Grinding apparatus for cultivating edible fungus

A technology for edible fungi and grinding debris, applied in cultivation, plant cultivation, mushroom cultivation and other directions, can solve the problems of increasing the labor intensity of operators, low production rate, increased energy consumption, etc., and achieve the effect of improving the generation rate of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

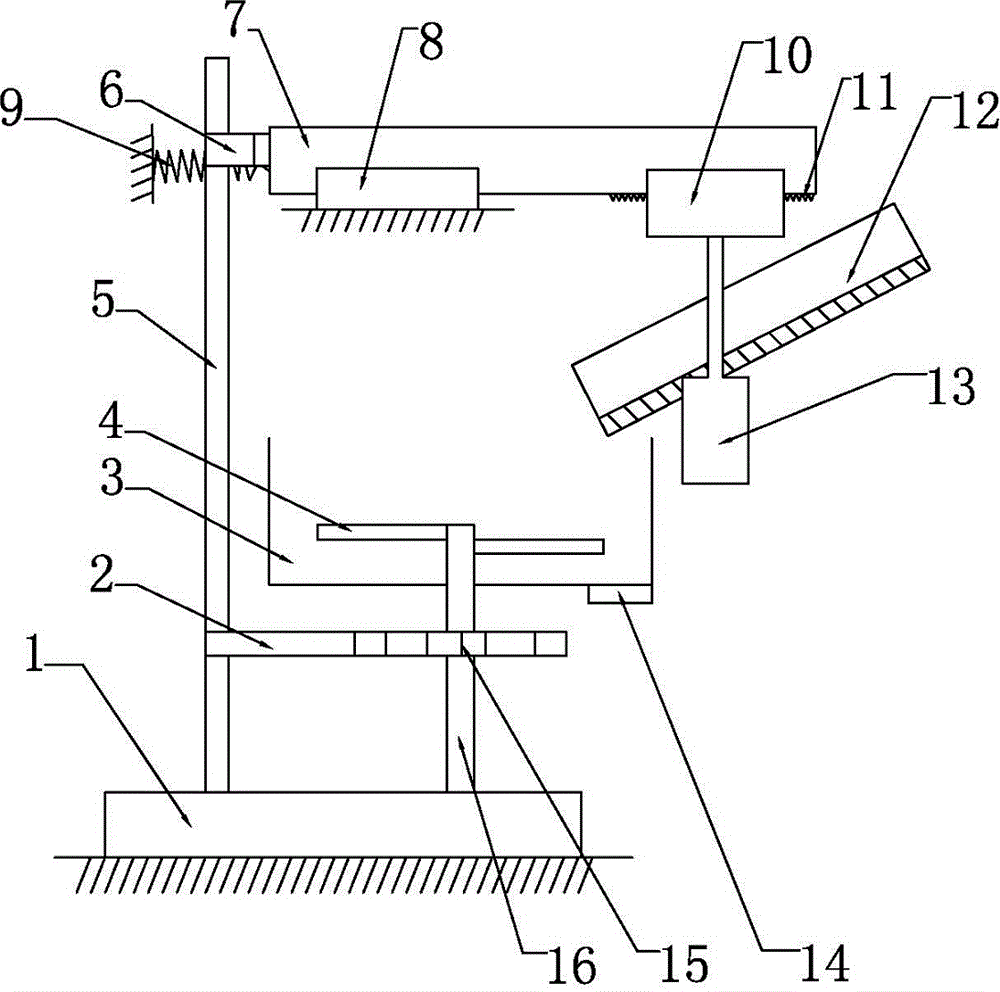

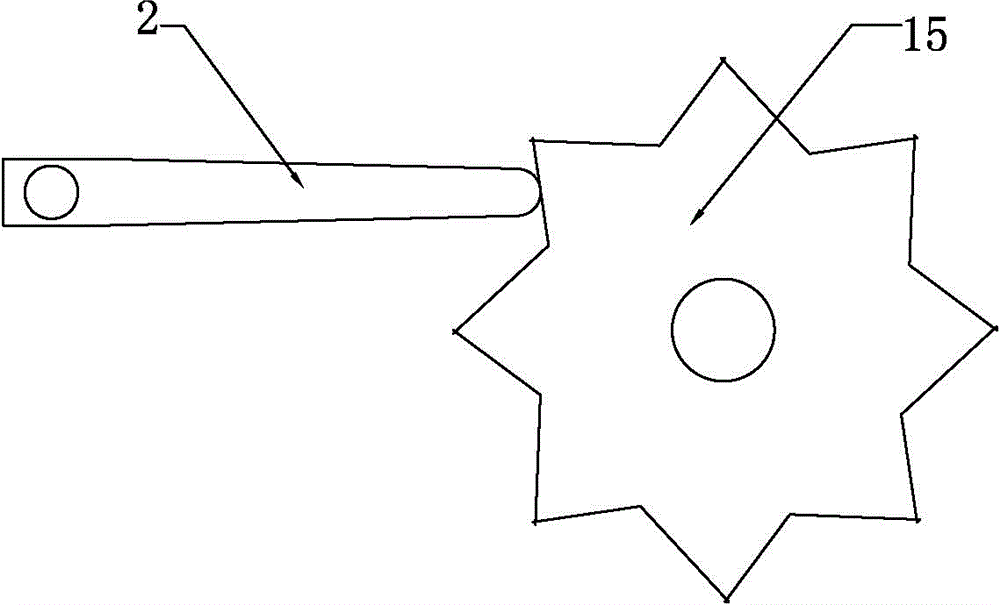

[0018] The reference signs in the drawings of the description include: base 1, swing rod 2, material collecting tank 3, rotary knife 4, main rotating rod 5, ram 6, slider 7, chute 8, spring 9, material tank 10 , Sawtooth 11, guide groove 12, cylinder 13, cover 14, cam 15, drive rotating rod 16.

[0019] The embodiment is basically as attached figure 1 Shown: a grinding device for cultivating edible fungi, including a base 1, the left and right sides of the base 1 are rotatably connected with a main rotating rod 5 and a driving rotating rod 16, and the driving rotating rod 16 is fixedly connected with a cam 15 and a cam 15 The peripheral surface is provided with continuous triangular teeth, the main rotating rod 5 is fixedly connected with a swing rod 2, one side of the swing rod 2 is offset against the cam 15, the main rotating rod 5 is located above the swing rod 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com