Energy-saving type high temperature resistant hearth roll

A technology of high temperature resistance and hearth roller, which is applied in the direction of furnace, heat treatment furnace, furnace type, etc., can solve the problems of bearing temperature rise, bearing failure, energy waste, etc., to improve high temperature oxidation resistance, reduce energy loss, and reduce heat The effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

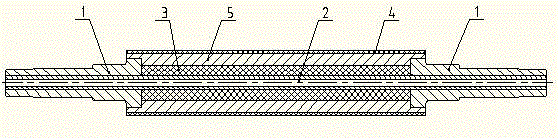

[0014] The energy-saving high-temperature-resistant furnace bottom roller shown in the accompanying drawings includes a roller 5, a sleeve 2, and a roller shaft 1 fixedly connected to the holes at both ends of the roller 5; the sleeve 2 axially runs through the roller shaft 1 and the roller 5 Cavity, both ends are fixedly connected in the inner hole of the roller shaft 1; the cavity between the outer wall of the casing 2 and the inner wall of the cavity of the roller 5 is filled with a heat insulating material 3. In this embodiment, the heat insulating material 3 is silicic acid aluminum fiber.

[0015] The outer wall of the roller 5 is provided with a high-temperature oxidation-resistant and wear-resistant coating 7. In this embodiment, the high-temperature oxidation-resistant and wear-resistant coating 7 is an MCrAlY coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com