Air-cooled hearth roll

A hearth roll, air-cooled technology, applied in the field of hearth rolls, can solve problems such as waste of fuel, difficult maintenance, large investment in circulating water systems, etc., to reduce fuel loss, reduce equipment investment, and improve bearing working conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

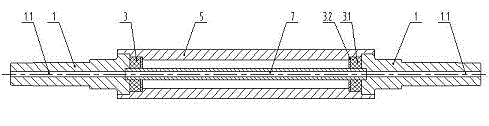

[0013] The air-cooled hearth roller shown in the accompanying drawings includes a roller 5, a sleeve 7, and a roller shaft 1 fixedly connected to the holes at both ends of the roller 5; the sleeve 7 is fixedly connected between the two roller shafts 1, and its The inner hole communicates with the shaft holes 1.1 of the two roller shafts 1 to form a cooling air duct.

[0014] The end of the connecting end of the roller shaft 1 and the roller 5 is provided with a heat insulating structure 3; the heat insulating structure 3 is arranged in the cavity inside the end face of the connecting end of the roller shaft 1 and the roller 5, including a heat insulating filler 3.1 and a baffle 3.2 The baffle plate 3.2 is sealed and connected to the inside of the inner cavity of the end surface connecting the roller shaft 1 and the roller 5, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com