A kind of active powder concrete and preparation method thereof

A technology of active powder and concrete, which is applied in the field of concrete, can solve the problems of low strength and poor heat insulation performance, and achieve the effect of improving heat insulation performance, increasing strength, improving strength and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

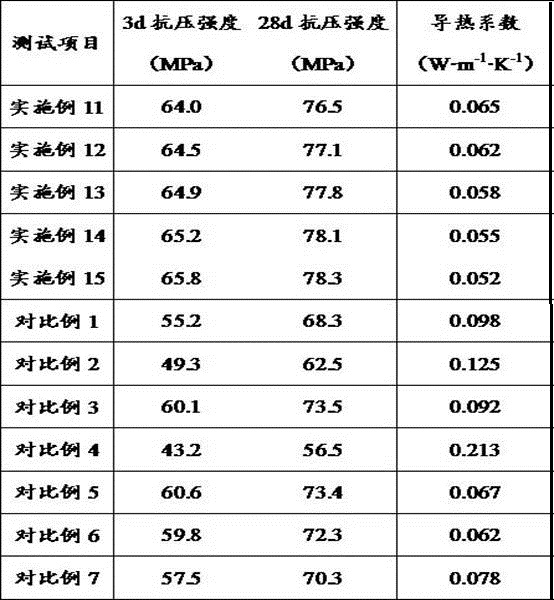

Examples

Embodiment 1

[0022] This embodiment provides a kind of active powder concrete, and its preparation method comprises the following steps:

[0023] S1. Weigh 40kg of cement, 5kg of fly ash, 5kg of modified glass fiber, 1kg of antimony tin oxide, 0.1kg of water reducer, and 15kg of water, and set aside; wherein, the cement is commercially available P.O 42.5R ordinary Portland cement; The water agent is an equal mass ratio mixture of commercially available polycarboxylate water reducer and naphthalenesulfonate water reducer.

[0024] In addition, nano-inorganic materials are electrostatically adsorbed on the surface of the modified glass fiber, and the modification method includes the following steps:

[0025] (1) Nano silicon dioxide with an average particle size of 10 nm and nano titanium dioxide with an average particle size of 10 nm are mixed according to a mass ratio of 4:6 to obtain a nano inorganic material.

[0026] (2) Mix the nano-inorganic material and the booster to obtain a modif...

Embodiment 2

[0030] This embodiment provides a kind of active powder concrete, and its preparation method comprises the following steps:

[0031] S1. Weigh 60kg of cement, 15kg of fly ash, 10kg of modified glass fiber, 5kg of antimony tin oxide, 2kg of water reducing agent, and 5kg of water, and set aside; wherein, the cement is commercially available P.O 42.5R ordinary Portland cement; The agent is a commercially available polycarboxylate water reducer.

[0032] In addition, nano-inorganic materials are electrostatically adsorbed on the surface of the modified glass fiber, and the modification method includes the following steps:

[0033] (1) Nano silicon dioxide with an average particle size of 100 nm and nano titanium dioxide with an average particle size of 100 nm are mixed according to a mass ratio of 6:4 to obtain a nano inorganic material.

[0034] (2) Mixing the nano-inorganic material and the charging agent to obtain a modified powder; wherein, the weight of the charging agent is...

Embodiment 3

[0038] This embodiment provides a kind of active powder concrete, and its preparation method comprises the following steps:

[0039] S1. Weigh 42kg of cement, 7kg of fly ash, 6kg of modified glass fiber, 2kg of antimony tin oxide, 0.2kg of water reducer, and 6kg of water, and set aside; wherein, the cement is commercially available P.O 42.5R ordinary Portland cement; The water agent is a commercially available naphthalenesulfonate water reducer.

[0040] In addition, nano-inorganic materials are electrostatically adsorbed on the surface of the modified glass fiber, and the modification method includes the following steps:

[0041] (1) Nano silicon dioxide with an average particle size of 20 nm and nano titanium dioxide with an average particle size of 30 nm are mixed according to a mass ratio of 4.5:5.5 to obtain a nano inorganic material.

[0042] (2) Mix the nano-inorganic material and the booster to obtain a modified powder; wherein, the mass of the booster is 0.2% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com