Micro-nano magnesia flame retardant and preparation method thereof

A magnesium oxide, micro-nano technology, applied in the field of nano-materials, can solve the problems of harmful gas generation and large smoke generation of flame retardants, and achieve excellent flame-retardant effects, stable chemical properties, and good smoke-suppressing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

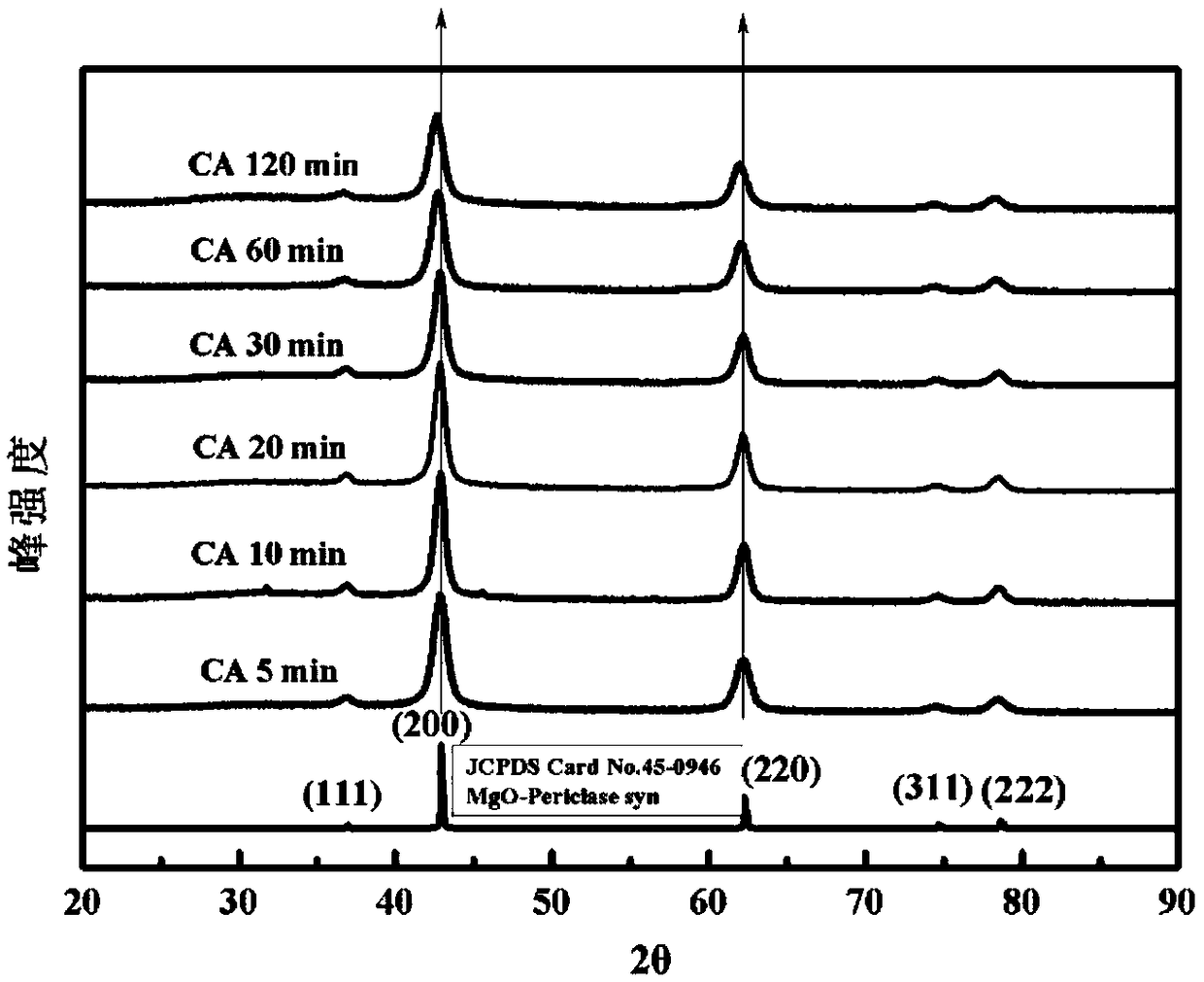

[0027] The preparation method of this flame retardant is as follows:

[0028] Prepare 200mL of aqueous sodium carbonate solution (0.1mol / L) and 200mL of magnesium chloride hexahydrate solution (0.1mol / L) respectively, and add the aqueous sodium carbonate solution dropwise at a rate of 50mL / min to the magnesium chloride hexahydrate solution stirred at a constant speed of 1000rpm ; After the dropwise addition, the mixture was aged in an oven at 90°C for 5 hours; after the aging was completed, the precipitate was filtered out, washed and dried at 30°C for 60 min; after the drying was completed, the precipitate was placed in a muffle furnace for 10 The heating rate of ℃ / min was calcined to 900 ℃, and the temperature was kept for 5 hours to obtain nano-MgO white powder.

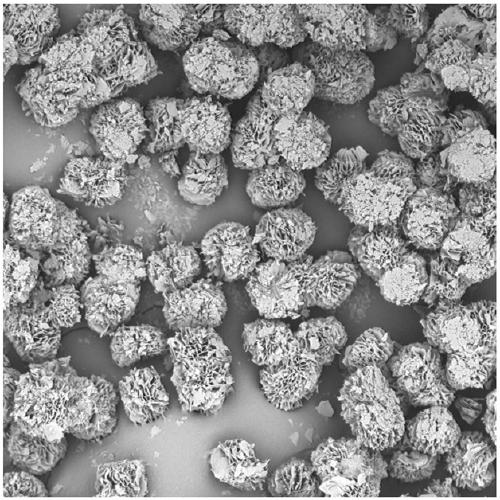

[0029] The MgO white powder was imaged by scanning electron microscope, the results are as follows figure 1 As shown, the microparticles are spherical in structure, stacked by multi-layer nanosheets, similar to f...

Embodiment 2

[0033] The preparation method of this flame retardant is as follows:

[0034] Prepare 200mL of aqueous sodium carbonate solution (0.1mol / L) and 200mL of magnesium chloride hexahydrate solution (0.1mol / L) respectively, and add the aqueous sodium carbonate solution dropwise at a rate of 1mL / min to the magnesium chloride hexahydrate solution stirred at a constant speed of 1000rpm ; After the dropwise addition, the mixture was aged in an oven at 50°C for 5 hours; after the aging was completed, the precipitate was filtered out, washed and dried at 100°C for 60 min; after drying, the precipitate was placed in a muffle furnace, and the Calcining at a heating rate of ℃ / min to 300 ℃ and holding for 0.5h to obtain micron MgO white powder.

[0035] The flame retardant effect test of this flame retardant is as follows:

[0036] MgO was spun into a film with a width of 15mm and a thickness of 0.1mm in the electrospinning solution doped with 5wt% cellulose acetate, and the combustion rate ...

Embodiment 3

[0038] The preparation method of this flame retardant is as follows:

[0039]Prepare 200mL of aqueous sodium carbonate solution (1.5mol / L) and 200mL of magnesium chloride hexahydrate solution (1.5mol / L) respectively, and add the aqueous sodium carbonate solution dropwise at a rate of 1mL / min to the magnesium chloride hexahydrate solution stirred at a constant speed of 1000rpm ; After the dropwise addition, the mixture was aged in an oven at 50°C for 1 h; after the aging was completed, the precipitate was filtered out, washed and dried at 30°C for 60 min; after drying, the precipitate was placed in a muffle furnace, and the The heating rate of ℃ / min was calcined to 900 ℃, and the temperature was kept for 0.5h to obtain nano-MgO white powder.

[0040] The flame retardant effect test of this flame retardant is as follows:

[0041] MgO was spun into a film with a width of 15 mm and a thickness of 0.1 mm in the electrospinning solution doped with 5 wt % of cellulose acetate, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com