Iron oxide scale sample preparation method and detection method

A technology of iron oxide scale and alumina, which is applied in the field of steelmaking, can solve problems such as incomplete structure, poor structural hardness and mechanical strength, and structural damage, and achieve the effects of reducing shrinkage, optimizing electrical conductivity, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

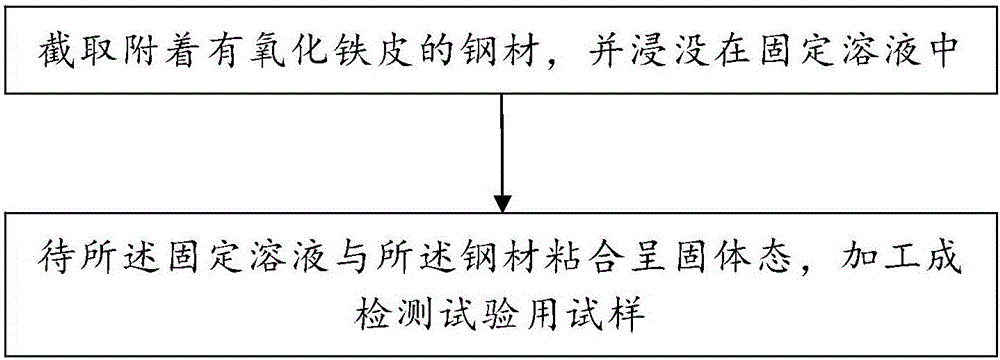

Method used

Image

Examples

Embodiment 1~ Embodiment 12

[0069] Cut off the hot-rolled wire rod with well-preserved iron oxide scale, the length is 80mm.

[0070] Put the obtained wire rod into a plastic water pipe with a diameter of 30mm, the length of the water pipe is not less than the length of the wire rod, and one end is sealed with a plug.

[0071] Pour the prepared solution into a plastic water pipe to submerge the wire rod, and let it stand at room temperature (0°C to 40°C) for 120min to 320min. The solution and the wire rod are tightly bonded to form a hard solid.

[0072] Remove the sealing plug at the bottom of the plastic tube, take out the cured wire rod, cut off the required metallographic sample length by wire cutting, and then grind and polish it.

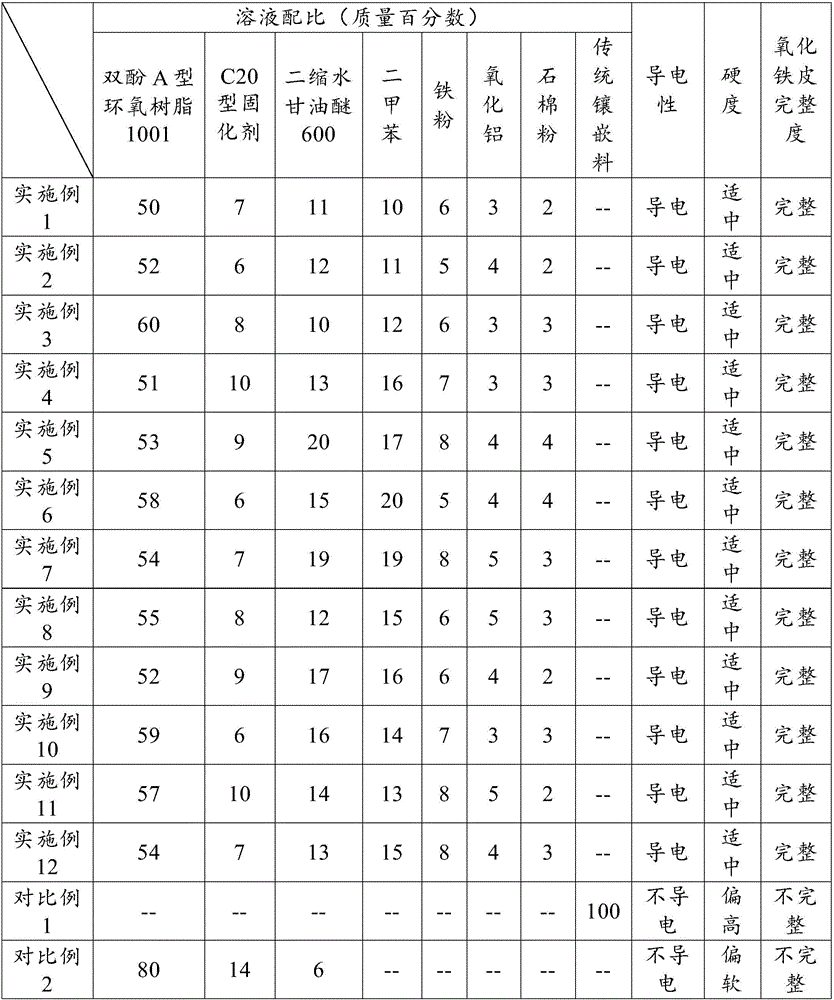

[0073] See Table 1, the solution ratio and effects of Examples 1-12.

[0074] Comparative example 1-2 mosaic material ratio and effect.

[0075] Among them, comparative example 1 is traditional metallographic inlay, and comparative example 2 is cold inlay.

[0076] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com