Method for preparing hollow blade inner chamber diffusion layer with high temperature resistance, oxidation resistance and corrosion resistance

A high-temperature oxidation-resistant, hollow blade technology, applied in the direction of solid-state diffusion cladding, blade support elements, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

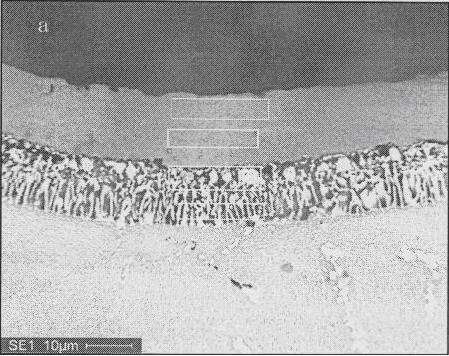

Image

Examples

Embodiment 1

[0033] The gas turbine hollow blade is prepared to resist high temperature oxidation and corrosion diffusion infiltration layer, and the material of the gas turbine hollow blade is K465 nickel-based superalloy. The specific preparation method is as follows:

[0034] ——Preparation of penetrating agent:

[0035] (1) Preparation of nickel chromizing agent: chromium powder, nickel powder, aluminum oxide powder, nickel-yttrium alloy powder, and ammonium chloride are prepared into nickel chromizing agent according to the following weight ratio;

[0036] Chromium powder 7%; Nickel powder 27%;

[0037] Aluminum oxide powder 60%; nickel-yttrium alloy powder 5%;

[0038] ammonium chloride balance;

[0039] (2) Preparation of chrome aluminizing agent: chrome powder, aluminum powder, aluminum oxide powder, nickel-yttrium alloy powder, and ammonium chloride are prepared according to the following weight ratio to prepare a chrome aluminizing agent;

[0040] Chromium powder 38%; Aluminum...

Embodiment 2

[0062] The gas turbine hollow blade is prepared to resist high temperature oxidation and corrosion diffusion infiltration layer, and the material of the gas turbine hollow blade is K465 nickel-based superalloy. The specific preparation method is as follows:

[0063] ——Preparation of penetrating agent:

[0064] (1) Preparation of nickel chromizing agent: chromium powder, nickel powder, aluminum oxide powder, nickel-yttrium alloy powder, and ammonium chloride are prepared into nickel chromizing agent according to the following weight ratio;

[0065] Chromium powder 10%; Nickel powder 24%;

[0066] Aluminum oxide powder 62%; nickel-yttrium alloy powder 3%;

[0067] ammonium chloride balance;

[0068] (2) Preparation of chrome aluminizing agent: chrome powder, aluminum powder, aluminum oxide powder, nickel-yttrium alloy powder, and ammonium chloride are prepared according to the following weight ratio to prepare a chrome aluminizing agent;

[0069] Chromium powder 39.7%; Alumi...

Embodiment 3

[0090] The gas turbine hollow blade is prepared to resist high temperature oxidation and corrosion diffusion infiltration layer, and the material of the gas turbine hollow blade is K465 nickel-based superalloy. The specific preparation method is as follows:

[0091] ——Preparation of penetrating agent:

[0092] (1) Preparation of nickel chromizing agent: chromium powder, nickel powder, aluminum oxide powder, nickel-yttrium alloy powder, and ammonium chloride are prepared into nickel chromizing agent according to the following weight ratio;

[0093] Chromium powder 8%; Nickel powder 25%;

[0094] Aluminum oxide powder 61%; nickel-yttrium alloy powder 4%;

[0095] ammonium chloride balance;

[0096] (2) Preparation of chrome aluminizing agent: chrome powder, aluminum powder, aluminum oxide powder, nickel-yttrium alloy powder, and ammonium chloride are prepared according to the following weight ratio to prepare a chrome aluminizing agent;

[0097] Chromium powder 39%; Aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com