Method for controlling hole group composite position degree error through optimizing clamp layout

A technology of compound position and control hole, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the control of compound position error, fails to consider the influence of the compound position error of the fixture hole group, and does not give Layout and other issues to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

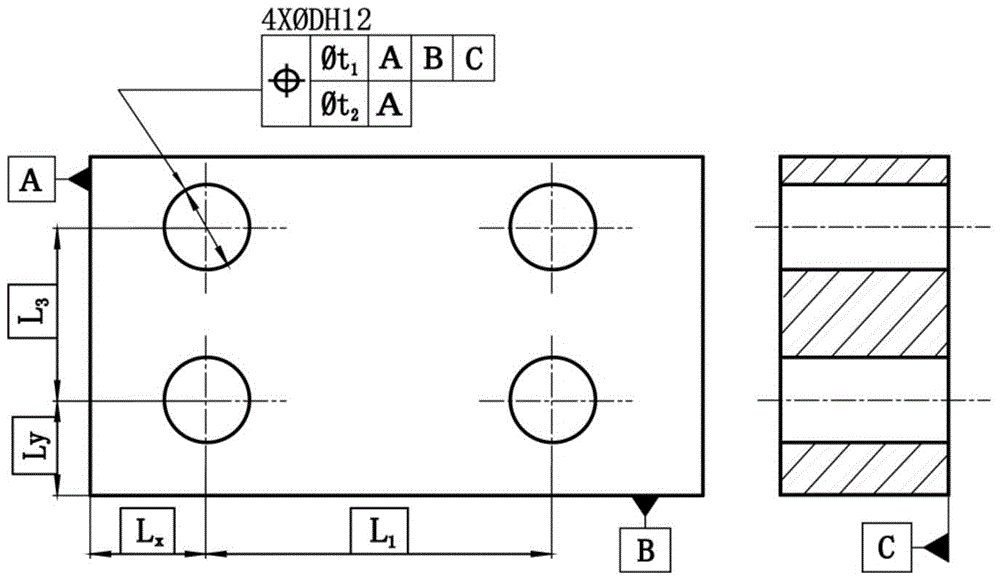

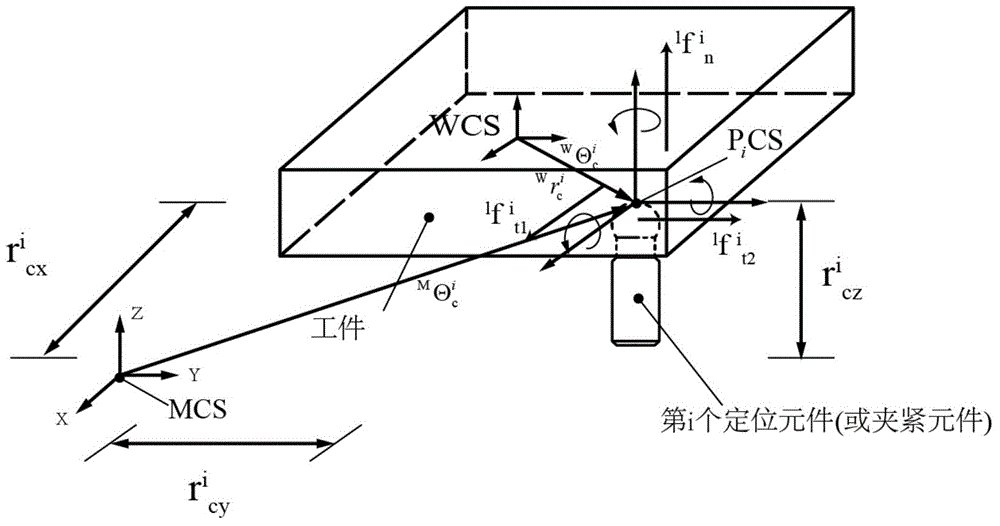

[0027] Hole group features such as figure 1 As shown, is a common feature in mechanical parts, and there is often a high requirement for the relative position accuracy of each hole in the hole group, and the position accuracy of the hole group features is affected by the fixture. The present invention reduces the compound position error of hole group feature processing by designing the positions of 6 positioning elements, and the steps are as follows:

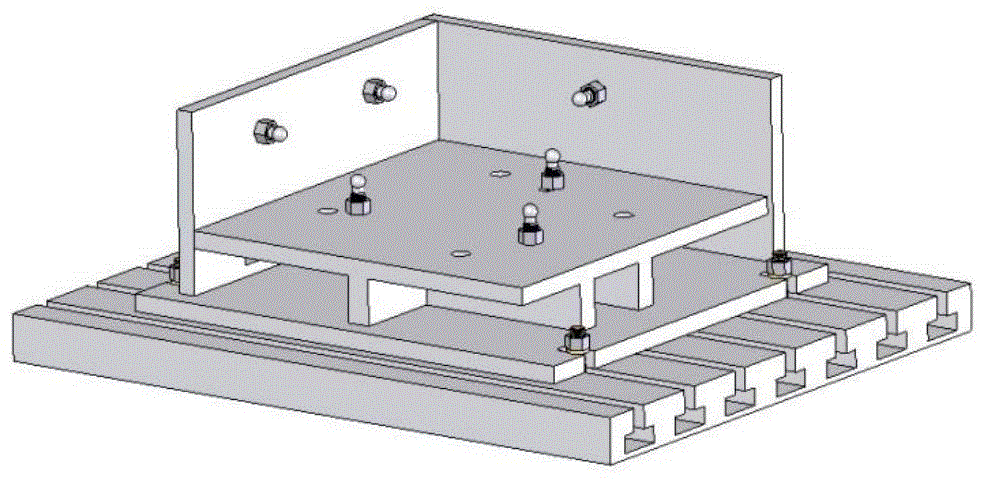

[0028] Among them, the six-point positioning fixture is a type of fixture, such as figure 2 As shown in Fig. 1, a fixture that achieves accurate positioning by limiting the six degrees of freedom of the workpiece through six positioning elements in contact with the workpiece, such as figure 1 shown. The key factor determining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com