Method for preventing interface oxidation of rolled metal composite plate

A metal clad plate, clad plate technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of expensive equipment, reduced bonding strength of clad plates, complicated processes, etc., to reduce interface oxidation, Ease of operation and improved composite quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for rolling a stainless steel clad plate, comprising the steps of:

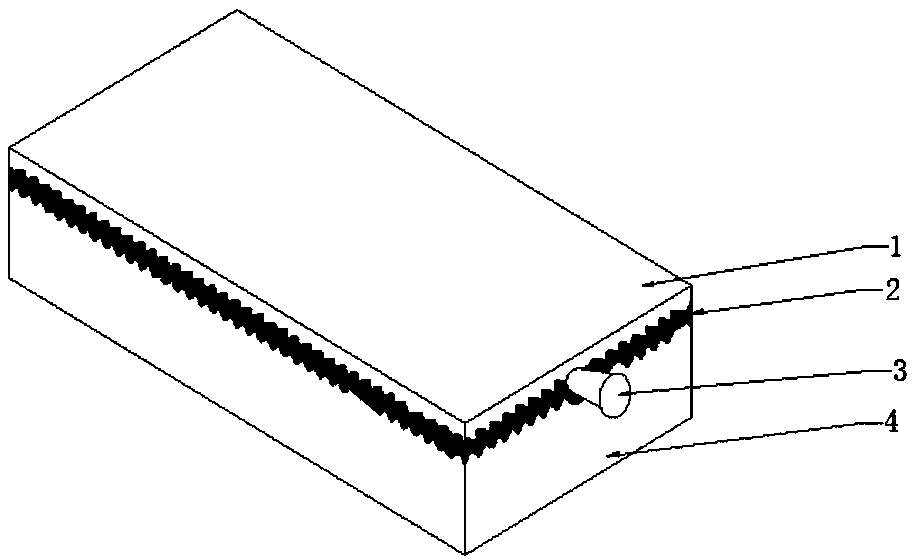

[0047](1) Raw material preparation: 316L stainless steel plate 1 and Q345R carbon steel plate 2 blanks of suitable size are cut from large-sized steel plates by wire cutting. Among them, the size specification of cut 316L stainless steel 1 is 200mm×100mm×5mm, and the size specification of Q345R carbon steel 4 is 200mm×100mm×25mm.

[0048] (2) Surface treatment: before welding the composite billet, it is necessary to treat the surface of the composite blank to increase the bonding rate of the composite surface. First, sand the surface with sandpaper to remove the rust layer and oxide layer on the surface; then repeatedly scrub the composite surface with acetone and alcohol to remove the organic matter and dirt on the surface, and quickly dry it with a hair dryer.

[0049] (3) Blank assembly and welding: In order to make the composite board have better welding quality, it is also necessary to p...

Embodiment 2

[0064] A method for rolling a stainless steel clad plate, comprising the steps of:

[0065] (1) Raw material preparation: cut the blanks of 316L stainless steel plate 1 and Q345R carbon steel plate 4 of appropriate size from the large-sized steel plate by wire cutting. Among them, the size specification of cut 316L stainless steel 1 is 200mm×100mm×5mm, and the size specification of Q345R carbon steel 4 is 200mm×100mm×25mm.

[0066] (2) Surface treatment: First, sand the surface with sandpaper to remove the rust layer and oxide layer on the surface; then repeatedly scrub the composite surface with acetone and alcohol to remove organic matter and dirt on the surface, and quickly dry it with a hair dryer.

[0067] (3) Blank assembly and welding: clean the surroundings of the composite board with sandpaper, and repeatedly scrub with acetone and alcohol to remove the oxide layer around the composite board; then stack the processed blanks together, first by spot welding Fix the com...

Embodiment 3

[0073] A method for rolling a stainless steel clad plate, comprising the steps of:

[0074] (1) Raw material preparation: 316L stainless steel plate 1 and Q345R carbon steel plate 4 blanks of suitable size are cut from large-sized steel plates by wire cutting. Among them, the size specification of cut 316L stainless steel 1 is 200mm×100mm×5mm, and the size specification of Q345R carbon steel 4 is 200mm×100mm×25mm.

[0075] (2) Surface treatment: First, sand the surface with sandpaper to remove the rust layer and oxide layer on the surface; then repeatedly scrub the composite surface with acetone and alcohol to remove organic matter and dirt on the surface, and quickly dry it with a hair dryer.

[0076] (3) Blank assembly and welding: clean the surroundings of the composite board with sandpaper, and repeatedly scrub with acetone and alcohol to remove the oxide layer around the composite board; then stack the processed blanks together, first by spot welding Fix the composite bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com