Passive containment condensate injection system

A passive containment and injection system technology, applied in the field of passive containment condensate water injection system, can solve the problems of pressure vessel failure uncertainty, reactor safety risk, etc., and achieve lower temperature, simple structure, and prevent melt-through Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

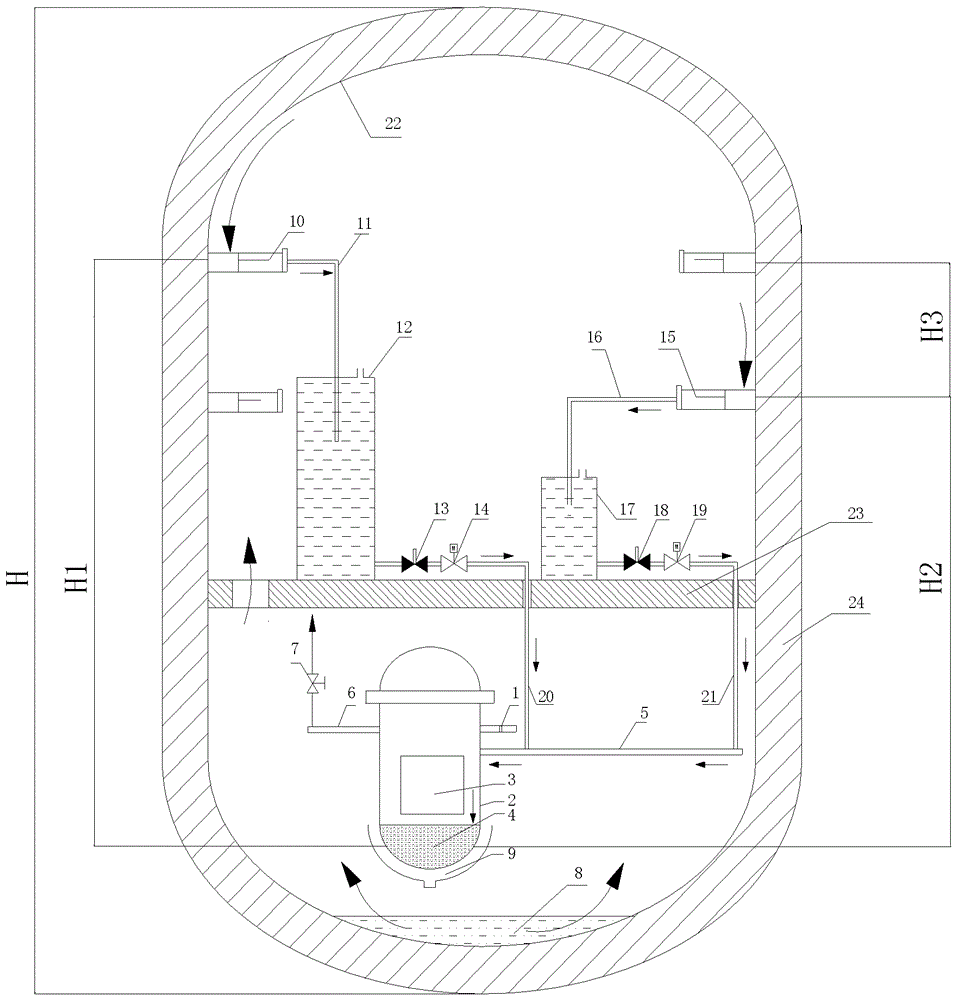

[0051] figure 1 It is a structural schematic diagram of a passive containment condensate water injection system arranged in the containment vessel 24 according to the first embodiment of the present invention (there are emergency water injection tanks 12, 17).

[0052] Such as figure 1 As shown, a nuclear reactor with a breach 1 , a reactor pressure vessel 2 , a core 3 , a pit 8 , and an internal melt retention-pressure vessel external cooling system (IVR-ERVC) 9 is contained in a containment vessel 24 . The operation platform 23 divides the inside of the containment vessel 24 into two inner spaces, upper and lower. The passive containment condensate injection system includes two sets of condensate collection structures, which are arranged between the top of the straight wall of the containment vessel 24 and the operation platform 23 . Among them, the high-level condensate collection structure (first height) is composed of a water collection groove 10 and a collection condui...

Embodiment 2

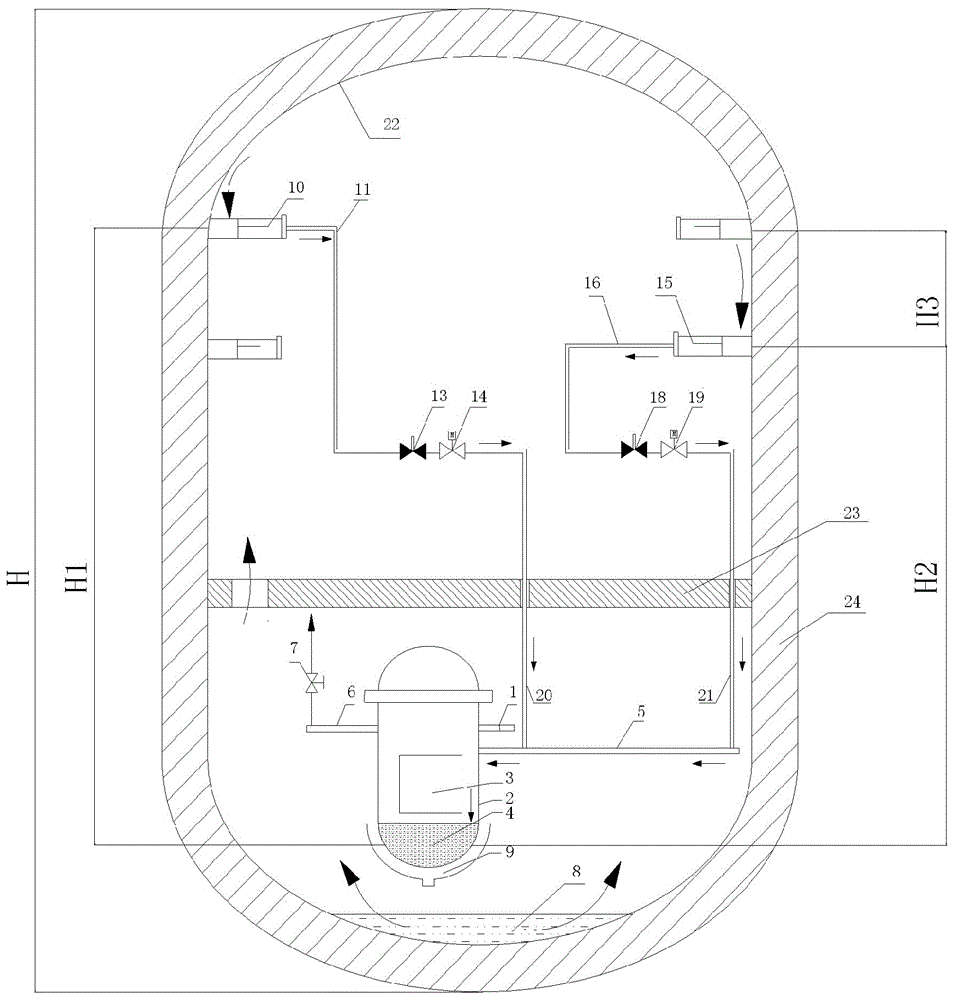

[0058] figure 2 It is a structural schematic diagram of a passive containment condensate water injection system arranged in the containment vessel 24 according to the second embodiment of the present invention (without an emergency water injection tank).

[0059] The present invention also provides another passive containment condensate water injection system, such as figure 2 shown. The main difference between this water injection system and Embodiment 1 is that the system is slightly modified, the structure is simplified, and the optional emergency water injection tanks 17 and 12 are removed. At the same time, the collection heights of the condensed water at two places were changed. The first height H1 and the second height H2 are respectively located at 75% of the total height H of the containment vessel (near the top of the straight cylinder wall) and 50% of the reactor core level. In Example 1, the height is increased and is in a high position. Containment condensate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com