Integrated manufacturing method of microminiature parts based on surface coating

A technology of surface coating and manufacturing method, which is applied in the direction of coating, sputtering coating, vacuum evaporation coating, etc., can solve the problems of low processing precision, small size, single processing material, etc., and achieve improved surface quality and high processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

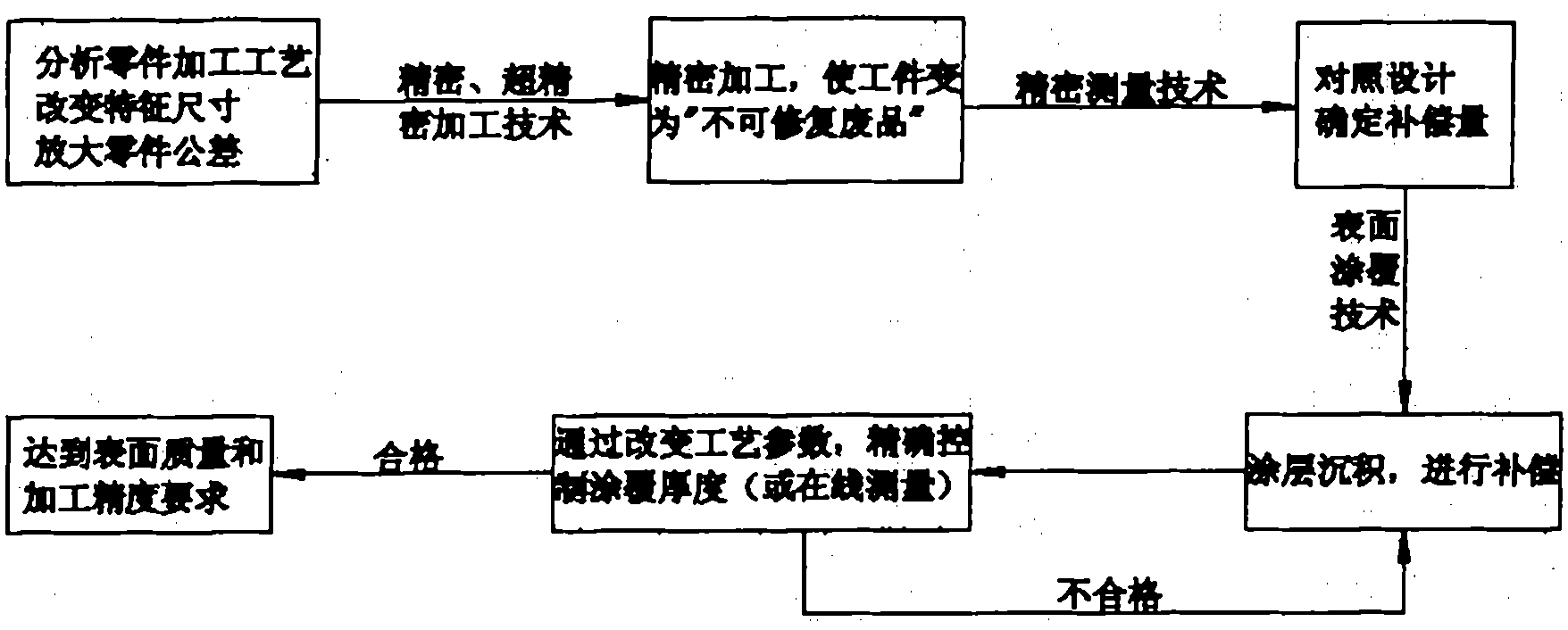

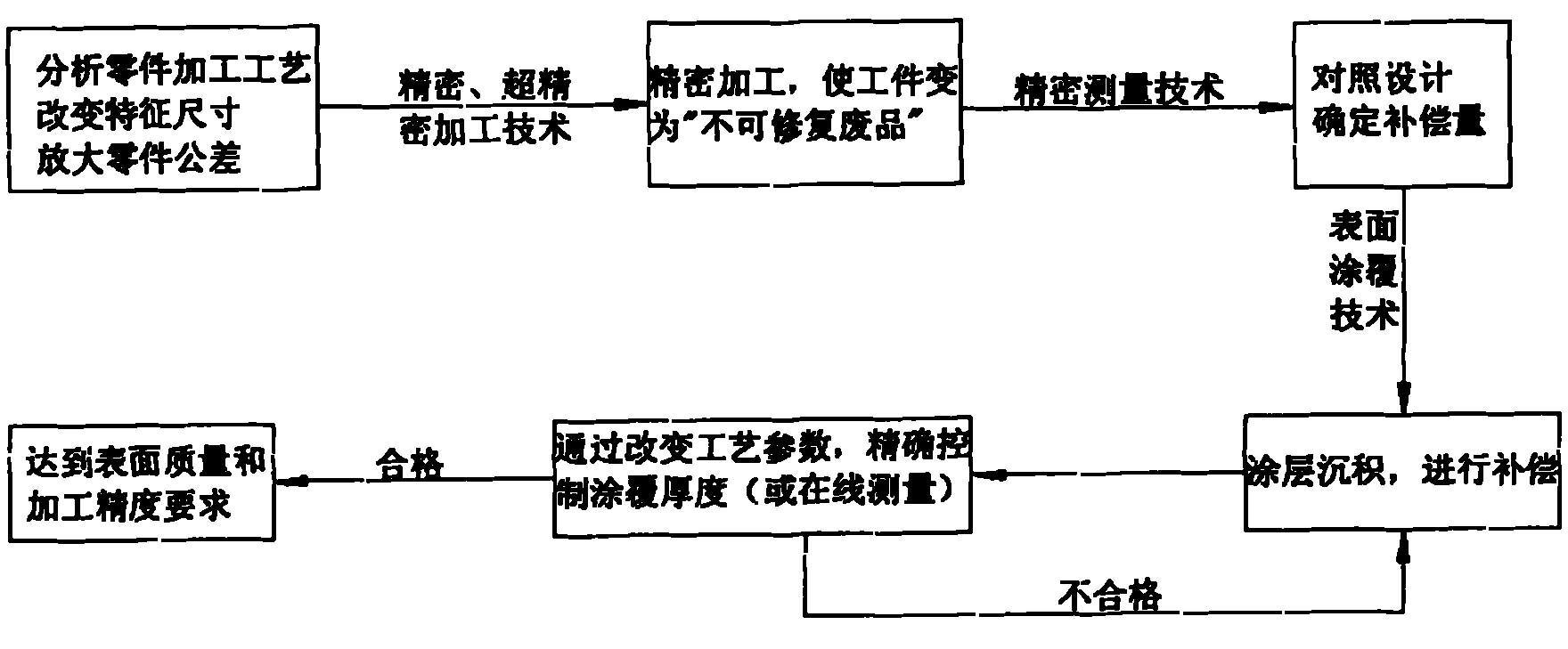

[0016] Below in conjunction with the accompanying drawings, the present invention will be further described in detail by taking the machining material as 45# steel and machining the outer surface of a shaft part with a diameter of 10mm as an example, and requiring certain strength and wear resistance.

[0017] 1) Analyze the machining process on the outer surface of the shaft part. The blank is selected as a round bar with a diameter of 15mm. It is determined to use rough turning, semi-finishing turning, and grinding technology. The machining allowance is 3mm, 1.5mm, and 0.6mm, respectively. To make the tolerance level reach IT7, according to the economical processing accuracy, the manufacturing tolerance of parts can be enlarged by 3-5μm.

[0018] 2) According to the processing technology determined in the previous step, carry out rough turning, fine turning processing, and then grinding processing, so that the parts become irreparable waste products.

[0019] 3) Use the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com