A kind of surface treatment method of aluminum electrolytic inert anode

An inert anode, surface treatment technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of poor uniformity, small oxide film thickness, high porosity, and achieve good resistance to aluminum electrolytic fluoride melting. Salt corrosion performance, good structural integrity, improved high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

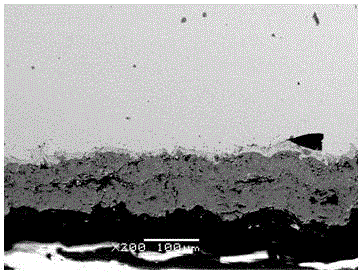

[0035] The surface of the cast-formed anode is firstly sandblasted to remove the surface oxide skin, and at the same time make the surface roughness reach Sa2.5~3.0 level. The surface of the anode was sprayed by plasma spraying, in which the inner coating was composed of Fe-Ni alloy powder with a weight ratio of 1:1, and 6% Cu powder was added to prepare an alloy inner coating with a thickness of 80 μm. The outer coating becomes mainly NiFe 2 o 4 Ceramic powder, and add 10% NiO ceramic powder, 5% Co powder, 0.5% La powder to prepare a ceramic-metal protective layer with a thickness of 100 μm.

[0036] The sprayed anode is placed in a horizontal muffle furnace for high-temperature oxidation treatment, the temperature rise rate is controlled: 8°C / min, the oxidation holding temperature: 800°C, the oxidation time: 24h, the holding oxygen pressure is 0.8atm, and the temperature is 4°C / min After slowly cooling down to 400°C, cool down to room temperature with the furnace. After s...

Embodiment 2

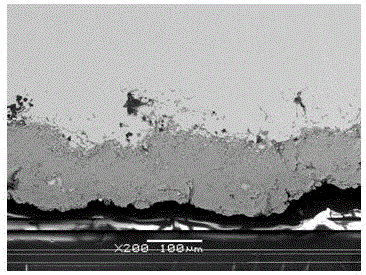

[0039] The surface of the cast-formed anode is firstly sandblasted to remove the surface oxide skin, and at the same time make the surface roughness reach Sa2.5~3.0 level. The surface of the anode was sprayed by plasma spraying, in which the composition of the inner coating was Fe-Ni alloy powder with a weight ratio of 1:2, and 2Al% powder was added to prepare an alloy inner coating with a thickness of 50 μm. The outer coating becomes mainly NiFe 2 o 4 Ceramic powder, and add 10% Fe 2 o 3 Ceramic powder and 2% Zn powder were used to prepare a ceramic-metal protective layer with a thickness of 120 μm.

[0040] The sprayed anode is placed in a horizontal muffle furnace for high-temperature oxidation treatment, the temperature rise rate is controlled: 10°C / min, the oxidation holding temperature: 950°C, the oxidation time: 0.5h, the holding oxygen pressure is 0.5atm, and the temperature is 5°C / min. min Slowly cool down to 450°C, then cool down to room temperature with the furn...

Embodiment 3

[0043] The surface of the cast-formed anode is firstly sandblasted to remove the surface oxide skin, and at the same time make the surface roughness reach Sa2.5~3.0 level. The surface of the anode is sprayed by plasma spraying, in which the composition of the inner coating is Fe-Ni alloy powder with a weight ratio of 2:1, and 5% Cu powder and 5% Co powder are added to prepare an alloy inner coating with a thickness of 50 μm. layer. The outer coating becomes mainly NiFe 2 o 4 Ceramic powder, and add 10% NiO ceramic powder, 2% Mn powder, 2% Co powder to prepare a ceramic-metal protective layer with a thickness of 150 μm.

[0044] The sprayed anode is placed in a horizontal muffle furnace for high-temperature oxidation treatment, controlled heating rate: 5°C / min, oxidation holding temperature: 880°C, oxidation time: 2.5h, holding oxygen pressure 1atm, at 3°C / min After slowly cooling down to 500°C, cool down to room temperature with the furnace. After spraying + high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com