Ultrathin composite core product and production system thereof

A composite core, ultra-thin technology, used in medical science, absorbent pads, underwear, etc., can solve the problems of poor diversion and diffusion performance and comfort, improve quality and wearing comfort, small reverse osmosis, and fluffy the effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

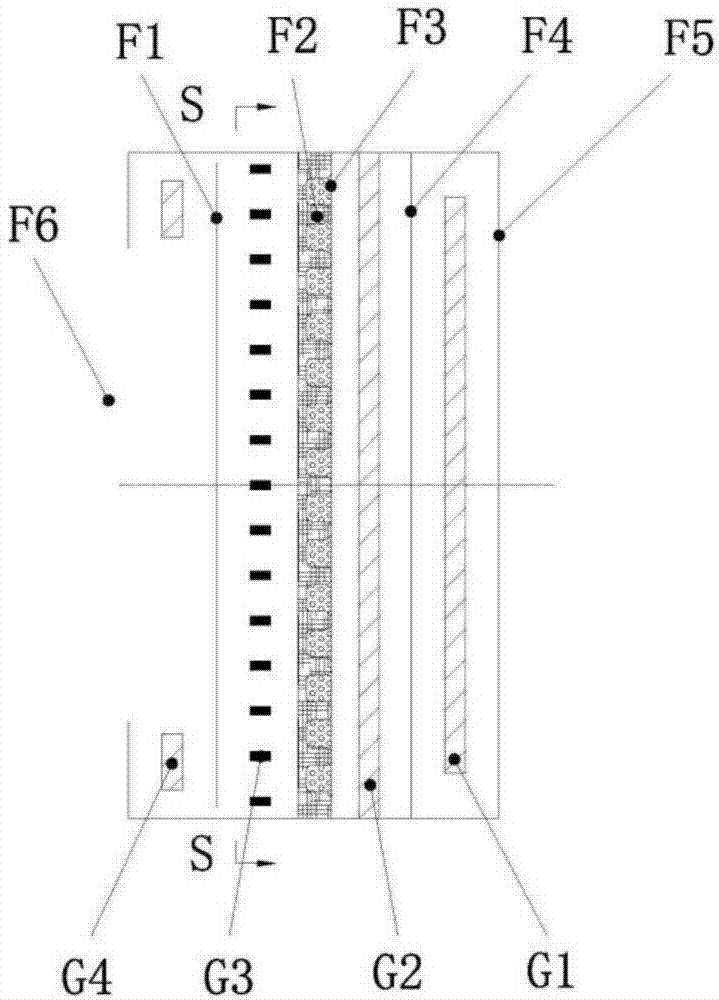

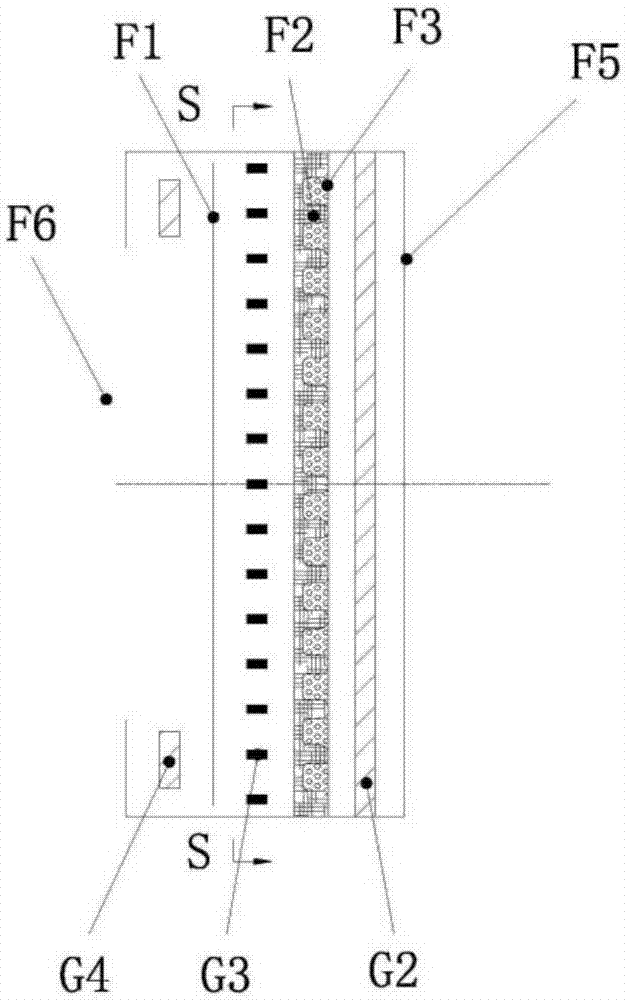

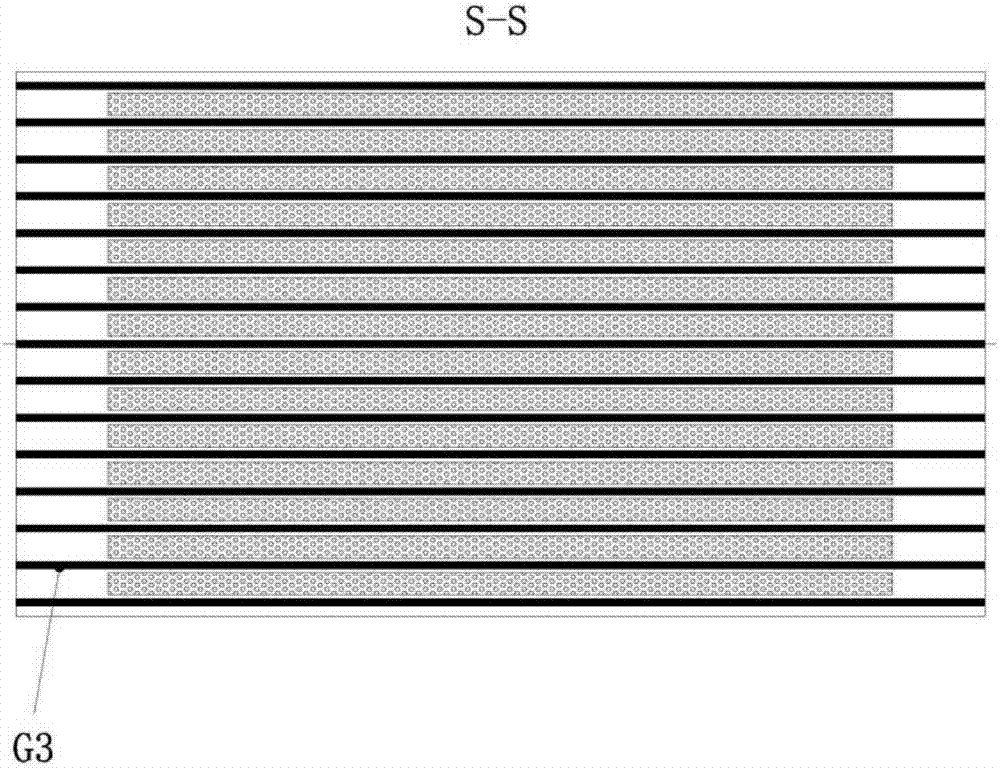

[0065] Such as Figure 6 As shown, the production system for producing the ultra-thin composite core product in this embodiment includes a plurality of pinch driving rollers, a polymer feeding device H, a composite drum device L and a coating device M. The manufacturing system of the present invention has high manufacturing precision, good product molding, and high degree of automation in the online generation process.

[0066] The pinch drive roller is arranged on the upstream or downstream side of the composite drum device L; the pinch drive roll includes a first pinch drive roll C1, a second pinch drive roll C2, a third pinch drive roll C3, the fourth pinch driving roller C4 and the fifth pinching driving roller C5, the first pinching driving roller C1, the second pinching driving roller C2, the third pinching driving roller C3, the fourth pinching driving roller The top rolls of C4 and the fifth pinch drive roll C5 are all pinch rolls, and the bottom rolls are all drive r...

Embodiment 2

[0087] Embodiment two, such as Figure 12 to Figure 13 As shown, the grooved raising device also includes a heating rod N9 arranged in the inner cavity of the drive shaft N3, the diameter of the heating rod N9 in this embodiment is compared with that of the heating rod N9 in Embodiment 1 Slightly thinner, an installation hole for installing the heating rod N9 is arranged on the wall surface of the inner cavity of the drive shaft N3. The heating rod N9 can heat the airflow in the airflow channel.

[0088] The installation and arrangement of the heating rods N9 can be properly selected according to actual needs, and are not limited to the above two arrangements. In the actual application process, one of the above two arrangements of heating rods N9 can be selected.

[0089] The slotting and fluffing device further includes a gas introduction block N5 installed at the end of the ventilation roller N7, and the gas introduction block N5 is communicated with the air duct N6.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com