Welding method for corner weld joint of Q690qD bridge steel box type rod piece

A welding method and welding direction technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as poor weldability, relatively harsh requirements, and reduced mechanical properties of yield strength, tensile strength, and elongation. Strong operability, reduced welding torsional deformation, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

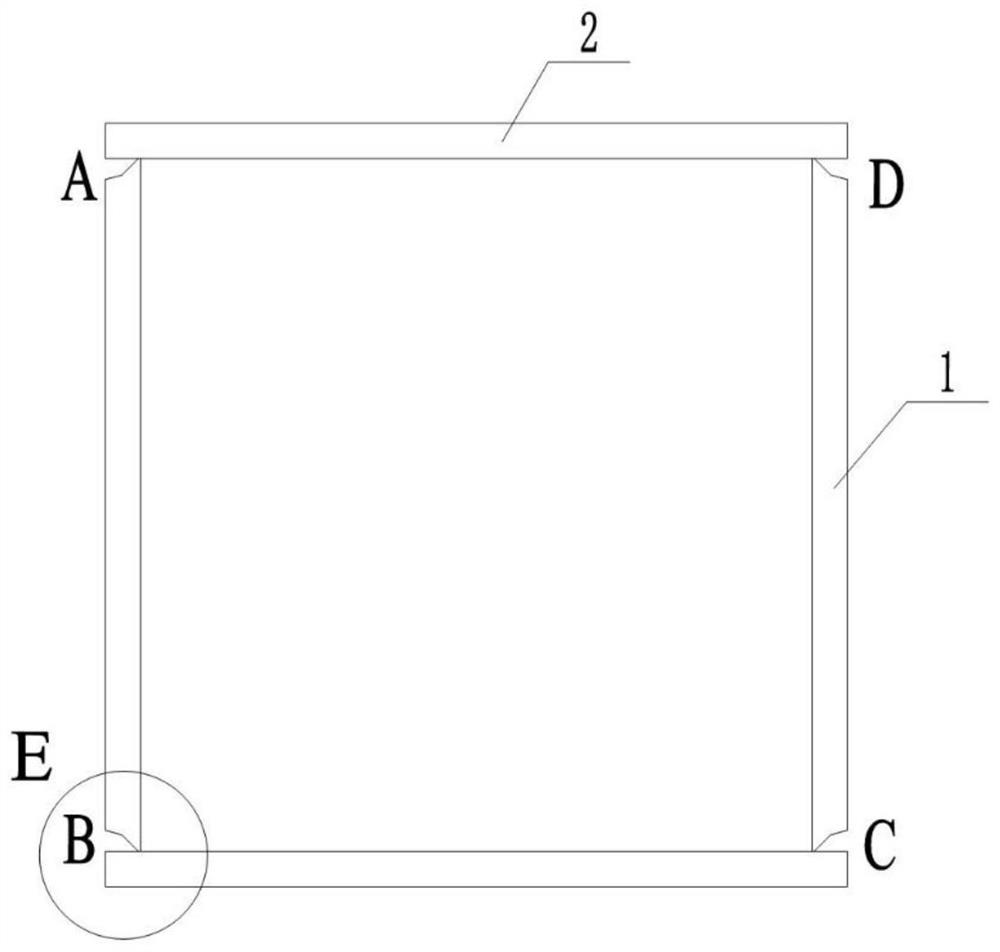

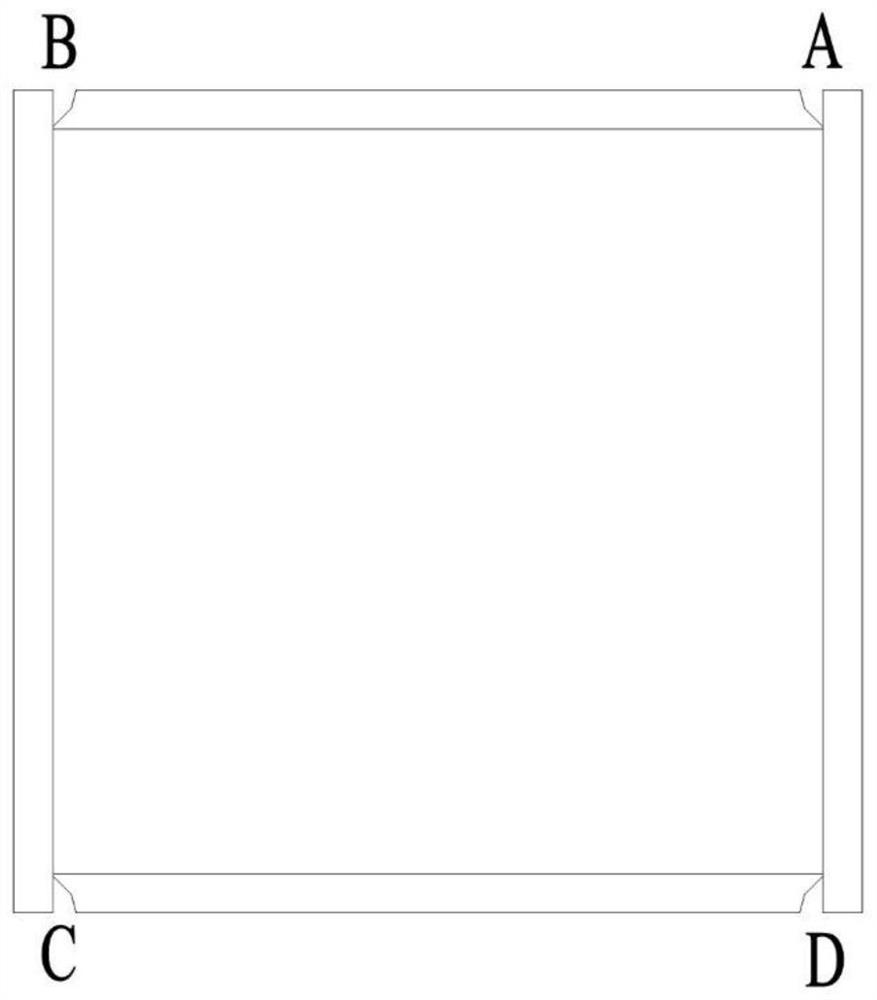

[0029] see also figure 1 ~ FIG. 3 , an embodiment of the present invention provides a welding method for a Q690qD bridge steel box-shaped edge weld. The Q690qD bridge steel box-shaped member consists of webs 1 on both sides and a cover plate 2 located on the upper and lower end faces of the web 1. The web 1 and the cover 2 are made of the same material, the thicknesses of the web 1 and the cover 2 are both 30-60 mm, and the edge weld between the cover 2 and the web 1 is a single-sided partial penetration weld , the welding method includes the following steps:

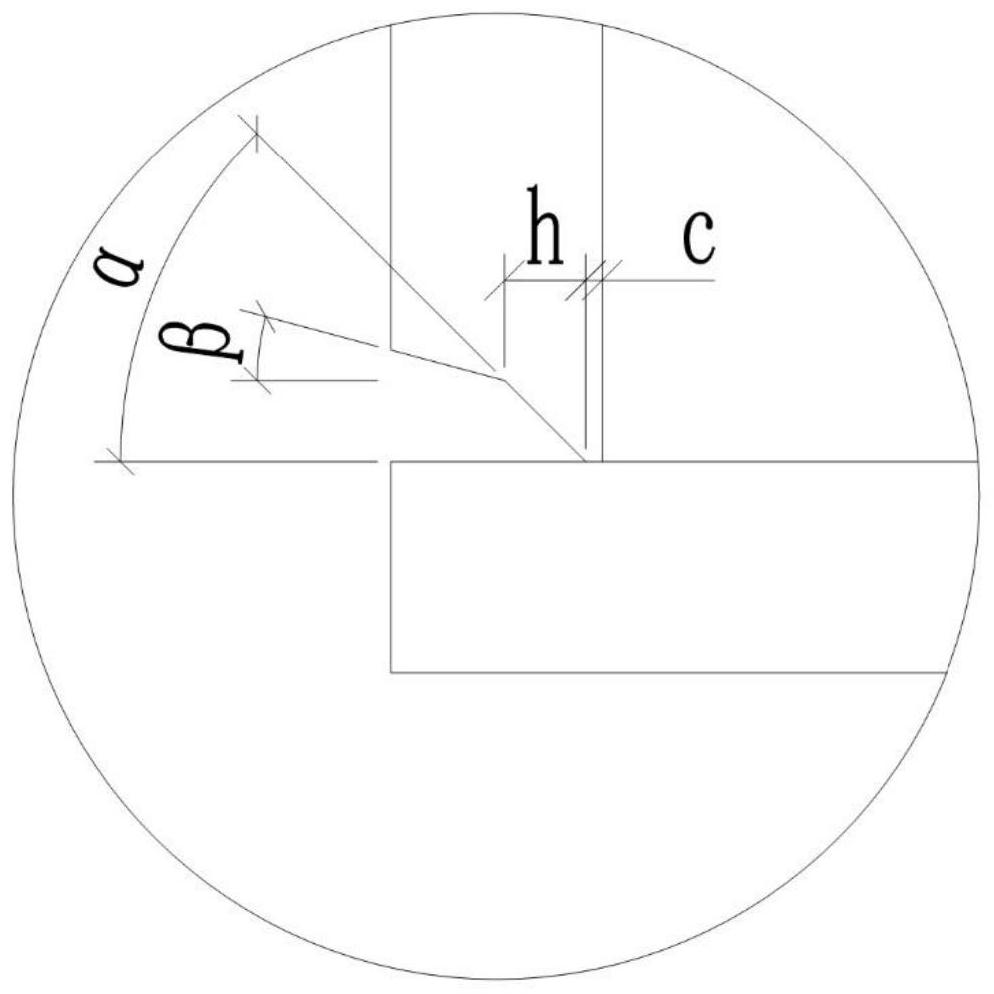

[0030] S1: The two long sides of the Q690qD bridge steel box-shaped member web are symmetrically machined out of the groove, and the groove shape is a unilateral double V-shaped groove with a blunt edge. The blunt edge thickness c of the V-shaped groove is 2mm; the β angle of the upper V-shaped groove is 10°, and the setting of this angle can reduce the filling amount; the α angle of the lower V-shaped groove is 45°, a...

Embodiment 2

[0042] see also figure 1 ~ FIG. 3 , an embodiment of the present invention provides a welding method for a Q690qD bridge steel box-shaped edge weld. The Q690qD bridge steel box-shaped member consists of webs 1 on both sides and a cover plate 2 located on the upper and lower end faces of the web 1. The web 1 and the cover 2 are made of the same material, the thicknesses of the web 1 and the cover 2 are both 30-60 mm, and the edge weld between the cover 2 and the web 1 is a single-sided partial penetration weld , the welding method includes the following steps:

[0043] S1: The two long sides of the Q690qD bridge steel box-shaped member web are symmetrically machined out of the groove, and the groove shape is a unilateral double V-shaped groove with a blunt edge. The blunt edge thickness c of the V-shaped groove is 4mm; the β angle of the upper V-shaped groove is 13°, and the setting of this angle can reduce the filling amount; the α angle of the lower V-shaped groove is 50°, a...

Embodiment 3

[0055] see also figure 1 ~ FIG. 3 , an embodiment of the present invention provides a welding method for a Q690qD bridge steel box-shaped edge weld. The Q690qD bridge steel box-shaped member consists of webs 1 on both sides and a cover plate 2 located on the upper end face of the web 1. The web 1 and the cover 2 are made of the same material, the thicknesses of the web 1 and the cover 2 are both 30-60 mm, and the edge weld between the cover 2 and the web 1 is a single-sided partial penetration weld , the welding method includes the following steps:

[0056] S1: The two long sides of the Q690qD bridge steel box-shaped member web are symmetrically machined out of the groove, and the groove shape is a unilateral double V-shaped groove with a blunt edge. The blunt edge thickness c of the V-shaped groove is 6mm; the β angle of the upper V-shaped groove is 15°, and the setting of this angle can reduce the filling amount; the α angle of the lower V-shaped groove is 55°, and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com