Tough high-temperature-oxidation-resistant molybdenum alloy and preparation method thereof

A technology of high temperature resistance and molybdenum oxide, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems that limit the development and application of molybdenum alloys, and achieve the effect of good room temperature fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

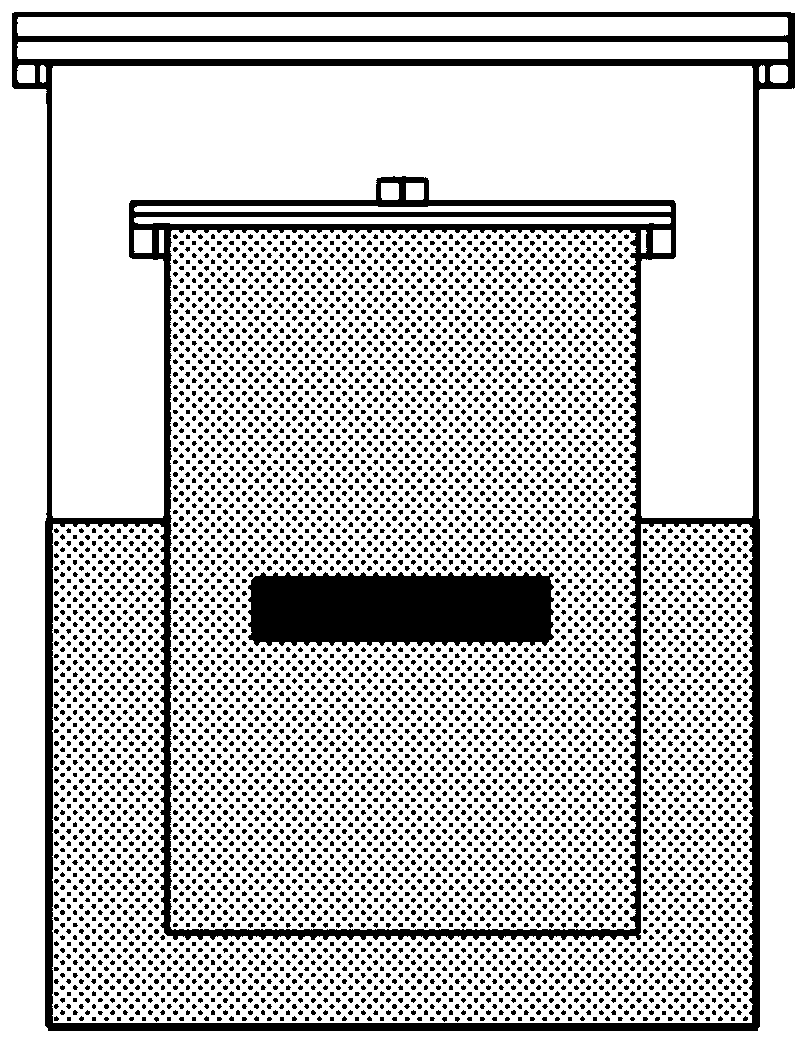

Image

Examples

Embodiment 1

[0025] Weigh 2520g of Mo powder, 75.6g of Si powder, 25.2g of B powder, and 20.16g of Zr powder and put it into a mixer for mixing for 15 hours, then put the mixture into a planetary ball mill (QM-3SP4) for ball milling for 20 hours. 5:1, speed 300r / min, the ball mill rotates once an hour to make it evenly milled and obtain pre-alloyed powder. Among them, the median particle size of the selected molybdenum powder particles is 1-3 μm, and the purity is not lower than 99.95%; the median particle size of the silicon powder particles is 2-4 μm, and the purity is not lower than 99.90%; The median particle size is 2-4 μm, and the purity is not lower than 99.50%; the median particle size of zirconium powder particles is 20-40 μm, and the purity is not lower than 99.90%.

[0026] Put the pre-alloyed powder into the graphite mold, and use graphite paper in the graphite mold to isolate the powder from the mold; after wrapping, put it into the cold isostatic pressing equipment, set the p...

Embodiment 2

[0030] Weigh 2548g of Mo powder, 39.6g of Si powder, 26.4g of B powder, and 25.8g of Zr powder and put it into a mixer for mixing for 20 hours, then put the mixture into a planetary ball mill (QM-3SP4) for ball milling for 20 hours. 5:1, speed 300r / min, the ball mill rotates once an hour to make it evenly milled and obtain pre-alloyed powder. Among them, the median particle size of the selected molybdenum powder particles is 1-3 μm, and the purity is not lower than 99.95%; the median particle size of the silicon powder particles is 2-4 μm, and the purity is not lower than 99.90%; The median particle size is 2-4 μm, and the purity is not lower than 99.50%; the median particle size of zirconium powder particles is 20-40 μm, and the purity is not lower than 99.90%.

[0031] Put the pre-alloyed powder into the graphite mold, and use graphite paper in the graphite mold to isolate the powder from the mold; after wrapping, put it into the cold isostatic pressing equipment, set the pr...

Embodiment 3

[0035] Weigh 2551g of Mo powder, 44.9g of Si powder, 21.6g of B powder, and 22.3g of Zr powder and put it into a mixer for mixing for 15 hours, then put the mixture into a planetary ball mill (QM-3SP4) for ball milling for 20 hours. 5:1, speed 300r / min, the ball mill rotates once an hour to make it evenly milled and obtain pre-alloyed powder. Among them, the median particle size of the selected molybdenum powder particles is 1-3 μm, and the purity is not lower than 99.95%; the median particle size of the silicon powder particles is 2-4 μm, and the purity is not lower than 99.90%; The median particle size is 2-4 μm, and the purity is not lower than 99.50%; the median particle size of zirconium powder particles is 20-40 μm, and the purity is not lower than 99.90%.

[0036] Put the pre-alloyed powder into the graphite mold, and use graphite paper in the graphite mold to isolate the powder from the mold; after wrapping, put it into the cold isostatic pressing equipment, set the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com