High-strength high-temperature-resistant furnace bottom roller

A technology of high temperature resistance and hearth roller, which is applied in the direction of furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of deteriorating bearing working conditions and rising bearing temperature, reduce heat transfer capacity, improve high temperature oxidation resistance, and reliable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below based on the drawings and the embodiments.

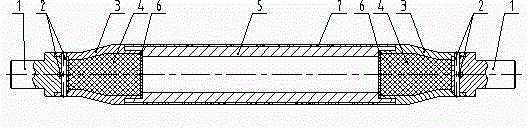

[0015] The high-strength and high-temperature furnace bottom roll shown in the figure includes a roll 5, a roll neck 3, and a roll head 1. The roll head 1 is arranged at both ends of the roll 5, and the roll neck 3 is fixedly connected between the roll 5 and the roll head 1. Between; the roll head 1 is inserted into the end of the roll neck 3 to form a fit and fixed connection; a partition 6 is provided at the junction of the roll 5 and the roll neck 3; between the partition 6, the end of the roll head 1 and the inner hole of the roll neck 3 A closed cavity is formed, and the cavity is filled with heat insulating material 4 to form a heat insulating structure.

[0016] There are two positioning pin shafts 2 radially penetrating the matching parts of the roll head 1 and the roll neck 3 at the matching parts of the roll head 1 and the roll neck 3, and one positioning pin 2 partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com