Turbine blade assembly thermal barrier coating and preparation method thereof

A technology of turbine blades and thermal barrier coatings, which is applied in the surface coatings containing ceramic layers and its preparation, can solve problems affecting the thermal fatigue performance of holes, accelerate crack extension, thermal fatigue cracks, etc., and achieve long-term stable work, Improve the effect of high temperature oxidation resistance and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

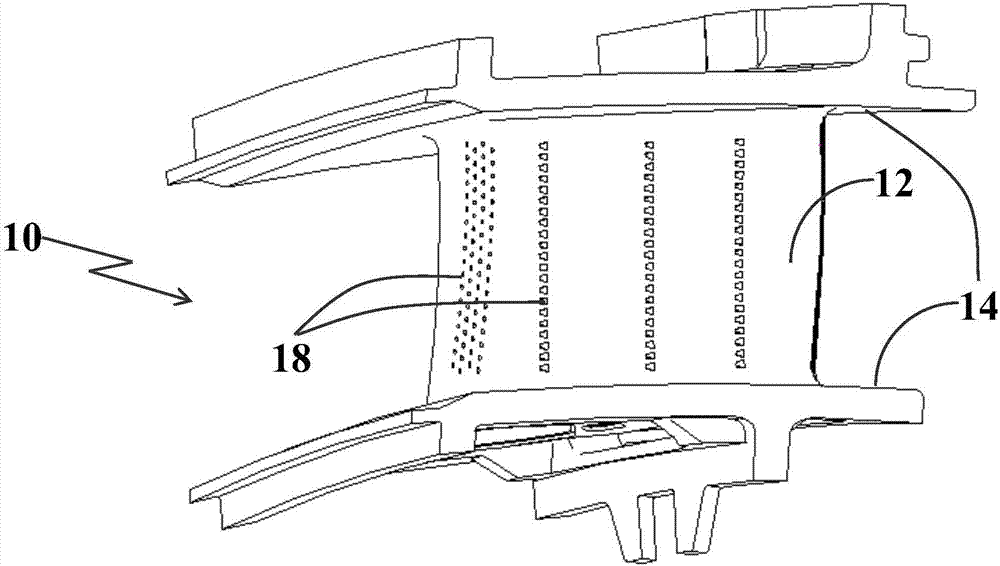

[0047] figure 1 is a perspective view of a turbine blade. The overall turbine blade 10 includes an airfoil 12 , an edge plate 14 (including upper and lower edge plates) and cooling holes 18 .

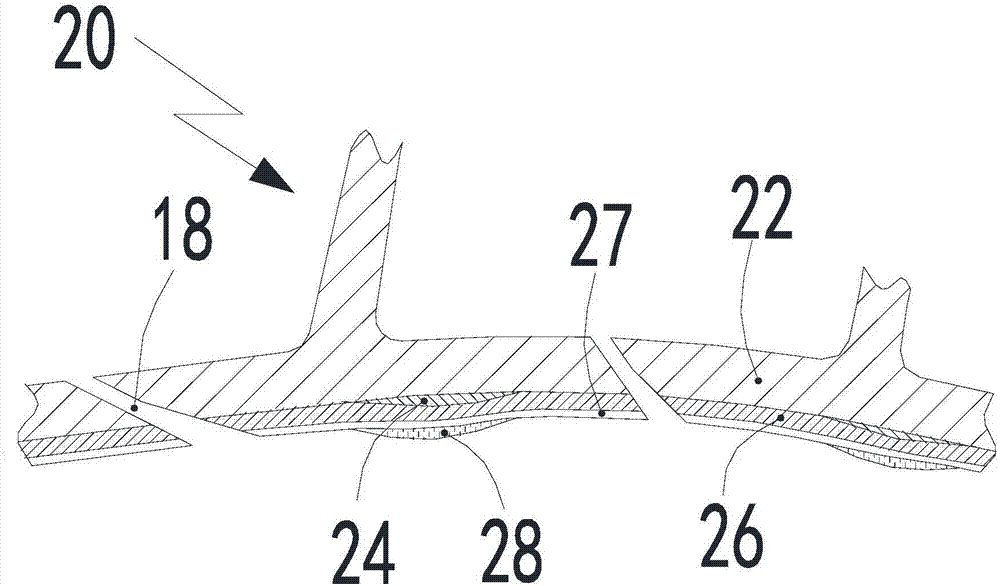

[0048] See figure 2 , this embodiment discloses a thermal barrier coating system for a superalloy substrate. The matrix is a gas turbine guide vane assembly, which mainly serves to provide sufficient strength under high temperature and mixed gas atmosphere, and acts as a structural part. The preparation process of each layer system of the coating mainly includes:

[0049] In the first step, a partial MCrAlY bonding layer is prepared. The selection principle of the application area of the adhesive layer is: firstly, exclude the peripheral area of the cooling hole, and the specific excluded area is the area within about 10 mm on the left and right sides of the cooling hole array. Then select several areas where the temperature of the outer surface of the blade body and the edg...

Embodiment 2

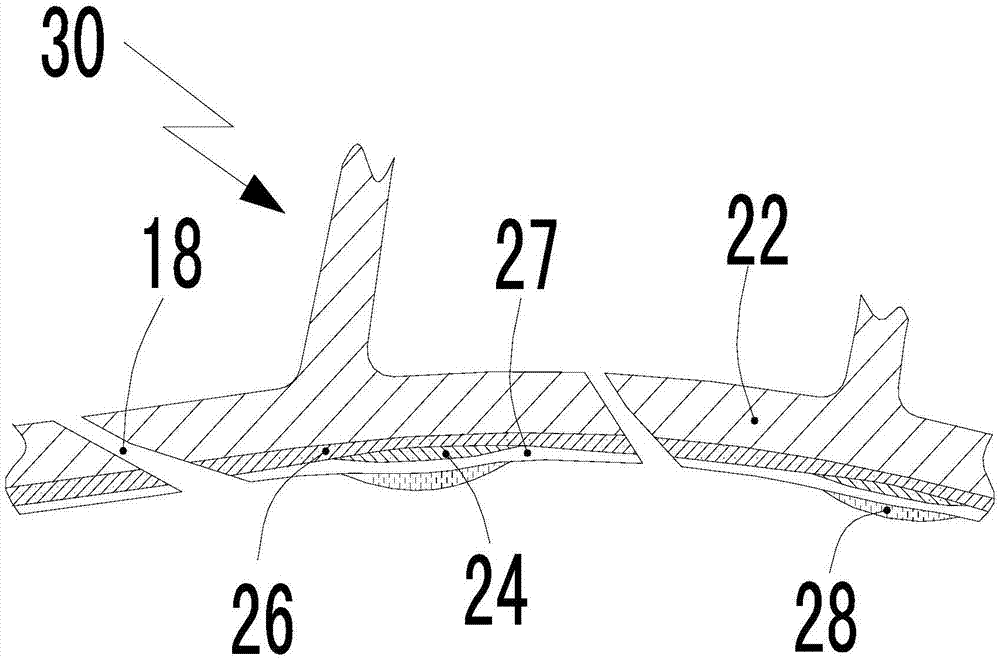

[0058] See image 3 . The matrix is a gas turbine guide vane assembly, which mainly serves to provide sufficient strength under high temperature and mixed gas atmosphere, and acts as a structural part. The coating process on the guide vane assembly overall 30 is:

[0059] In the first step, a chemical vapor deposition treatment is applied to the entire airfoil and the outer surface area of the edge plate.

[0060] For the aluminide layer 26 in this embodiment, a platinum-modified aluminide coating is prepared by a typical chemical vapor deposition process in which reaction gases are mixed externally and then fed into the chamber. The specific process steps are as follows: first, a layer of platinum-nickel alloy is electrochemically deposited on the surface of the substrate 22, and then platinum diffusion annealing is performed before chemical vapor deposition aluminizing. The gas phase interface is the β-NiAl sublayer in solid solution of platinum, and the point-like se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com