Tundish having speed regulation function

A tundish, functional technology, applied in manufacturing tools, casting melt containers, metal processing equipment, etc., can solve problems such as difficulty in calculation and control, and achieve the effect of simple operation and accurate flow rate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

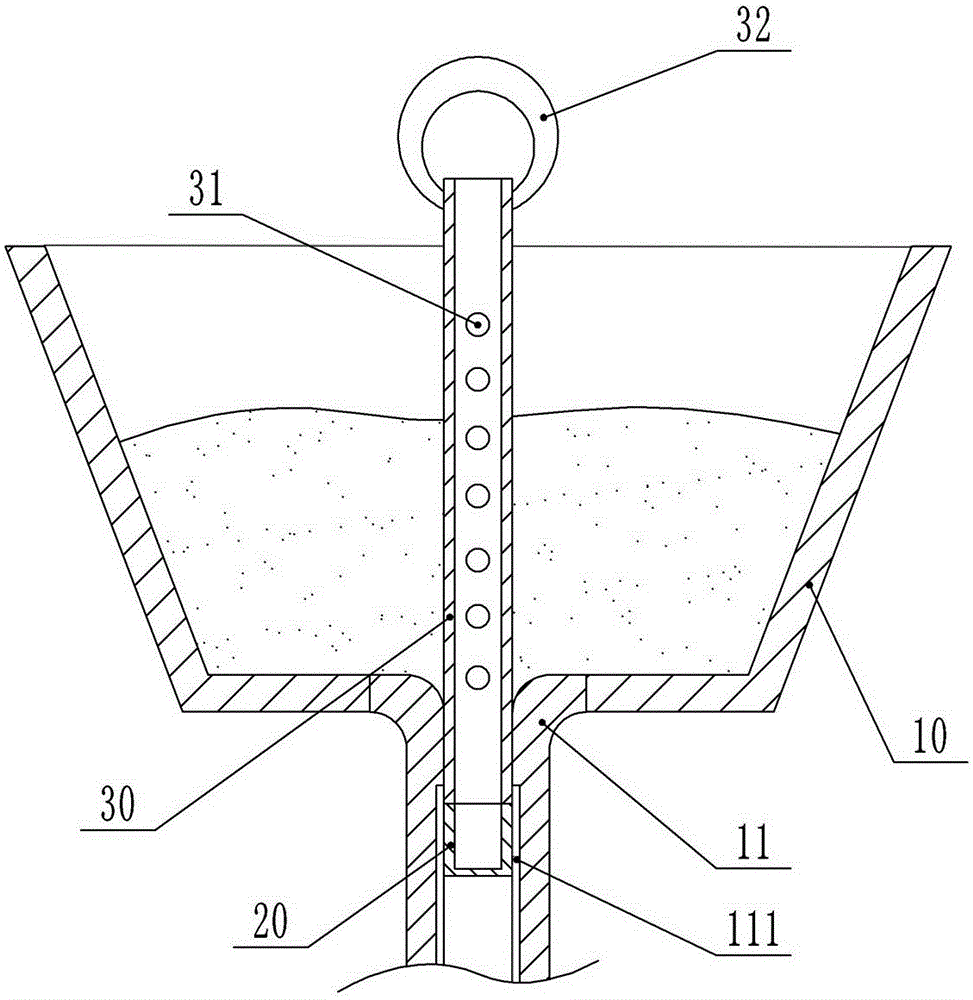

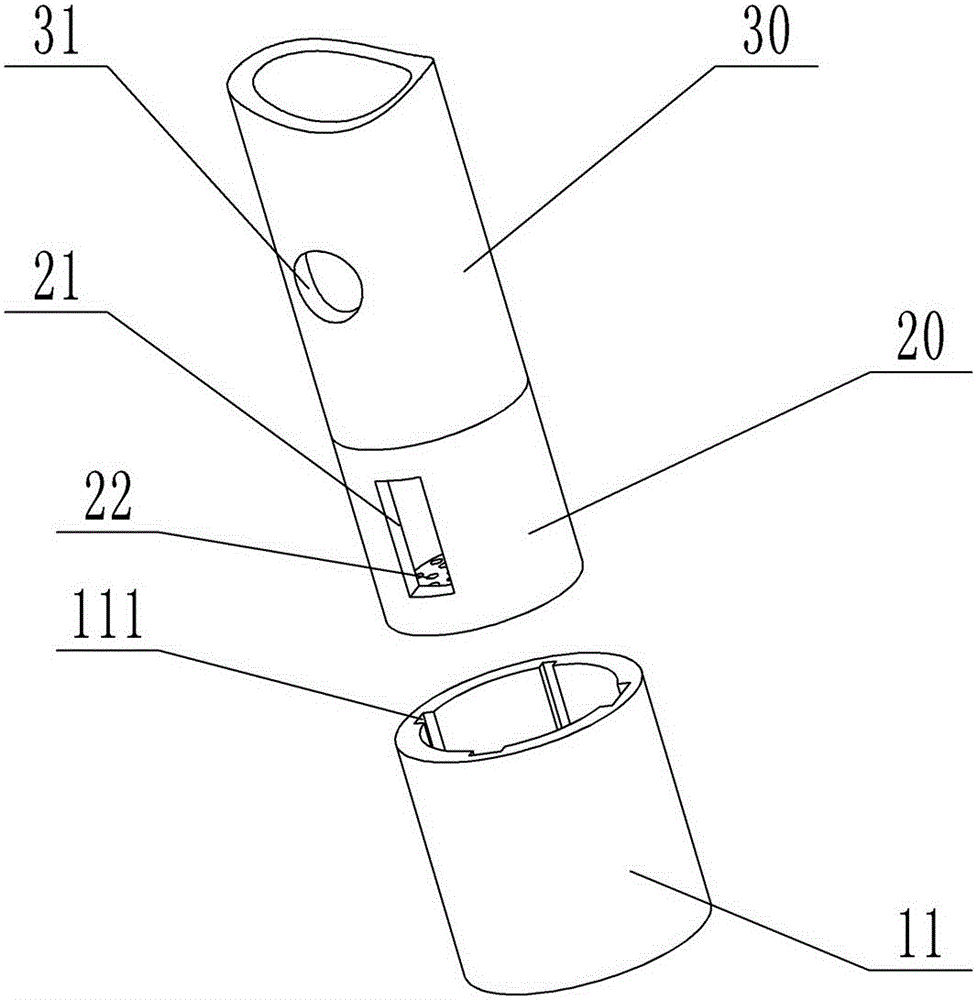

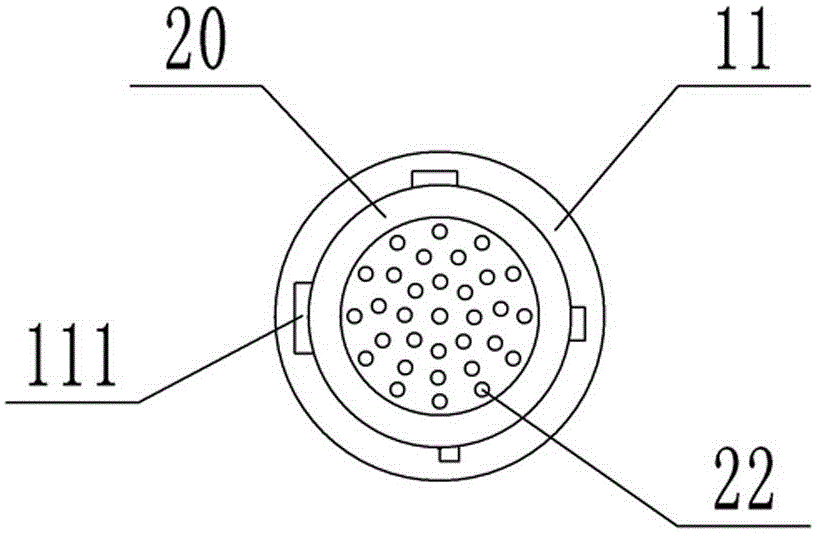

[0016] The reference signs in the drawings of the specification include: tundish body 10, liquid outlet pipe 11, liquid outlet tank 111, stopper 20, liquid outlet 21, through hole 22, stopper rod 30, liquid inlet 31, grip ring 32 .

[0017] Such as figure 1 As shown, the tundish with speed regulating function includes a tundish body 10 , a stopper rod 30 , a liquid outlet pipe 11 and a stopper 20 . A second cavity is processed in the stopper rod 30, and a liquid inlet 31 communicating with the second cavity is also provided on the stopper rod 30. The upper end of the stopper rod 30 is welded with a grip ring 32, and the stopper 20 is welded on the The lower end, and the first cavity communicates with the second cavity.

[0018] Such as figure 2 , image 3 As shown, the block 20 is processed with a first cavity and a liquid outlet 21 communicating with the first cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com