Novel composite position controller

A level controller and composite technology, applied in the direction of liquid level control, non-electric variable control, control/adjustment system, etc., can solve the problem of compounding, reduce the impact resistance and reliability of the instrument, and the length of the whole machine should not be too short and other problems, to achieve the effects of shortened length, easy maintenance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

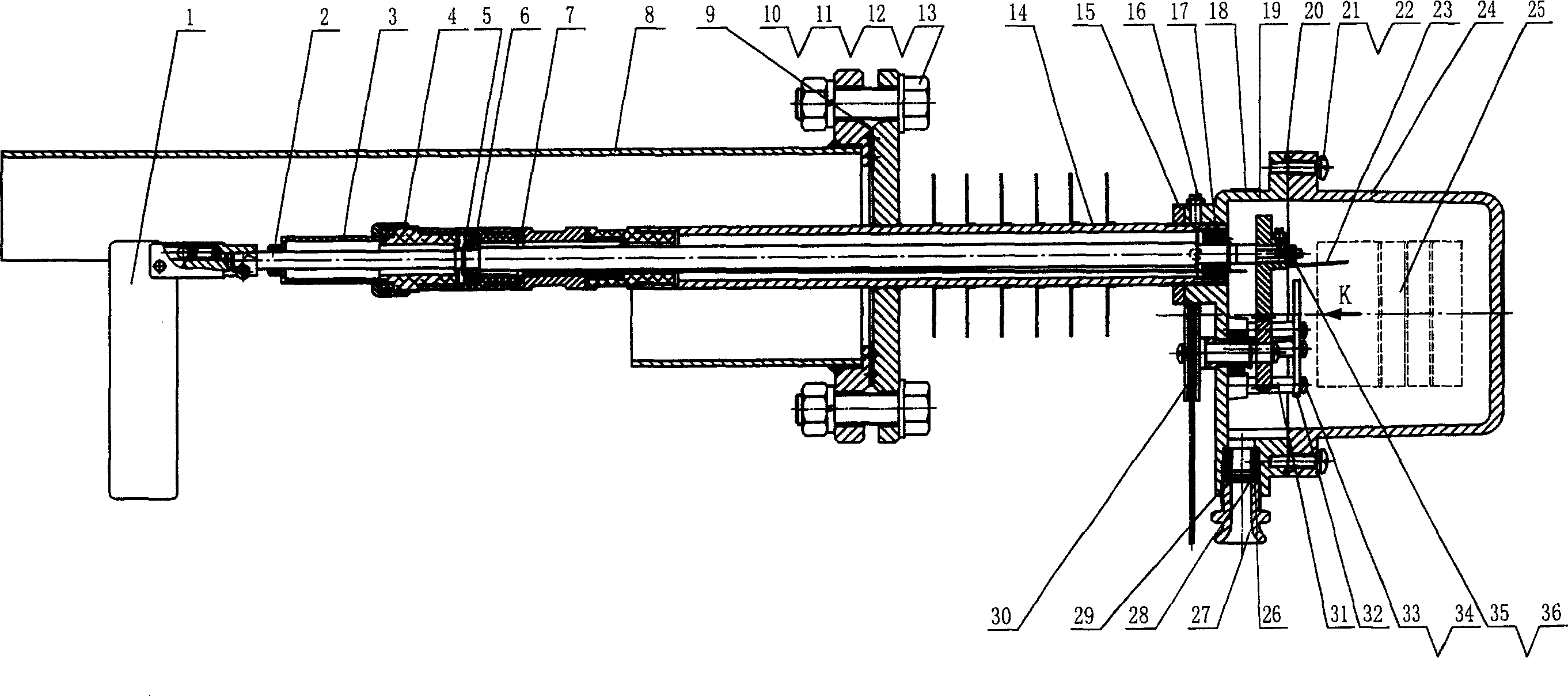

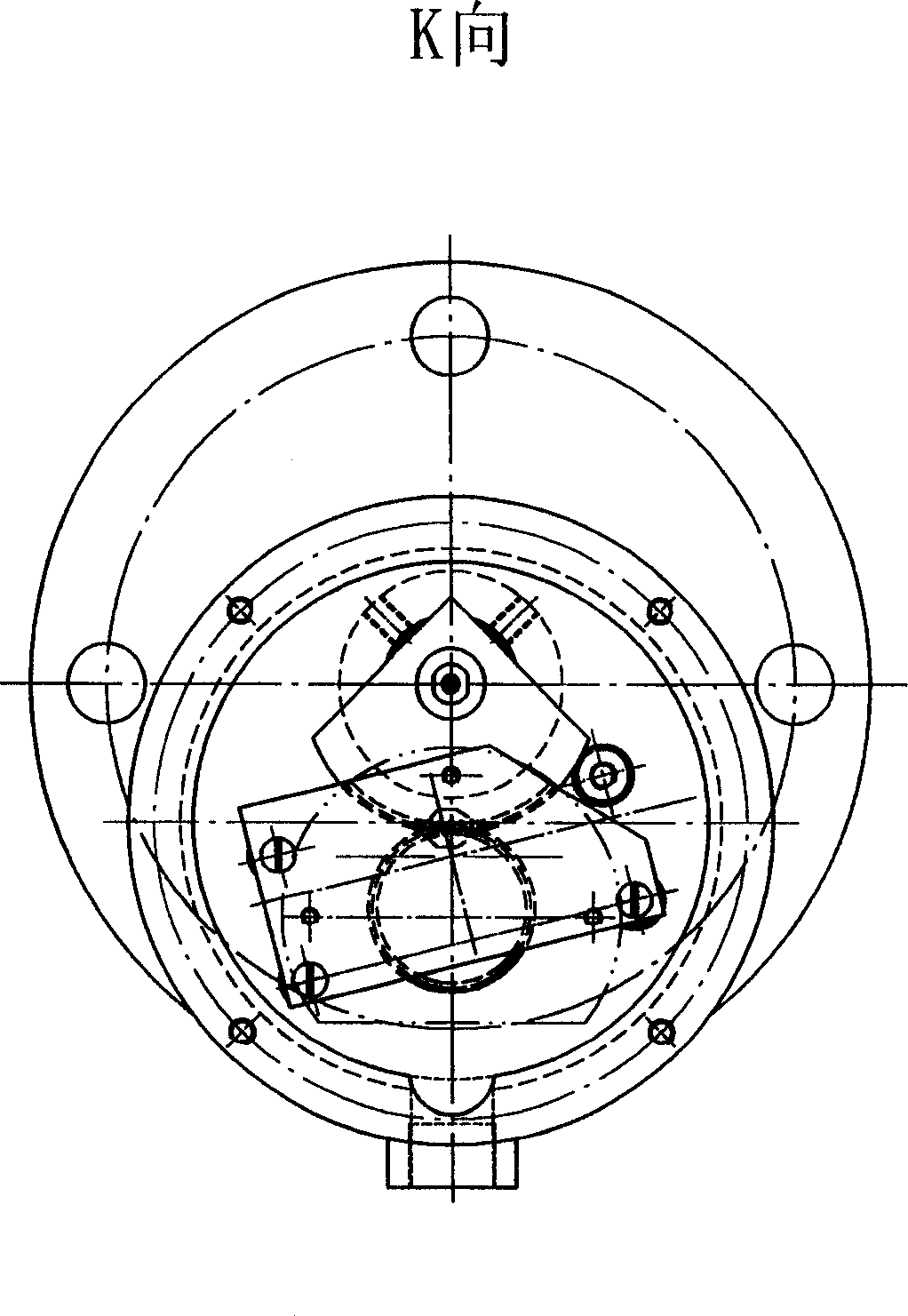

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

[0022] As shown in the figure: put the adjustment pad on the insulating joint of the composite probe assembly 4 and then screw it into the shaft cylinder of the shaft cylinder assembly 14, and tighten it. Put a Teflon gasket on the shielding pole, and then tighten it with the insulating joint. Put the shielding lead wire assembly 7 into the shielding pole, after the shielding pole lead wire passes through the small hole of the shaft cylinder and the sliding bearing 17, tighten the shaft cylinder of the sliding bearing 17. Put the adjusting pad 29 into the shielding pole on the bearing outer shell of the composite probe assembly 4, and compress the flat pad. Penetrate the rolling bearing 6 on the main shaft 2, fix it firmly with the circlip 5 for the shaft, then put the shaft cylinder through which the main shaft 2 passes and the large hole of the sliding bearing 17, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com