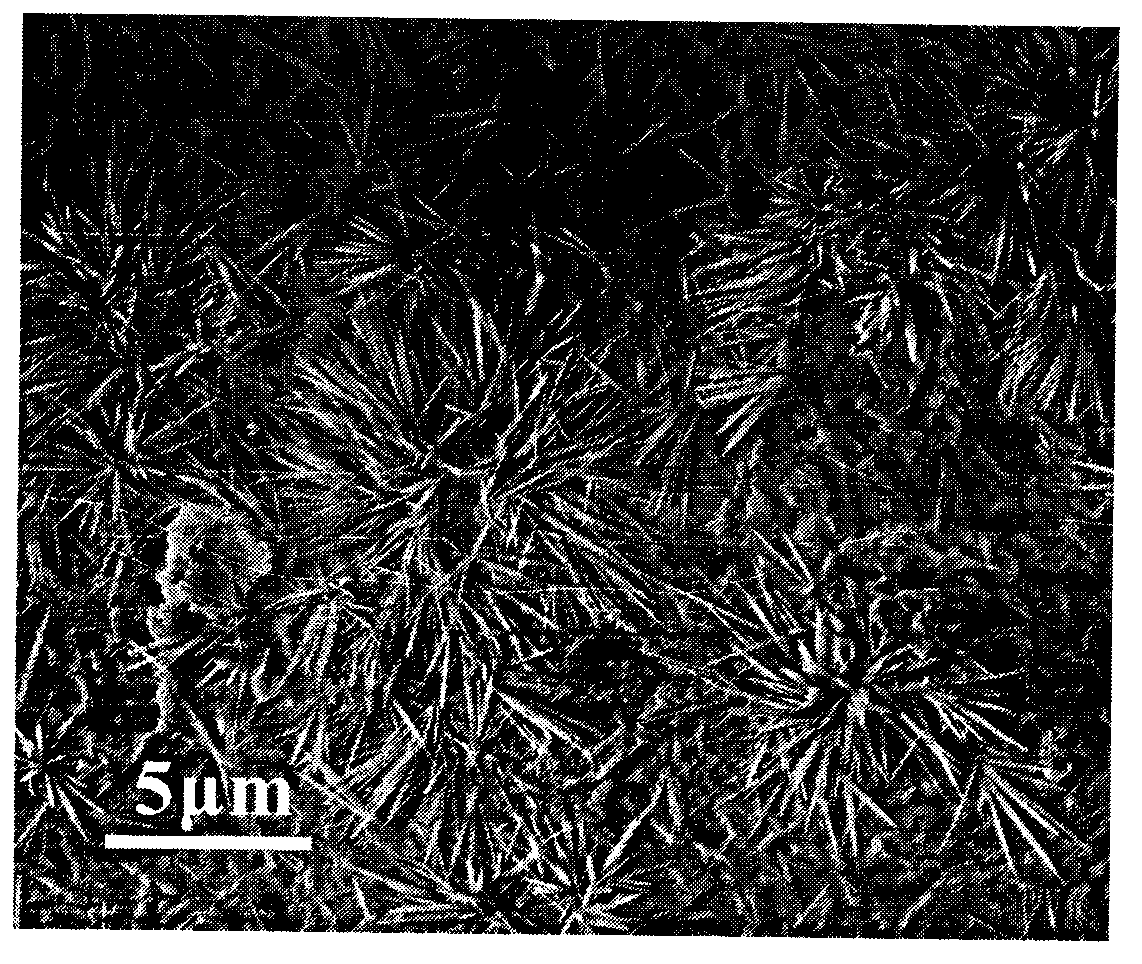

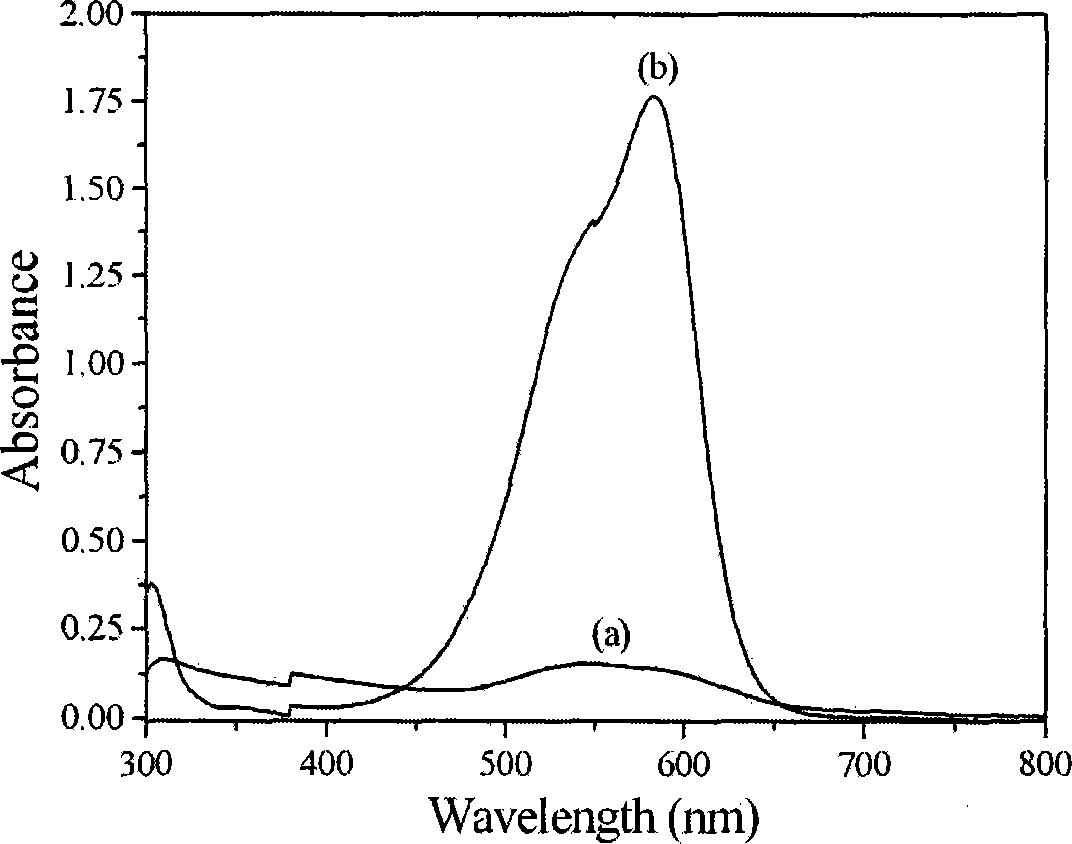

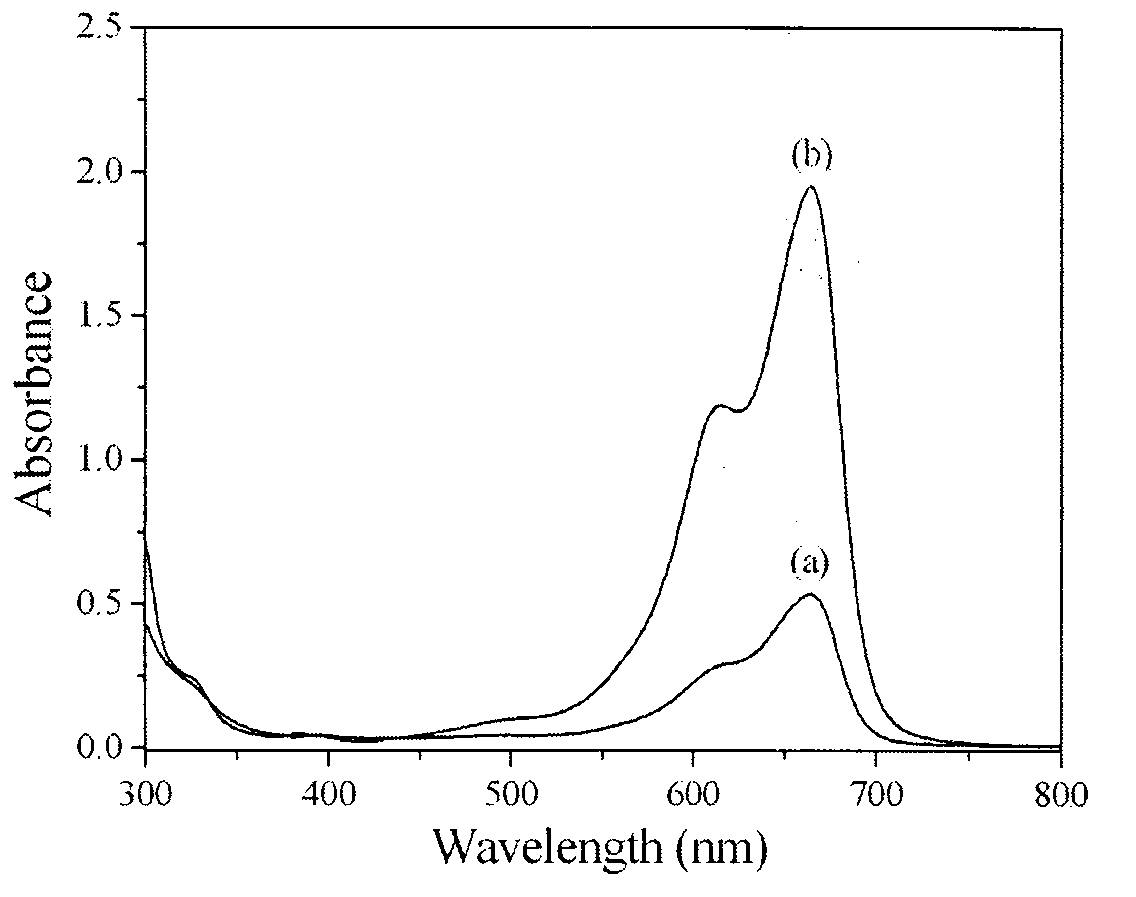

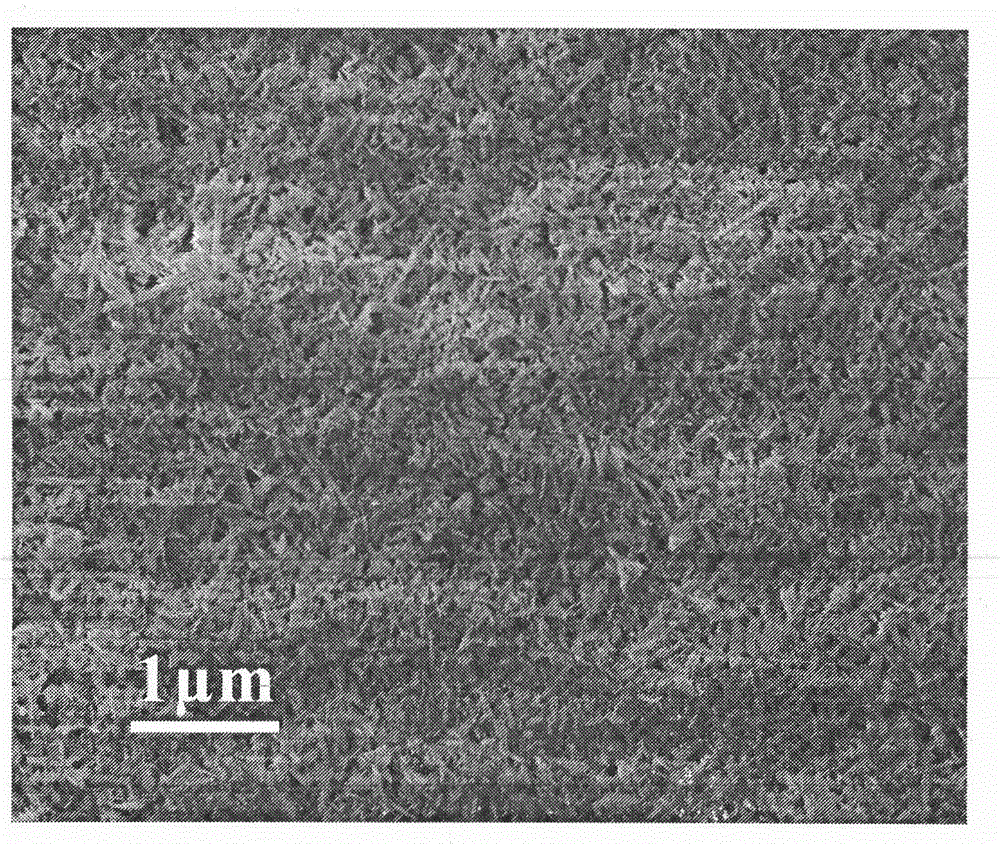

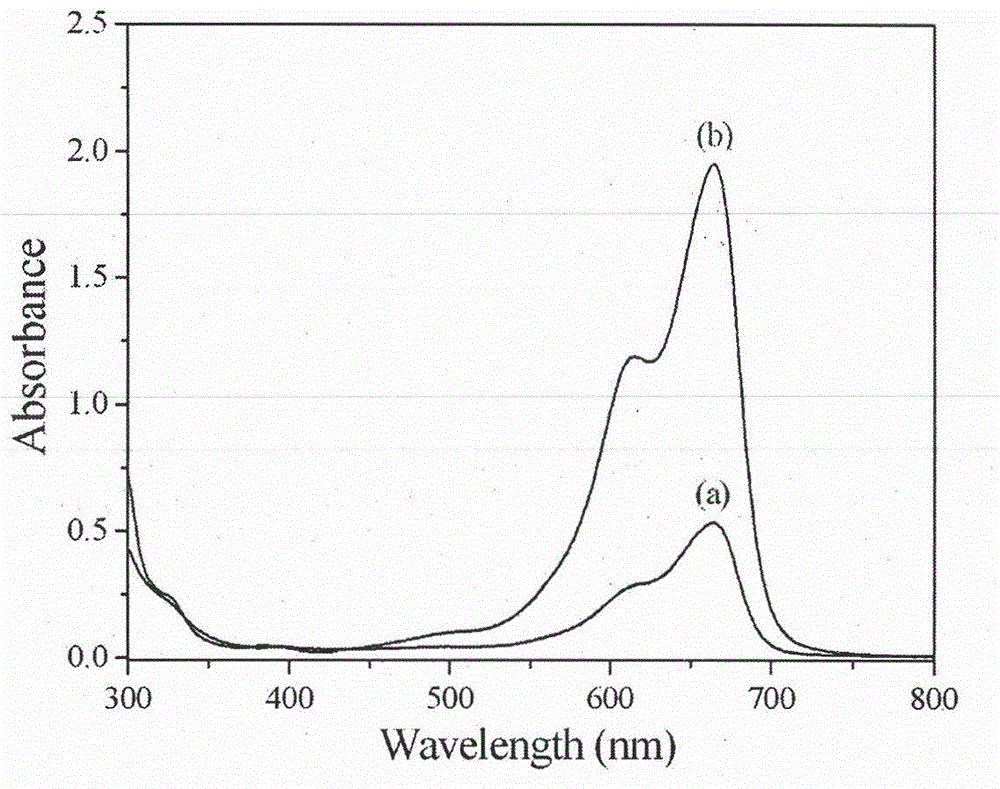

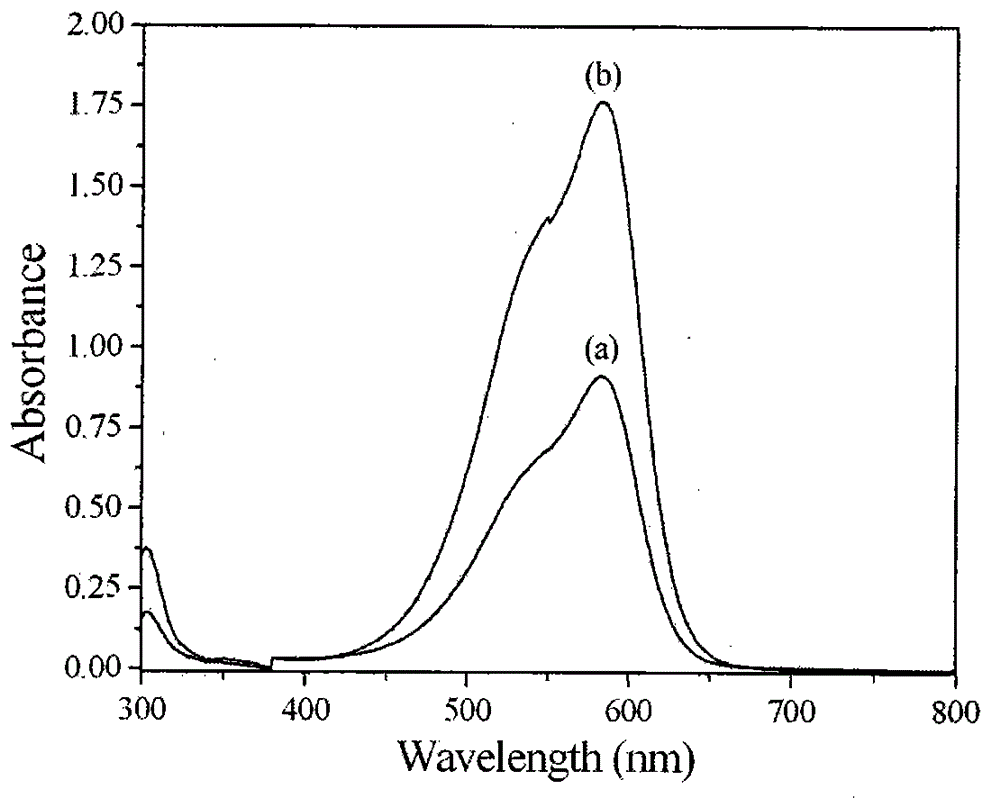

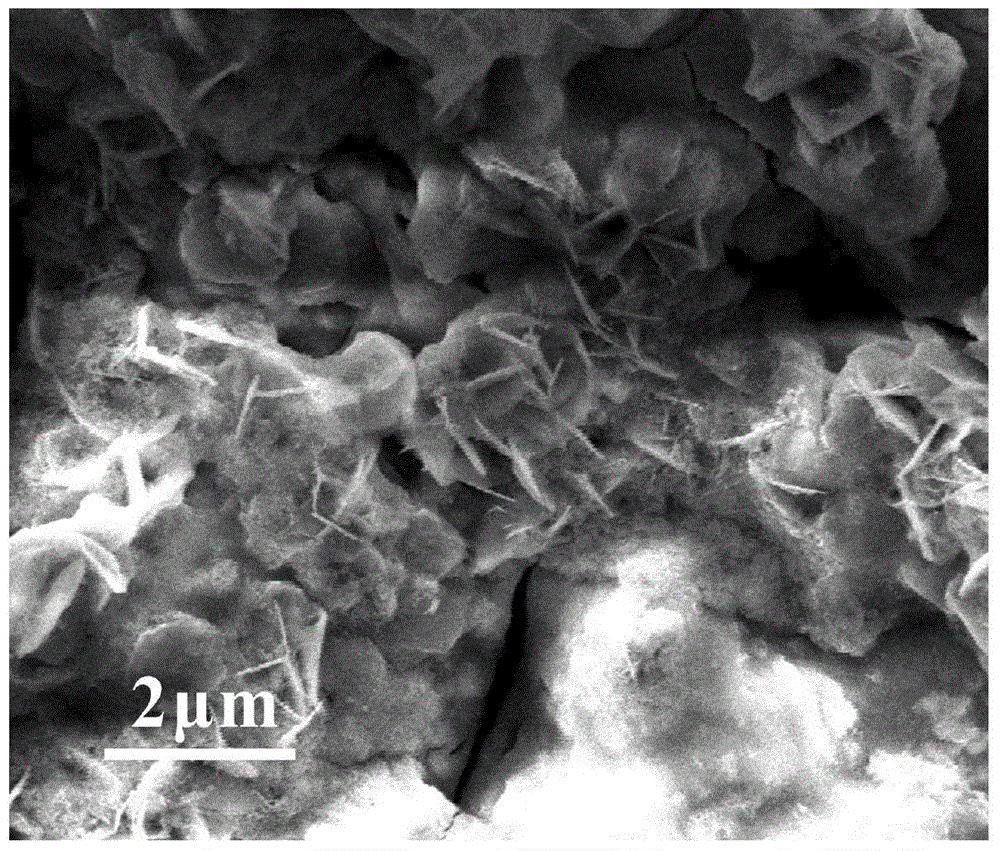

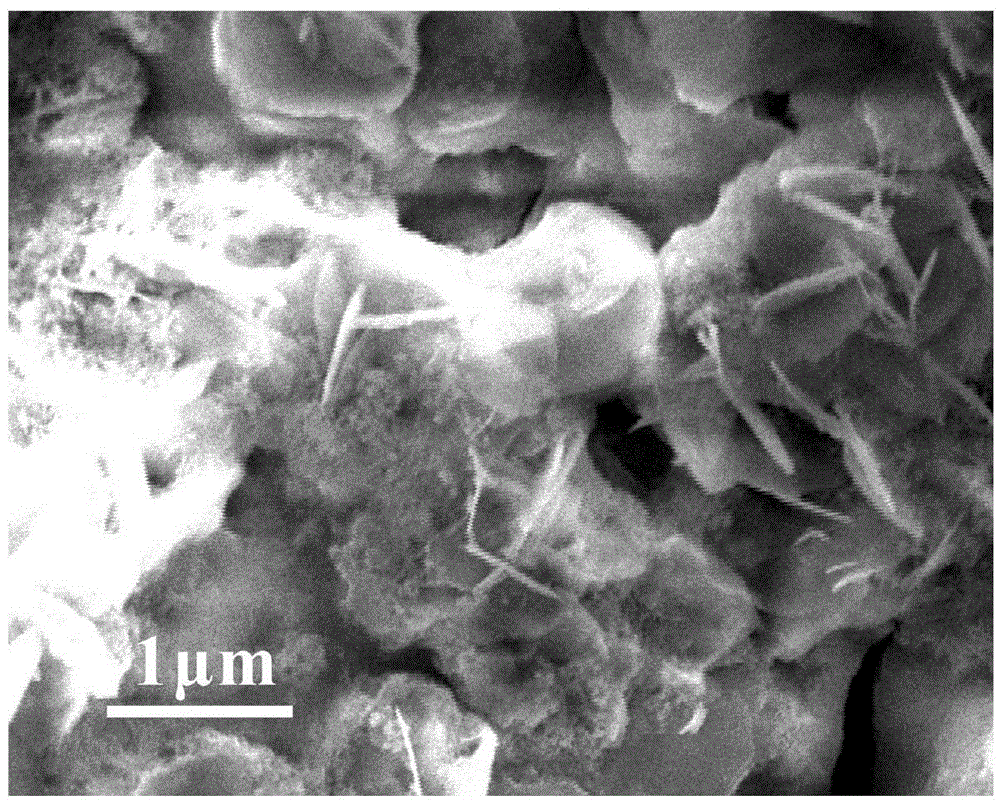

Nanoneedle-structure manganese vanadate self-cleaning paint

The invention discloses a nanoneedle-structure manganese vanadate self-cleaning paint, belonging to the technical field of functional materials. The nanoneedle-structure manganese vanadate self-cleaning paint is composed of the following components in percentage by mass: 20-40% of nanoneedle-structure manganese vanadate, 15-30% of vinyl acetate-acrylic emulsion, 30-50% of water, 6-20% of nano silicon dioxide, 0.05-0.2% of alcohol ester-12, 0.5-2% of tributyl phosphate, 0.5-2% of 10% sodium hexametaphosphate water solution, 0.5-2% of ethylene glycol and 0.5-2% of polyurethane. The nanoneedle-structure manganese vanadate self-cleaning paint disclosed by the invention has the properties of self-cleaning, pollution prevention, thermal insulation, heat preservation and the like, has the advantages of stable performance and low cost, and is convenient for construction.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

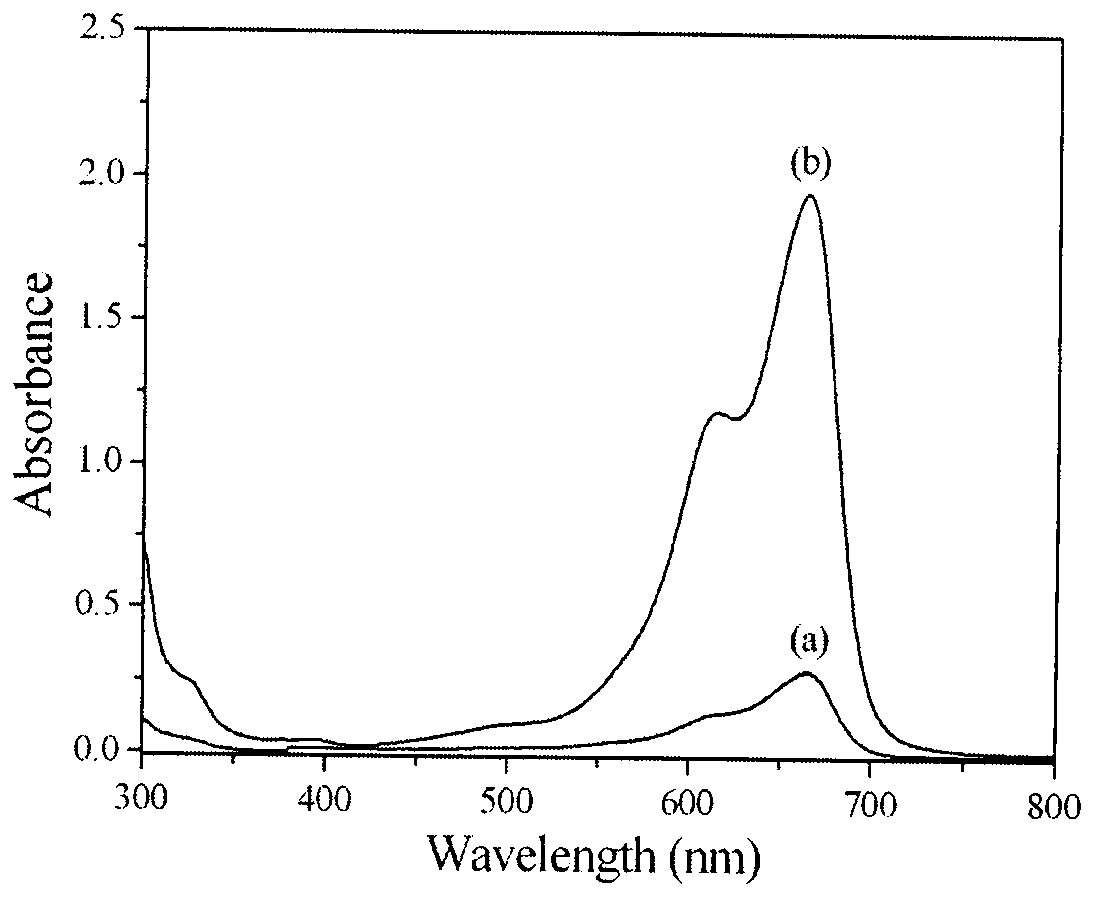

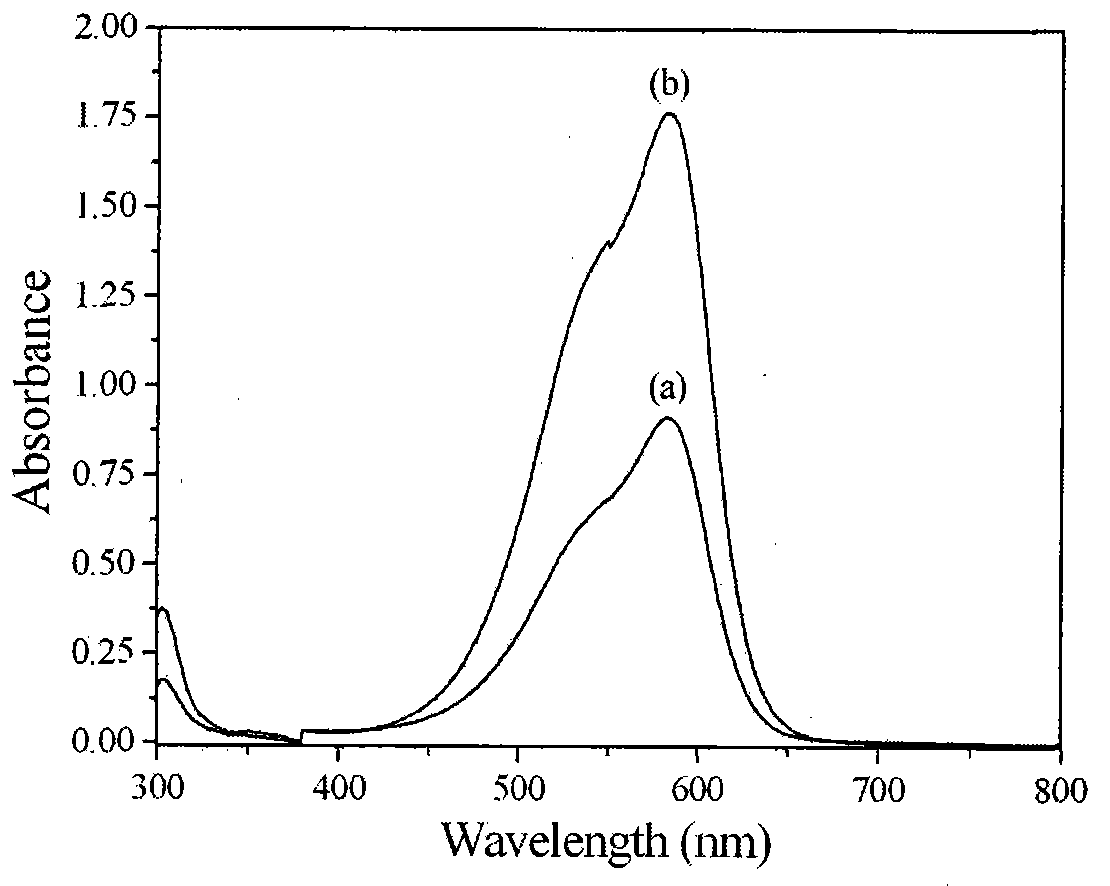

Zinc vanadate nanorod composite paint

The invention discloses a vanadate vanadate nanorod composite paint, belonging to technical field of functional materials. The vanadate vanadate nanorod composite paint is prepared from the following components in percentage by mass: 20-40% of zinc vanadate nanorod, 15-25% of styrene-acrylic emulsion, 30-45% of water, 5-20% of nano aluminum oxide, 0.05-0.2% of alcohol ester-12, 0.5-2% of polyurethane, 0.5-2% of 10% sodium hexametaphosphate water solution, 0.5-2% of tributyl phosphate and 0.5-2% of ethylene triol. By adopting the zinc vanadate nanorods, the invention has the characteristics of high activity, high stability, no toxicity, low cost and the like, and can implement mass preparation of the vanadate nanorod composite paint. The vanadate vanadate nanorod composite paint disclosed by the invention has stable self-cleaning and anti-fouling properties.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

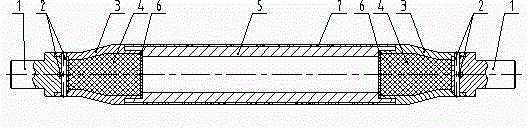

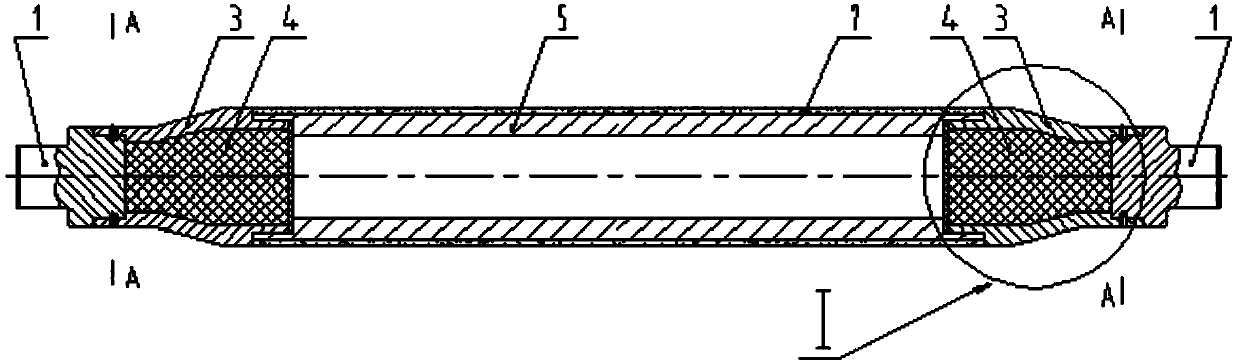

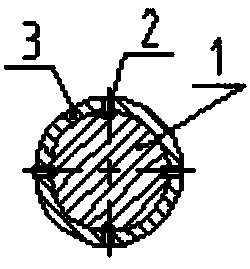

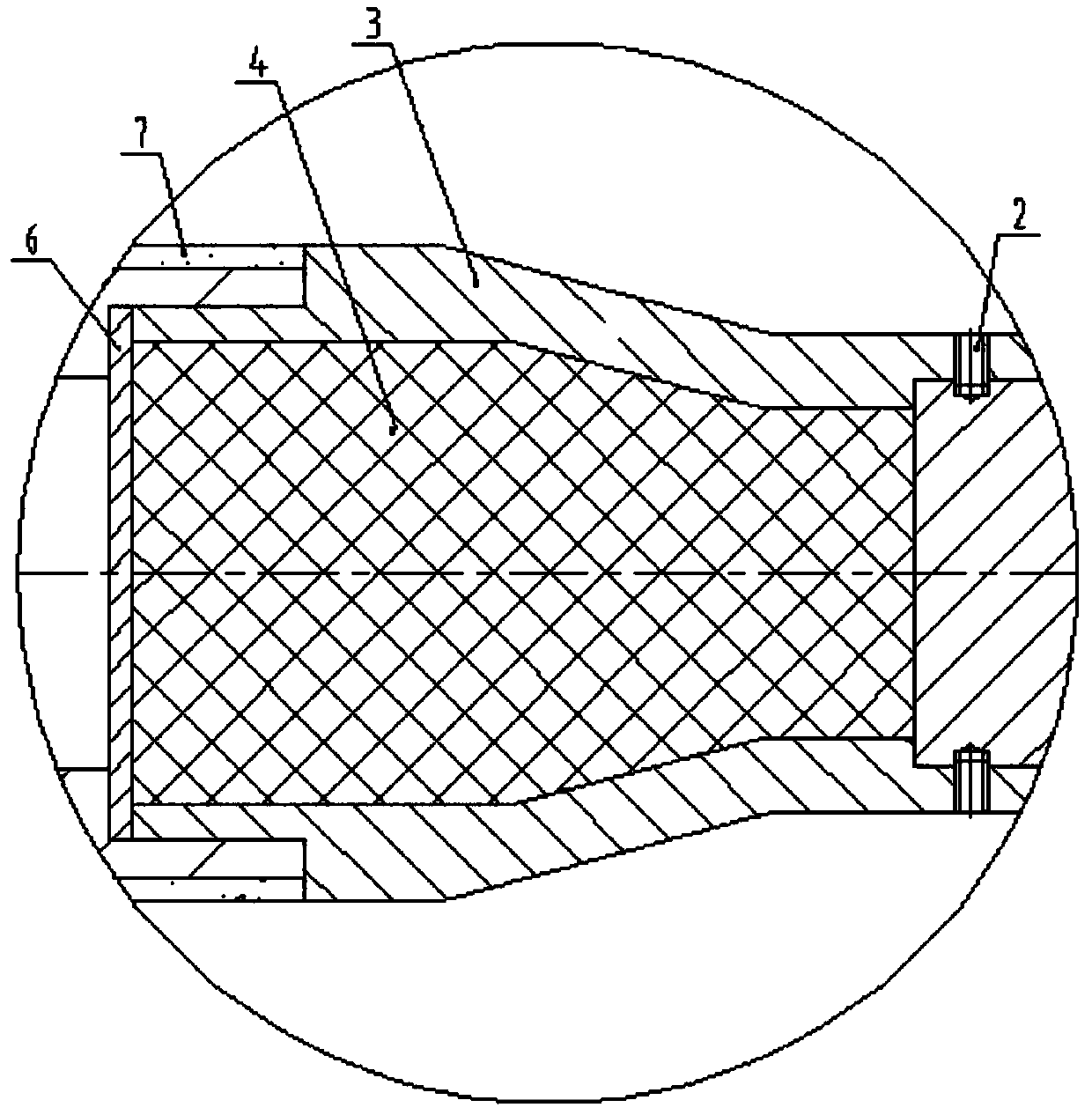

High-strength high-temperature-resistant furnace bottom roller

InactiveCN104561507AImprove working conditionsReduced heat transfer capabilityFurnace typesHeat treatment furnacesWear resistantThermal insulation

The invention discloses a high-strength high-temperature-resistant furnace bottom roller; the high-strength high-temperature-resistant furnace bottom roller comprises a roll cylinder, a roll neck and a roll head; the roll head is arranged at two ends of the roll cylinder; the roll neck is fixedly connected between the roll cylinder and the roll head; the roll head is inserted into the end part of the roll neck, so that the roll head and the roll neck are matched and fixedly connected; a clapboard is arranged at the joint of the roll cylinder and the roll neck; a closed cavity is formed among the clapboard, the end part of the roll head and the inner hole of the roll neck; a thermal insulation material is filled in the cavity, so that a thermal insulation structure is formed; the high-strength high-temperature-resistant furnace bottom roller disclosed by the invention is further characterized in that two locating pin shafts penetrating through the matched part of the roll head and the roll neck in the radial direction are arranged at the matched part of the roll head and the roll neck; a part of one locating pin shaft passes through another locating pin shaft; and a high-temperature-resistant oxidized wear-resistant coating is arranged on the outer wall of the roll cylinder. According to the invention, the capability of transferring heat from the roll cylinder to a roll shaft is low; the working conditions of a bearing are obviously improved; the connection part of the roll head and the roll neck is high in strength; and the high-strength high-temperature-resistant furnace bottom roller is high-temperature-resistant, oxidization-resistant and wear-resistant.

Owner:TAIZHOU SANJIANG SPECIAL STEEL MFG

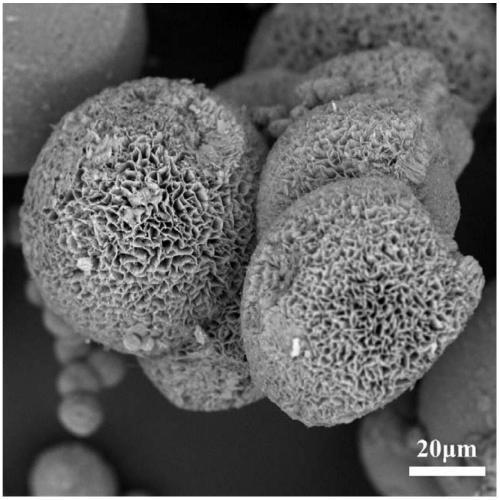

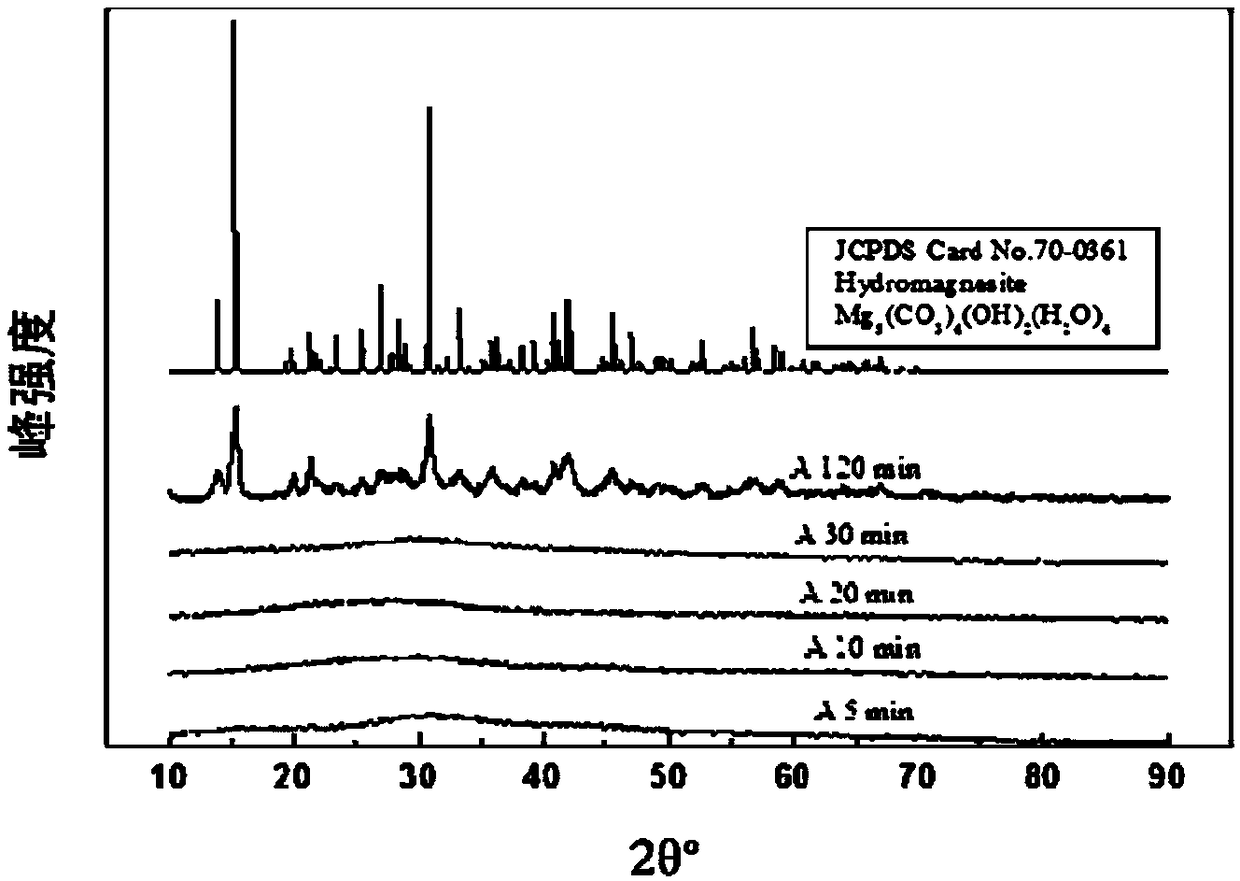

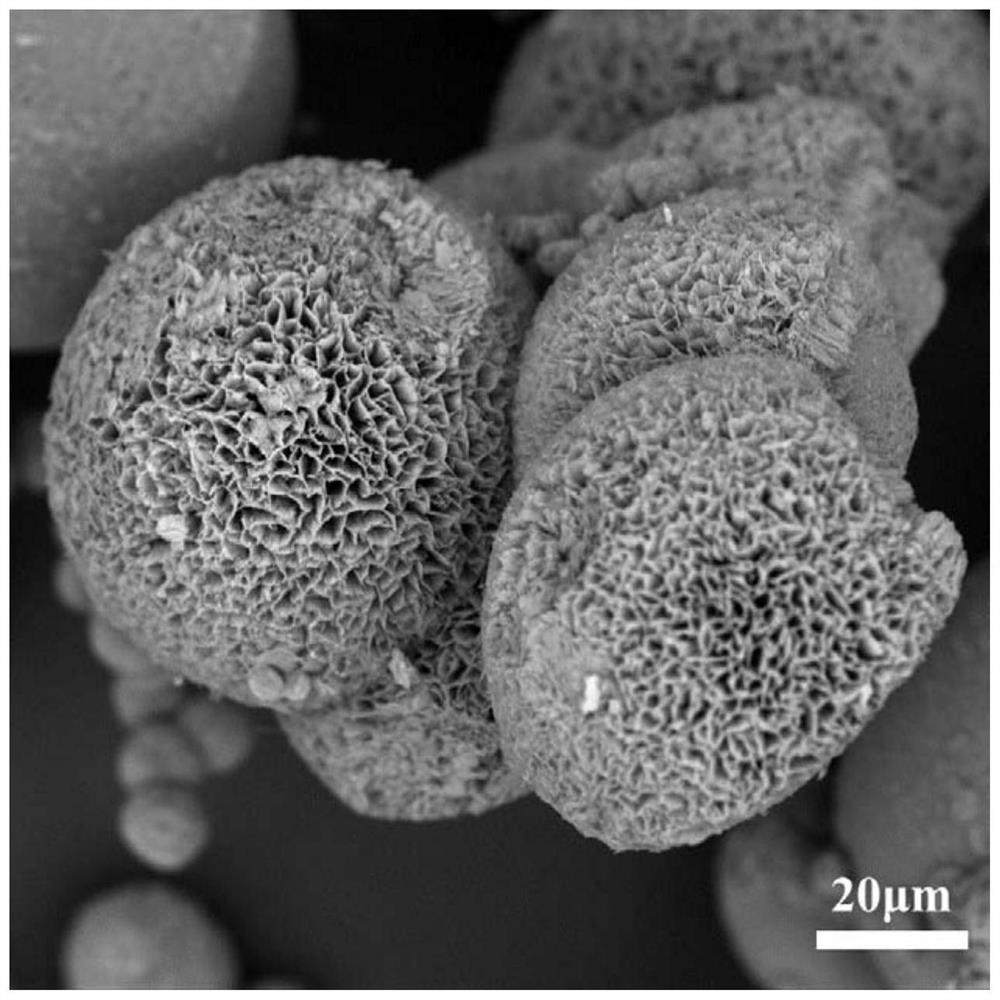

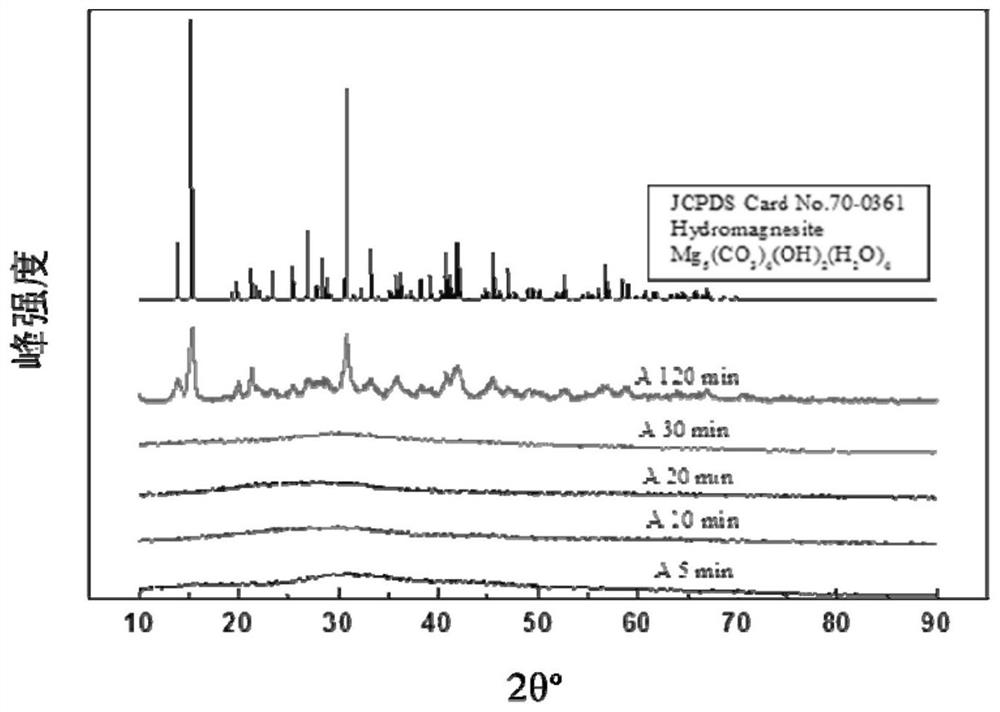

Micro-nano basic magnesium carbonate flame retardant and preparation method thereof

ActiveCN109437262ASimple preparation processWide variety of sourcesMagnesium carbonatesNanotechnologyEnvironmental resistanceCooking & baking

The invention provides a micro-nano basic magnesium carbonate flame retardant and a preparation method thereof. The preparation method comprises the following steps: firstly, dropwise adding a solublecarbonate aqueous solution with the concentration of 0.1 to 1.5 mol / L into a uniformly-stirred magnesium chloride hexahydrate aqueous solution with the concentration of 0.1 to 1.5 mol / L at the speedof 1 to 50 mL / min; secondly, putting a mixed solution obtained in the first step into a baking oven for curing at the curing temperature of 50 to 90 DEG C for 0.5 to 5 hours; thirdly, further filtering the mixed solution obtained in the second step, washing and drying at the temperature of 30 to 100 DEG C for 30 to 60 minutes, thus obtaining the basic magnesium carbonate flame retardant with a chemical formula of Mg5(CO3)4(OH)2.4H2O. The micro-nano basic magnesium carbonate flame retardant provided by the invention has excellent flame-retardant effect and good smoke suppression effect; a preparation process does not need to use an organic solvent, so that greenness and environment friendliness are realized.

Owner:WUHAN TEXTILE UNIV

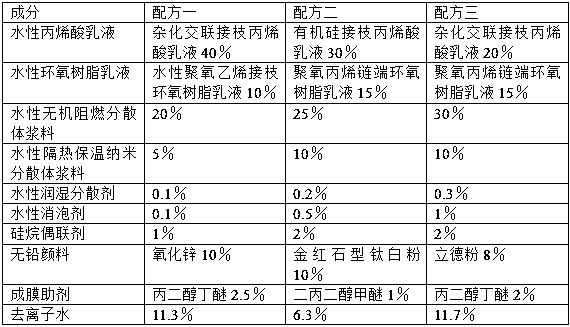

Water-based environmentally friendly flame-retardant and heat-insulating coating and preparation method thereof

InactiveCN105331217BSolve the problem of anti-combustion performanceGuarantee the safety of lifeFireproof paintsEpoxy resin coatingsEpoxyWater based

Owner:CHANGSHA MINDE FIRE ENG PAINT CO LTD

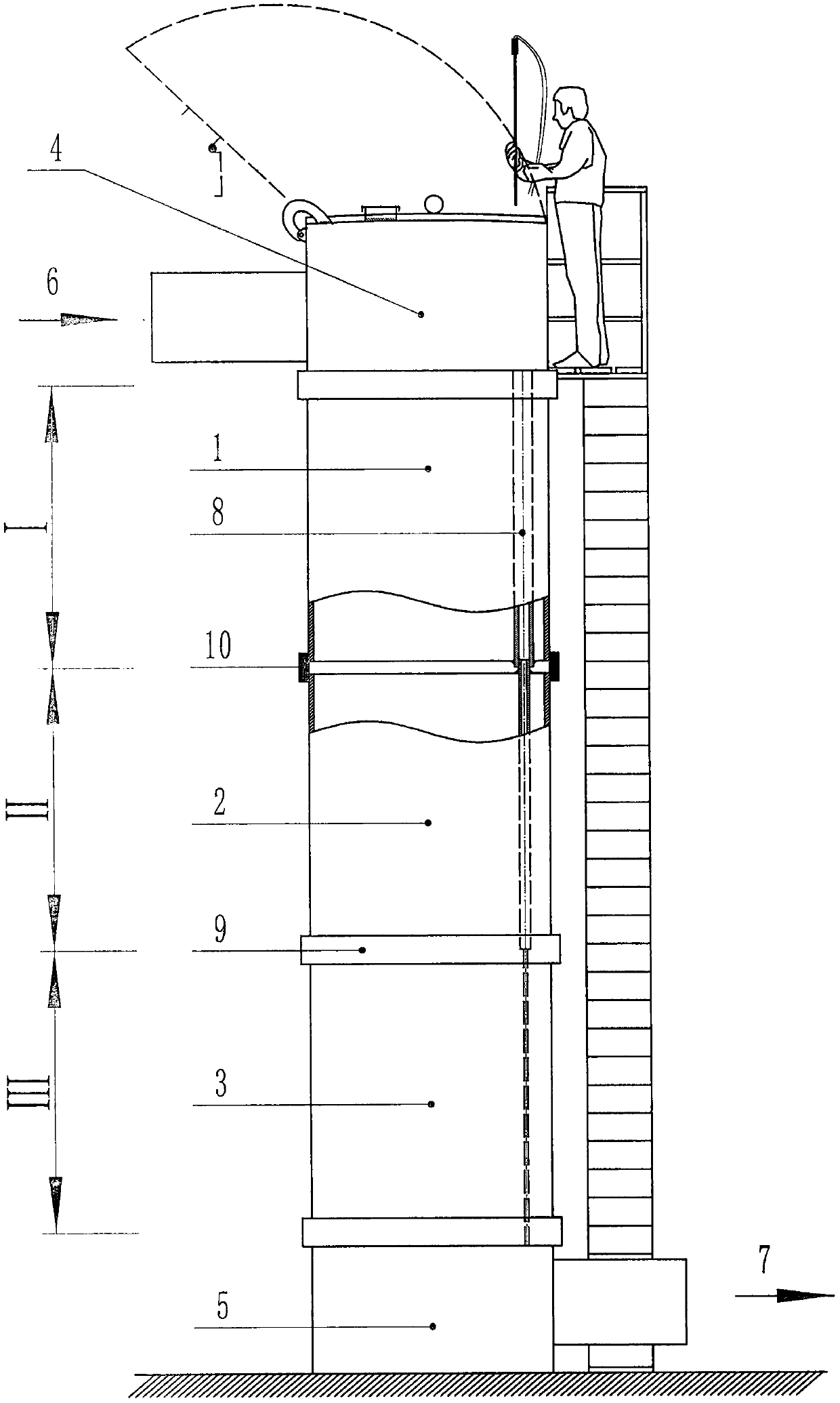

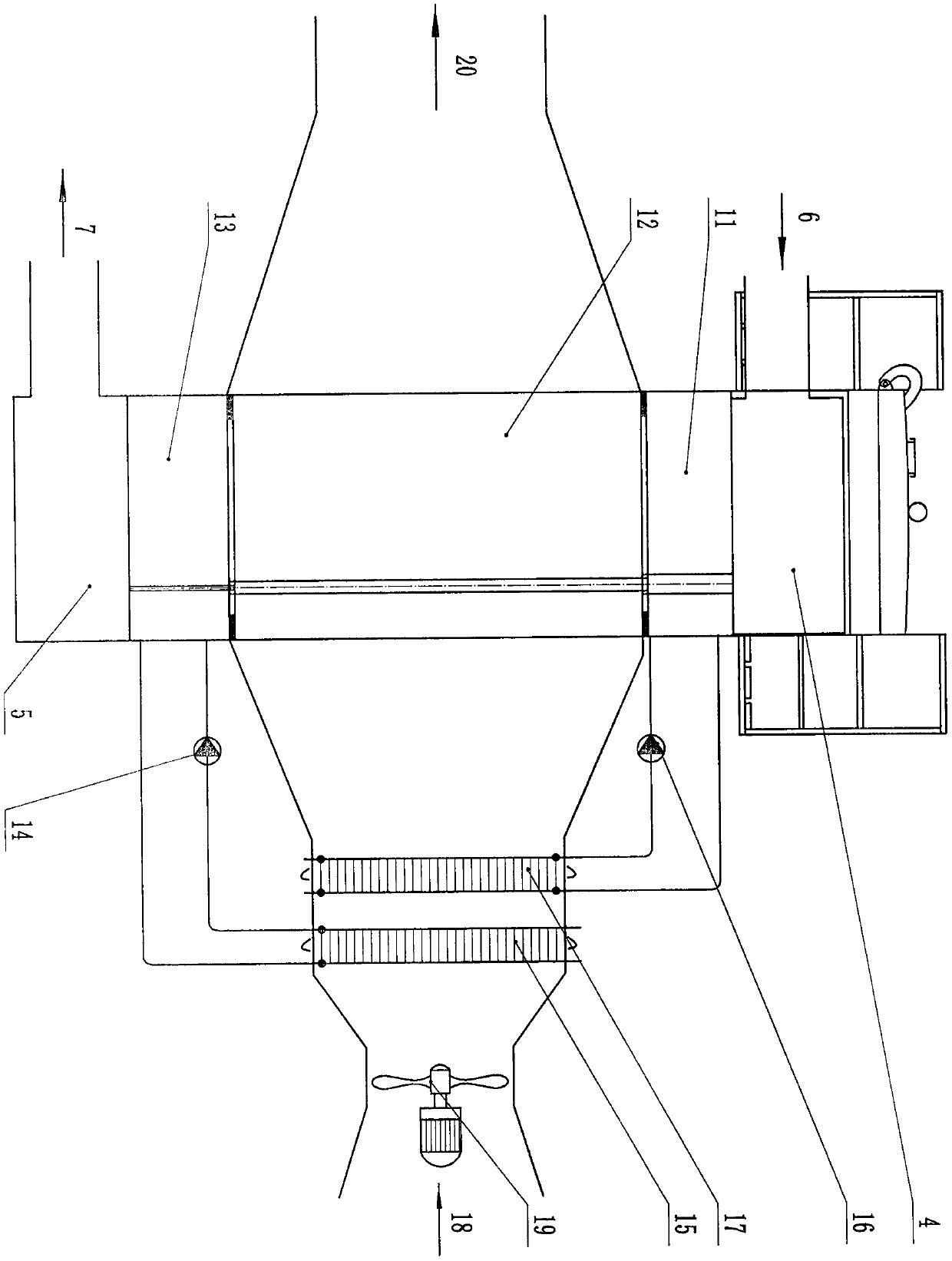

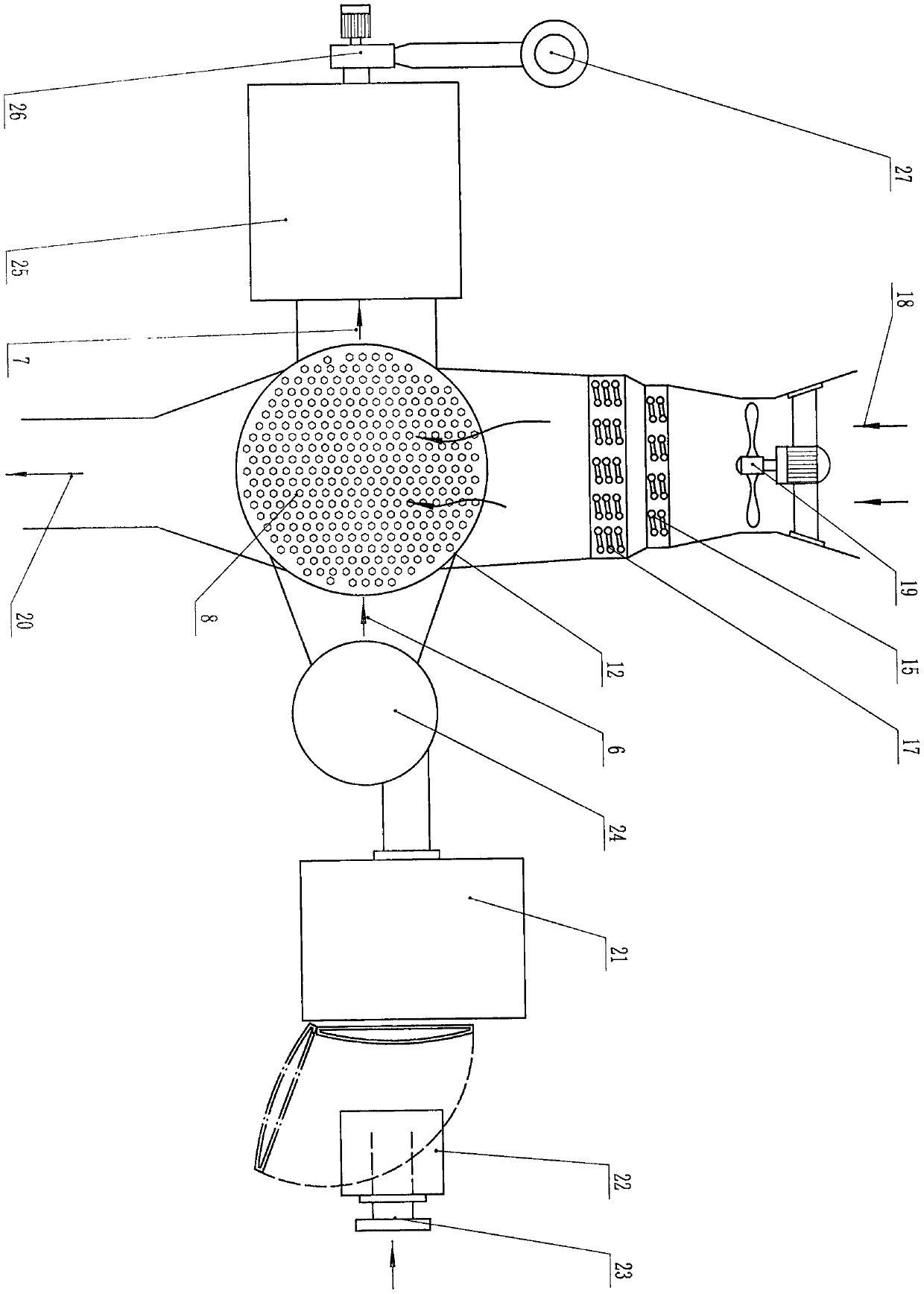

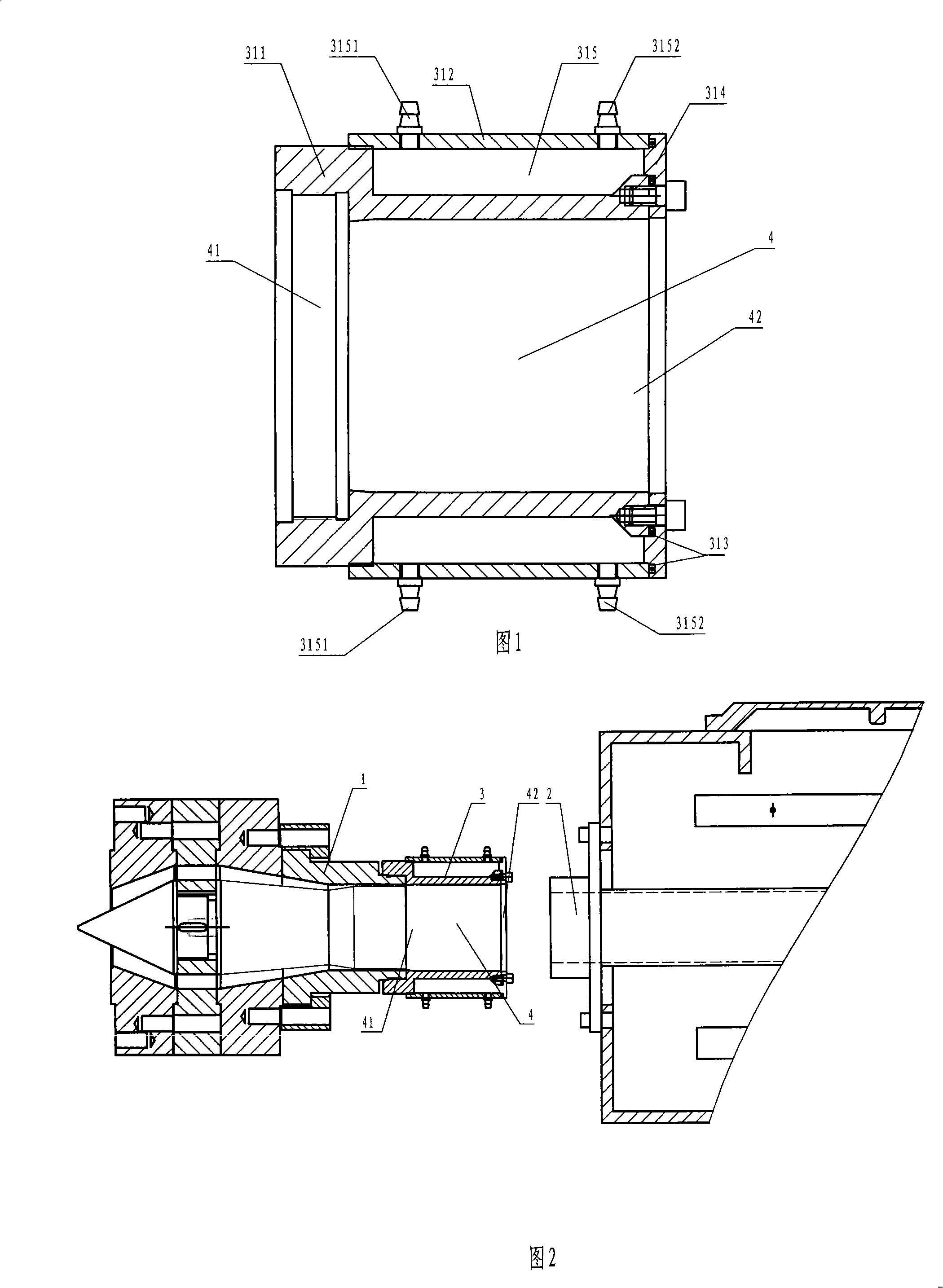

Modular heat exchange method and device particularly suitable for biomass combustion system

PendingCN110030548AImprove energy conversion efficiencyReduce the risk of fireSolid fuel combustionSolid removalFlue gasBiomass combustion

The invention relates to a modular heat exchange method and device particularly suitable for a biomass combustion system. A plurality of standardized heat exchange modules capable of using various heat carrier media are included. Flue gas (6) flows in heat exchange pipes (8), and the heat exchange pipes (8) are coaxially arranged between the different heat exchange modules. Thus, when the heat exchange modules operate, a compressed air cleaning spraying gun (30) can be used for effectively cleaning dust on the heat exchange pipes. Due to the fact that dust purifying no longer has to be achieved through the high flowing speed of the flue gas (6), it is possible to decrease the speed of the flue gas and lower the power demand of an induced draft fan. The modular heat exchange method and device are particularly suitable for construction of a system generating hot air through indirect heating, for example, the hot air at 100 DEG C or above is generated efficiently when the modular heat exchange method and device are used for grain drying. The heat exchange device can be arranged in the vertical or horizontal direction according to the needs, the size and the length of the heat exchangedevice can also be designed according to the needs, and the great performance is achieved.

Owner:黑龙江赫尔特生物质能源发展有限公司

Zinc vanadate nanorod composite paint

The invention discloses a vanadate vanadate nanorod composite paint, belonging to technical field of functional materials. The vanadate vanadate nanorod composite paint is prepared from the following components in percentage by mass: 20-40% of zinc vanadate nanorod, 15-25% of styrene-acrylic emulsion, 30-45% of water, 5-20% of nano aluminum oxide, 0.05-0.2% of alcohol ester-12, 0.5-2% of polyurethane, 0.5-2% of 10% sodium hexametaphosphate water solution, 0.5-2% of tributyl phosphate and 0.5-2% of ethylene triol. By adopting the zinc vanadate nanorods, the invention has the characteristics of high activity, high stability, no toxicity, low cost and the like, and can implement mass preparation of the vanadate nanorod composite paint. The vanadate vanadate nanorod composite paint disclosed by the invention has stable self-cleaning and anti-fouling properties.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

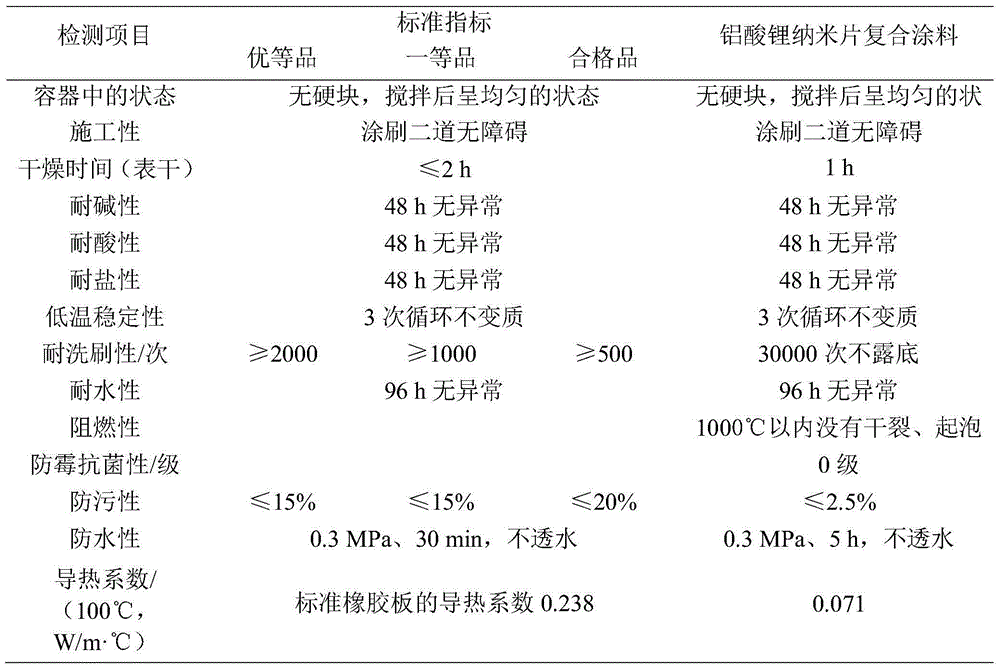

Multifunctional composite coating for lithium aluminate nanosheets

ActiveCN104592849AImprove antibacterial propertiesFunction increaseFireproof paintsAntifouling/underwater paintsOil emulsionThermal insulation

The invention discloses multifunctional composite coating for lithium aluminate nanosheets and belongs to the field of functional materials. The multifunctional composite coating for lithium aluminate nanosheets is composed of the following components in percentage by mass: 18-35% of lithium aluminate nanosheets, 5-15% of nano zirconia, 11-20% of terpene resin emulsion, 6-12% of styrene-acrylate copolymer emulsion, 3-8% of propylene glycol methyl ether acetate, 3-8% of methyl silicone oil emulsion, 20-35% of water, 1-3% of polyethylene glycol, 0.2-1% of polyacrylamide, 0.1-1% of propylene glycol, 0.05-0.2% of polyoxypropylene glycerol ether, 0.5-3% of diethylene glycol and 0.05-0.5% of polyether modified polydimethylsiloxane. The multifunctional composite coating for lithium aluminate nanosheets provided by the invention has malfunctions of corrosion resistance, fire resistance, mildew proofing, antisepsis, antifouling, water resistance and thermal insulation and the like, and has a good application prospect in coating of buildings and equipment.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Constructional fireproof heat-insulation coating and preparation method thereof

InactiveCN108641527AImprove insulation effectImprove fire performanceFireproof paintsAluminium hydroxideMicrosphere

The invention discloses a constructional fireproof heat-insulation coating and a preparation method thereof. The constructional fireproof heat-insulation coating comprises the following raw materialsin parts by weight: 20-40 parts of a silicone acrylic emulsion, 25-50 parts of ammonium polyphosphate, 5-12 parts of melamine, 8-25 parts of vinyl acetate-ethylene dispersible emulsion powder, 6-20 parts of expanded perlite, 2-6 parts of polypropylene fiber, 5-15 parts of modified aluminium hydroxide, 12-24 parts of a fire retardant, 5-10 parts of titanium dioxide, 4-12 parts of sodium hexametaphosphate, 3-14 parts of magnesium oxide, 5-10 parts of polymer hollow microsphere, 15-35 parts of light calcium carbonate, and 60-100 parts of deionized water. The constructional fireproof heat-insulation coating has excellent fire resistance and thermal insulation performance, can satisfy the fire resistance and thermal insulation requirement of the building material, at the same time, the preparation method is simple, realization is easy, and the method is adapted to large-scale industrial production.

Owner:合肥昂诺新材料有限公司

Fluorocarbon thermal insulation radiation-type coating with strong adhesion and preparation method thereof

InactiveCN106479289AReduce transmissionReduced heat transfer capabilityFireproof paintsAntifouling/underwater paintsPolyvinyl butyralVinyl ether

A fluorocarbon thermal insulation radiation-type coating with strong adhesion is characterized by being prepared from the following raw materials: chlorotrifluoroethylene, infrared-absorbing nano powder, perfluoromethyl vinyl ether, hydroxyethyl methacrylate, triglycidyl isocyanurate, zinc acetate, phenyltriethoxysilane, polyvinyl butyral, flaky aluminum powder, ethyl orthosilicate, 30% aqueous ammonia, isopropyl alcohol, aluminum stearate, aluminum oxide, hydroxyethyl cellulose, aluminum tripolyphosphate, acetyl trihexyl citrate, a proper amount of sodium bicarbonate, and a proper amount of deionized water. The fluorocarbon thermal insulation radiation-type coating with strong adhesion has good thermal insulation effects, excellent mechanical properties, excellent adhesion, and excellent weather resistance, water resistance, stain resistance and scrub resistance; in addition, the coating is safe and environmentally friendly, and has wide range of applications.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

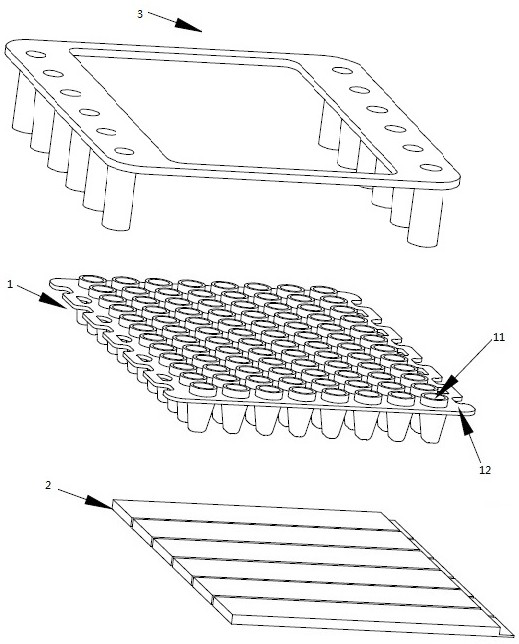

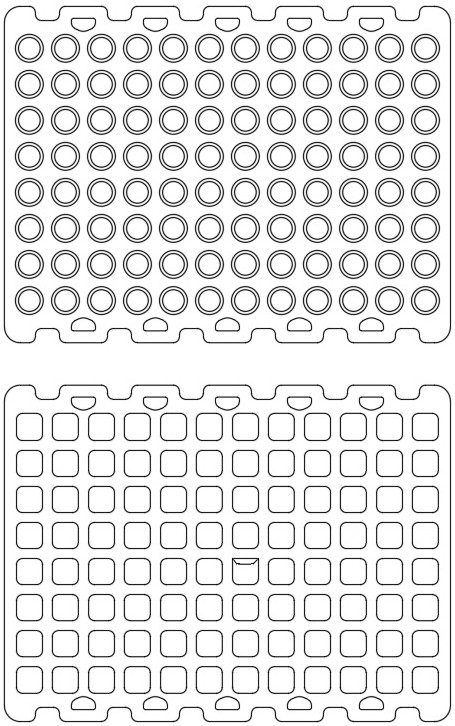

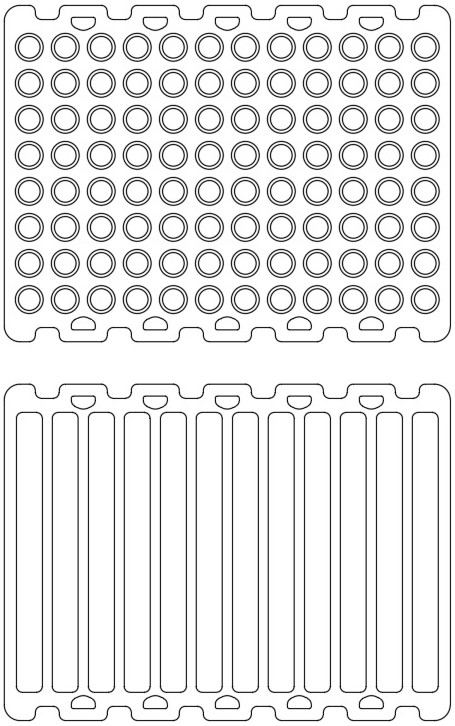

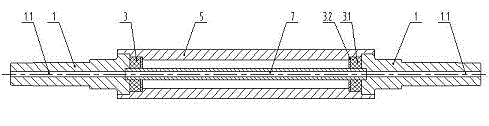

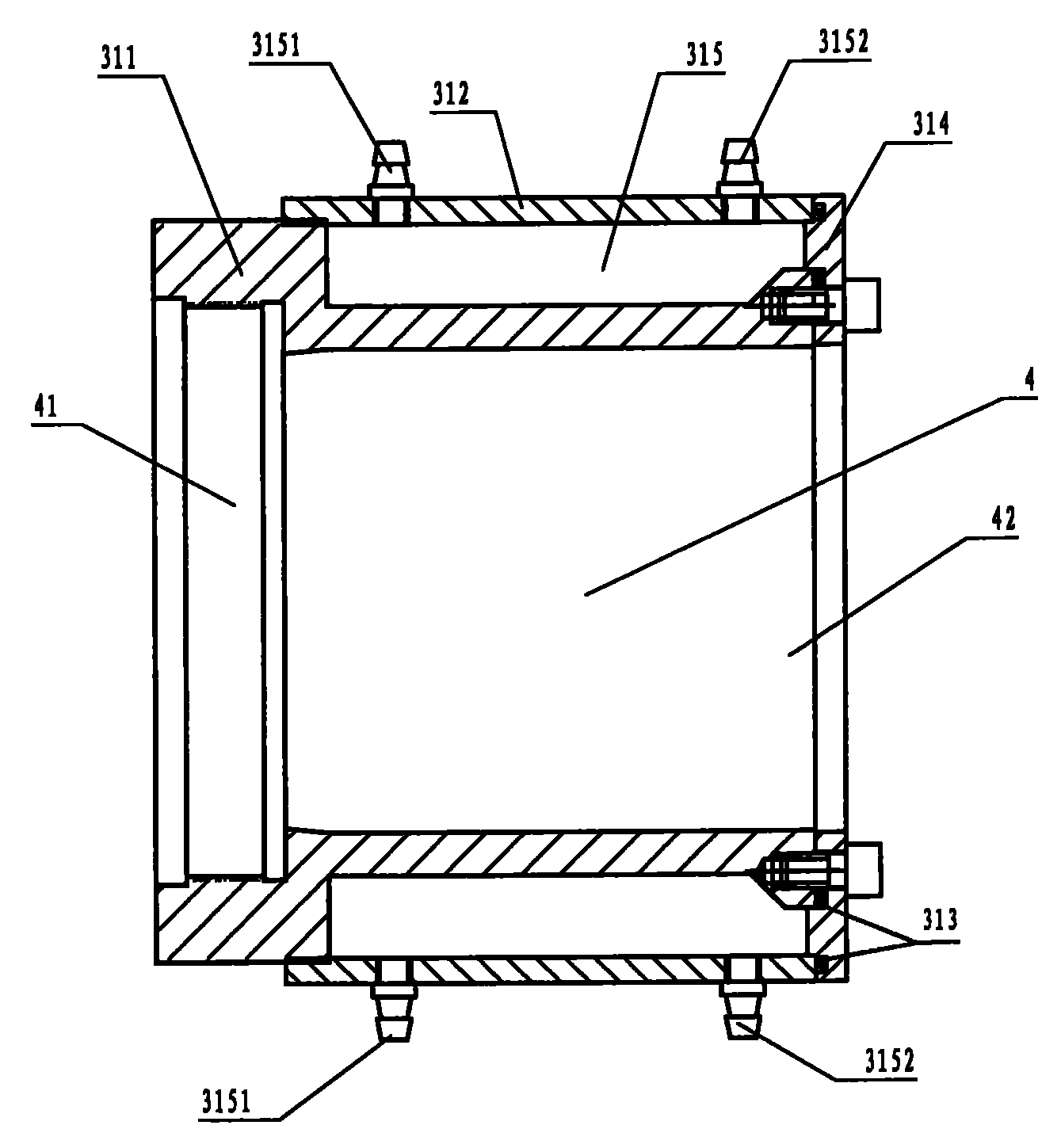

A thermocirculator

InactiveCN112827524AReduced heat transfer capabilityImprove accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlHeat recirculation

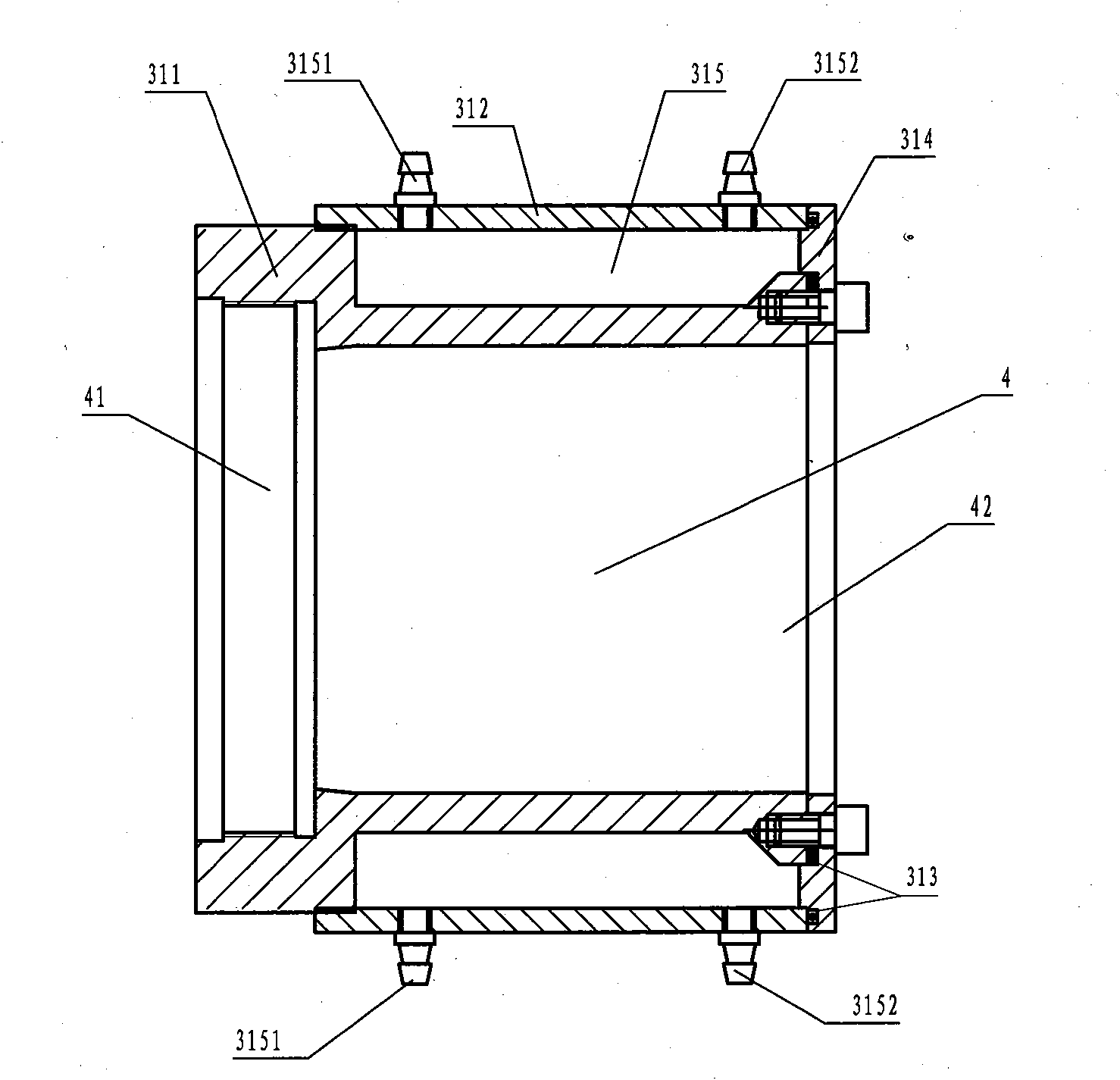

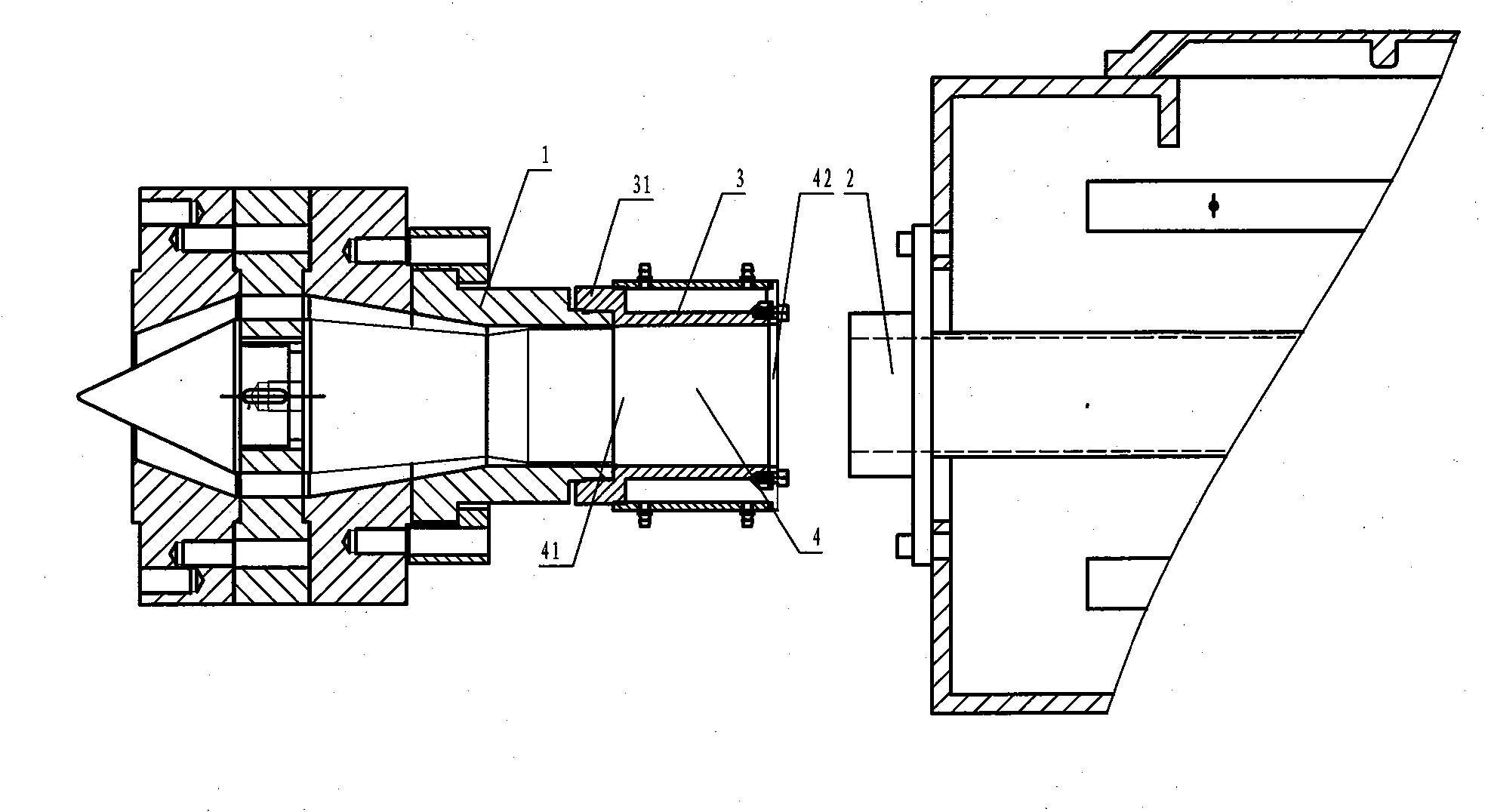

The embodiment of the invention provides a thermocirculator. The thermocirculator comprises a sample block (1) provided with a blind hole array; and N heating and cooling means (2), N being a positive integer greater than 2; wherein the upper parts of all the blind holes (11) are connected, the N heating and cooling devices (2) respectively heat and / or cool the bottoms of the blind holes (11) in N different areas of the sample block (1), and each area comprises one or more blind holes (11). According to the embodiment of the invention, the upper parts of the blind holes in the sample block are connected, and the bottoms of the blind holes in different areas of the sample block are respectively heated and / or cooled through the N heating and cooling devices, so that the heat transfer effect among the blind holes in different areas of the sample block is reduced; and the accuracy of temperature control of different areas of the sample block and the repeatability of the experiment are improved.

Owner:RWD LIFE SCI

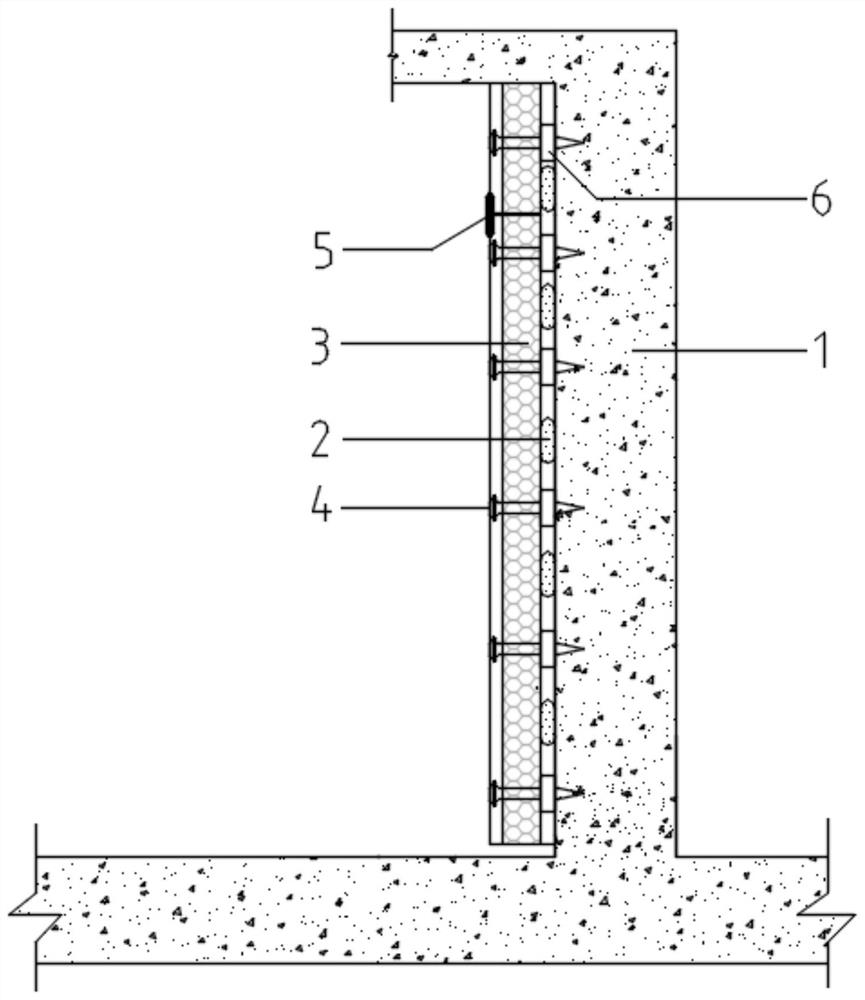

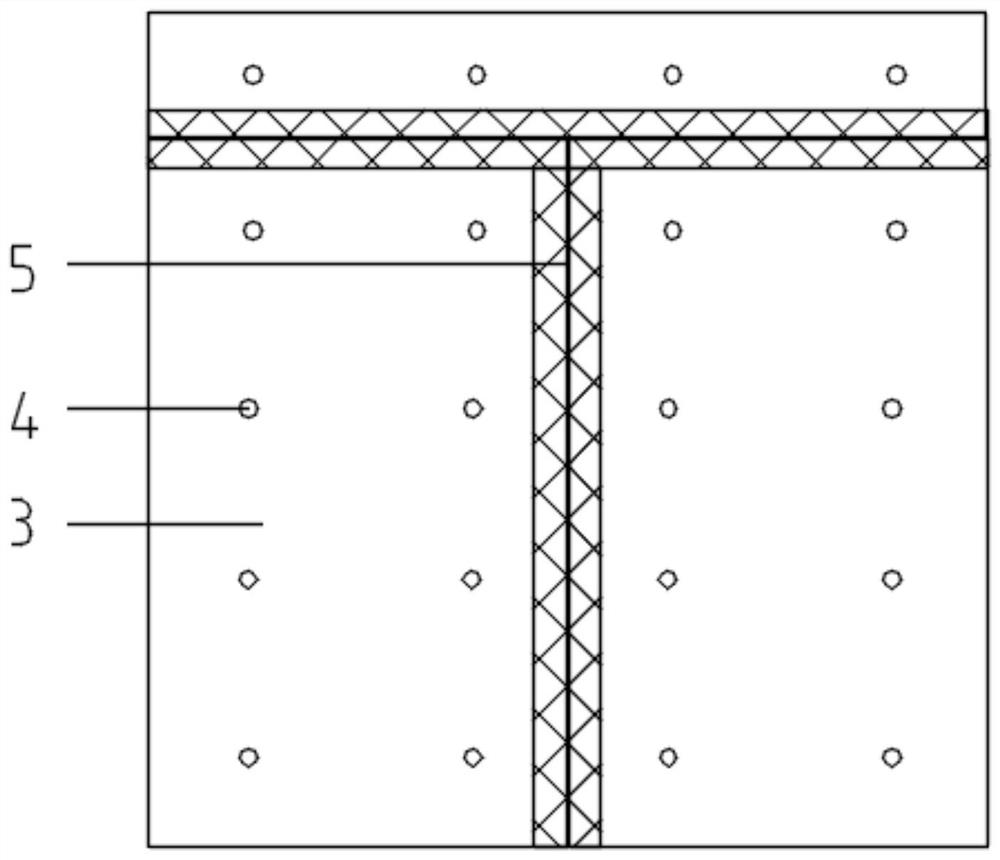

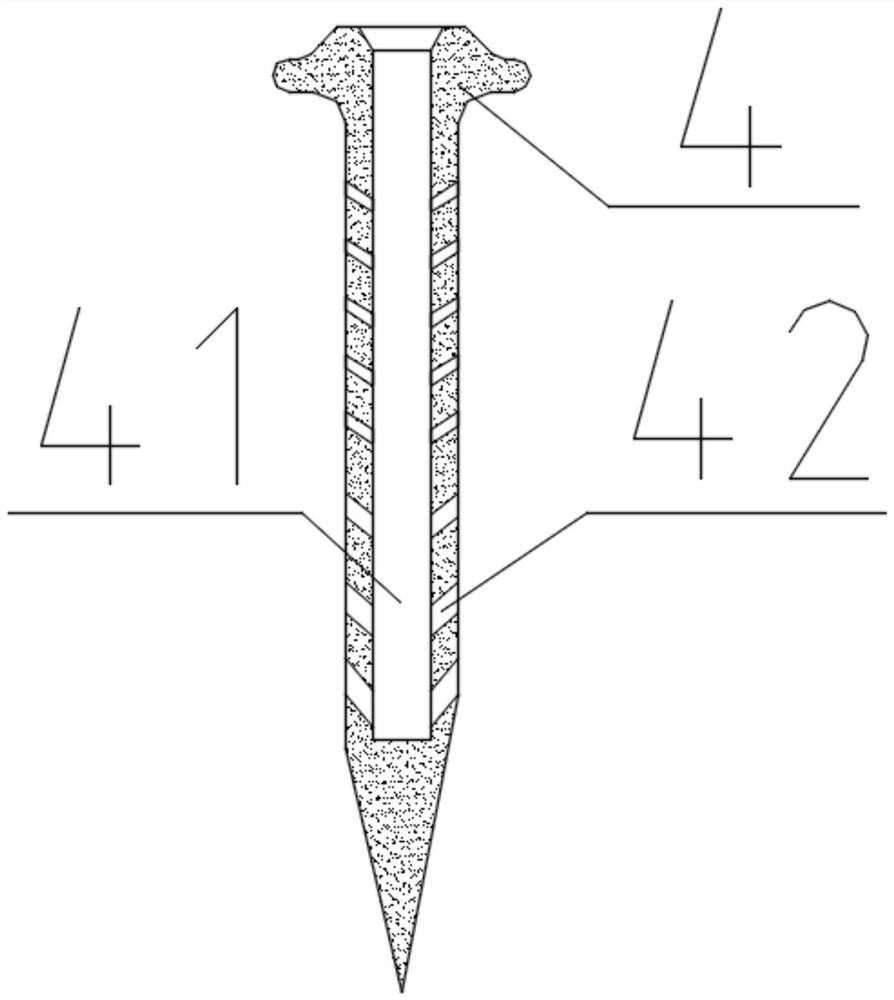

External wall heat preservation structure and construction method thereof

PendingCN112160452AFirmly connectedInhibit sheddingWallsHeat proofingArchitectural engineeringExternal cladding

The invention relates to the technical field of building construction, in particular to an external wall heat preservation structure and a construction method thereof. The external wall heat preservation structure comprises bonding mortar, an XPS gypsum board and fixing anchor bolts, wherein the XPS gypsum board is bonded to a concrete external wall through the bonding mortar, drill holes are formed in the positions, corresponding to the concrete external wall, of the XPS gypsum board, the fixing anchor bolts penetrate through the drill holes to be fixed to the concrete external wall, a glue storage frame is arranged on the outer sides of the fixing anchor bolts, embedded in the XPS gypsum board and connected with the concrete external wall in an abutting mode, openings are formed in the upward side walls of the glue storage frame, glue injection holes are formed in the fixing anchor bolts in the axial direction, a plurality of glue outlet holes are evenly formed in the side walls of the fixing anchor bolts, and the glue outlet holes are communicated with the glue injection holes. The external wall heat preservation structure is novel in design and convenient to use, can realize firm connection between the XPS gypsum board and a wall body, prevents the XPS gypsum board from falling off in the use process, and is suitable for further popularization and application.

Owner:CHINA CONSTR FOURTH ENG DIV +1

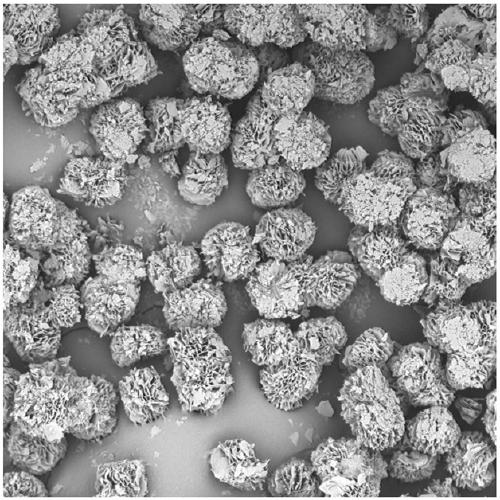

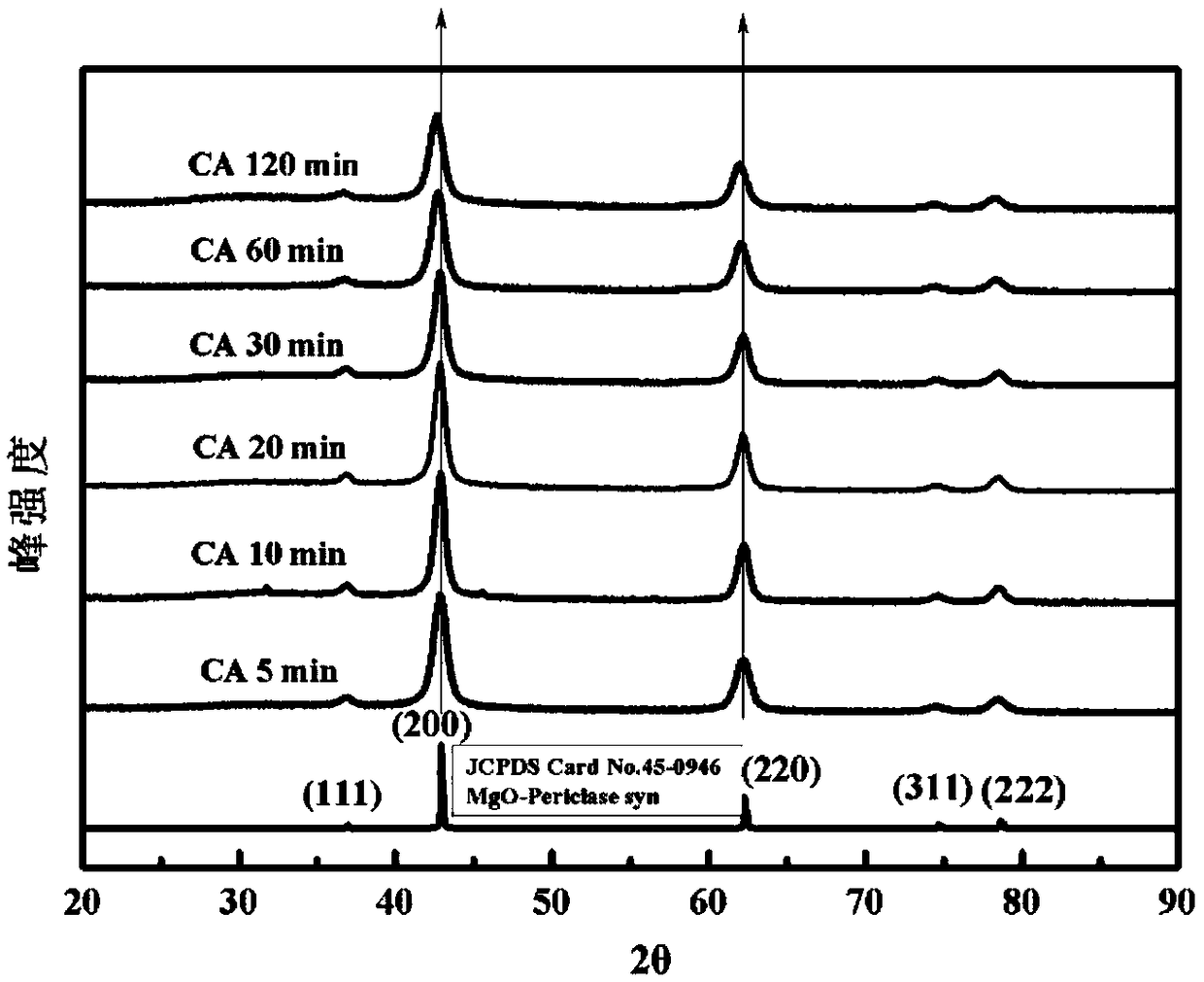

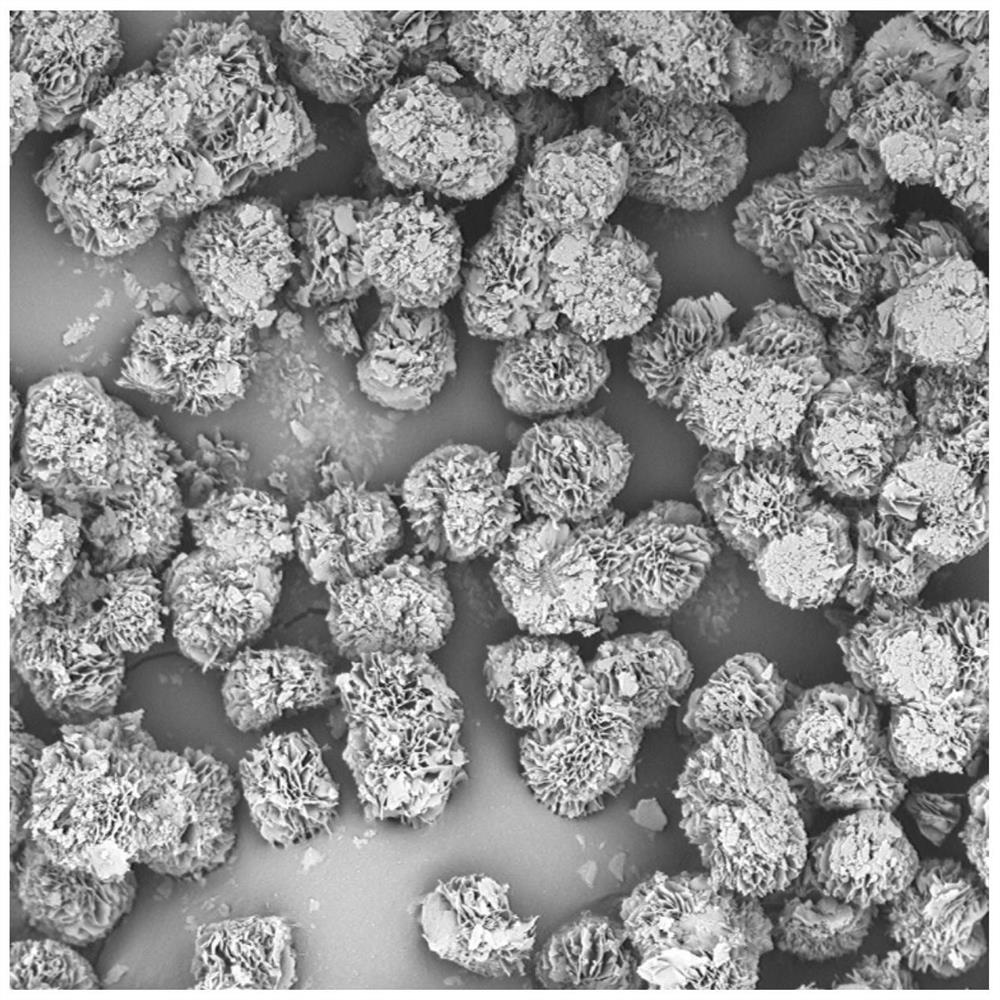

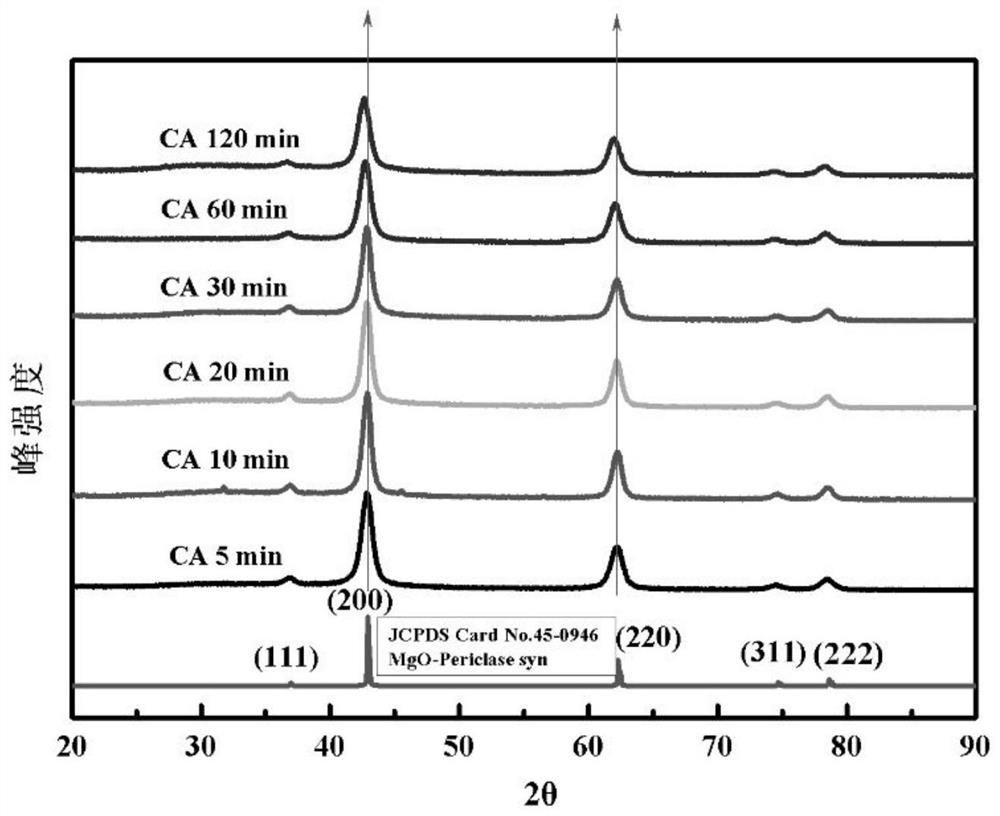

Micro-nano magnesia flame retardant and preparation method thereof

ActiveCN109437256ASimple manufacturing processWide variety of sourcesFlame-proof filament manufactureArtificial filaments from cellulose derivativesMicro nanoOrganic solvent

The invention provides a micro-nano magnesia flame retardant and a preparation method thereof. The preparation method comprises the following steps: firstly, dropwise adding a soluble carbonate aqueous solution with the concentration of 0.1 to 1.5 mol / L into a uniformly-stirred magnesium chloride hexahydrate aqueous solution with the concentration of 0.1 to 1.5 mol / L at the speed of 1 to 50 mL / min; secondly, putting a mixed solution obtained in the first step into a baking oven for curing at the curing temperature of 50 to 90 DEG C for 1 to 5 hours; thirdly, further filtering the mixed solution obtained in the second step, washing and drying; fourthly, putting a product obtained in the third step into a muffle furnace and calcining to 300 to 900 DEG C at the heating rate of 1 to 10 DEG C / min for 0.5 to 5 hours, thus obtaining the micro-nano magnesia flame retardant. The micro-nano magnesia flame retardant provided by the invention has excellent flame-retardant effect and good smoke suppression effect; a preparation process does not need to use an organic solvent, so that greenness and environment friendliness are realized.

Owner:WUHAN TEXTILE UNIV

Precooling apparatus of plastic tube product line

InactiveCN101293396AImprove toughnessImprove plasticizing effectTubular articlesSizingManufacturing line

The invention discloses a pre-cooling device of a plastic tubular product manufacture line, which includes a shell with a sandwich; the inlet end of a material circulating channel in the inner cavity of the shell is communicated with the material outlet of a handpiece finish mold; the outlet end is communicated with the inlet of a sizing sleeve; the two ends of the sandwich of the shell are closed; the sandwich of the shell and the two end surfaces of the sandwich form the refrigerating channel of the pre-cooling device; a refrigerant inlet on the refrigerating channel is arranged on the refrigerating channel near the end of the handpiece finish mold; the outlet is arranged on the refrigerating channel near the end of the sizing sleeve. The pre-cooling device of the invention has the advantages that a high temperature material blank extruded from the handpiece finish mold is cooled by the pre-cooling device of the plastic tubular product manufacture line; therefore, the temperature of the extruded material blank is reduced and the material blank is contracted; the outer diameter of the material blank is almost consistent with the inner diameter of the sizing sleeve, thus being easier to enter the sizing sleeve, reducing the heat transferring action between the material blank and the sizing sleeve and avoiding the problems of over-heating of the sizing sleeve and blocking of the material blank from happening; thereby effectively improving the manufacture speed of the plastic tubular product manufacture line and stabilizing the manufacture.

Owner:福建祥龙塑胶有限公司

A kind of micronano basic magnesium carbonate flame retardant and preparation method thereof

ActiveCN109437262BSimple preparation processWide variety of sourcesMagnesium carbonatesNanotechnologyMicro nanoOrganic solvent

The invention provides a micronano basic magnesium carbonate flame retardant and a preparation method thereof. The preparation method comprises the following steps: 1) Adding a soluble carbonate aqueous solution with a concentration of 0.1 to 1.5 mol / L dropwise at a rate of 1 to 50 mL / min to a uniformly stirred aqueous solution of magnesium chloride hexahydrate with a concentration of 0.1 to 1.5 mol / L 2) put the mixed solution obtained in step 1) into an oven for curing, the curing temperature is 50-90° C., and the time is 0.5-5 hours; and 3) further filter the mixed solution obtained in step 2), wash it, and heat it at 30-100° C. Dry for 30-60 minutes to prepare a micronano basic magnesium carbonate flame retardant, whose chemical formula is Mg 5 (CO 3 ) 4 (OH) 2 4H 2 O. According to the micronano basic magnesium carbonate flame retardant provided by the present invention, the preparation process does not need to use organic solvents, is environmentally friendly, has excellent flame retardant effect, and good smoke suppression effect.

Owner:WUHAN TEXTILE UNIV

Air-cooled hearth roll

InactiveCN105695723AReduce the temperatureReduce lossFurnace typesHeat treatment furnacesFiberWater circulation

The invention discloses an air-cooled hearth roll. The air-cooled hearth roll comprises a roll cylinder, a sleeve, and roll shafts fixedly connected in two end holes of the roll cylinder; the sleeve is fixedly connected between the two roll shafts, and the inner hole of the sleeve is connected with the shaft holes of the two roll shafts to form a cooling air channel; the end portion of one end of each of the roll shafts connected with the roll cylinder is provided with a heat insulation structure; the heat insulation structure is arranged in a cavity at the inner side of the end surface of one end of the corresponding roll shaft connected with the roll cylinder, and comprises a heat insulation filler and a baffle plate; the baffle plate is in sealing connection to the inner side of a cavity at the inner side of the end surface of one end of the corresponding roll shaft connected with the roll cylinder, and a cavity between the baffle plate and the end surface of one end of the corresponding roll shaft connected with the roll cylinder is filled with the heat insulation filler; and the heat insulation filler is alumina silicate fibers. The air-cooled hearth roll adopting an air cooling system and cancelling a water circulation cooling system has the advantages of low fuel loss, low device investment and low device maintenance.

Owner:孙萍

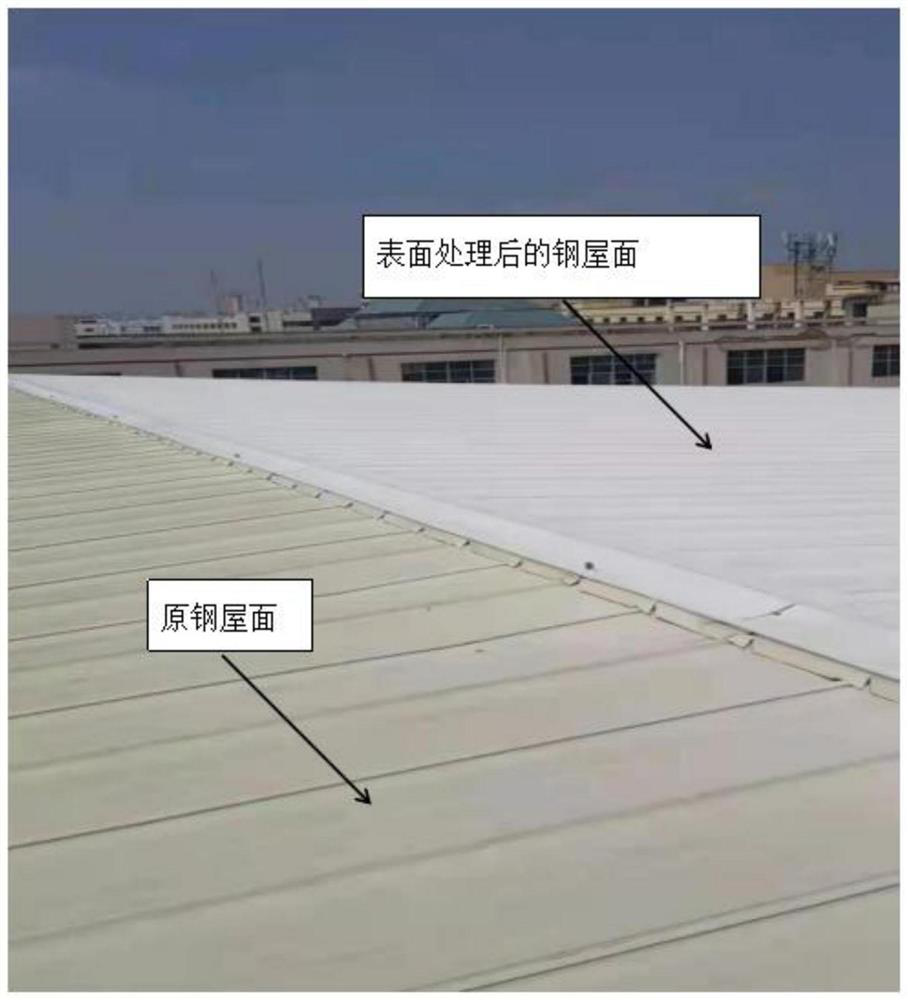

Steel roof surface treatment method

PendingCN114437586AImprove barrier propertiesImprove corrosion resistanceAnti-corrosive paintsMetallic material coating processesCoated surfaceChemical reduction

The invention provides a steel roof surface treatment method, and belongs to the technical field of paint corrosion prevention. The invention provides a steel roof surface treatment method which comprises the following steps: cleaning a steel roof surface to obtain a pretreated clean steel roof surface; the surface of the pretreated clean steel roof is coated with rust conversion paint, and a closed coating is obtained; and the surface of the sealing coating is coated with a nanometer anti-corrosion coating, and the treated steel roof surface is obtained. The surface of the steel roof is treated through the chemical reduction reaction and the nano corrosion coating, corrosion of atmosphere, water, sunlight and ultraviolet rays to the steel roof can be blocked, and the purpose of full-life-cycle protection is achieved.

Owner:施国全 +1

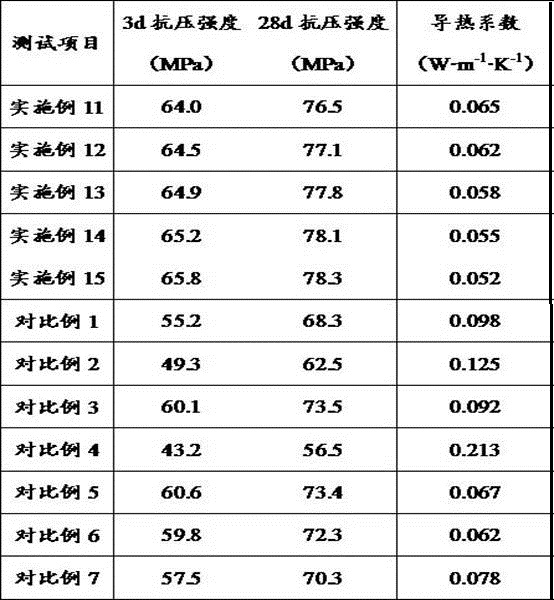

A kind of active powder concrete and preparation method thereof

The invention is applicable to the technical field of concrete, and provides an active powder concrete and a preparation method thereof. The active powder concrete includes the following components: cement, fly ash, modified glass fiber, antimony tin oxide, water reducing agent, and water; The surface of the modified glass fiber is electrostatically adsorbed with nanometer inorganic materials. In the embodiments of the present invention, by adding modified glass fiber and antimony tin oxide, synergistic effects can be achieved, thereby significantly improving the strength and heat insulation performance of the active powder concrete. Among them, antimony tin oxide can reduce light transmission and heat transfer effects, and can significantly improve the thermal insulation performance of reactive powder concrete under the compounding effect of modified glass fibers. In addition, in the embodiment of the present invention, the nano-inorganic material is adsorbed on the surface of the glass fiber by electrostatic adsorption, which can improve the dispersion of the glass fiber in the concrete system, and can significantly improve the strength and other properties of the active powder concrete.

Owner:深圳市利建新材料有限公司

A kind of micronano magnesium oxide flame retardant and preparation method thereof

ActiveCN109437256BSimple manufacturing processWide variety of sourcesFlame-proof filament manufactureArtificial filaments from cellulose derivativesMicro nanoOrganic solvent

The invention provides a micronano magnesium oxide flame retardant and a preparation method thereof. The preparation method comprises the following steps: 1) Adding a soluble carbonate aqueous solution with a concentration of 0.1 to 1.5 mol / L dropwise at a rate of 1 to 50 mL / min to magnesium chloride hexahydrate with a concentration of 0.1 to 1.5 mol / L stirred at a constant speed in an aqueous solution; 2) placing the mixed solution obtained in step 1) in an oven for aging at a temperature of 50-90°C for 1-5 hours; 3) further filtering, washing and drying the mixed solution obtained in step 2); and 4) The product obtained in step 3) is calcined in a muffle furnace, and calcined to 300-900° C. at a heating rate of 1-10° C. / min for 0.5-5 hours to prepare a micronano-sized magnesium oxide flame retardant. According to the micronano magnesium oxide flame retardant provided by the present invention, the preparation process does not need to use organic solvents, is environmentally friendly, has excellent flame retardant effect, and good smoke suppression effect.

Owner:WUHAN TEXTILE UNIV

High-strength high-temperature-resistant furnace bottom roller

InactiveCN107893157AImprove working conditionsReduced heat transfer capabilityFurnace typesHeat treatment furnacesRefractoryPulp and paper industry

The invention discloses a high-strength and high-temperature-resistant furnace bottom roller, which comprises a roller, a roller neck and a roller head; the roller head is arranged at both ends of the roller, and the roller neck is fixedly connected between the roller and the roller head; the roller head is inserted into the roller The end of the neck forms a fit and a fixed connection; the roll neck is inserted into the spigot hole at the end of the roll to form a fit and a fixed connection; the joint between the roll and the roll neck is provided with a partition; the cavity in the roll neck is provided with heat insulation Structure: there is more than one anti-loosening screw at the connection between the spigot hole at the end of the roller and the end of the roll neck, the anti-loosening screw penetrates radially, and the threaded connection is inserted into the wall of the spigot hole at the end of the roller; further The improvement lies in that: the outer wall of the roller is provided with a high-temperature oxidation-resistant and wear-resistant coating; the anti-loosening screws are evenly distributed on the circumference of the connection between the notch hole at the end of the roller and the end of the roller neck. The invention has low heat transfer capability from the roller to the roller shaft, and the working condition of the bearing is obviously improved; the joint structure of the roller head and the roller neck has high strength, high disassembly efficiency; high temperature resistance, oxidation resistance and wear resistance.

Owner:江苏亚太特种铸钢厂有限公司

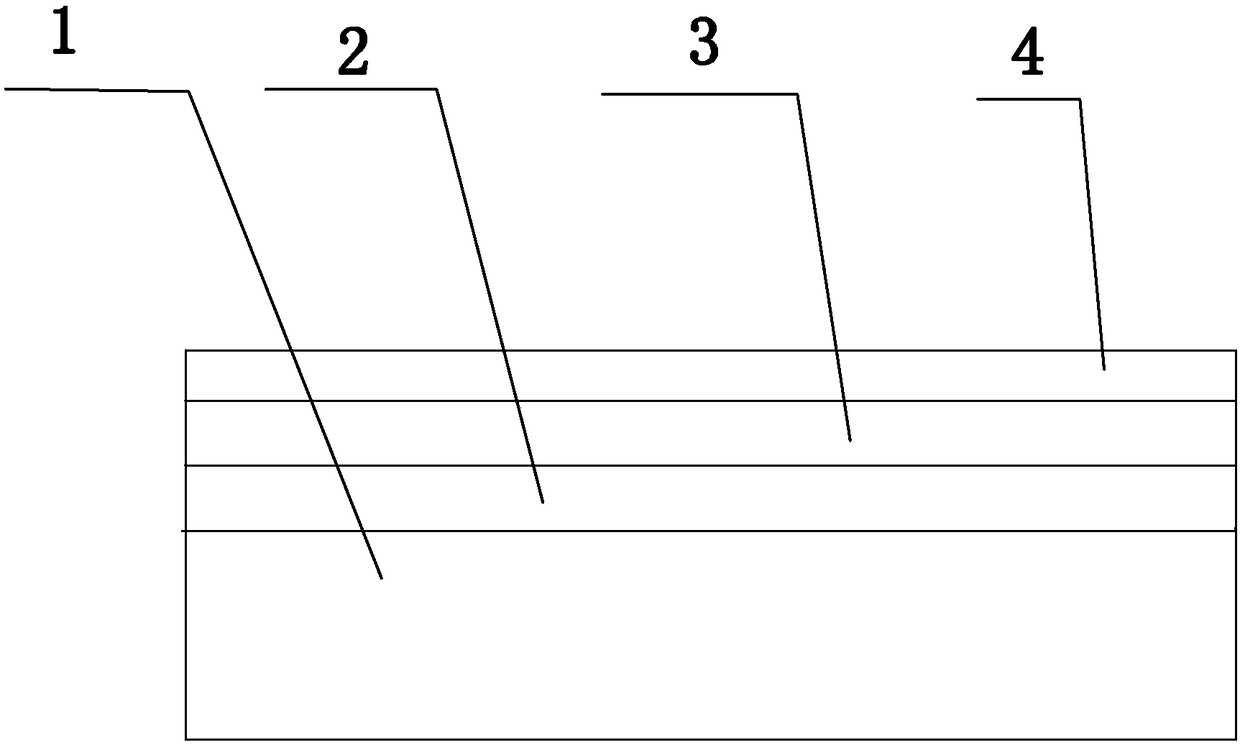

Production method of artificial stone composite board

InactiveCN109138187AGood adhesionAvoid destructionClimate change adaptationHeat proofingLower limitHeat transmission

The invention provides a production method of an artificial stone composite board. The production method of the artificial stone composite board comprises a wall base layer; a melamine resin bonding layer, an algae mud active silicate thermal insulation layer and an acrylic waterproof layer are coated on the wall base layer from inside to outside in sequence; as the melamine resin bonding layer isadopted, the adhesion is good so that a thermal insulation coating is integrally firm and durable; through adoption of the algae mud active silicate thermal insulation layer, the heat transfer capability of a material declines or approaches the lowest limit so that the artificial stone composite board is a super thermal insulation material; as heat conduction is realized between an object and anobject through heat transmission, and the heat transmission capability of the heat transmission mode of the algae mud active silicate thermal insulation layer declines to a lowest degree, the seekingof people to the thermal insulation performance can be satisfied; and due to the existence of the waterproof layer, water can be very well prevented from permeating into the thermal insulation layer so that the thermal insulation layer can be effectively prevented from being destroyed by water.

Owner:秦春玉

Thalatherm reactive silicate heat insulating layer building exterior wall

InactiveCN107201787AGood adhesionPrevent moisture penetrationHeat proofingBuilding insulationsMelamine resinPolymer chemistry

The patent of the present invention discloses an exterior wall of a building with an algae mud active silicate insulation layer, which includes a wall base layer, and the wall base layer is sequentially coated with a melamine resin bonding layer and an algae mud active silicate insulation layer from the inside to the outside. The layer and the acrylic waterproof layer adopt melamine resin bonding layer, which has good adhesion and makes the insulation coating firm and durable as a whole; Materials, because objects and objects are used to conduct heat through heat transfer, and the algae mud active silicate insulation layer reduces this essential heat transfer method to the lowest level, which can meet people's pursuit of thermal insulation performance. The existence of the waterproof layer can well prevent moisture from penetrating into the insulation layer, and can effectively prevent the insulation layer from being destroyed by water.

Owner:肖挺超

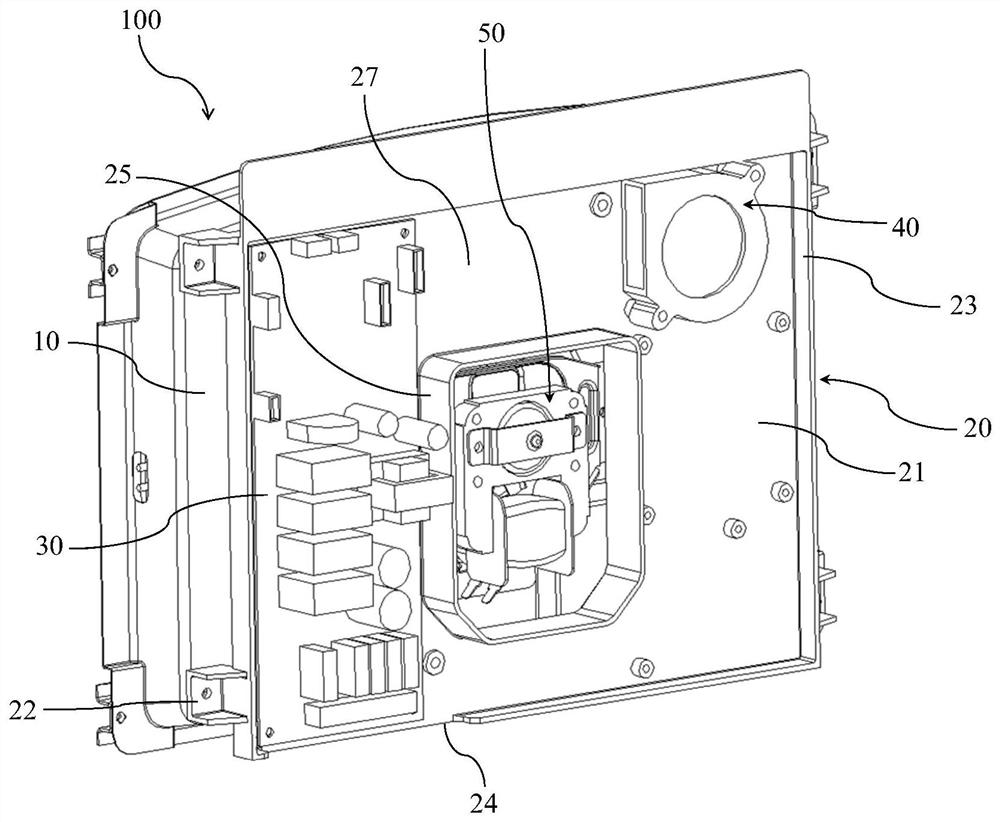

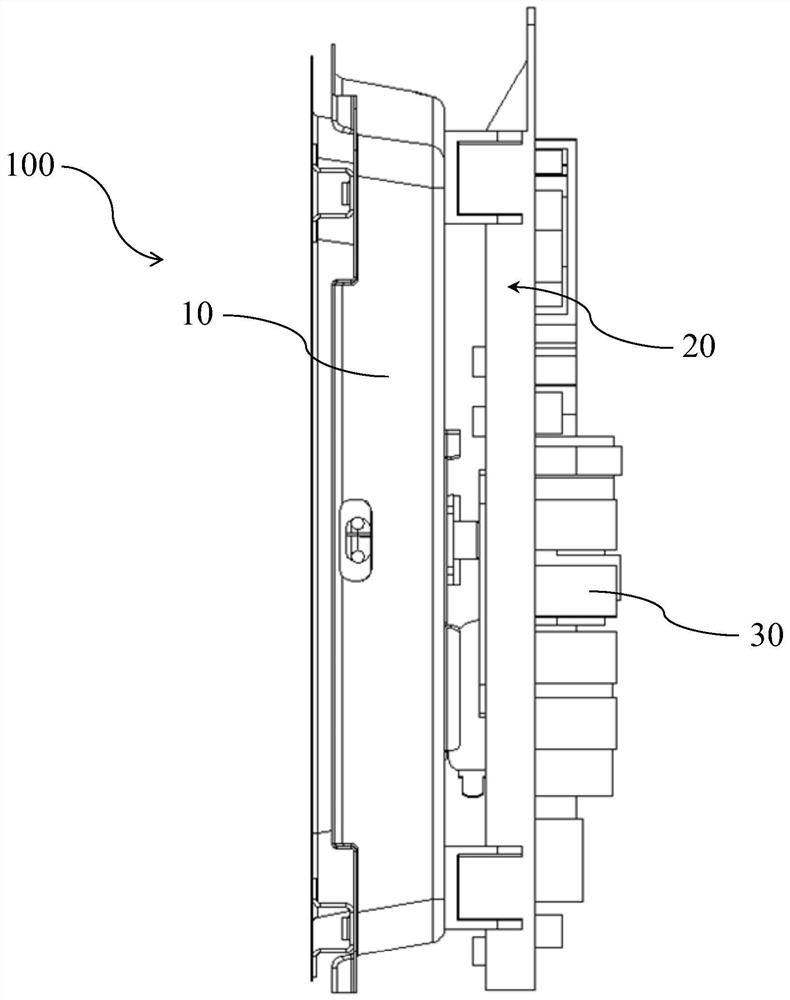

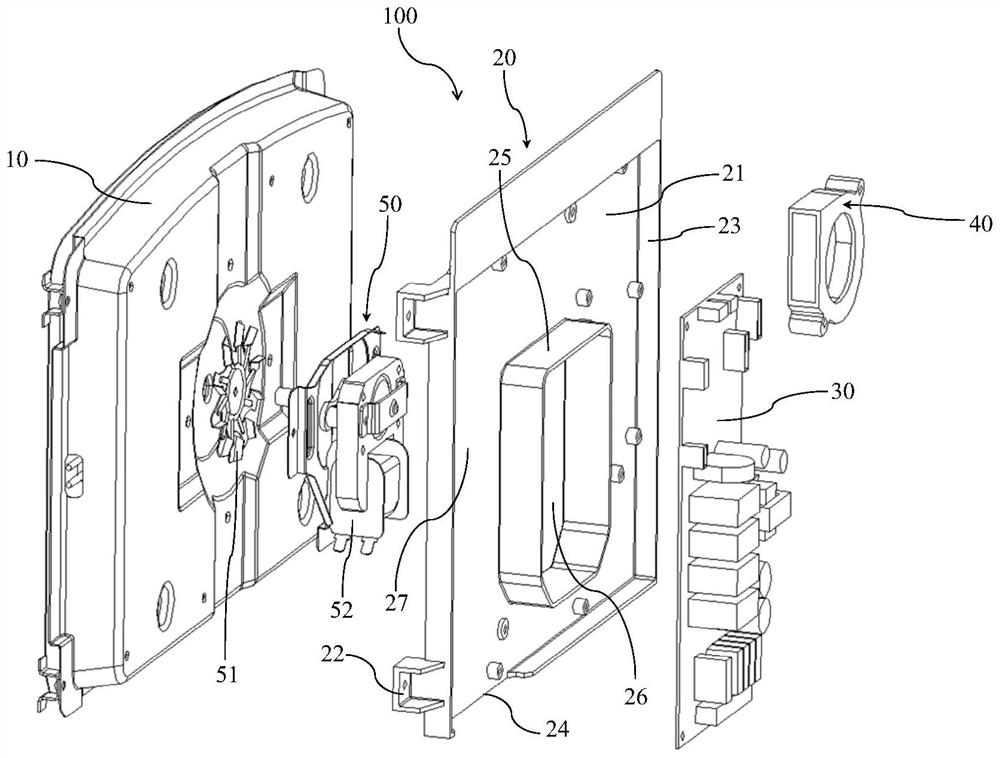

Heat dissipation structure of pcb circuit board and cooking utensil with same

ActiveCN111010856BExtended service lifeReduced heat transfer capabilityRoasters/grillsSupport structure mountingThermodynamicsMechanical engineering

The invention belongs to the field of kitchen appliances, and in particular relates to a heat dissipation structure of a PCB circuit board and a cooking appliance having the same. The heat dissipation structure of the PCB circuit board includes: a base body, the base body is arranged inside the cooking utensil; a mounting plate, the mounting plate includes a board main body and a connecting part, the mounting plate is installed on the base body through the connecting part, and there is a gap between the board main body and the base body Setting: PCB circuit board, the PCB circuit board is arranged on the first side of the board main body, and the first side is the side of the board main body away from the substrate. In the heat dissipation structure of the PCB circuit board of the present invention, the substrate and the main body of the board are separated by air, thereby weakening the heat transfer effect between the substrate and the main body of the board, and there is not only an air isolation layer between the PCB circuit board and the substrate, but also The heat transfer from the substrate to the PCB circuit board is further reduced by the isolation of the mounting board, so as to weaken the influence of the high temperature of the substrate on the PCB circuit board, thereby improving the service life of the PCB circuit board.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Production method of artificial-stone composite board

InactiveCN109138186AGood adhesionAvoid destructionClimate change adaptationHeat proofingThermal insulationArtificial stone

The invention discloses a production method of an artificial-stone composite board. The artificial-stone composite board comprises a wall base layer, wherein the wall base layer is sequentially coatedwith a melamine resin bonding layer, an algal mud active silicate thermal-insulation layer and an acrylic acid waterproof layer from inside to outside. The melamine resin bonding layer which is adopted is good in adhesion so as to allow a thermal-insulation coating to be firm and durable as a whole. The algal mud active silicate thermal-insulation layer allows the heat transfer capacity of the material to reduce or approach the minimum limit, and is a super thermal insulation material. The heat conduction among objects is realized by heat transfer in the prior art, while the algal mud activesilicate thermal-insulation layer reduces the essential heat transfer mode to a minimum so as to satisfy the pursuit by people on thermal insulation performance. The waterproof layer can well preventmoisture from permeating into the thermal insulation layer and can effectively prevent the thermal insulation layer from being destroyed by water.

Owner:高玉涛

Energy-saving type air-cooled hearth roll

InactiveCN105755275AReduce stress concentrationReduce lossFurnace typesHeat treatment furnacesStress concentrationThermal insulation

The invention discloses an energy-saving type air-cooled hearth roll, which includes a roller, roll heads and roll necks. The roll heads are arranged at both ends of the roller; the roll necks are tapered tubular roll necks with small ends facing the roll heads, and fixedly connect the roller and the roll heads. Further improvement lies in that: the hearth roll also includes a casing; the casing runs through the roll heads, the roll necks and the roller axially, and fixedly connects the inner holes of the two end roll heads; the joints of the roller and the roll necks are provided with partition plates; the partition plates are sleeved on the outer wall of the casing, and airtight cavities are formed between the partition plates and the roll heads' ends and the roll necks' inner holes, the cavities are filled with a thermal insulation material to form a thermal insulation structure. tapered tubular roll neck transition connection is adopted between the roller and the roll heads to significantly reduce stress concentration at the joints of the roller and the roller shaft; the casing is disposed for ventilation cooling so as to significantly lower fuel loss, at the same time a water circulation cooling system is canceled, thus reducing equipment investment and simplifying equipment maintenance. The roll necks are internally provided with a thermal insulation structure, thus significantly reducing the capability of heat transfer from the roller to the roll heads, and obviously improving the bearing working condition.

Owner:孙萍

Precooling apparatus of plastic tube product line

Owner:福建祥龙塑胶有限公司

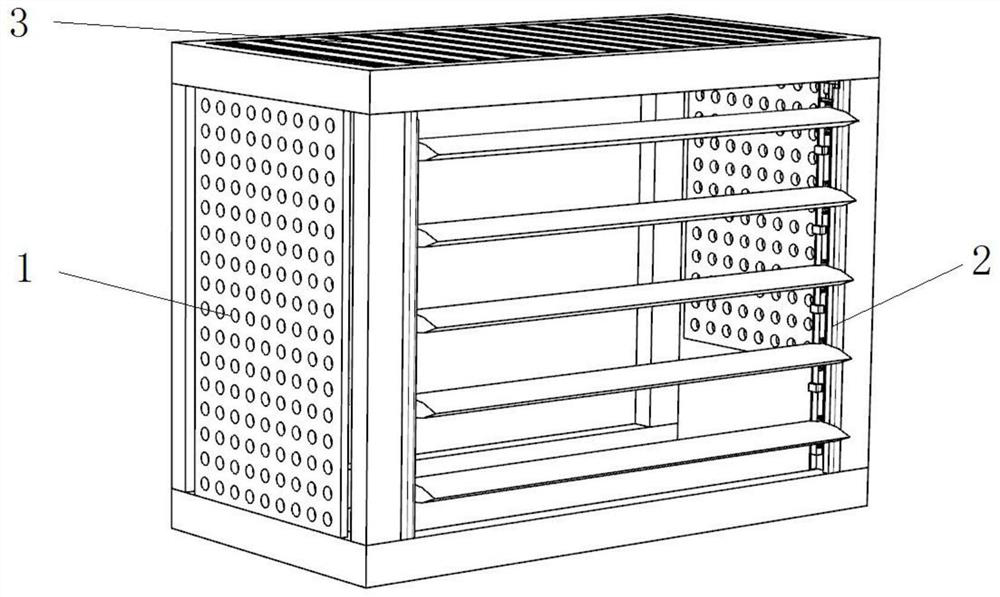

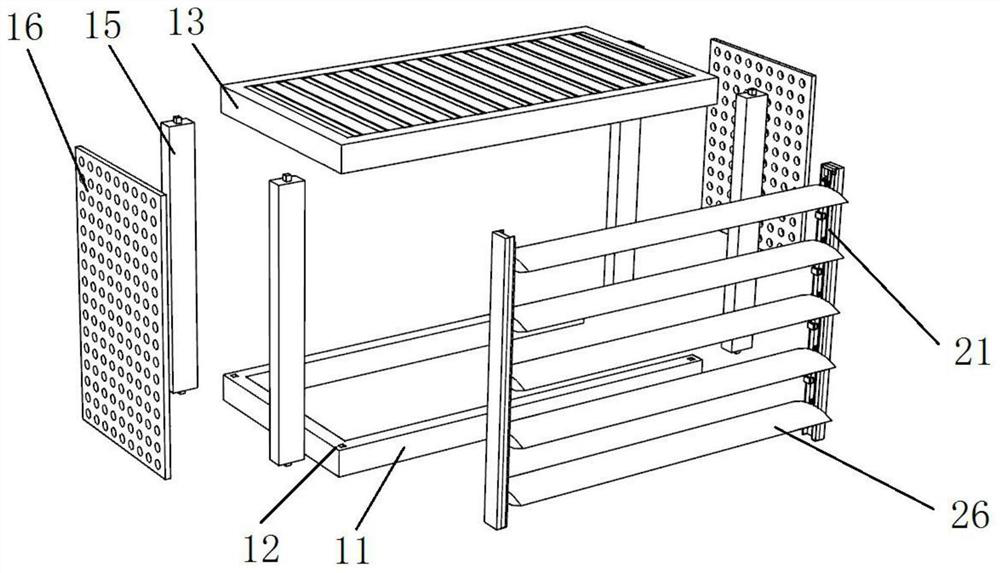

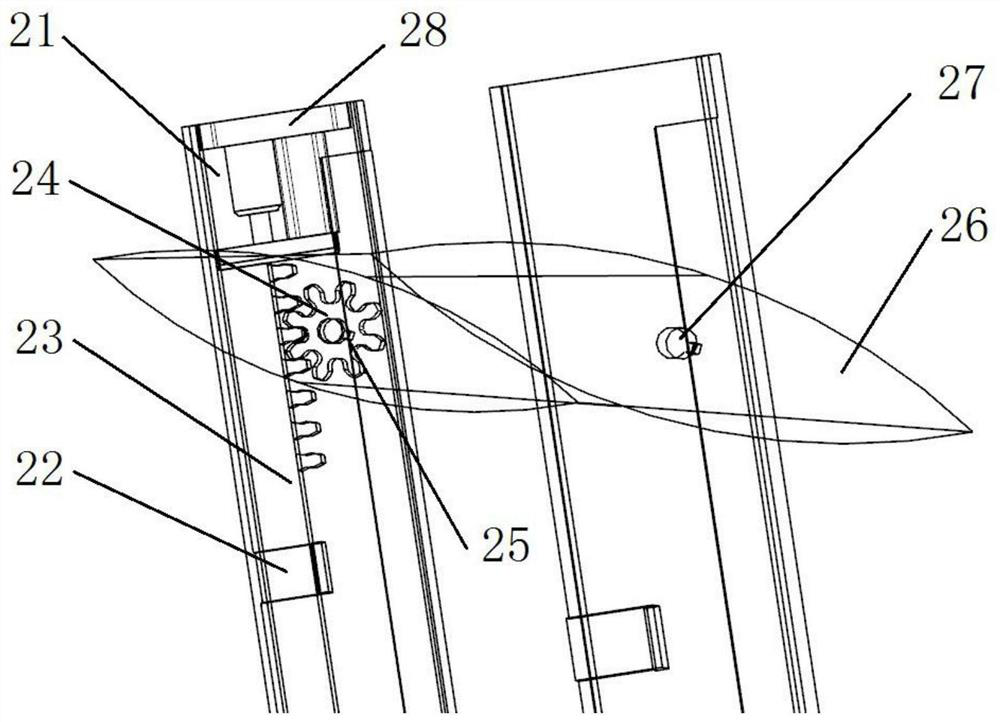

Air conditioner outdoor unit protective cover with electric shutter structure

PendingCN114440329AExtended service lifeGuaranteed heat transfer effectLighting and heating apparatusAir conditioning systemsHeat transmissionEngineering

The invention provides an air conditioner outdoor unit protective cover with an electric shutter structure, which comprises a cover shell, an electric shutter is mounted on the front side of the cover shell, an electric control assembly is mounted at the top of the cover shell, and the electric control assembly controls the opening angle of the electric shutter. When the air conditioner outdoor unit is not used for a long time, the electric blind window rotates to be closed, erosion of the sun, wind, rain and dust is effectively shielded, the air conditioner outdoor unit is protected, and the service life of the air conditioner outdoor unit is prolonged. When the air conditioner outdoor unit works at a high speed, the electric blind window rotates to be completely opened and closed, and the heat transfer effect is ensured when the air conditioner outdoor unit works; when external direct sunlight is serious, the temperature of the air conditioner outdoor unit is too high, and the heat transfer effect of the air conditioner outdoor unit is poor, the electric blind window rotates to 45 degrees to be opened and closed, the air conditioner outdoor unit is prevented from being directly exposed to the sun, the temperature of the air conditioner outdoor unit is effectively reduced, and the heat transfer effect of the air conditioner outdoor unit during working is guaranteed.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com