Integrally-formed explosion-proof membrane used on top cover of automobile lithium battery, and preparation method for explosion-proof membrane

A technology of lithium batteries and explosion-proof membranes, which is applied to battery pack parts, circuits, electrical components, etc., to achieve the effects of high industrial automation, high product qualification rate, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing an explosion-proof film integrally formed on the top cover of an automobile lithium battery, which specifically includes the following steps:

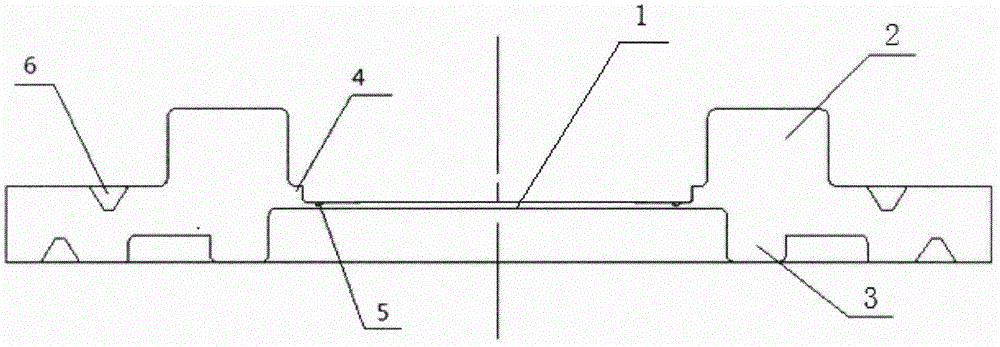

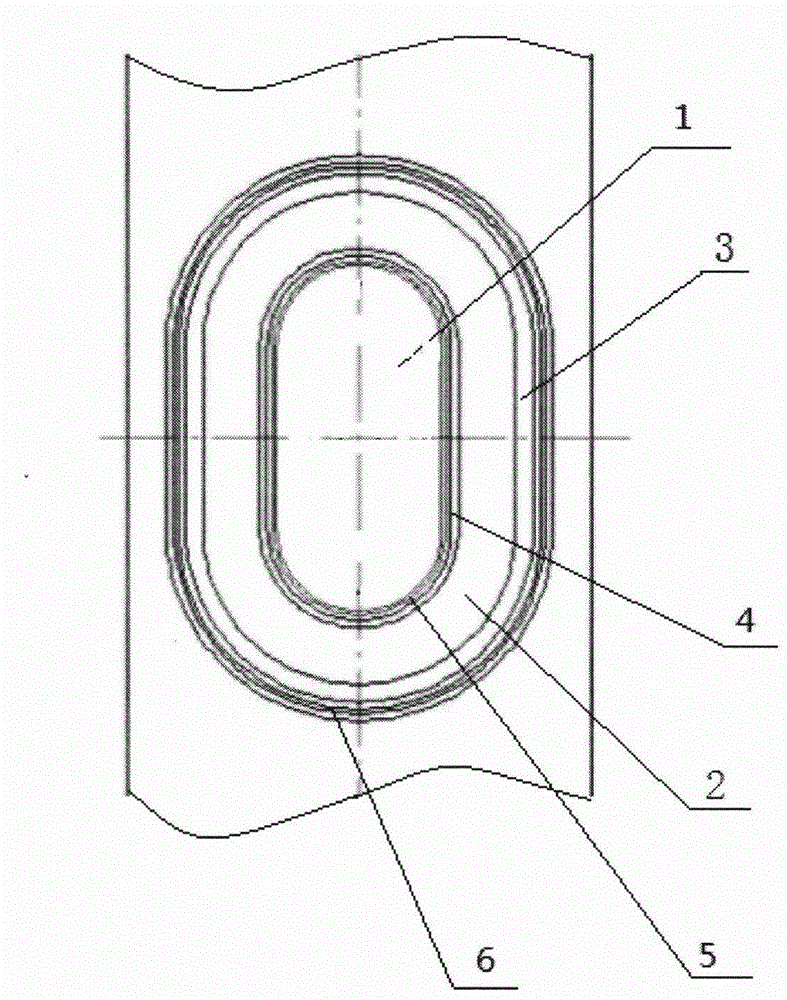

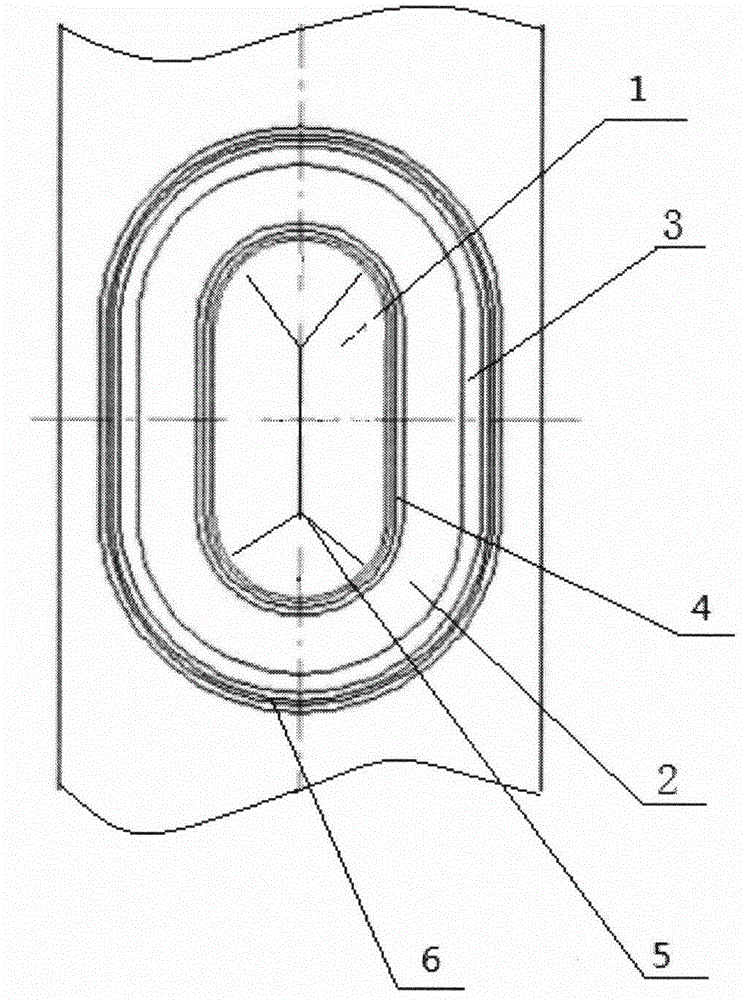

[0040] ①Upper and lower forming: Preliminarily press the entire flat cuboid lithium battery top cover, press the middle of the lower surface into an oval groove, and extrude the protruding material to the upper surface to form an oval wall 2; the initial shape of the integrally formed explosion-proof membrane product Finish.

[0041] ② Stamping forming: the outer side of the oval wall 2 of the product formed in step ① and the upper and lower sides connected to the top cover of the lithium battery have trapezoidal grooves 6 formed by pressure ribs. 0.2mm and a height of 0.6mm, the two sides of the trapezoidal groove 6 form an included angle of about 67°. It plays the role of fixing the shape of the entire explosion-proof membrane and avoids changing the shape of the explosion-proof membrane in the next pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com