High-temperature resistant and abrasion resistant type furnace bottom roller

A hearth roller and high temperature resistant technology, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the time-consuming and troublesome problems of assembling or disassembling rollers and roller shafts, achieve convenient and quick assembly or disassembly, and improve high temperature resistance The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

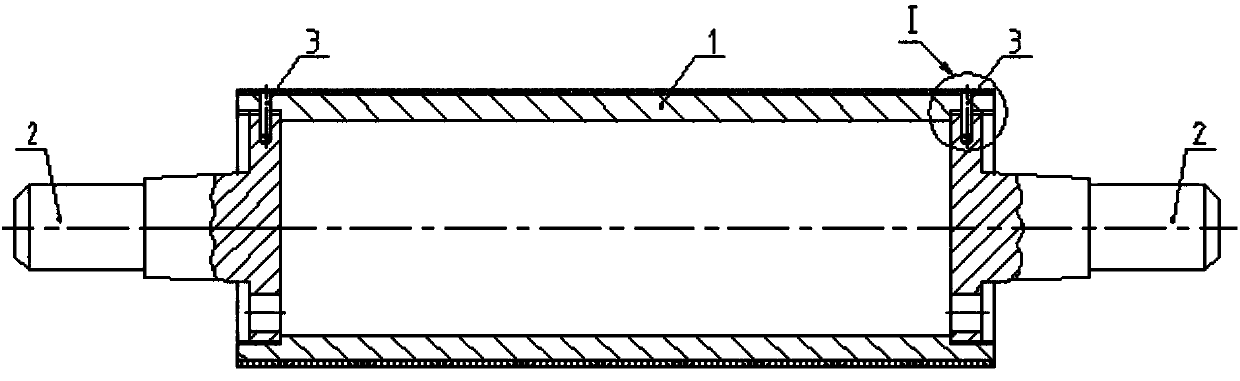

[0016] The high-temperature and wear-resistant hearth roller shown in the accompanying drawing includes a roller 1, two roller shafts 2, and a positioning pin shaft 3; the ends of the roller shaft 2 are provided with external threads, and the ends of the roller 1 are provided with internal thread holes , The external thread at the end of the roller shaft 2 is threadedly connected with the internal threaded hole at the end of the roller 1.

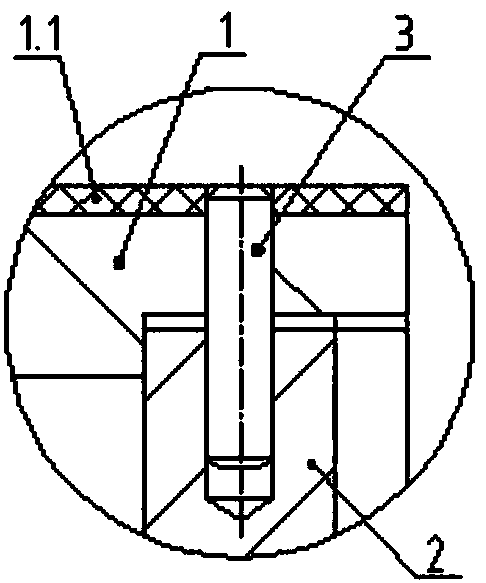

[0017] The positioning pin shaft 3 radially penetrates the inner threaded hole wall at the end of the roller 1 and is inserted into the end of the roller shaft 2 .

[0018] The surface of the roller 1 is provided with a high-temperature oxidation-resistant wear-resistant coating 1.1. In this embodiment, the high-temperature oxidation-resistant wear-resistant coating 1.1 is a MCrAlY coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com