Super-thick super-hard coating and preparation method thereof

A kind of hard coating, superhard technology, applied in coating, chemical instrument and method, metal material coating process, etc., can solve the problems of easy peeling and failure of coating, poor bonding performance of film base, large residual stress of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

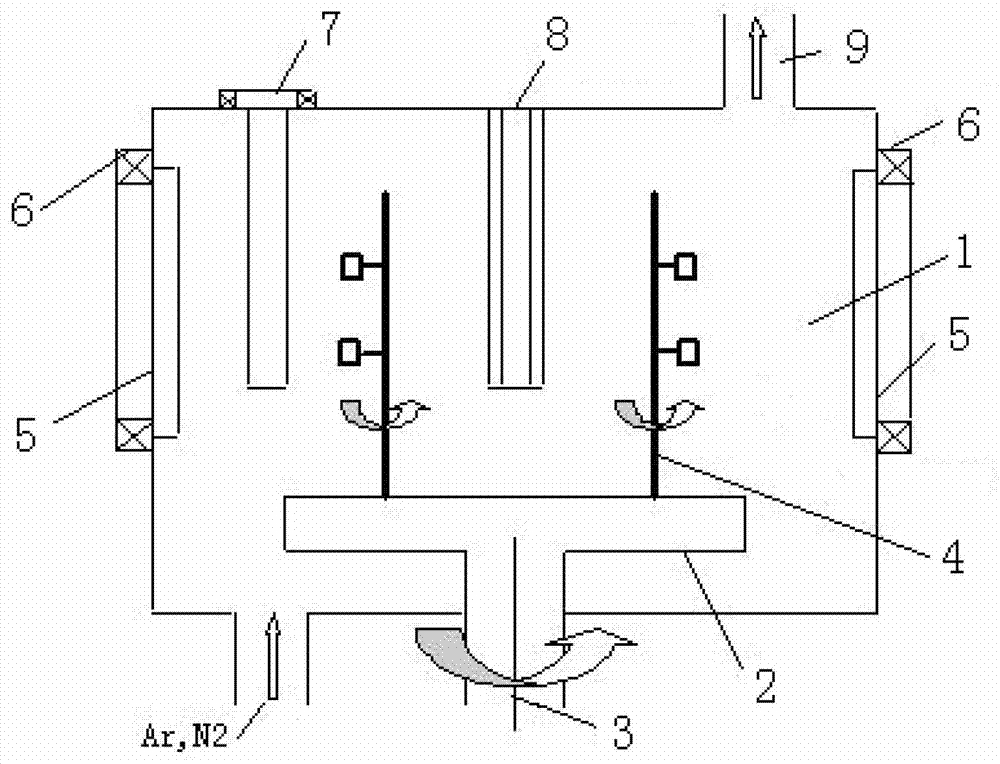

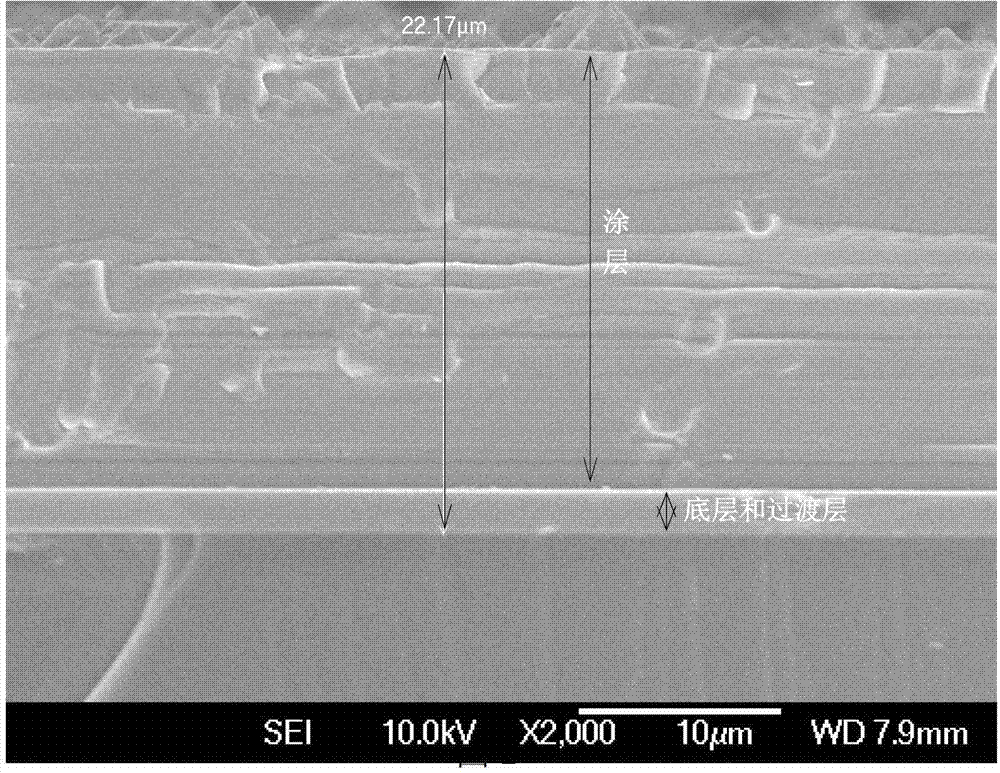

[0022] The invention adopts the arc-enhanced magnetron sputtering ion plating technology to prepare TiAlSiCN super-thick and super-hard coating material. This embodiment provides a method for preparing a TiAlSiCN ultra-thick superhard coating on a high-speed steel substrate. It should be noted that the TiAlSiCN ultra-thick superhard coating prepared by the method of the present invention can be used on any steel substrate material. carried out, not limited to this example.

[0023] The concrete preparation process of this embodiment is:

[0024] (1) Substrate pretreatment: use a high-speed steel substrate (W18Cr4V) with a hardness of HRC=60 after quenching at 1170°C and tempering at 550°C as the sample. After degreasing and polishing the surface, the sample is immersed in acetone for ultrasonic cleaning, and then alcohol dehydration;

[0025] (2) Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com