Composite core and manufacturing device and technology thereof

A technology for manufacturing devices and composite cores, which is applied in medical science, bandages, absorbent pads, etc. It can solve problems such as user discomfort, uneven surfaces, and inability to combine polymer resins uniformly, so as to achieve good product molding and high automation , making high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

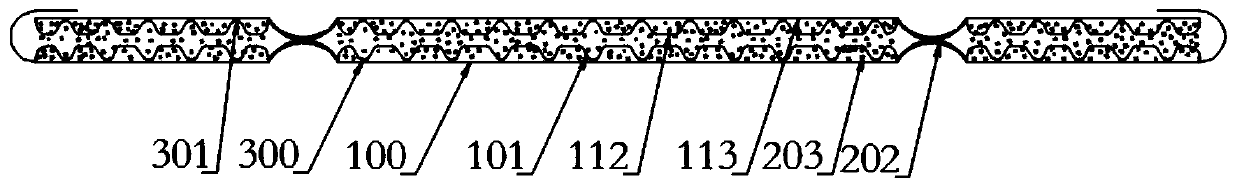

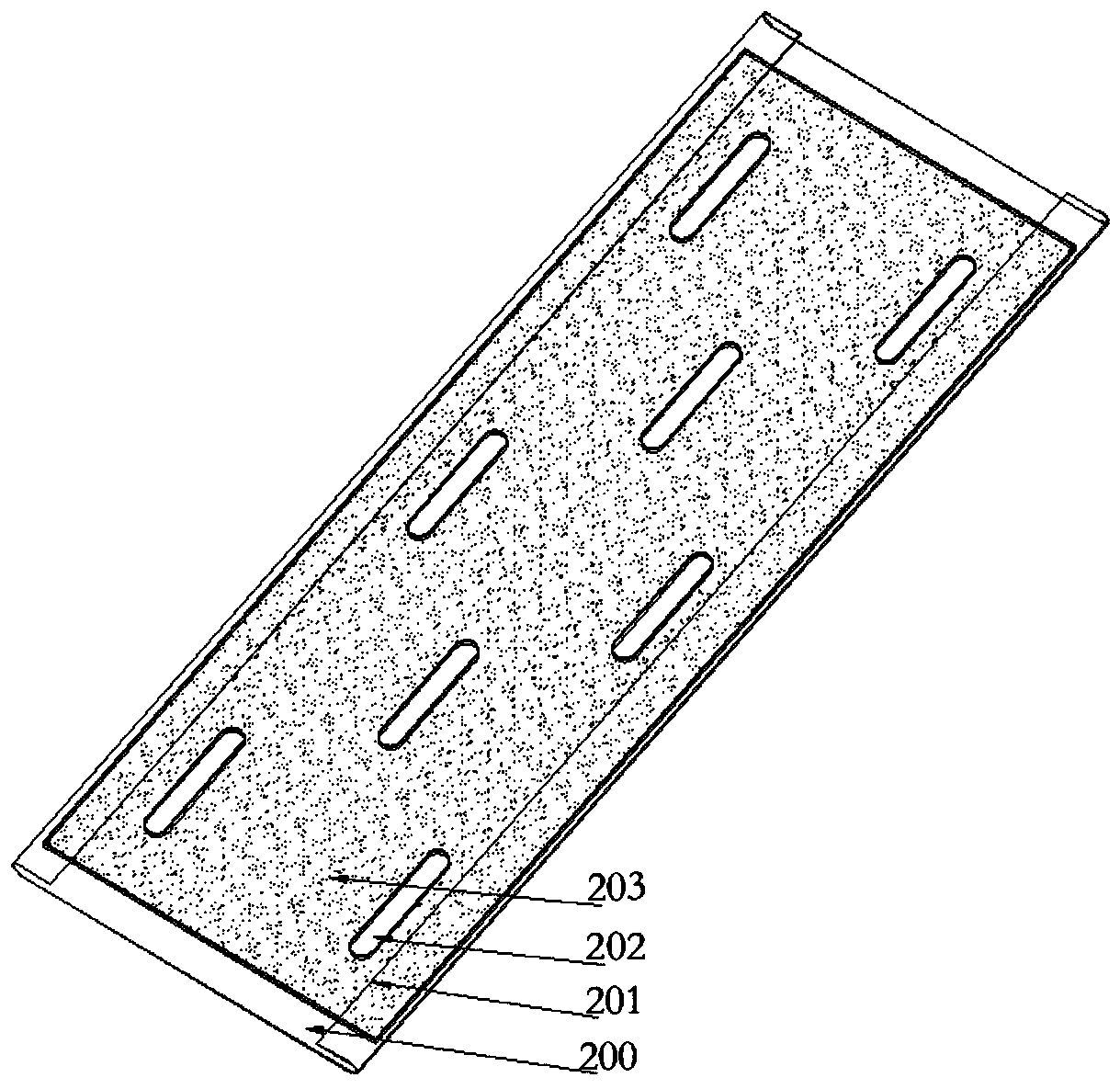

[0055] Such as figure 2 , in this embodiment, the first filler and the second filler are the same, and both are polymer materials 203 .

[0056] The manufacturing process of the composite core of the present embodiment comprises the following steps:

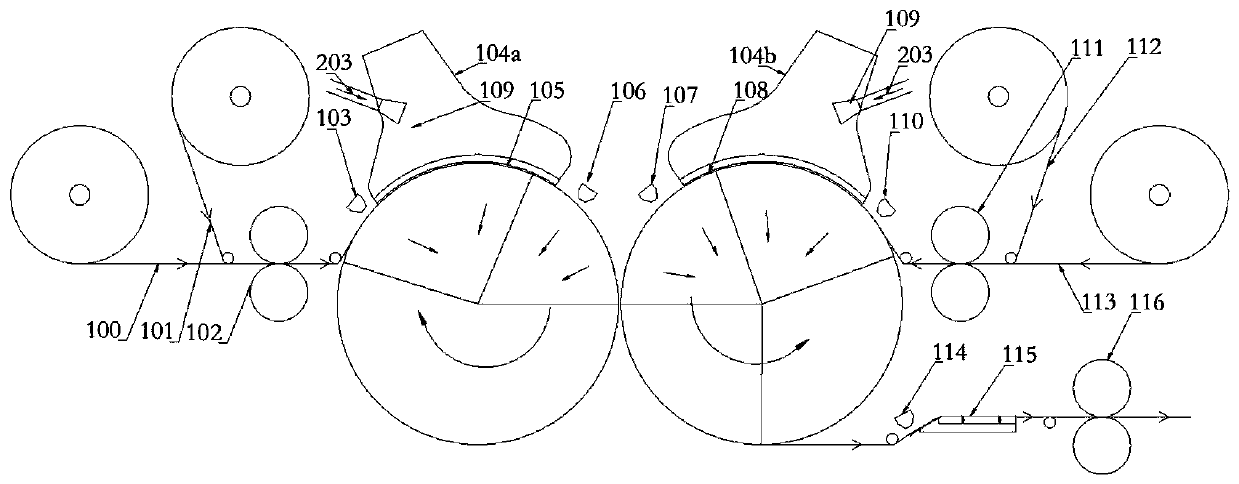

[0057] Step 1: The coated non-woven fabric 100 and the lower layer of hot-air non-woven fabric 101 are transported by traction and bonded to obtain the lower composite layer, which is transported to the first transfer wheel 105; specifically, the coated non-woven fabric 100 and the lower layer of hot-air non-woven fabric 101 is heat-sealed by the first heat-sealing device 102, and the bonding point 300 of the lower composite layer is formed after heat-sealing; the upper non-woven fabric 113 and the upper hot-air non-woven fabric 112 are transported by traction and bonded to obtain the upper composite layer, which is transported to the second transfer wheel 108; Specifically, the upper non-woven fabric 113 and the upper hot-air ...

Embodiment 2

[0062] Such as Figure 6 , the first filler and the second filler are a mixture of polymer material 203 and fluff pulp 310,

[0063] The manufacturing process of the composite core body of the present embodiment, such as Figure 5 , including the following steps:

[0064] Step 1: The coated non-woven fabric 100 and the lower layer of hot-air non-woven fabric 101 are transported by traction and bonded to obtain the lower composite layer, which is transported to the first transfer wheel 105; specifically, the coated non-woven fabric 100 and the lower layer of hot-air non-woven fabric 101 is heat-sealed by the first heat-sealing device 102, and the bonding point 300 of the lower composite layer is formed after heat-sealing; the upper non-woven fabric 113 and the upper hot-air non-woven fabric 112 are transported by traction and bonded to obtain the upper composite layer, which is transported to the second transfer wheel 108; Specifically, the upper non-woven fabric 113 and the ...

Embodiment 3

[0069] Such as Figure 8 , the first filler and the second filler both include a polymer material layer and a fluff pulp layer, and the polymer material layer is located on the upper layer of the fluff pulp layer.

[0070] The manufacturing process of the composite core body of the present embodiment, such as Figure 7 , including the following steps:

[0071] Step 1: The coated non-woven fabric 100 and the lower layer of hot-air non-woven fabric 101 are transported by traction and bonded to obtain the lower composite layer, which is transported to the first transfer wheel 105; specifically, the coated non-woven fabric 100 and the lower layer of hot-air non-woven fabric 101 is heat-sealed by the first heat-sealing device 102, and the bonding point 300 of the lower composite layer is formed after heat-sealing; the upper non-woven fabric 113 and the upper hot-air non-woven fabric 112 are transported by traction and bonded to obtain the upper composite layer, which is transporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com