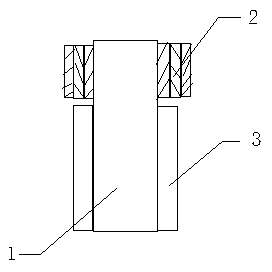

Soft package power lithium ion battery cathode pole ear structure and preparation method

A lithium-ion battery and tab technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as affecting the life of power batteries, chronic corrosion of tabs, easy over-welding or virtual welding, etc. Industrial production, improved yield and consistency, improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Heat the copper base material with a purity of 99.995% to 930°C, keep it warm for 6 minutes, then pickle it with HF with a concentration of 6% by mass, and roll it after baking. The thickness of the roll is 20 microns.

[0030] In the second step, the copper strip made in the first step is divided into strips with a strip width of 80 mm, and then the cut edge is deburred, and then the deburred copper strip is DC electroplated, and the coating is made of metallic nickel with a width of 40 mm. The thickness is 5 microns, and the deburring copper strip is partially nickel-plated to make a strip-shaped coated copper strip.

[0031] The 3rd step cleans the strip-shaped coated copper strip made in the second step, and the cleaning is at first to adopt the NaOH lye cleaning of 5% in mass percentage concentration, then neutralize with the HF acid solution of 5% in mass percentage concentration, and finally It is deionized water cleaning, ultrasonic vibration during the clean...

Embodiment 2

[0036] The first step is to heat the copper substrate with a purity of 99.993% to 940°C and keep it warm for 12 minutes, then pickle it with HF with a concentration of 7% by mass, and roll it after baking. The thickness of the roll is 15 microns.

[0037] In the second step, the copper strip made in the first step is divided into strips with a strip width of 75mm, and then the cut edge is deburred, and then the deburred copper strip is DC electroplated, and the coating is made of nickel-tin alloy with a width of 35mm. , with a thickness of 3 microns, and partially nickel-plate the deburring copper strip to form a strip-shaped coated copper strip.

[0038] The third step is to clean the strip-shaped nickel-tin alloy copper strip made in the second step. At first, the cleaning is to use a mass percent concentration of 6% NaOH lye to clean, and then use a mass percent concentration of 7% HF acid to neutralize , and finally deionized water cleaning, ultrasonic vibration during the...

Embodiment 3

[0043] The first step is to heat the copper substrate with a purity of 99.990% to 945°C and keep it warm for 8 minutes, then pickle it with HF with a concentration of 6% by mass, and roll it after baking. The thickness of the roll is 10 microns.

[0044] In the second step, the copper strip made in the first step is divided into strips with a strip width of 45 mm, and then the cut edge is deburred, and then the deburred copper strip is subjected to chemical plating, and the coating is metallic nickel with a width of 26 mm. , The thickness of the coating is 3 microns, and the deburring copper strip is partially nickel-plated to form a strip-shaped coated copper strip.

[0045]The 3rd step cleans the strip-shaped coated copper strip made in the second step, and the cleaning is at first to adopt the NaOH lye cleaning that the mass percent concentration is 6%, then neutralize with the HF acid solution that the mass percent concentration is 7.5%, and finally It is deionized water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com