Patents

Literature

33results about How to "Improve resistance to high temperature oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-base superalloy complex gradient coating and preparation technique thereof

InactiveCN101310971ADoes not bring strippingImprove scoreLayered productsVacuum evaporation coatingSuperalloyDepth direction

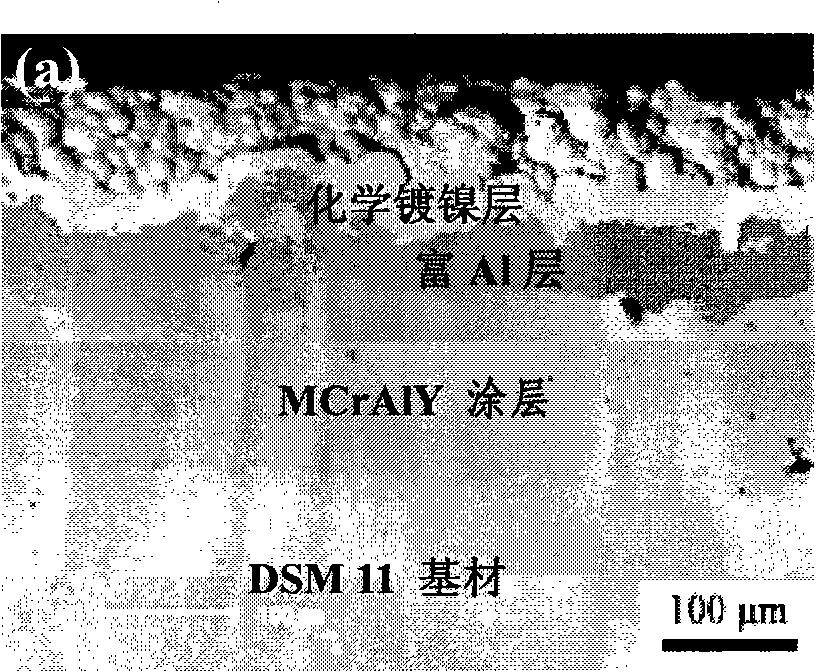

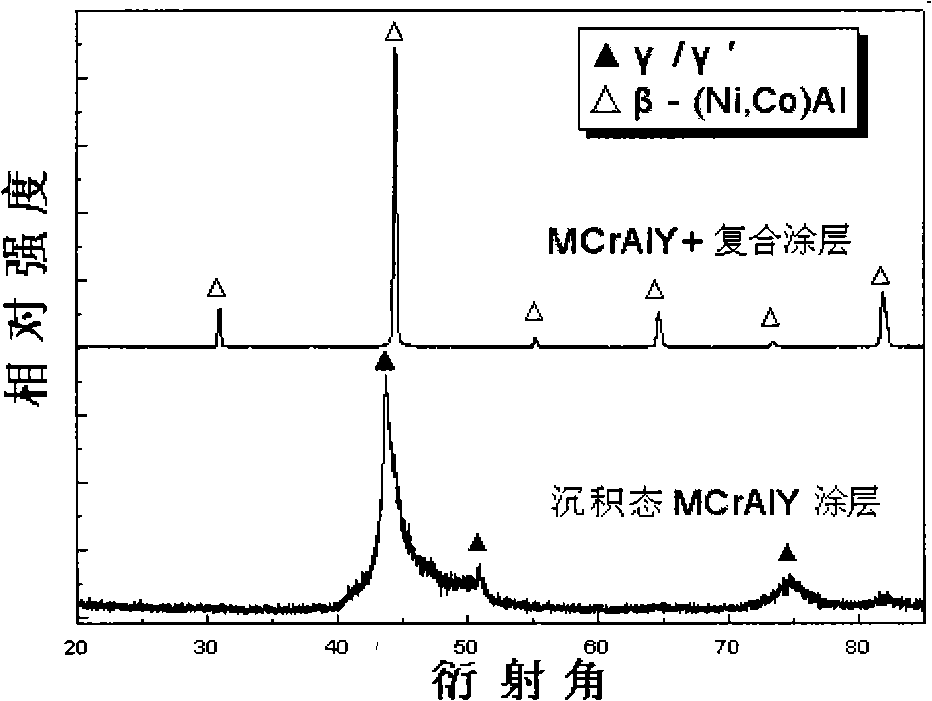

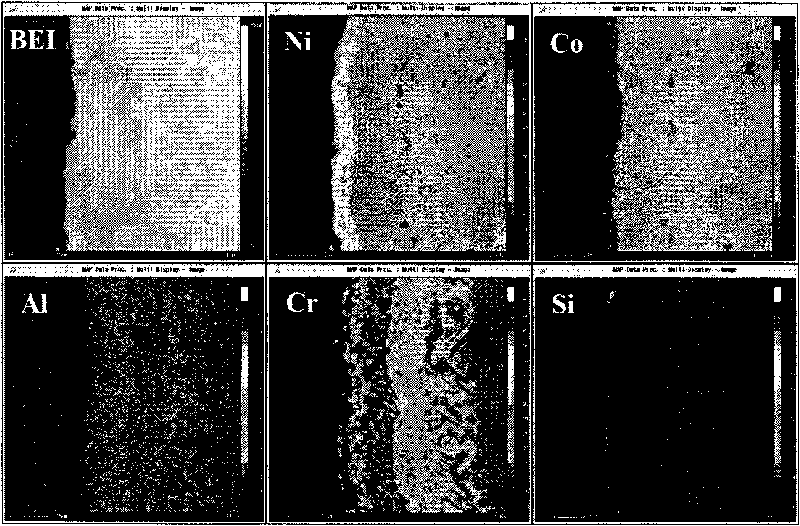

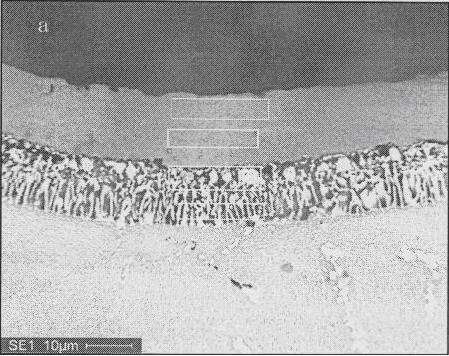

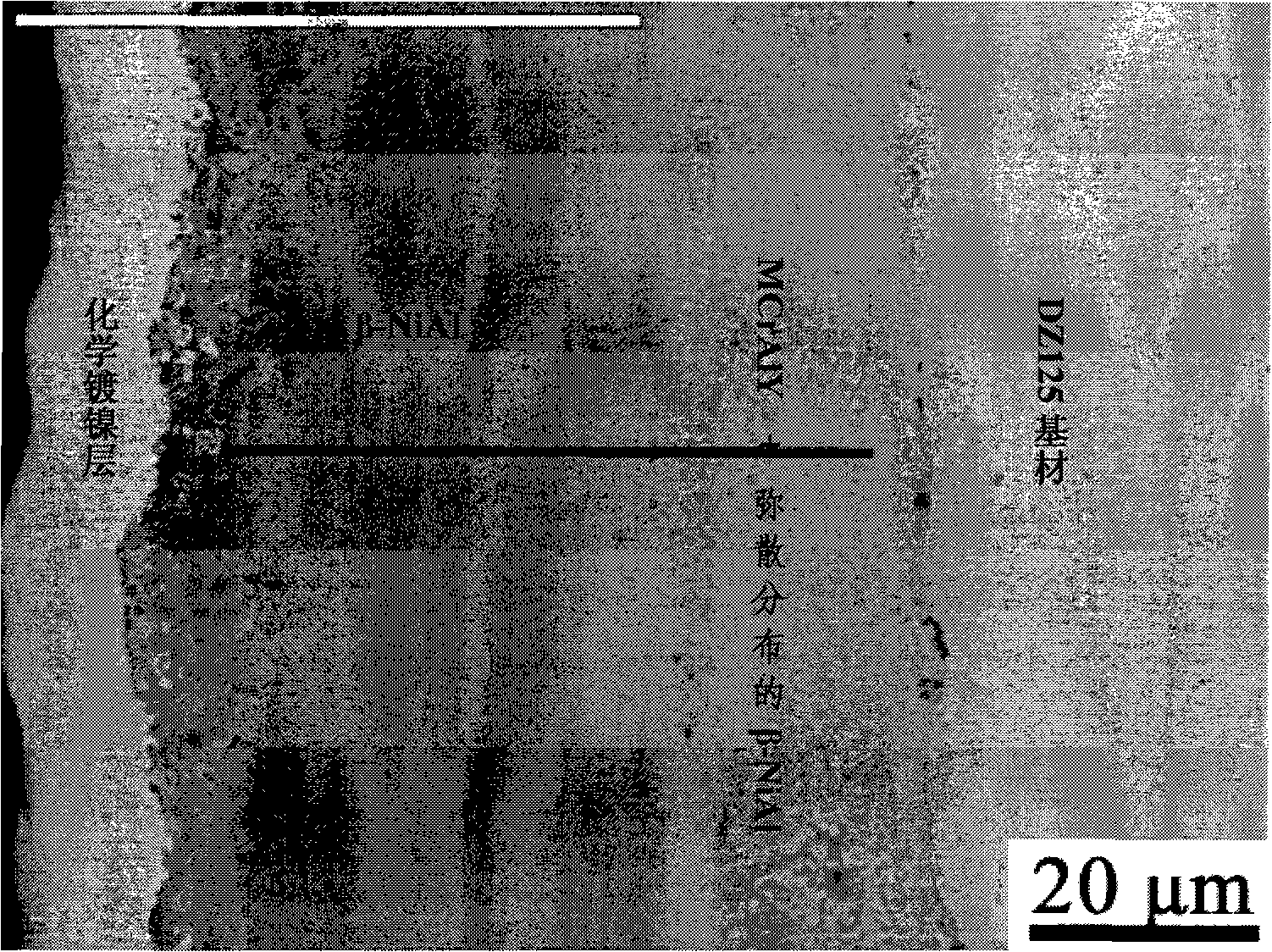

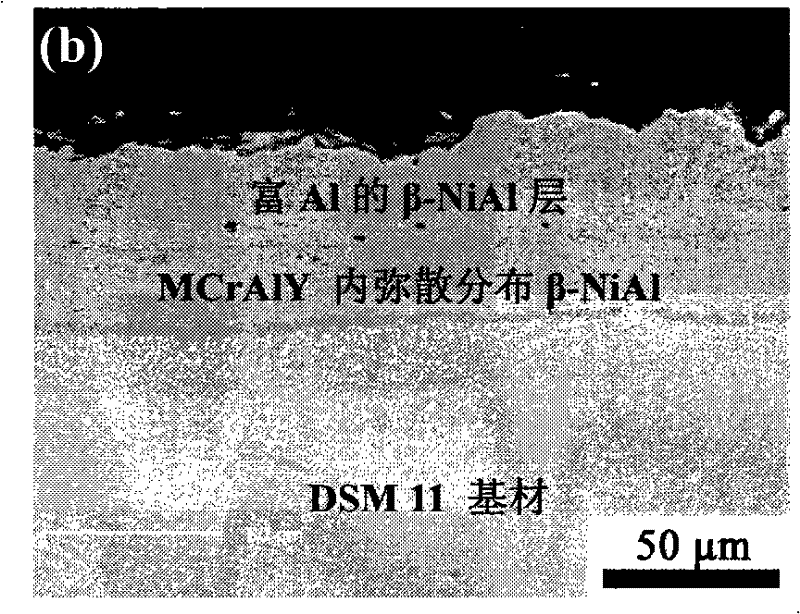

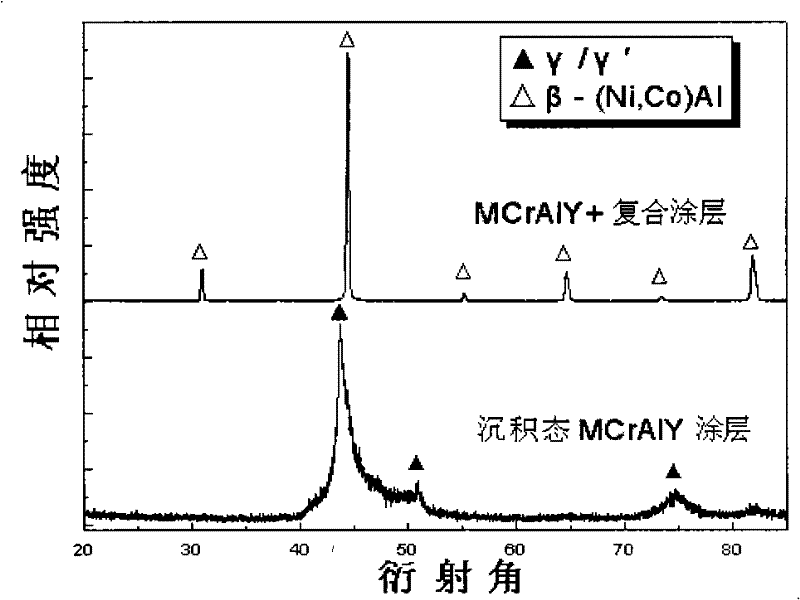

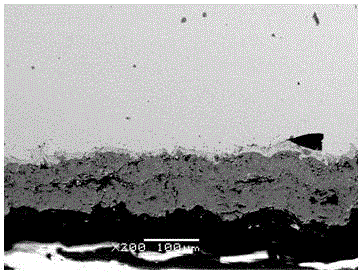

The invention mainly relates to the coating technique, in particular to a gradient MCrAlY coating used for protecting high-temperature alloy and a preparation method thereof. The invention prepares an MCrAlY composite gradient coating by adopting the method combining the arc ion plating (AIP) and the diffusion aluminizing. The thickness of an aluminum-rich layer on the surface of the MCrAlY composite coating can be controlled by setting the aluminizing temperature and the period of heat preservation and the Al elements are distributed in a gradient way along the depth direction; in addition, the chemical vapor deposition method used for the aluminizing has the advantages of good uniformity on the aluminum-rich layer and being not affected by the size and shape of a sample. Since the method of direct diffusion is adopted without introducing a weak interface, the MCrAlY high-temperature protective coating can increase the content of Al memory phase to the utmost extent under the condition that the mechanical property of the coating is guaranteed, so as to improve the high-temperature oxidization resistance and the heat corrosion resistance of the coating, and can effectively prolong the service life of the coating. The MCrAlY composite gradient coating and the preparation method of the invention can be applied to the protection of Ni-based and Co-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

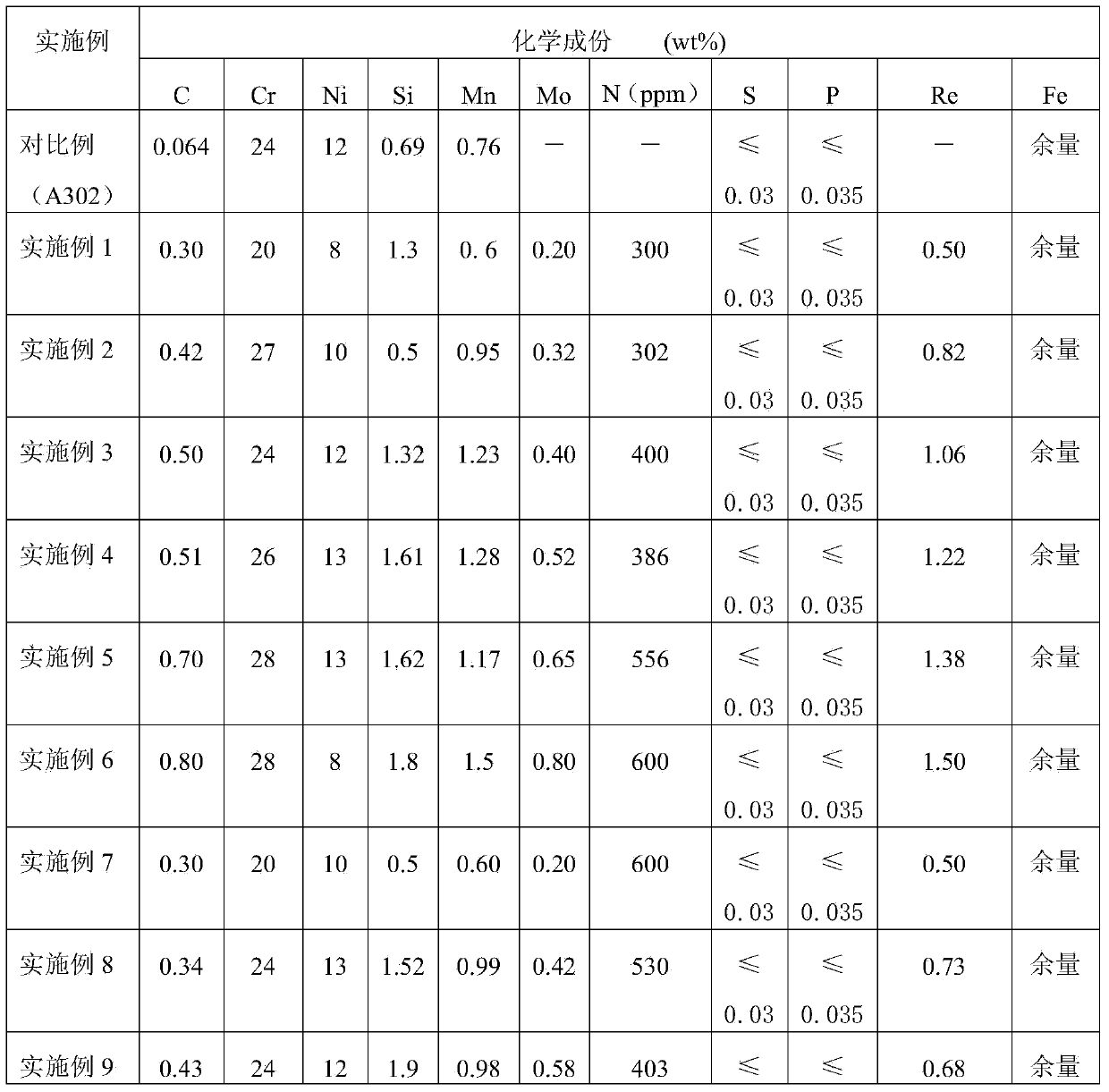

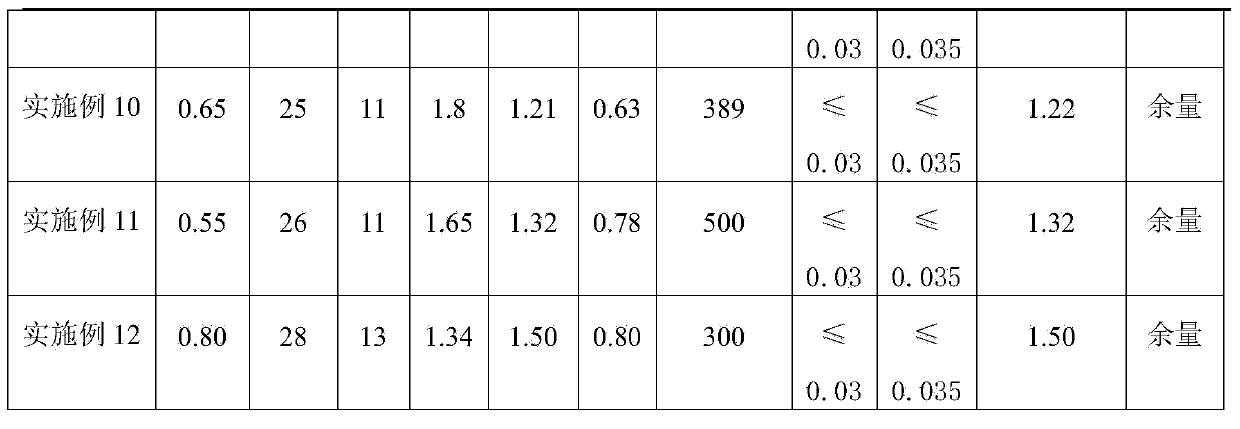

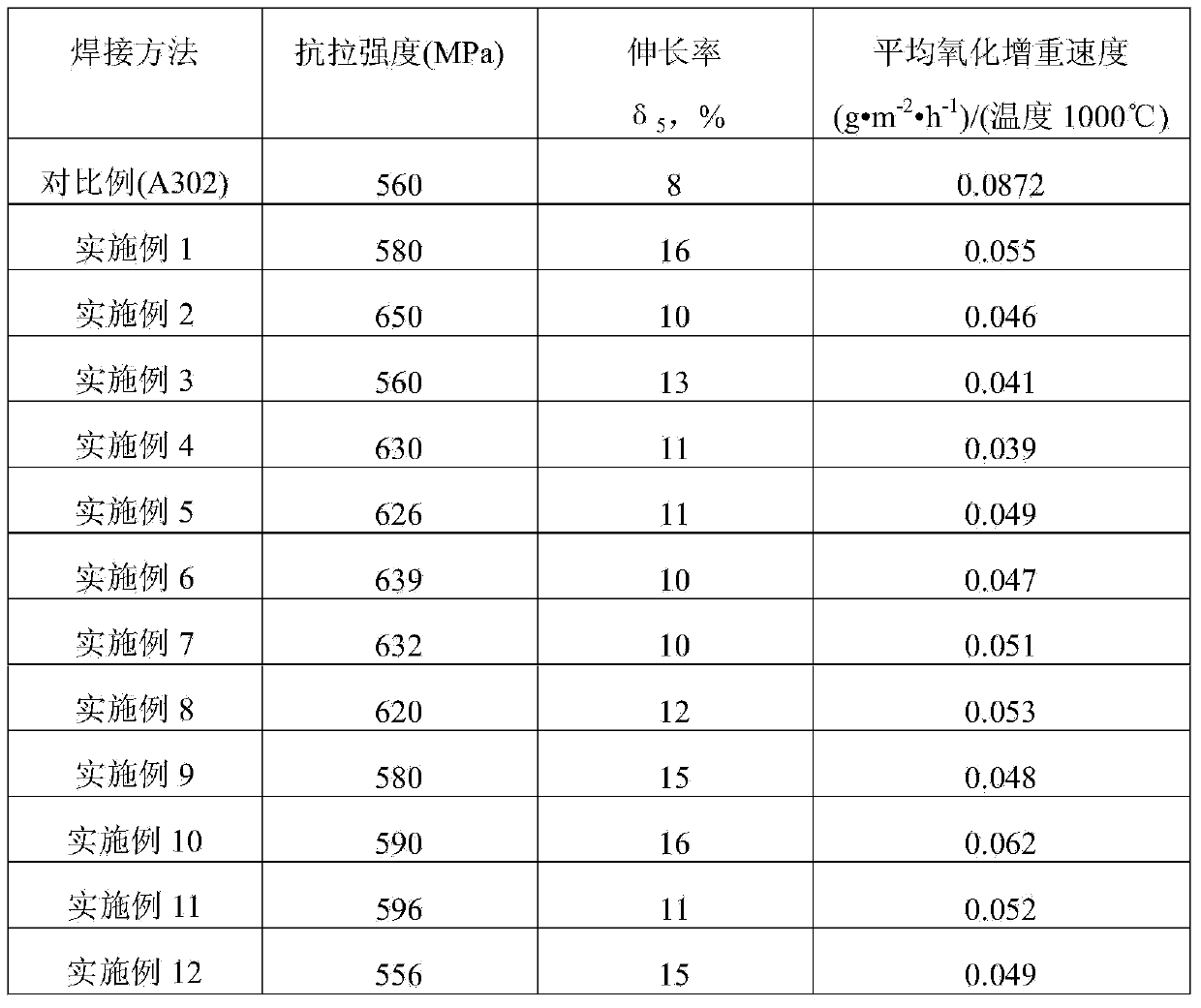

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

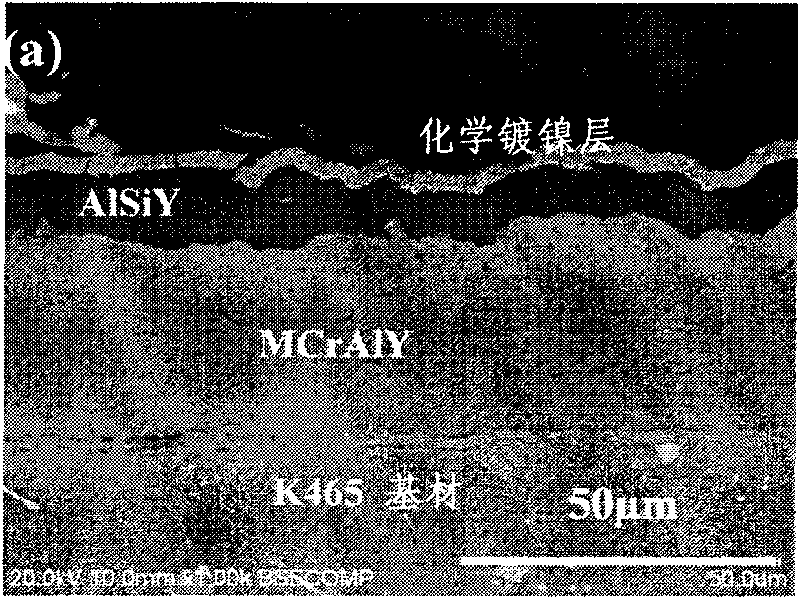

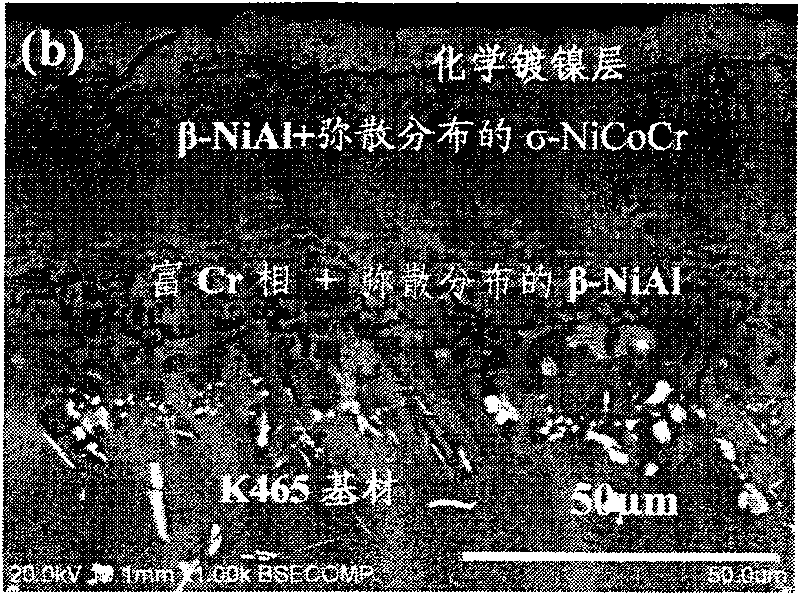

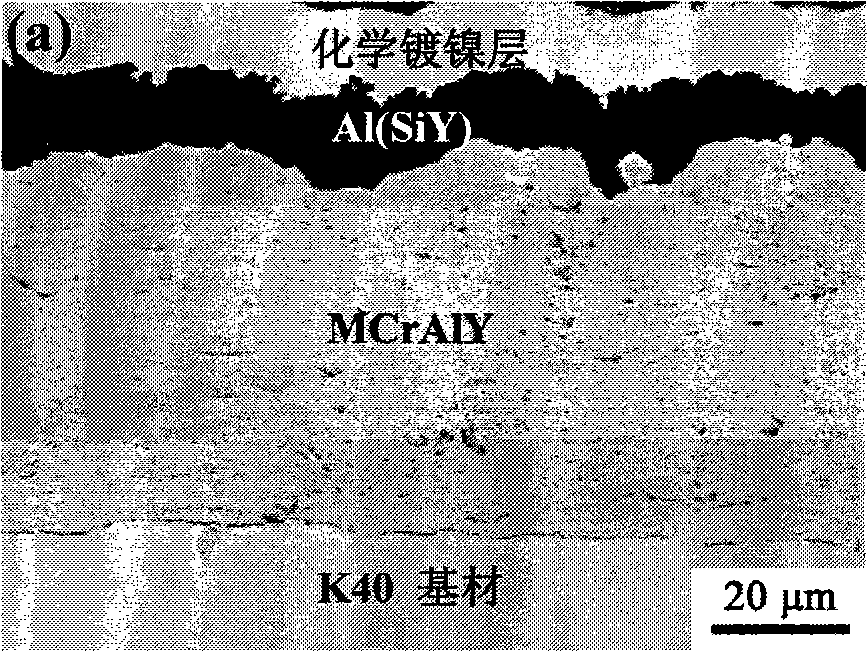

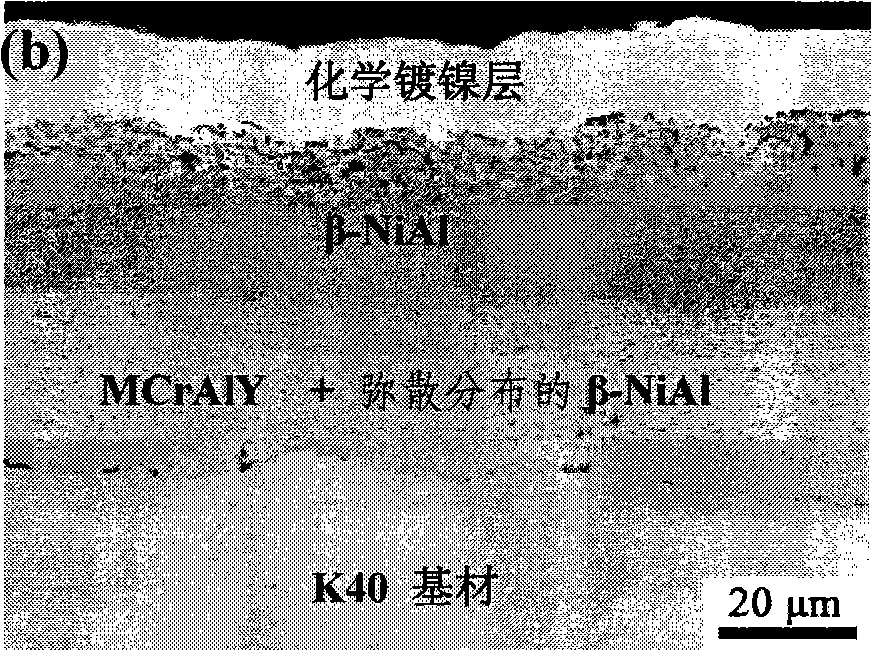

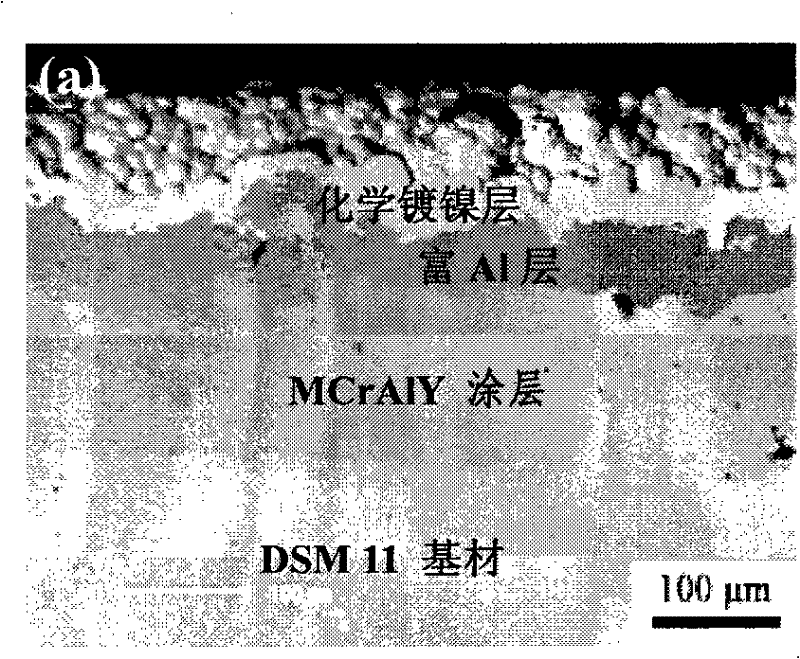

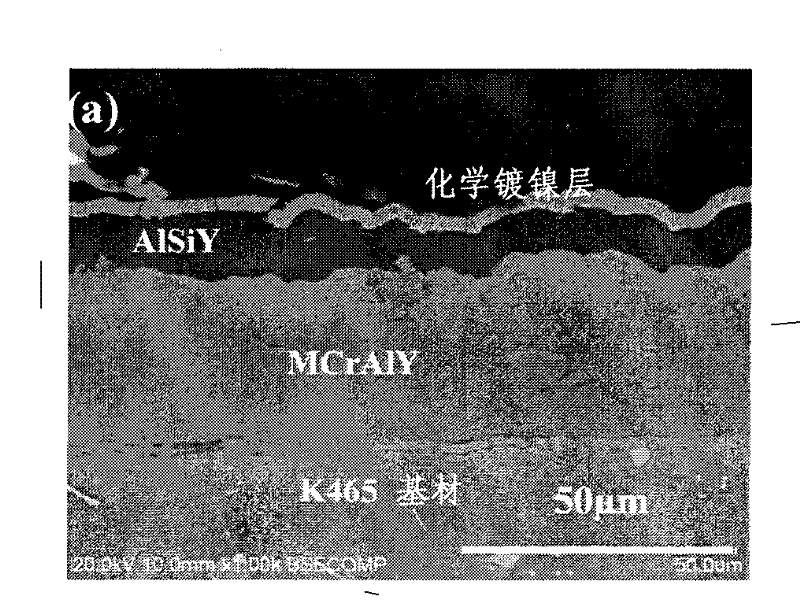

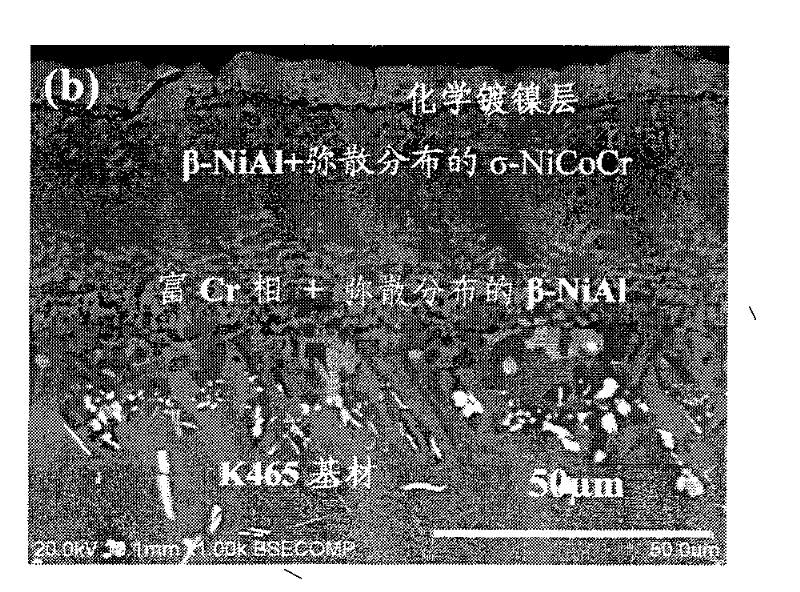

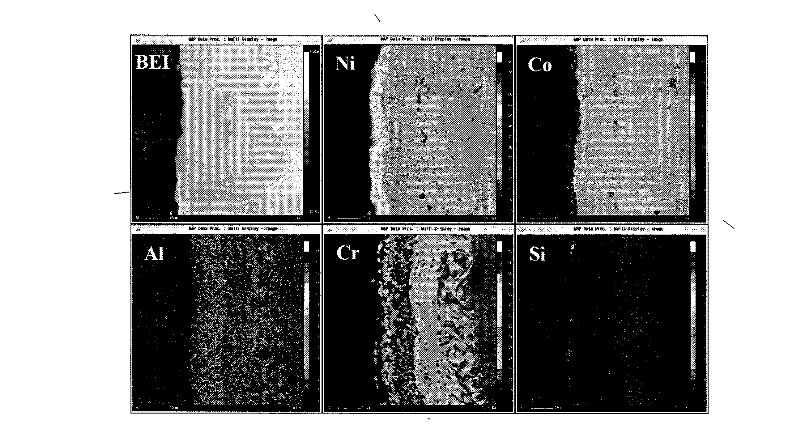

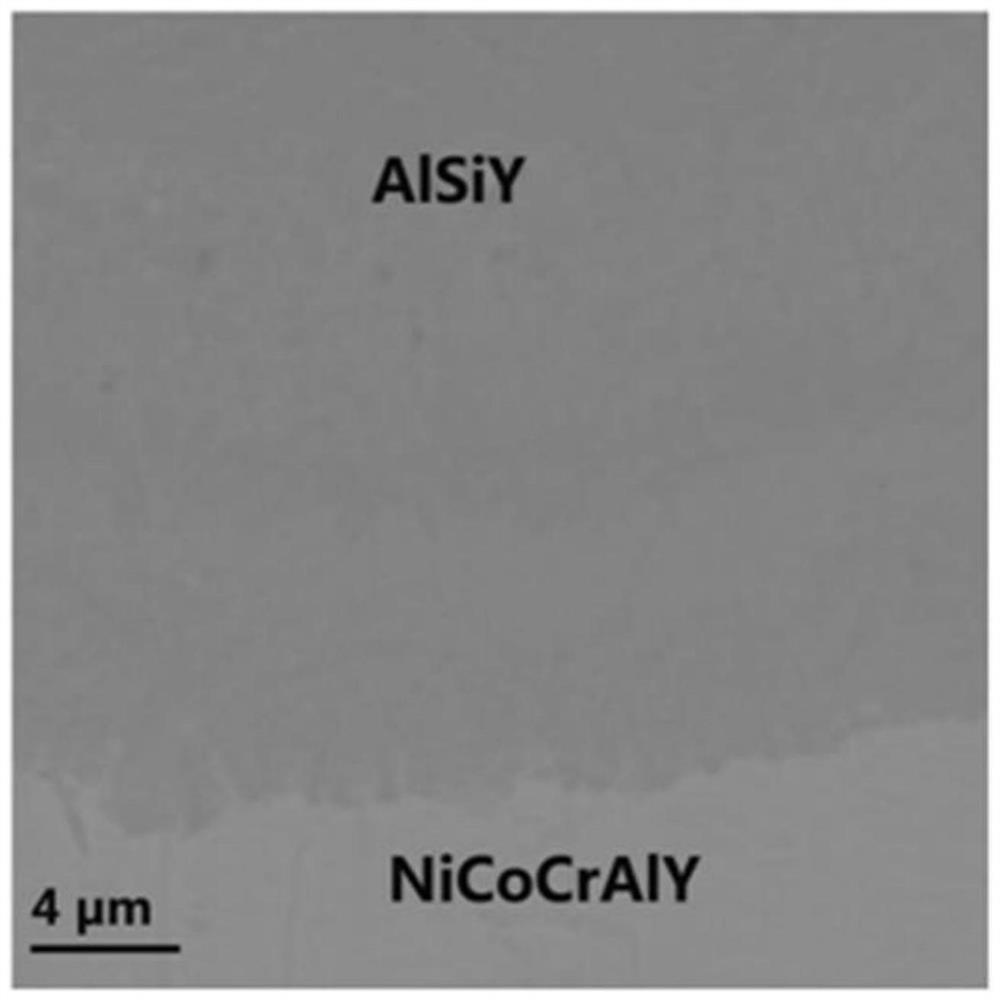

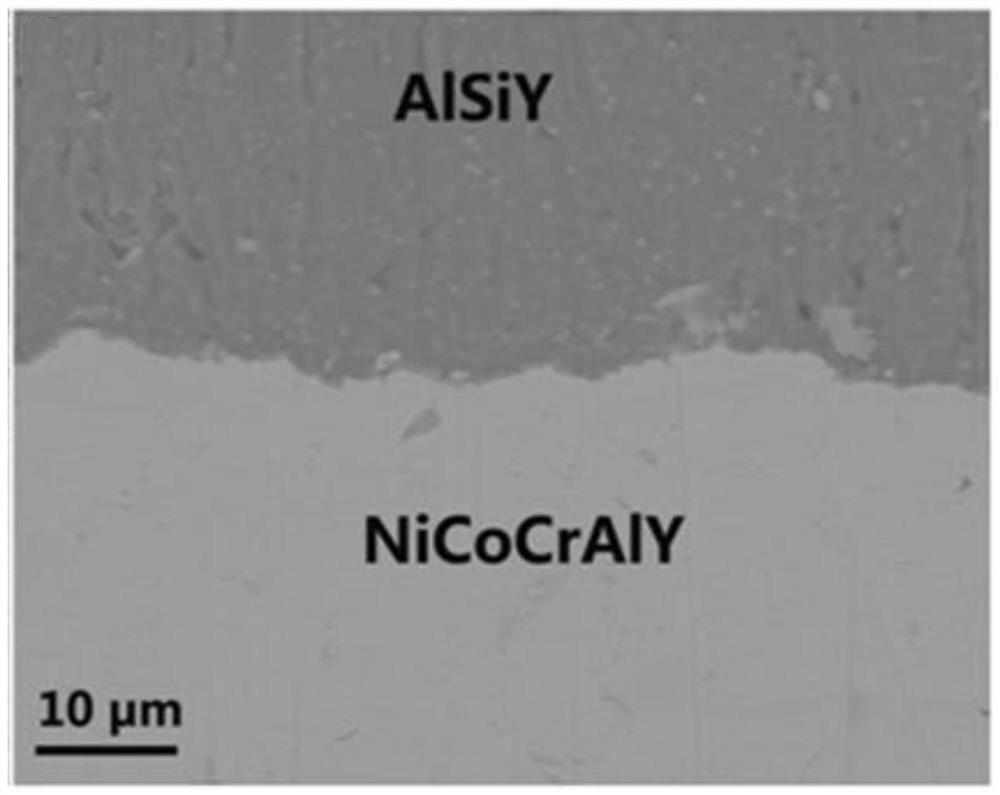

MCrAlY+AlSiY composite coating and preparation technique thereof

InactiveCN101724301AExtended service lifeIncrease contentFireproof paintsVacuum evaporation coatingSurface layerSuperalloy

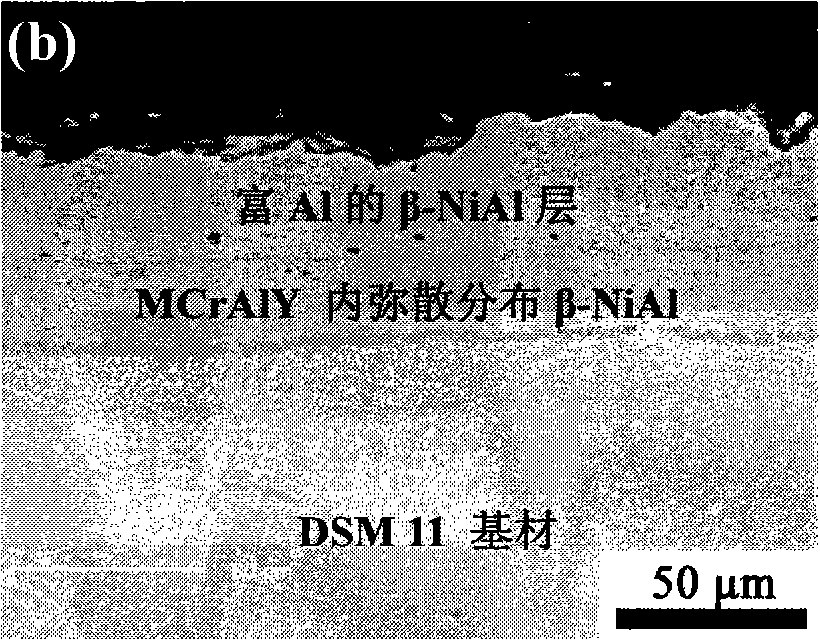

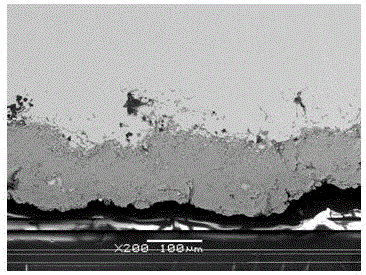

The invention relates to high-temperature protective coating technology, in particular to an MCrAlY+AlSiY composite coating and a preparation technique thereof. A MCrAlY composite coating, which is rich in Al on an outer layer and rich in Cr on an inner layer and is distributed in a gradient form, is formed by depositing an AlSiY coating on a MCrAlY coating and by using a vacuum diffusion annealing method. The concentration of Al elements on the surface layer of the composite coating is 18 to 22 weight percent, and the concentration of Cr elements on the inner layer is 28 to 45 weight percent. The MCrAlY composite coating, which is rich in Al on the outer layer and rich in Cr on the inner layer and is distributed in a gradient form, is prepared by combination of arc ion plating deposition and the vacuum diffusion annealing. Compared with the existing conventional MCrAlY high-temperature protective coating, the MCrAlY+AlSiY composite coating of the invention effectively improves an A1 storage phase content and Si content in the surface layer of the coating; and the layer rich in Cr is formed on the inner layer of the coating, so the high temperature oxidation resistance and hot-corrosion resistance of the coating are improved, and the service life of the coating can be effectively prolonged. The composite coating and a preparation method thereof are suitable for protecting Ni-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing hollow blade inner chamber diffusion layer with high temperature resistance, oxidation resistance and corrosion resistance

ActiveCN102485934AImprove resistance to high temperature oxidationAccelerated corrosionBlade accessoriesSolid state diffusion coatingOsmolyteNichrome

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Nano composite ceramic coating, pressure casting die and preparation method of pressure casting die

ActiveCN106929849AReduce internal stressHigh hardnessFoundry mouldsFoundry coresComposite ceramicPressure casting

The invention provides a nano composite ceramic coating, a pressure casting die and a preparation method of the pressure casting die and belongs to the technical field of preparation of coatings and pressure casting dies. The problems that existing pressure casting dies are poor in property and short in service life are solved. The nano composite ceramic coating comprises a Cr metal bonding layer, a CrN transition layer arranged on the Cr bonding layer, a supporting layer arranged on the CrN transition layer and a function layer arranged on the supporting layer. The supporting layer is a nano periodical TiSiN-CrAlN structural coating of a gradient structure, and the function layer is a nano composite TiCrAlSiN structural coating. The invention further provides the pressure casting die prepared with the composite ceramic coating and further provides the preparation method of the pressure casting die. The nano composite ceramic coating has the bonding force exceeding 70 N, the internal stress being smaller than 0.15 Gpa and the hardness being higher than 35 GPa, and the service life of the pressure casting die is three times or above longer than that of common pressure casting dies.

Owner:吉林省力科科技有限公司 +1

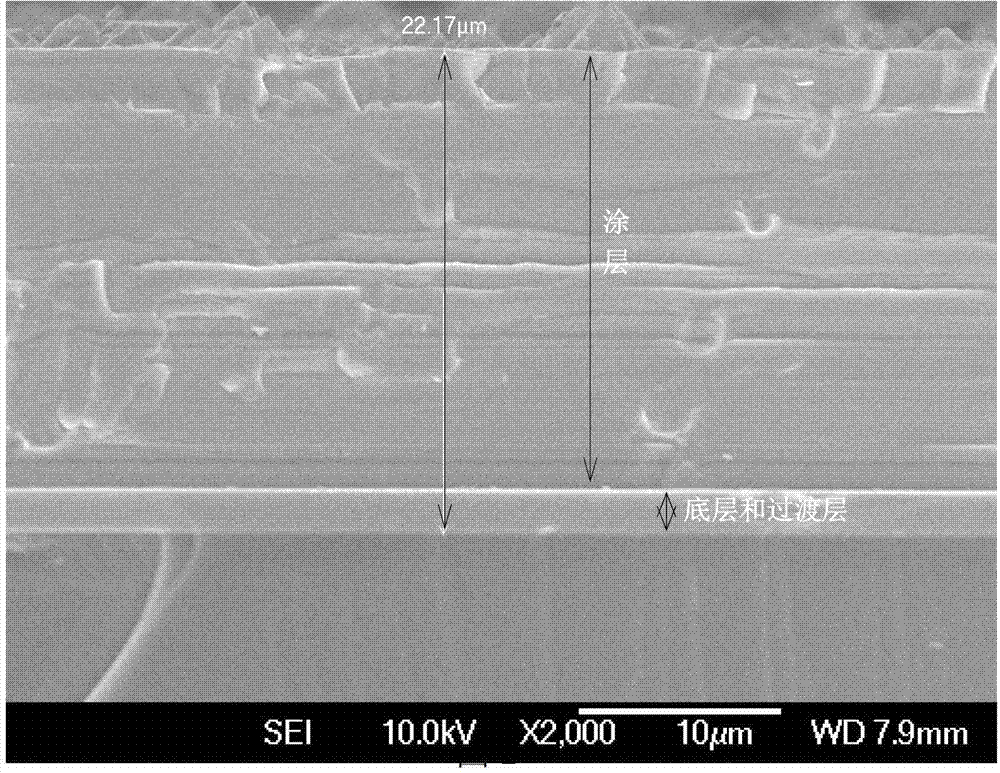

Super-thick super-hard coating and preparation method thereof

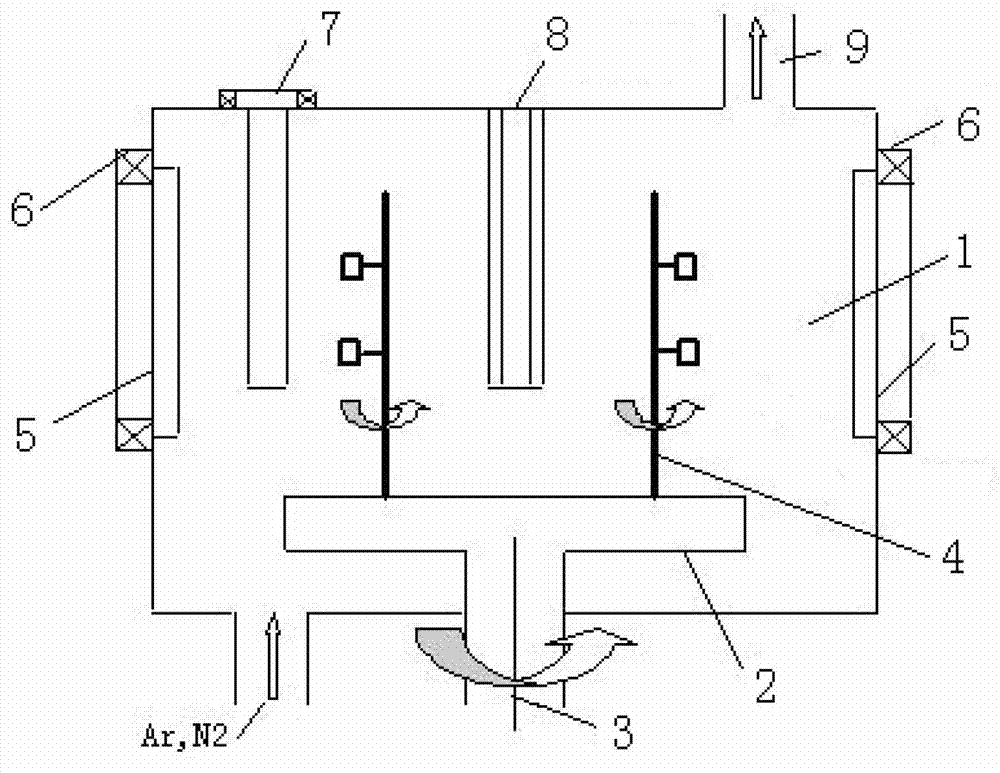

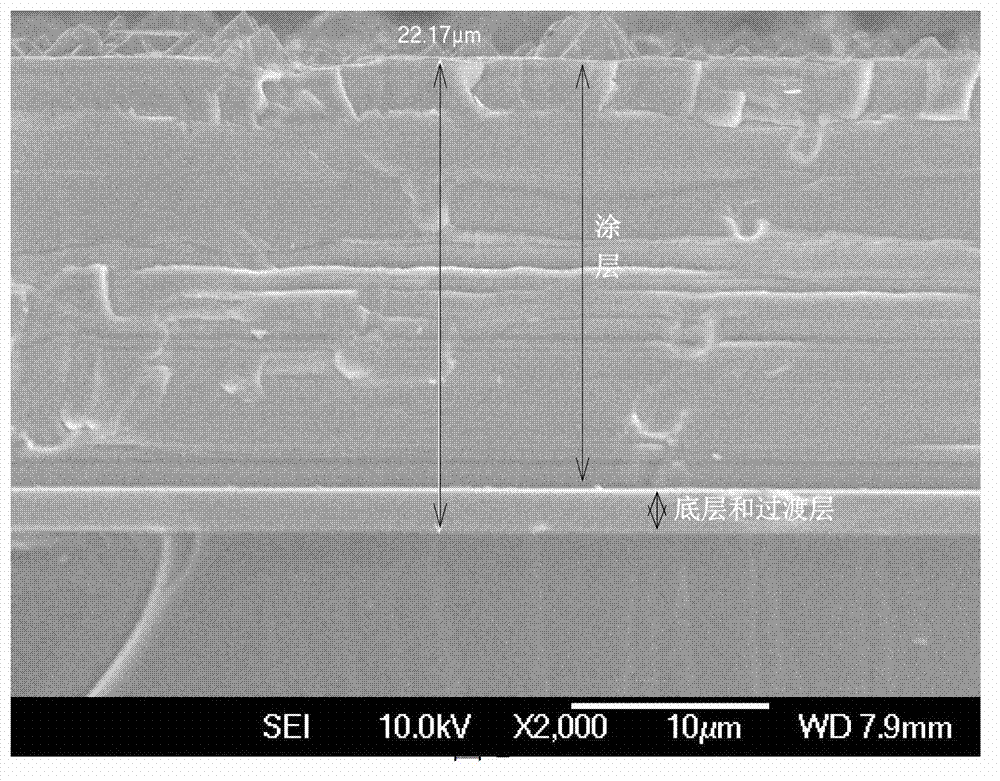

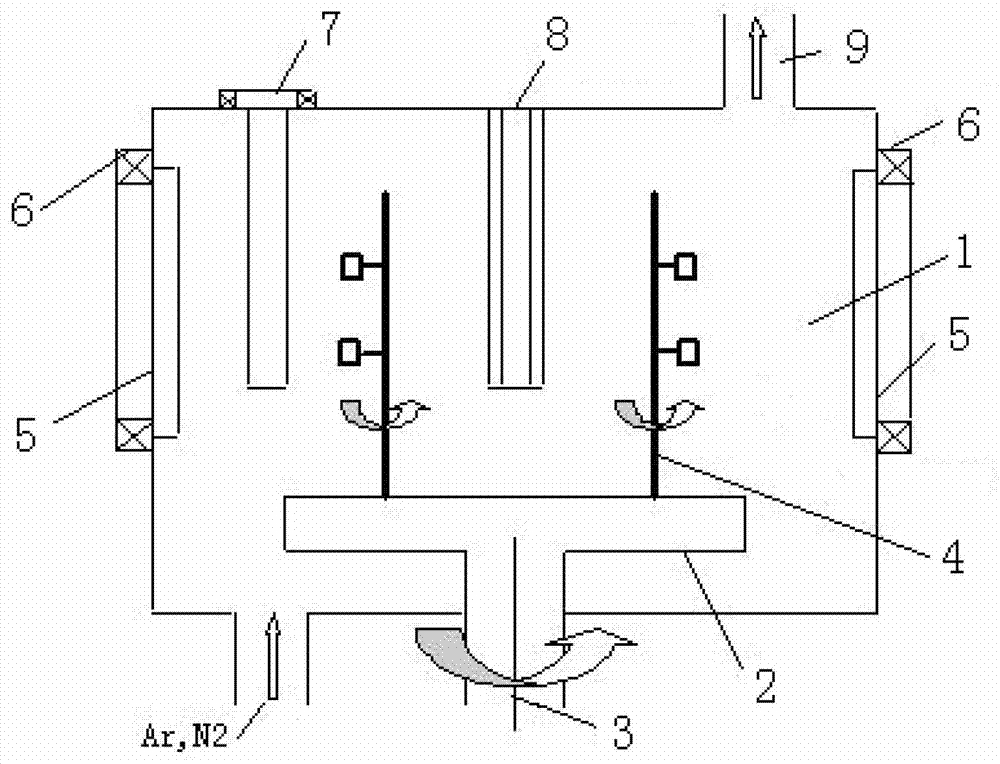

InactiveCN102756514AIncreasing the thicknessImprove bindingVacuum evaporation coatingSputtering coatingIonizationAs element

The invention provides a super-thick super-hard coating and a preparation method thereof. The super-thick super-hard coating comprises a Ti bottom layer deposited on the surface of a basal body, a TiN transitional layer prepared on the Ti bottom layer, and a TiAlSiCN coating prepared on the TiN transitional layer; and the thickness of the super-thick super-hard coating is larger than or equal to 20 microns. During preparation, a columnar electric arc Ti target serves as a Ti source; a planar magnetron sputtering Si target, a planar magnetron sputtering Al target and a planar magnetron sputtering target serve as sources of Si, Al and C correspondingly; Ar serves as an ionization gas; and N2 serves as a reaction gas. According to the invention, the binding force of the basal body to a TiAlSiCN coating as well as the thickness of the TiAlSiCN coating prepared on the basal body is remarkably improved; and as elements such as Si, C and Al are added into the TiN coating, the TiAlSiCN coating with five elements is obtained, and the hardness, the abrasion resistance, the anti-friction quality, the high-temperature oxidization resistance and the corrosion resistance of the coating are further improved.

Owner:XI AN JIAOTONG UNIV

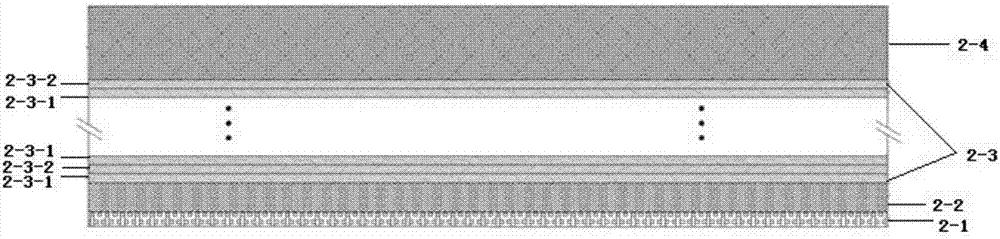

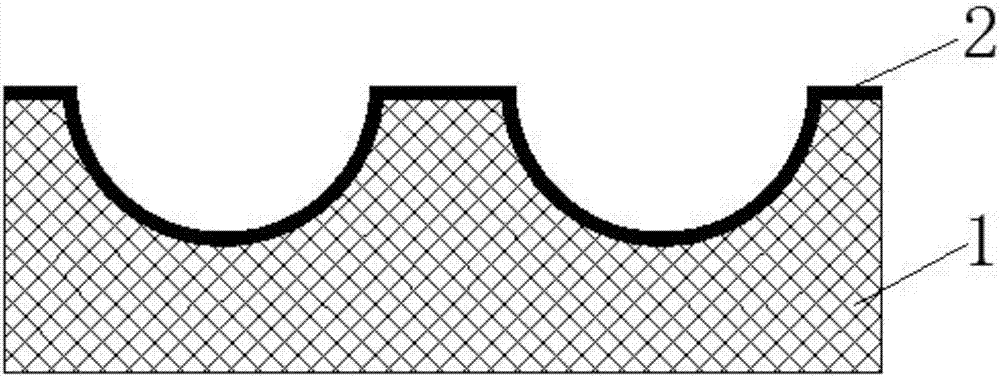

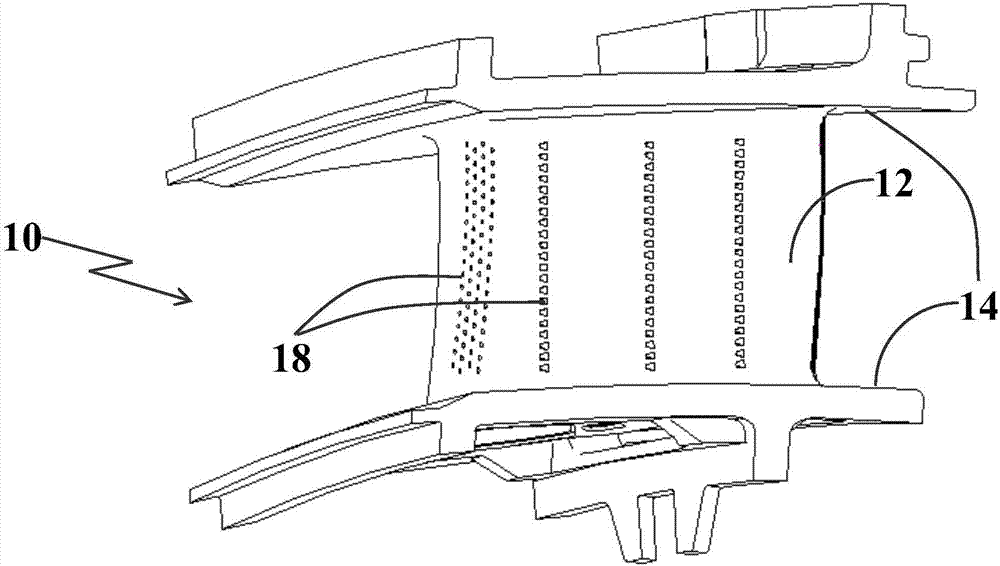

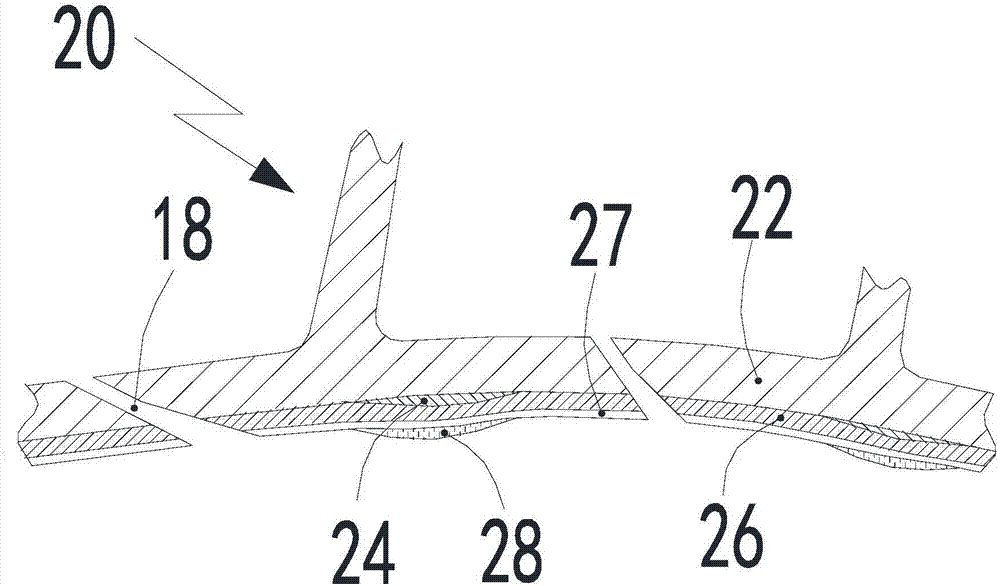

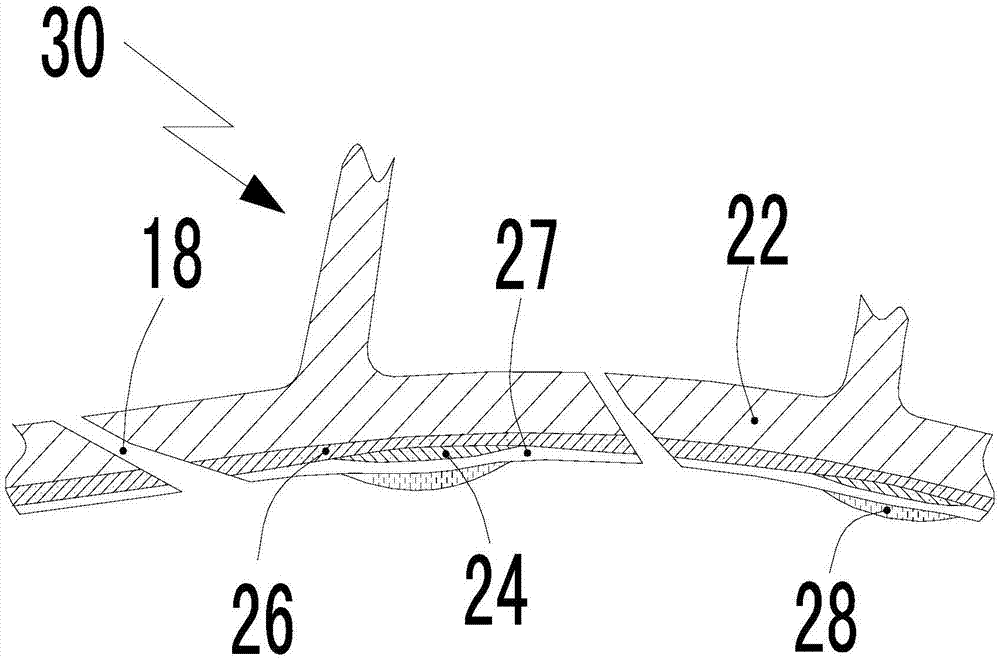

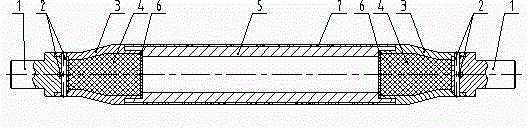

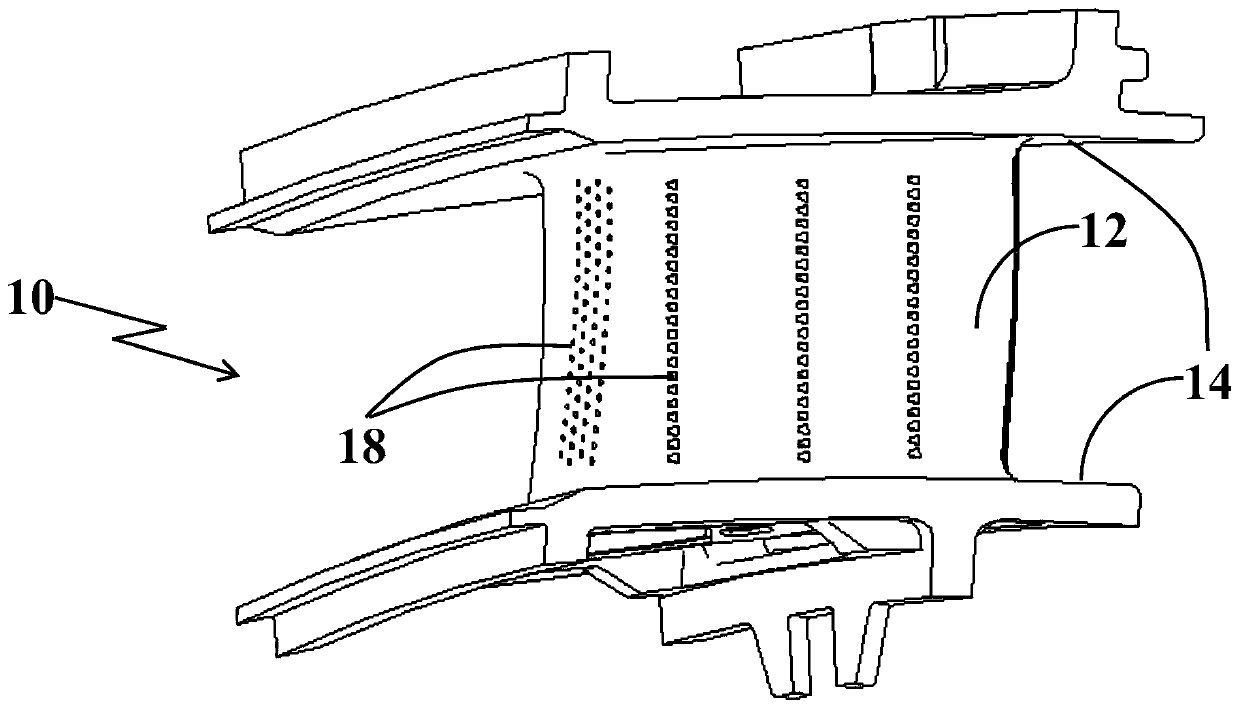

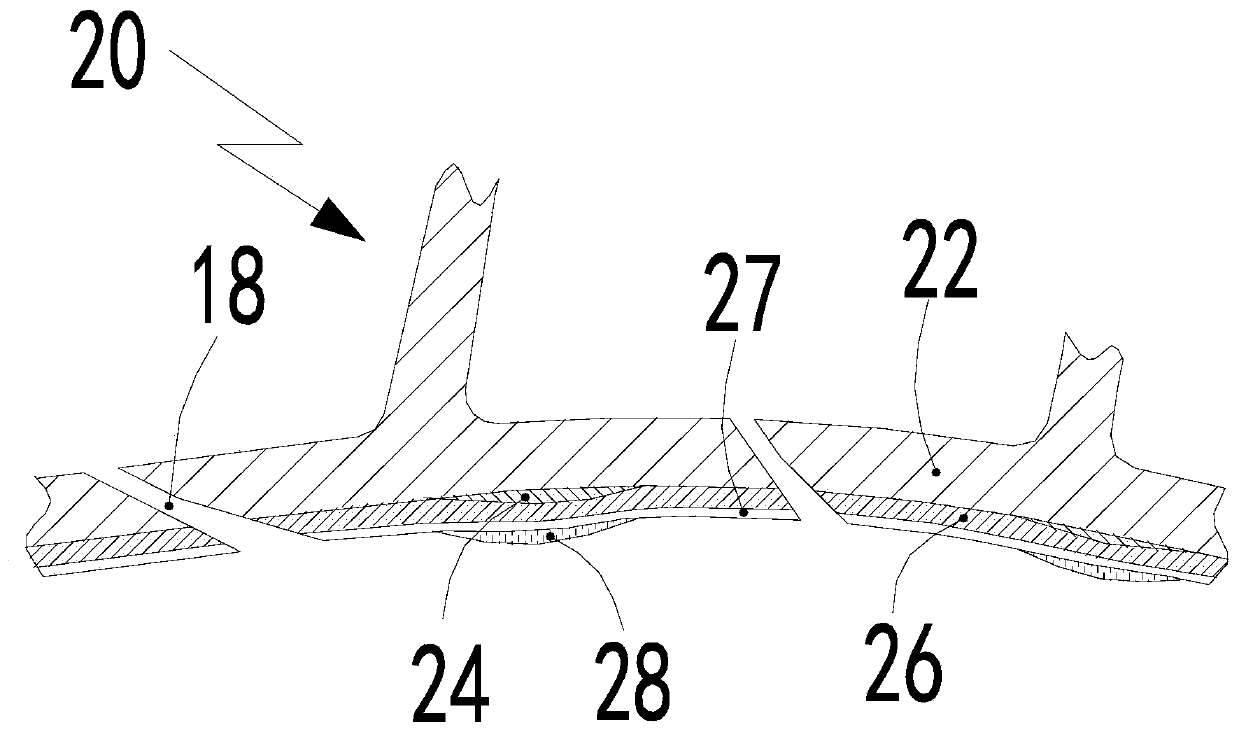

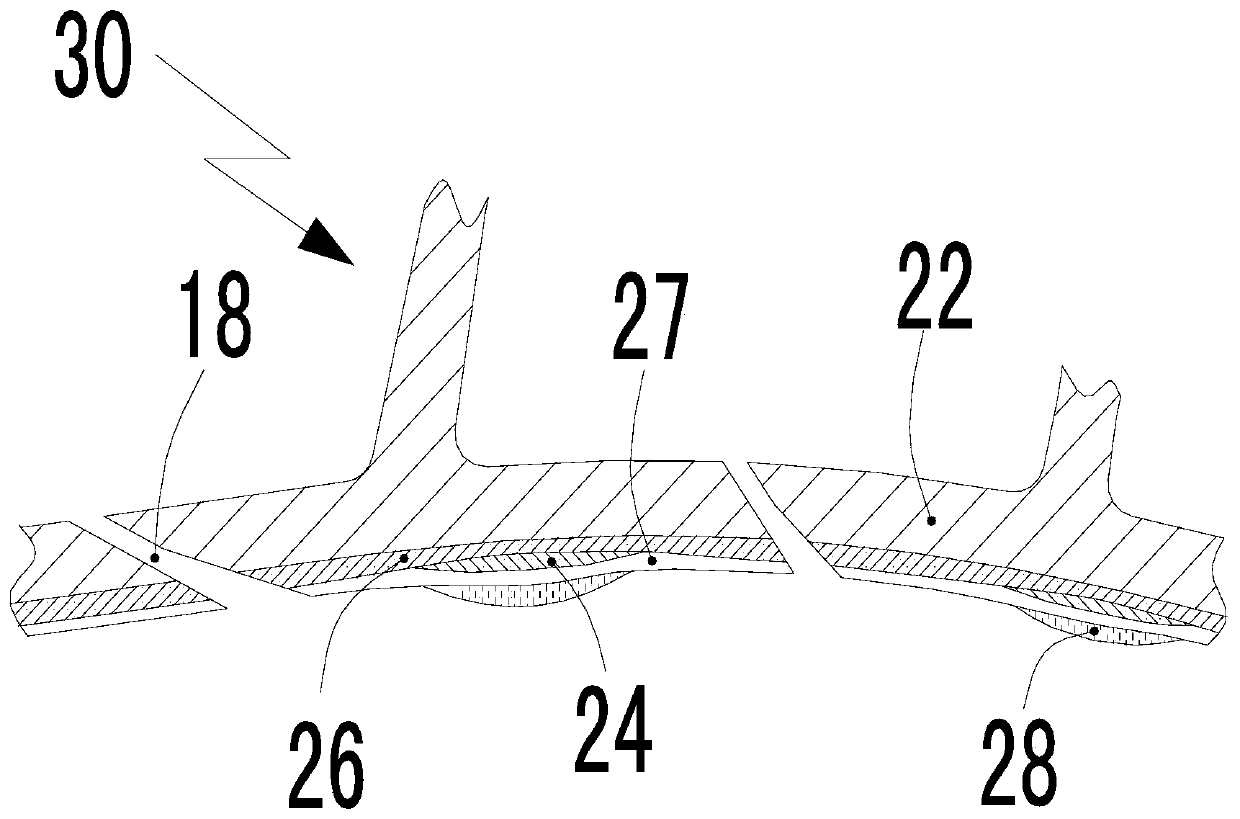

Turbine blade assembly thermal barrier coating and preparation method thereof

ActiveCN107345299AImprove resistance to high temperature oxidationExtend service lifeEfficient propulsion technologiesSuperimposed coating processAluminideCorrosion

The invention provides a turbine blade assembly thermal barrier coating. The turbine blade assembly thermal barrier coating comprises a bonding layer, an aluminide layer, an aluminum oxide layer and a ceramic layer which are sequentially arranged in an upward mode from a turbine blade assembly base material or comprises an aluminide layer, a bonding layer, an aluminum oxide layer and a ceramic layer which are sequentially arranged. The bonding layer is a MCrAlY layer, and M represents one or two or three sorts of nickel, cobalt and iron. According to the thermal barrier coating system provided by the invention, the high-temperature oxidation resistance, thermal corrosion resistance and endurance property of the thermal barrier coating are improved on the premise that the thermal barrier effect of the thermal barrier coating is guaranteed, and thus the service life of a turbine blade assembly is prolonged. By means of the thermal barrier coating system prepared through the method, the weight of the blade assembly can be lowered obviously, and therefore the creep degree of the assembly by tension of the turbine blade assembly in the high-speed rotating process is decreased and the service life of the turbine blade assembly is prolonged.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

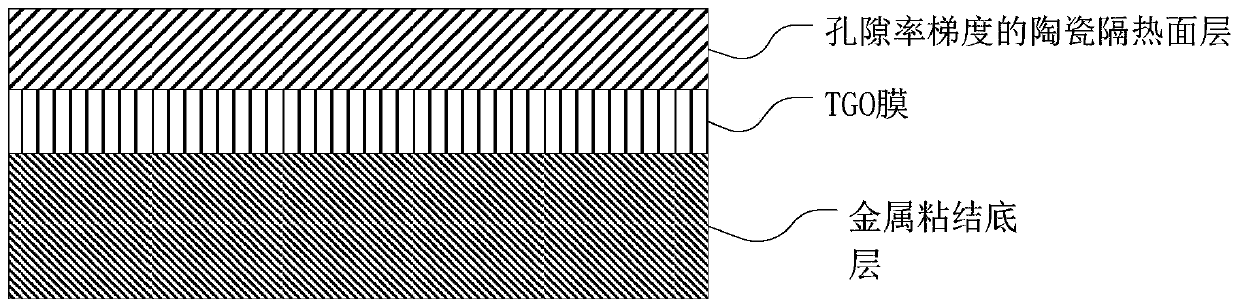

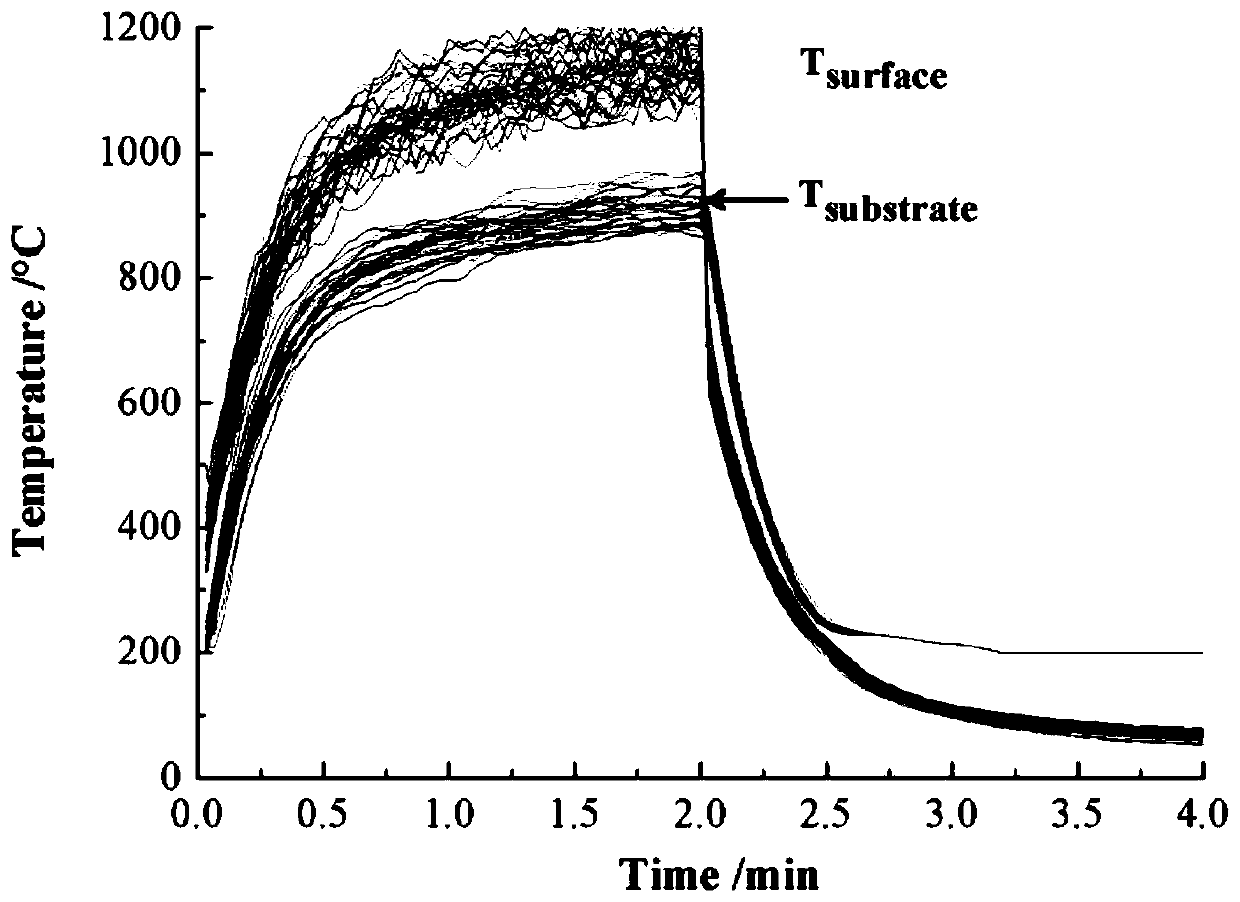

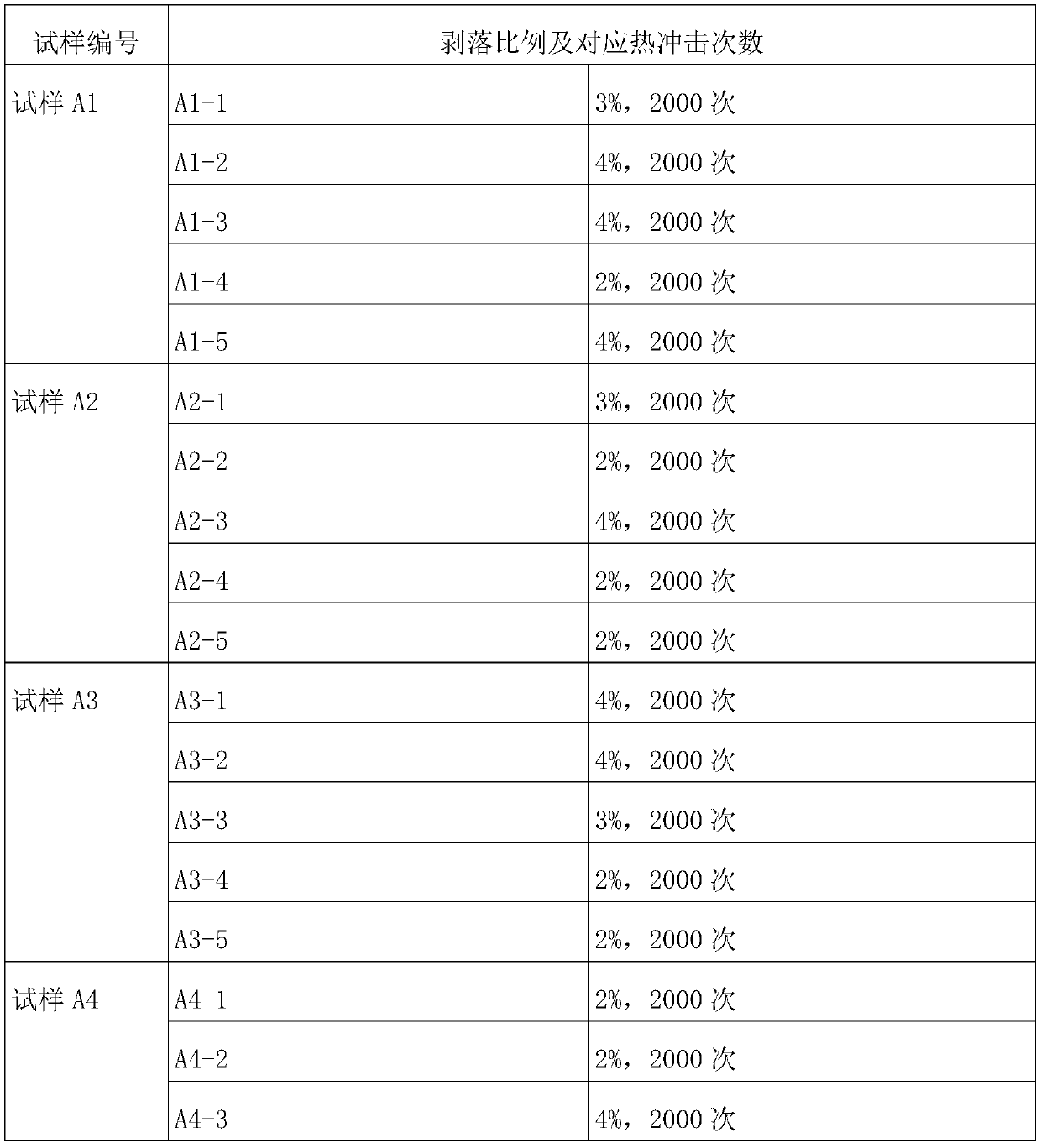

Novel porosity gradient thermal barrier coating

InactiveCN110284096AImprove impact performanceExtended service lifeMolten spray coatingVacuum evaporation coatingPorosityCompound a

The invention relates to a novel porosity gradient thermal barrier coating which comprises a metal bonding bottom layer growing on the surface of a substrate, a thermally grown oxide (TGO) layer growing above the metal bonding bottom layer, and a ceramic thermal insulating surface layer growing above the TGO layer, wherein the ceramic thermal insulating surface layer is made of a single ceramic material composition or a ceramic material formed through compounding a plurality of ceramic material compositions; and the porosity of the ceramic thermal insulating surface layer is in a continuous gradient reduced trend in the direction from the interface between the TGO layer and the ceramic thermal insulating surface layer to the outer surface of the ceramic thermal insulating surface layer. The thermal barrier coating system disclosed by the invention improves the thermal insulating efficiency and the thermal shock resistance of the thermal barrier coating on the premise of ensuring the thermal insulating effect of the thermal barrier coating to further prolong the service life of a turbine blade component.

Owner:江苏源清动力技术有限公司

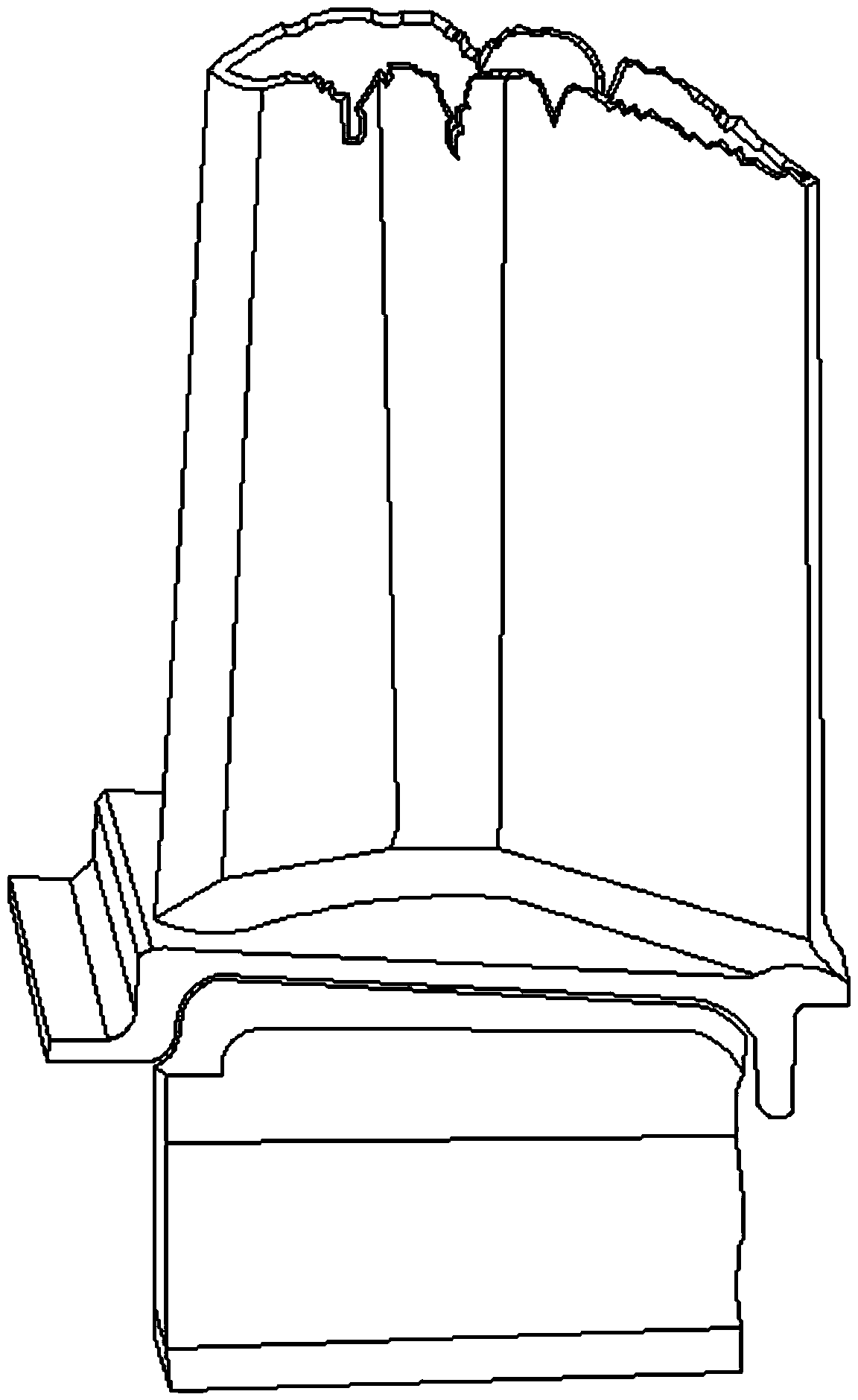

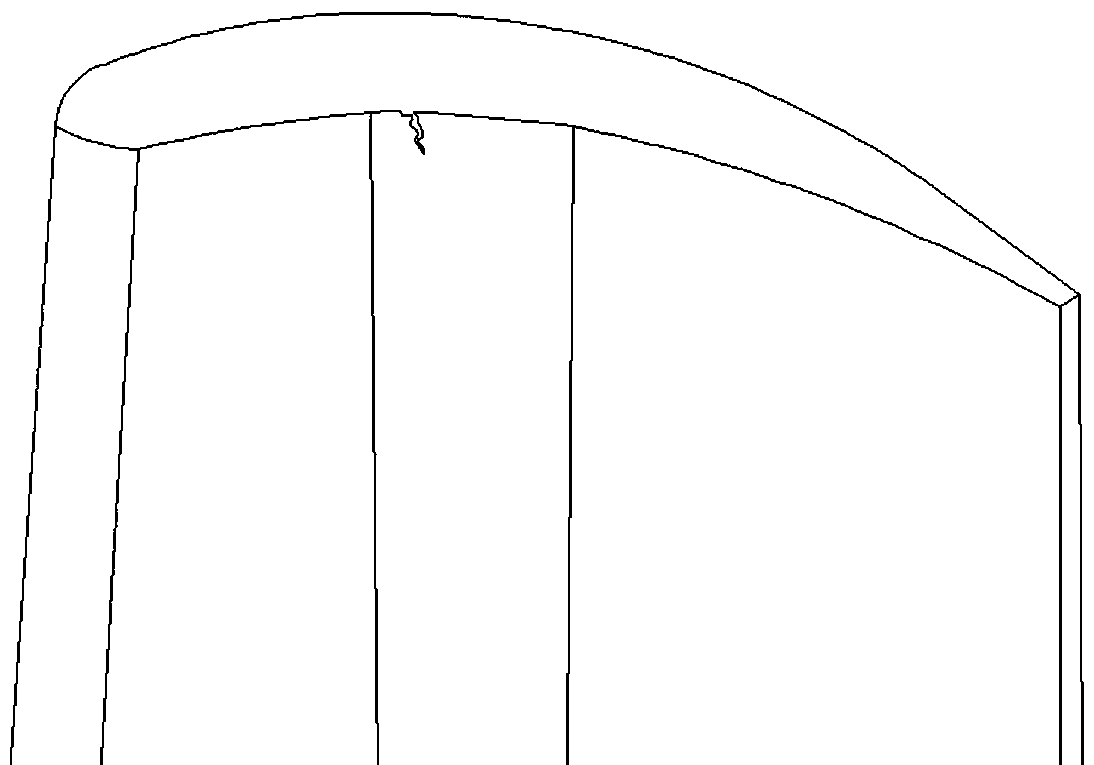

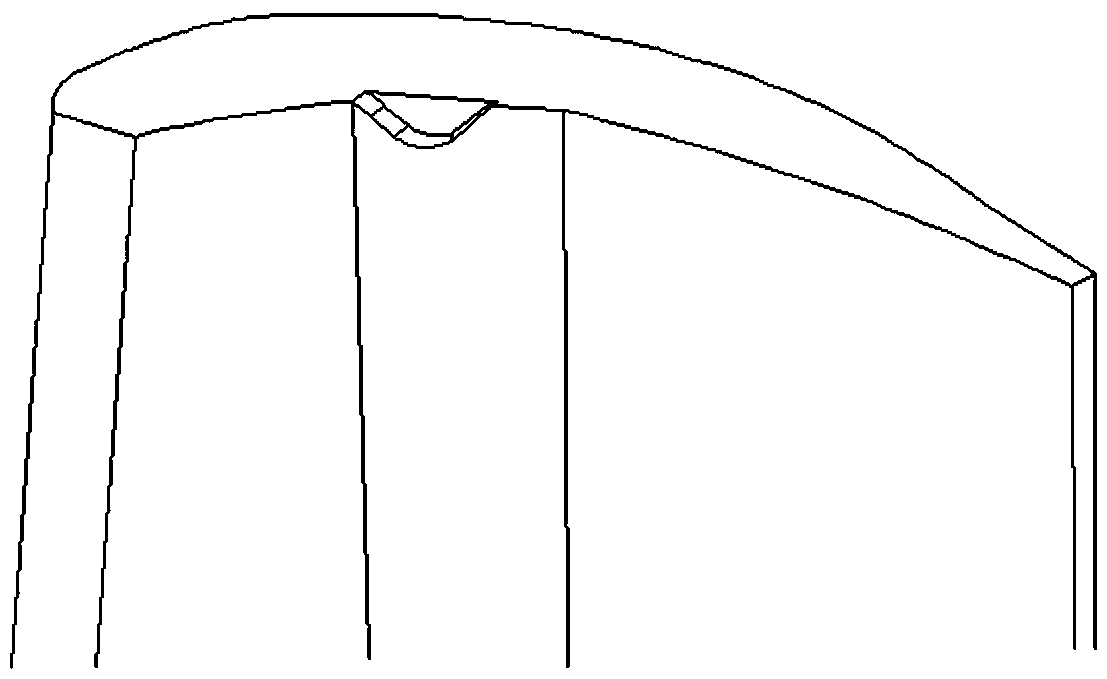

Integral repair method for longitudinal intensive damage of blade crown of aero-engine turbine rotor blade

InactiveCN110202158AReduce the difficulty of operationAvoid crack regenerationAdditive manufacturing apparatusIncreasing energy efficiencyRepair materialNondestructive testing

The invention discloses an integral repair method for the longitudinal intensive damage of a blade crown of an aero-engine turbine rotor blade. The integral repair method for the longitudinal intensive damage of the blade crown of the aero-engine turbine rotor blade comprises the following steps of firstly mechanically grinding the blade, integrally removing a damaged blade crown, adopting laser for repairing cracks under a casting cover plate, and fixing a blade tip cover plate onto the blade crown of the blade; then adopting an integral type laser solid forming technology for integrally forming the blade crown, manually processing a formed blade crown surface, and recovering a runner type surface; and finally, carrying out nondestructive testing on the repaired turbine blade, and puttinginto use after the blade meets a criterion. According to the integral repair method for the longitudinal intensive damage of the blade crown of the aero-engine turbine rotor blade provided by the invention, the integral repairing method is adopted, so that not only is degradation material removed thoroughly, but also the one-by-one repair process is avoided, and the workload is reduced; and meanwhile, through using a special repair material, a combination property of the crown material is improved.

Owner:PLA NO 5719 FACTORY

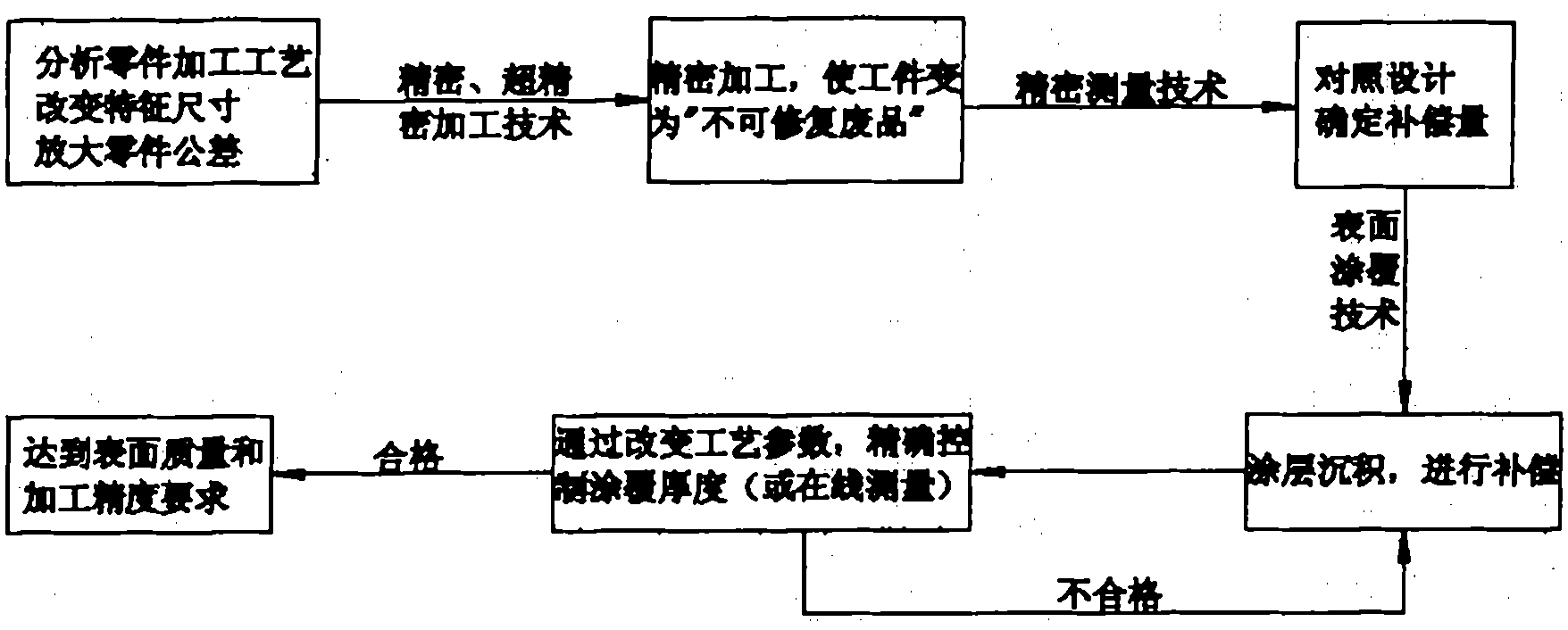

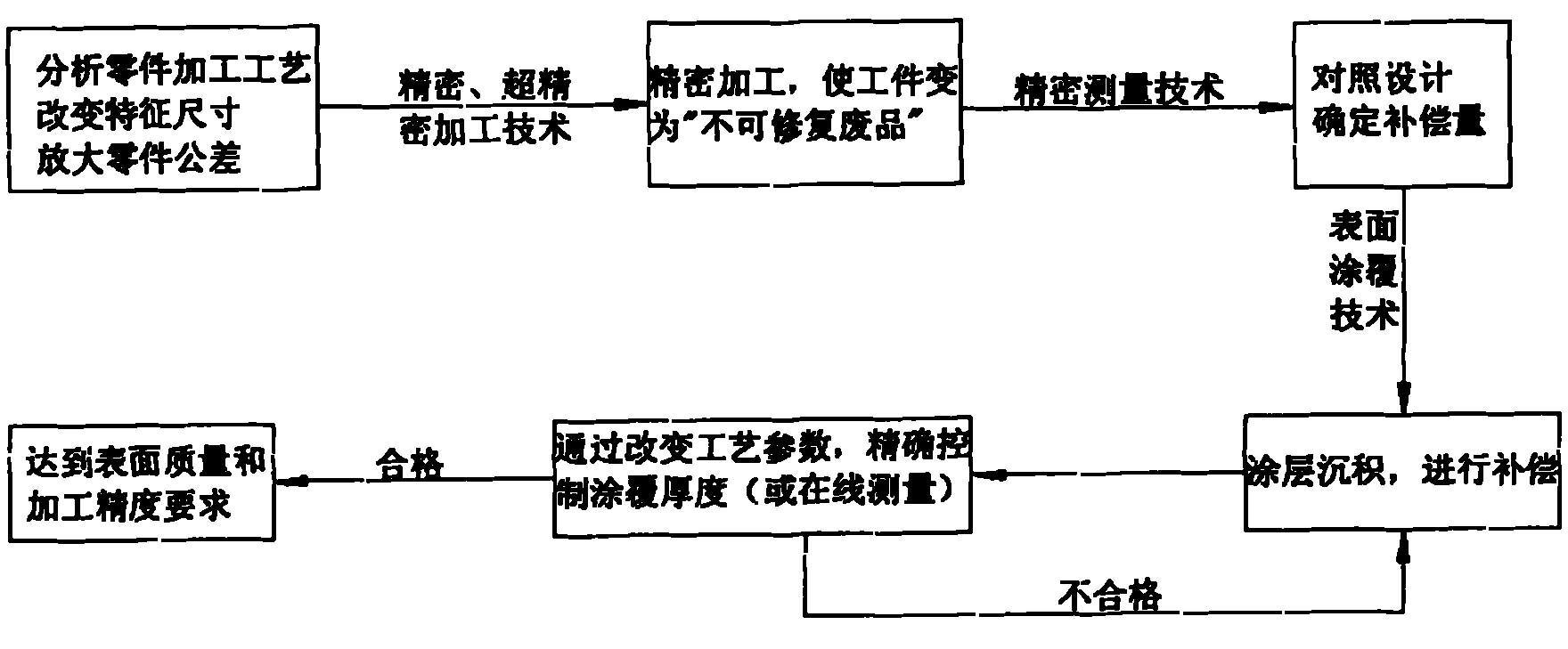

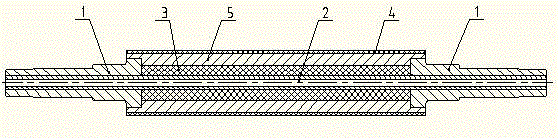

Integrated manufacturing method of microminiature parts based on surface coating

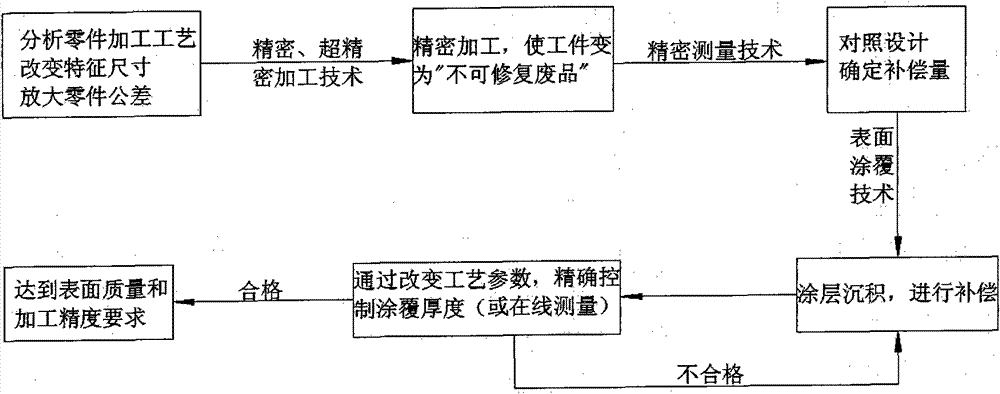

InactiveCN101864553AImprove surface qualityHas the effect of "killing two birds with one stone"Vacuum evaporation coatingSputtering coatingAlloyMachining

The invention relates to an integrated manufacturing method of microminiature parts based on surface coating. The technology integrates multiple technologies such as precision machining / ultraprecision machining, surface coating, precision measurement and the like, adopts the parts precision machining mode of firstly '-'(removing machining) and then '+' (combination machining), and compensates thesizes of parts through accurately controlling the thickness of a coating (plating) layer on the basis of precision measurement, thus improving machining precision and surface quality considering thatthe thickness of the coating layer can be precisely controlled to be in the nanometer level. The precision / ultraprecision machining technologies have wide range of machining materials and simple method, and can realize mass production of microminiature parts with three-dimensional complex structures; and the method of the invention be widely applied to the machining of various microminiature parts such as steel, alloy and the like.

TiB<w>-Ti composite layer and laser in-situ preparation method thereof

ActiveCN109989059AImprove toughnessImprove resistance to high temperature oxidationMetallic material coating processesMelting layerTitanium alloy

The invention provides a TiB<w>-Ti composite layer and a laser in-situ preparation method thereof. Specifically, the composite layer is prepared from the raw materials: Ti powder and TiB2 powder, a melting layer with a gradient change of TiB<w> / Ti content is prepared on the surface of a substrate, the melting layer is remelted, and a cladding layer is prepared on the surface of a remelting layer by means of a synergistic effect of induction heating and laser quenching. In the cladding layer, the interface structure of alpha-Ti and TiB<w> is in the form of coherent combination or semi-coherentcombination, and the strength and toughness, the high-temperature oxidation resistance, the fretting abrasion resistance and the fretting fatigue resistance can be remarkably improved. The TiB<w>-Ti composite layer can be widely applied to a modification layer and a repair layer of an aircraft engine shell auxiliary part made of a titanium alloy material.

Owner:PUTIAN UNIV

Tough high-temperature-oxidation-resistant molybdenum alloy and preparation method thereof

ActiveCN111041319AImprove resistance to high temperature oxidationGood room temperature fracture toughnessSolid state diffusion coatingAlloyOxidation resistant

The invention provides a tough high-temperature-oxidation-resistant molybdenum alloy and a preparation method thereof. The molybdenum alloy is composed of molybdenum, silicon, boron and zirconium, andthe molybdenum alloy comprises, by mass percentage, 2.2%-4% of silicon, 0.8%-1% of boron, 0.8%-1% of zirconium and the balance molybdenum. According to the preparation method, a solid-solid mixing mode is adopted for material mixing, pre-alloyed powder with uniform particles is prepared through mechanical ball milling or high-energy ball milling, the alloyed ball-milled powder is sintered to obtain a molybdenum alloy material, and then embedding siliconizing treatment is carried out to obtain the tough and antioxidant molybdenum alloy. The molybdenum alloy prepared through the method has goodcompactness, high toughness and high-temperature oxidation resistance, and thus the molybdenum alloy has wide application prospects and popularization value.

Owner:AIR FORCE UNIV PLA

Novel nickel alloy and preparation method thereof

The invention provides a novel nickel alloy. The novel nickel alloy comprises the following components in percentage by weight: 0.001-0.002% of Mg, 0.12-0.14% of Mn, 0.45-0.85% of W, 0.013-0.019% of Co, 0.12-0.18% of Nb, 0.89-0.95% of Sn, 1.3-1.9% of Mo, 1.2-2.4% of Zn, 1.5-2.8% of Ti, 0.51-0.71% of Fe, 1.7-1.9% of Y, 0.73-0.93% of Er, 0.007-0.011% of Sb, 37-45% of Cu and the rest of Ni. The nickel alloy is high-temperature resistant, high in corrosion resistance, low in manufacture cost and high in quality; the service life is greatly prolonged.

Owner:洋紫荆牙科器材(深圳)有限公司

Alloy powder for die steel laser cladding remanufacturing and preparation method of alloy powder

InactiveCN110238383AImprove high temperature mechanical propertiesGood high temperature mechanical propertiesMetallic material coating processesCrack resistanceAlloy

The invention discloses alloy powder for die steel laser cladding remanufacturing and a preparation method of the alloy powder. The alloy powder comprises the following components of, in percentage by weight, 0.45%-0.60% of C, 4.20%-8.50% of Co, 3.20%-4.80% of Cr, 1.20%-3.35% of Mo, 0.60%-2.40% of Mn, 0.40%-0.85% of Nb, 0.50%-2.40% of Si, 0.8%-3.2% of B, 0.01%-0.03% of Y2O3, 0.01%-0.03% of La2O3, less than or equal to 0.035% of P, less than or equal to 0.025% of S and the balance Ni. According to the alloy powder for die steel laser cladding remanufacturing and the preparation method of the alloy powder, the crack resistance, the formability, the process stability and the component uniformity of the alloy powder in the laser cladding process can be improved, the high-temperature mechanical property of 4Cr5Mo3V die steel is improved, the service life of the 4Cr5Mo3V steel is prolonged, and the economical efficiency is good.

Owner:CHANGSHAN SHUANGMING BEARING

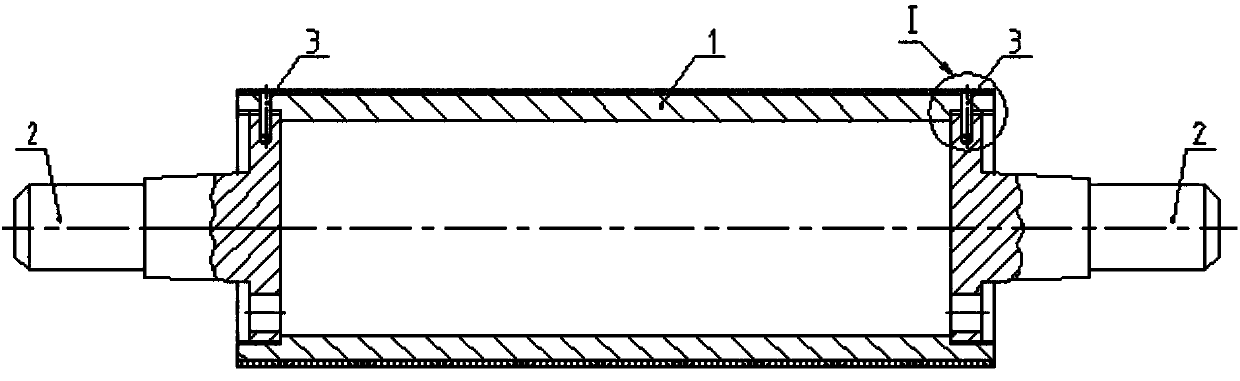

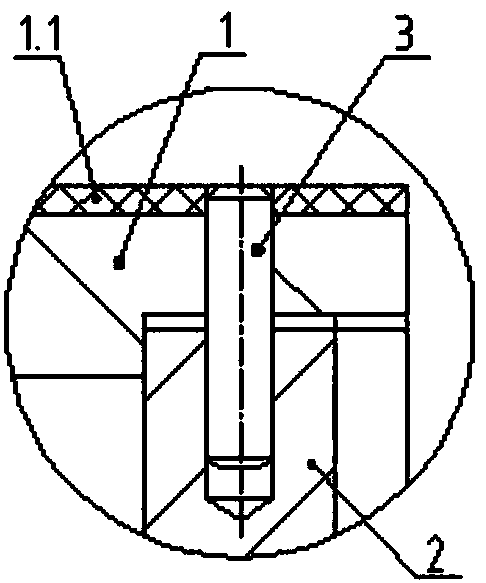

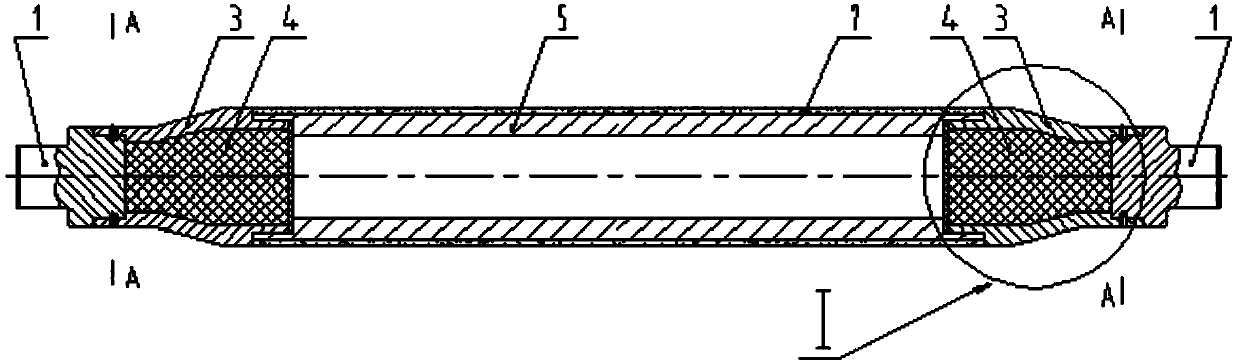

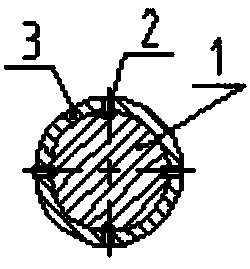

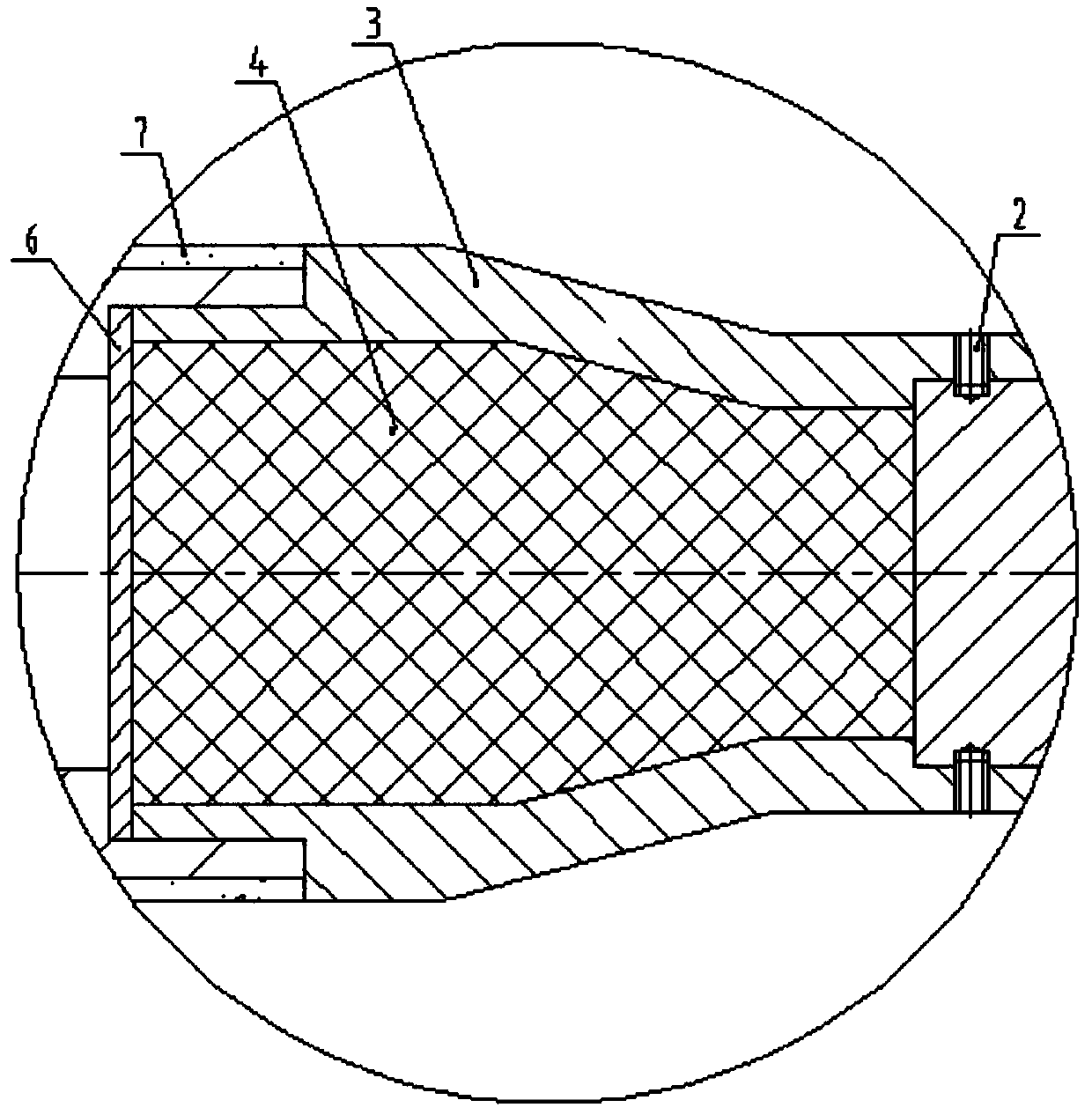

High-strength high-temperature-resistant furnace bottom roller

InactiveCN104561507AImprove working conditionsReduced heat transfer capabilityFurnace typesHeat treatment furnacesWear resistantThermal insulation

The invention discloses a high-strength high-temperature-resistant furnace bottom roller; the high-strength high-temperature-resistant furnace bottom roller comprises a roll cylinder, a roll neck and a roll head; the roll head is arranged at two ends of the roll cylinder; the roll neck is fixedly connected between the roll cylinder and the roll head; the roll head is inserted into the end part of the roll neck, so that the roll head and the roll neck are matched and fixedly connected; a clapboard is arranged at the joint of the roll cylinder and the roll neck; a closed cavity is formed among the clapboard, the end part of the roll head and the inner hole of the roll neck; a thermal insulation material is filled in the cavity, so that a thermal insulation structure is formed; the high-strength high-temperature-resistant furnace bottom roller disclosed by the invention is further characterized in that two locating pin shafts penetrating through the matched part of the roll head and the roll neck in the radial direction are arranged at the matched part of the roll head and the roll neck; a part of one locating pin shaft passes through another locating pin shaft; and a high-temperature-resistant oxidized wear-resistant coating is arranged on the outer wall of the roll cylinder. According to the invention, the capability of transferring heat from the roll cylinder to a roll shaft is low; the working conditions of a bearing are obviously improved; the connection part of the roll head and the roll neck is high in strength; and the high-strength high-temperature-resistant furnace bottom roller is high-temperature-resistant, oxidization-resistant and wear-resistant.

Owner:TAIZHOU SANJIANG SPECIAL STEEL MFG

Codeposition gradient Ni-base superalloy coating preparation technique

InactiveCN101310972BExtended service lifeExtend service timeVacuum evaporation coatingSputtering coatingSuperalloyDepth direction

The invention mainly relates to the coating technique, in particular to a gradient MCrAlY coating used for protecting high-temperature alloy and a preparation method thereof. The invention adopts a method combining the arc ion plating (AIP) co-deposition and the vacuum diffusion annealing to prepare an MCrAlY coating with the Al element concentration distributed along the depth direction in a gradient way. Compared with the existing conventional MCrAlY high-temperature protective coating, the gradient MCrAlY coating of the invention effectively increases the content of Al memory phase in the coating, so as to improve the high-temperature oxidization resistance and the heat corrosion resistance of the coating, and can effectively prolong the service life of the coating. The MCrAlY gradientcoating and the preparation method of the invention can be applied to the protection of Ni-based and Co-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-performance organic silicon resin-polymethyl methacrylate composite material mixed with nanometer silicon nitride for LED package, and preparation method of high-performance organic silicon resin-polymethyl methacrylate composite material

InactiveCN105001649AGood compatibilityImprove surface activityMagnesium Sulfate whiskersCvd graphene

The invention discloses a high-performance organic silicon resin-polymethyl methacrylate composite material mixed with nanometer silicon nitride for LED package. The composite material is a high-performance material which is formed by polymerization and curing of vinylphenyl silicone oil, hydrogen containing silicon resin, vinyl silicone resin and methyl methacrylate and has the hybrid advantages of organic silicon resin and polymethyl methacrylate; besides, powder formed by compounding nanometer silicon nitride which is mixed in the composite material, surface-treated with a silane coupling agent and wrapped by silica sol, magnesium sulfate whiskers and grapheme is good in compatibility with resin, and high in surface activity, after the powder is uniformly dispersed in the resin, the refractive index, the heat-conducting property, the heat dissipation performance, the high-temperature oxidation resistance, the insulation performance and other performance of the composite material can be improved greatly, and the prepared material is high in mechanical property, long in service life, high in transparency, and excellent in optical performance.

Owner:朱志

Automotive nylon plastic part processing technology

The invention discloses an automotive nylon plastic part processing technology which comprises the following process steps: (1) preparing raw materials; (2) mixing; (3) smelting; (4) molding materials; (5) modifying; (6) crystallizing and separating; and (7) cleaning the surface. The performances of high-temperature oxidation and corrosion resistance are improved, the crystallization rate is high, and the nylon plastic part is easy to mold and process and has the characteristics of high impact resistance and the like.

Owner:ANHUI CAREMIC CONSULTING CO LTD

A kind of nickel alloy and preparation method thereof

The invention provides a novel nickel alloy. The novel nickel alloy comprises the following components in percentage by weight: 0.001-0.002% of Mg, 0.12-0.14% of Mn, 0.45-0.85% of W, 0.013-0.019% of Co, 0.12-0.18% of Nb, 0.89-0.95% of Sn, 1.3-1.9% of Mo, 1.2-2.4% of Zn, 1.5-2.8% of Ti, 0.51-0.71% of Fe, 1.7-1.9% of Y, 0.73-0.93% of Er, 0.007-0.011% of Sb, 37-45% of Cu and the rest of Ni. The nickel alloy is high-temperature resistant, high in corrosion resistance, low in manufacture cost and high in quality; the service life is greatly prolonged.

Owner:洋紫荆牙科器材(深圳)有限公司

High-temperature resistant and abrasion resistant type furnace bottom roller

InactiveCN107619918AEasy and fast assemblyQuick and easy to disassembleFurnace typesHeat treatment furnacesOxidation resistantPulp and paper industry

The invention discloses a high-temperature resistant and abrasion resistant type furnace bottom roller comprising a roller cylinder and roller shafts connected to the two ends of the roller cylinder.Outer threads are arranged at the ends of the roller shafts. Inner thread holes are formed in the two ends of the roller cylinder. The outer threads at the ends of the roller shafts are connected withthe inner thread holes in the ends of the roller cylinder in a threaded mode. The further-improved aspects are that positioning pin shafts radially penetrating through the hole walls of the inner thread holes in the ends of the roller cylinder to be inserted in the ends of the roller shafts are arranged in the connection parts of the inner thread holes in the ends of the roller cylinder and the outer threads at the ends of the roller shafts, and a high-temperature oxidation resistant and abrasion resistant coating is arranged on the surface of the roller cylinder. Assembly or disassembly of the roller cylinder and the roller shafts is convenient and rapid, and high-temperature resistance, oxidation resistance and abrasion resistance are achieved.

Owner:孙荣华

Ni-base superalloy complex gradient coating and preparation technique thereof

InactiveCN101310971BExtended service lifeReduce degradationLayered productsVacuum evaporation coatingSuperalloyDepth direction

The invention mainly relates to the coating technique, in particular to a gradient MCrAlY coating used for protecting high-temperature alloy and a preparation method thereof. The invention prepares an MCrAlY composite gradient coating by adopting the method combining the arc ion plating (AIP) and the diffusion aluminizing. The thickness of an aluminum-rich layer on the surface of the MCrAlY composite coating can be controlled by setting the aluminizing temperature and the period of heat preservation and the Al elements are distributed in a gradient way along the depth direction; in addition, the chemical vapor deposition method used for the aluminizing has the advantages of good uniformity on the aluminum-rich layer and being not affected by the size and shape of a sample. Since the method of direct diffusion is adopted without introducing a weak interface, the MCrAlY high-temperature protective coating can increase the content of Al memory phase to the utmost extent under the condition that the mechanical property of the coating is guaranteed, so as to improve the high-temperature oxidization resistance and the heat corrosion resistance of the coating, and can effectively prolongthe service life of the coating. The MCrAlY composite gradient coating and the preparation method of the invention can be applied to the protection of Ni-based and Co-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of tough high temperature resistant molybdenum oxide alloy and its preparation method

ActiveCN111041319BImprove resistance to high temperature oxidationGood room temperature fracture toughnessSolid state diffusion coatingAlloyOxidation resistant

Owner:AIR FORCE UNIV PLA

Thermal barrier coating for turbine blade assembly and preparation method thereof

ActiveCN107345299BGuaranteed insulation effectImprove resistance to high temperature oxidationEfficient propulsion technologiesSuperimposed coating processTurbine bladeBarrier effect

The invention provides a turbine blade assembly thermal barrier coating. The turbine blade assembly thermal barrier coating comprises a bonding layer, an aluminide layer, an aluminum oxide layer and a ceramic layer which are sequentially arranged in an upward mode from a turbine blade assembly base material or comprises an aluminide layer, a bonding layer, an aluminum oxide layer and a ceramic layer which are sequentially arranged. The bonding layer is a MCrAlY layer, and M represents one or two or three sorts of nickel, cobalt and iron. According to the thermal barrier coating system provided by the invention, the high-temperature oxidation resistance, thermal corrosion resistance and endurance property of the thermal barrier coating are improved on the premise that the thermal barrier effect of the thermal barrier coating is guaranteed, and thus the service life of a turbine blade assembly is prolonged. By means of the thermal barrier coating system prepared through the method, the weight of the blade assembly can be lowered obviously, and therefore the creep degree of the assembly by tension of the turbine blade assembly in the high-speed rotating process is decreased and the service life of the turbine blade assembly is prolonged.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

MCrAlY+AlSiY composite coating and preparation technique thereof

InactiveCN101724301BExtended service lifeIncrease contentFireproof paintsVacuum evaporation coatingIon platingCr element

The invention relates to high-temperature protective coating technology, in particular to an MCrAlY+AlSiY composite coating and a preparation technique thereof. A MCrAlY composite coating, which is rich in Al on an outer layer and rich in Cr on an inner layer and is distributed in a gradient form, is formed by depositing an AlSiY coating on a MCrAlY coating and by using a vacuum diffusion annealing method. The concentration of Al elements on the surface layer of the composite coating is 18 to 22 weight percent, and the concentration of Cr elements on the inner layer is 28 to 45 weight percent. The MCrAlY composite coating, which is rich in Al on the outer layer and rich in Cr on the inner layer and is distributed in a gradient form, is prepared by combination of arc ion plating depositionand the vacuum diffusion annealing. Compared with the existing conventional MCrAlY high-temperature protective coating, the MCrAlY+AlSiY composite coating of the invention effectively improves an A1 storage phase content and Si content in the surface layer of the coating; and the layer rich in Cr is formed on the inner layer of the coating, so the high temperature oxidation resistance and hot-corrosion resistance of the coating are improved, and the service life of the coating can be effectively prolonged. The composite coating and a preparation method thereof are suitable for protecting Ni-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

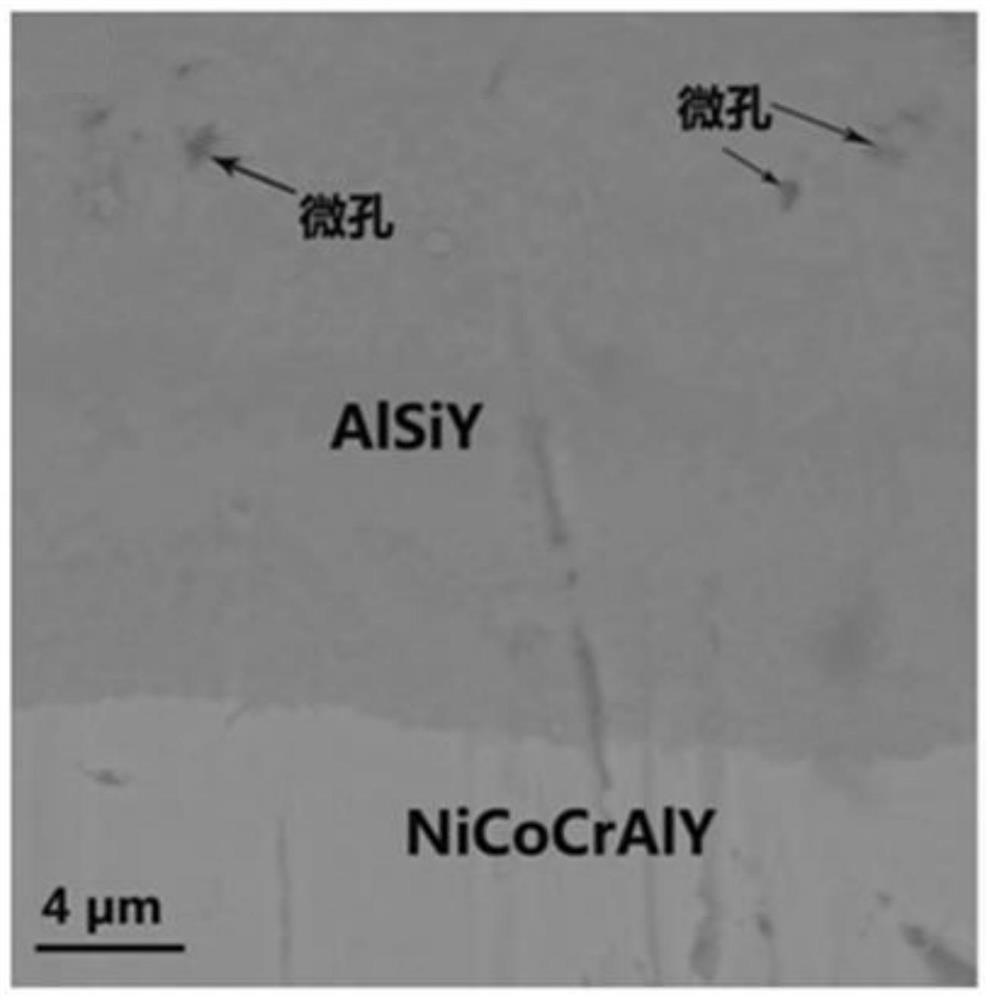

A kind of titanium alloy blade protective coating and preparation method thereof

ActiveCN112663001BHigh bonding strengthImprove compactnessVacuum evaporation coatingSputtering coatingTitanium alloyHot and humid

The invention provides a titanium alloy blade protective coating and a preparation method thereof. The MCrAlY+AlSiY composite coating arranged on a titanium alloy substrate is adopted. The MCrAlY layer is deposited on the surface of the titanium alloy substrate by an arc ion plating process, and the AlSiY layer is ionized by The assisted arc ion plating process is deposited on the MCrAlY layer. By adopting the scheme of the present invention, the obtained protective coating has high bonding strength with the titanium alloy blade substrate, the surface of the protective coating and its interior have no large particle size and number, no micropores, and the coating has excellent compactness, which can not only improve the titanium alloy The high temperature oxidation resistance and thermal corrosion resistance of the alloy blade protective coating are especially suitable for high temperature protection in hot and humid salt spray environment (such as marine service environment), and can effectively prolong the service life of the titanium alloy blade protective coating.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND +1

High-strength high-temperature-resistant furnace bottom roller

InactiveCN107893157AImprove working conditionsReduced heat transfer capabilityFurnace typesHeat treatment furnacesRefractoryPulp and paper industry

The invention discloses a high-strength and high-temperature-resistant furnace bottom roller, which comprises a roller, a roller neck and a roller head; the roller head is arranged at both ends of the roller, and the roller neck is fixedly connected between the roller and the roller head; the roller head is inserted into the roller The end of the neck forms a fit and a fixed connection; the roll neck is inserted into the spigot hole at the end of the roll to form a fit and a fixed connection; the joint between the roll and the roll neck is provided with a partition; the cavity in the roll neck is provided with heat insulation Structure: there is more than one anti-loosening screw at the connection between the spigot hole at the end of the roller and the end of the roll neck, the anti-loosening screw penetrates radially, and the threaded connection is inserted into the wall of the spigot hole at the end of the roller; further The improvement lies in that: the outer wall of the roller is provided with a high-temperature oxidation-resistant and wear-resistant coating; the anti-loosening screws are evenly distributed on the circumference of the connection between the notch hole at the end of the roller and the end of the roller neck. The invention has low heat transfer capability from the roller to the roller shaft, and the working condition of the bearing is obviously improved; the joint structure of the roller head and the roller neck has high strength, high disassembly efficiency; high temperature resistance, oxidation resistance and wear resistance.

Owner:江苏亚太特种铸钢厂有限公司

Energy-saving type high temperature resistant hearth roll

InactiveCN105755276AReduce deliveryReduce lossFurnace typesHeat treatment furnacesFiberThermal insulation

The invention discloses an energy-saving type high temperature resistant hearth roll, which includes a roller, a casing, and roll shafts fixedly connected in two end holes of the roller. The casing runs through the roll shafts and the roller cavity axially, and the two ends are fixedly connected in the inner holes of the roll shafts; the cavity between the casing outer wall and the roller cavity is filled with a thermal insulation material. The further improvement lies in that: the thermal insulation material is aluminum silicate fiber. The outer wall of the roller is provided with a high temperature oxidation resistant and wearproof coating. The energy-saving type high temperature resistant hearth roll provided by the invention significantly reduces heat transfer from the roller to the casing and energy loss, and has the advantages of high temperature resistance, oxidation resistance, and wear resistance.

Owner:孙萍

A kind of surface treatment method of aluminum electrolytic inert anode

ActiveCN103820816BImprove resistance to high temperature oxidationImproved resistance to molten salt corrosionMolten spray coatingElectrolysisSpray coating

The invention relates to a surface treatment method for an aluminum electrolyzing inert anode. The surface treatment method is characterized by comprising the following steps: firstly, forming a protective layer on the surface of a Ni-Fe-based inert anode through spray coating, wherein the protective layer consists of a bottom layer Fe-Ni-X1 alloy layer and an outer layer Fe-Ni-X2-O ceramic-metal layer; secondly, sealing holes of the protective layer through a high-temperature oxidation method to form a uniform and compact oxide film layer, wherein the oxide film can improve high-temperature oxidation resistance and molten salt corrosion resistance of the anode; the inert anode subjected to coating and oxidation has good high-temperature oxidation resistance and aluminum electrolyzing fluoride molten salt corrosion resistance; after being subjected to electrolyzing molten salt corrosion for 300 hours, the inert anode still keep good structural integrity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Integrated manufacturing method of microminiature parts based on surface coating

InactiveCN101864553BImprove surface qualityHas the effect of "killing two birds with one stone"Vacuum evaporation coatingSputtering coatingAlloyMachining

The invention relates to an integrated manufacturing method of microminiature parts based on surface coating. The technology integrates multiple technologies such as precision machining / ultraprecision machining, surface coating, precision measurement and the like, adopts the parts precision machining mode of firstly '-'(removing machining) and then '+' (combination machining), and compensates the sizes of parts through accurately controlling the thickness of a coating (plating) layer on the basis of precision measurement, thus improving machining precision and surface quality considering that the thickness of the coating layer can be precisely controlled to be in the nanometer level. The precision / ultraprecision machining technologies have wide range of machining materials and simple method, and can realize mass production of microminiature parts with three-dimensional complex structures; and the method of the invention be widely applied to the machining of various microminiature parts such as steel, alloy and the like.

Owner:NANJING UNIV OF SCI & TECH

Super-thick super-hard coating and preparation method thereof

InactiveCN102756514BIncreasing the thicknessImprove bindingVacuum evaporation coatingSputtering coatingAs elementSputtering

The invention provides a super-thick super-hard coating and a preparation method thereof. The super-thick super-hard coating comprises a Ti bottom layer deposited on the surface of a basal body, a TiN transitional layer prepared on the Ti bottom layer, and a TiAlSiCN coating prepared on the TiN transitional layer; and the thickness of the super-thick super-hard coating is larger than or equal to 20 microns. During preparation, a columnar electric arc Ti target serves as a Ti source; a planar magnetron sputtering Si target, a planar magnetron sputtering Al target and a planar magnetron sputtering target serve as sources of Si, Al and C correspondingly; Ar serves as an ionization gas; and N2 serves as a reaction gas. According to the invention, the binding force of the basal body to a TiAlSiCN coating as well as the thickness of the TiAlSiCN coating prepared on the basal body is remarkably improved; and as elements such as Si, C and Al are added into the TiN coating, the TiAlSiCN coating with five elements is obtained, and the hardness, the abrasion resistance, the anti-friction quality, the high-temperature oxidization resistance and the corrosion resistance of the coating are further improved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com