Spiral cutter for composite positioned cutting

A compound positioning and cutting tool technology, which is applied to twist drills and other directions, can solve the problems of reduced hardness of the cutter head, poor centering structure, and wear of the cutter head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

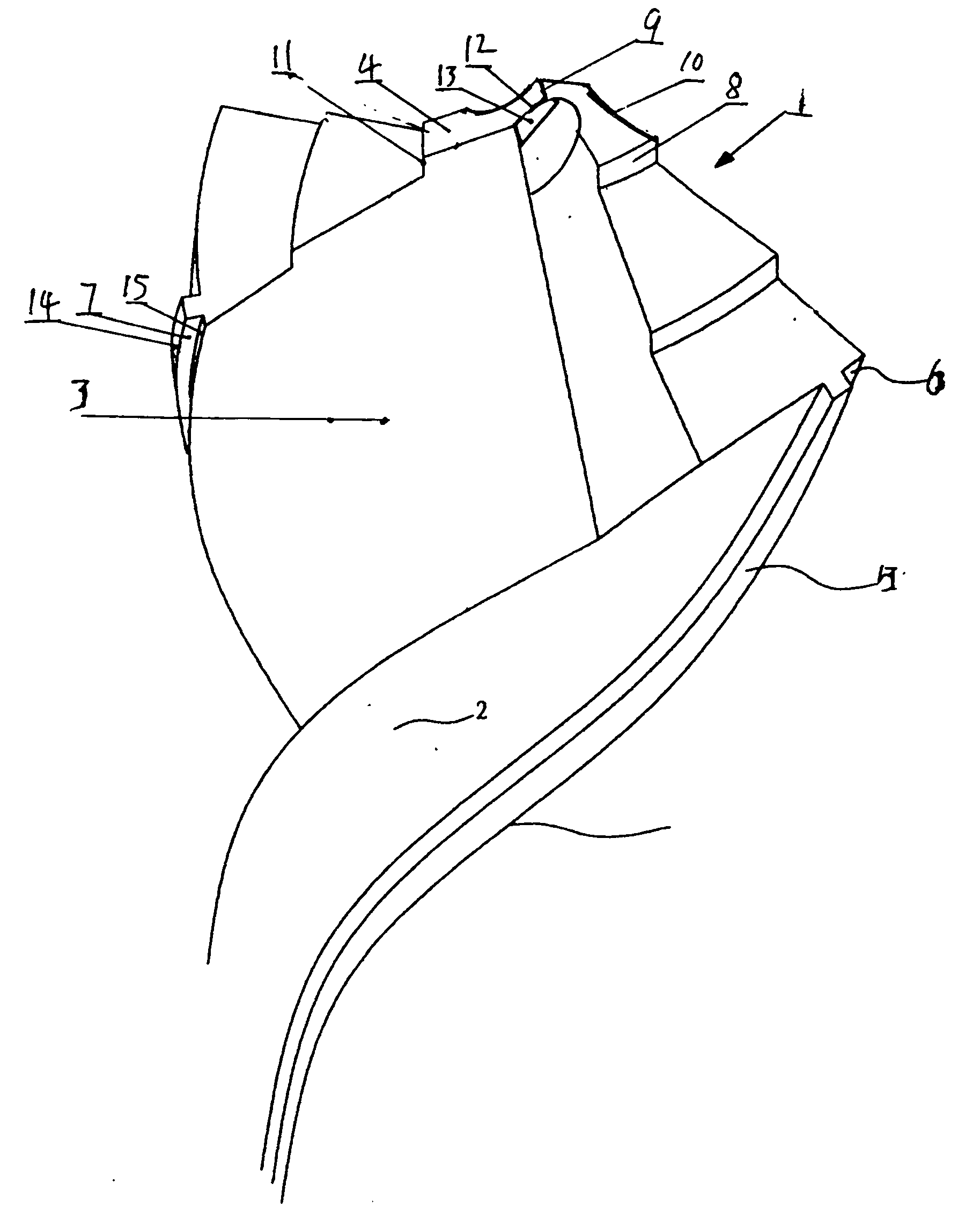

Embodiment approach 1

[0034] Such as figure 1 As shown, the spiral tool for composite positioning cutting according to the first embodiment of the present invention includes a tool head 1. The tool head 1 is integrally provided with two spiral strips 2, and the surface of the spiral strip 2 facing the cutting direction is the cutting surface 3. The top and back side of the cutting surface 3 is the rear cutting surface 4, and the outermost surface of the spiral strip 2 is the secondary cutting surface 5. The cutting surface 3 and the secondary cutting surface 5 intersect to form a secondary cutting edge 14, and the inner side of the cutting surface 3 is axially The center begins to form one or more steps 6 in a manner that gradually decreases in height to the outside. The outermost one is the reinforcement platform 7, and the convex cutting surface 3 intersects with a composite secondary edge 15 formed on the rear cutting surface 4. From the chisel edge 9 to both outer sides, a stepped portion 8 is fo...

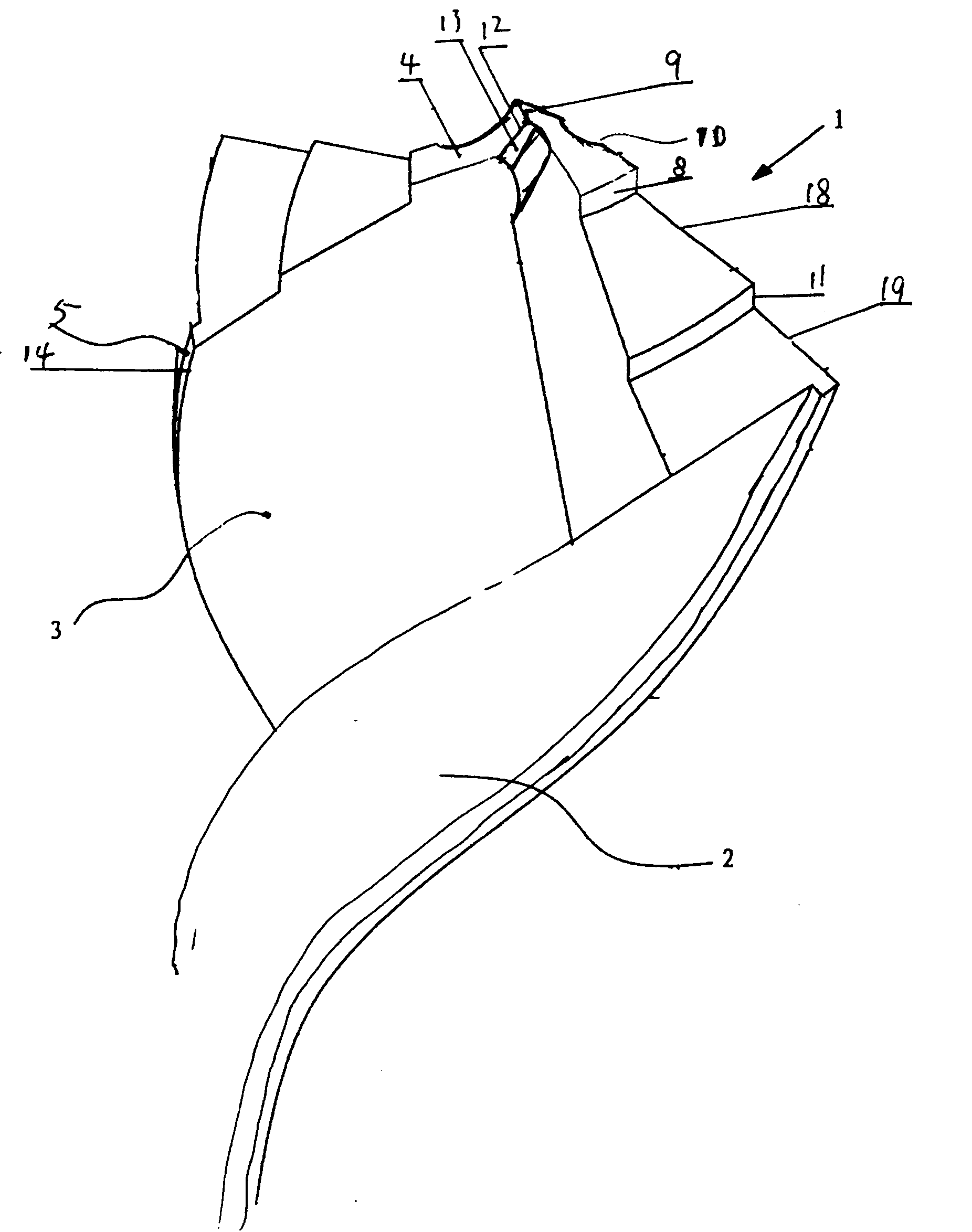

Embodiment approach 2

[0037] Such as figure 2 As shown, the spiral tool for composite positioning cutting according to the second embodiment of the present invention includes a tool head 1. The tool head 1 is integrally provided with two spiral strips 2, and the surface of the spiral strip 2 facing the cutting direction is the cutting surface 3. The top and back side of the cutting surface 3 is the rear cutting surface 4, and the outermost surface of the spiral 2 is the secondary cutting surface 5. The cutting surface 3 and the secondary cutting surface 5 intersect to form a secondary cutting edge 14, and the chisel edge of the rear cutting surface 4 At 8 places, one or more steps 8 are formed in such a way that the height gradually decreases toward the outside. The convex rear cutting surface 4 and the cutting surface 3 intersect the cutting surface 3 to form at least one level of composite cutting edge 18 or 19, the cutting edge 10 A stepped edge 11 is formed on the stepped cutting surface. A cham...

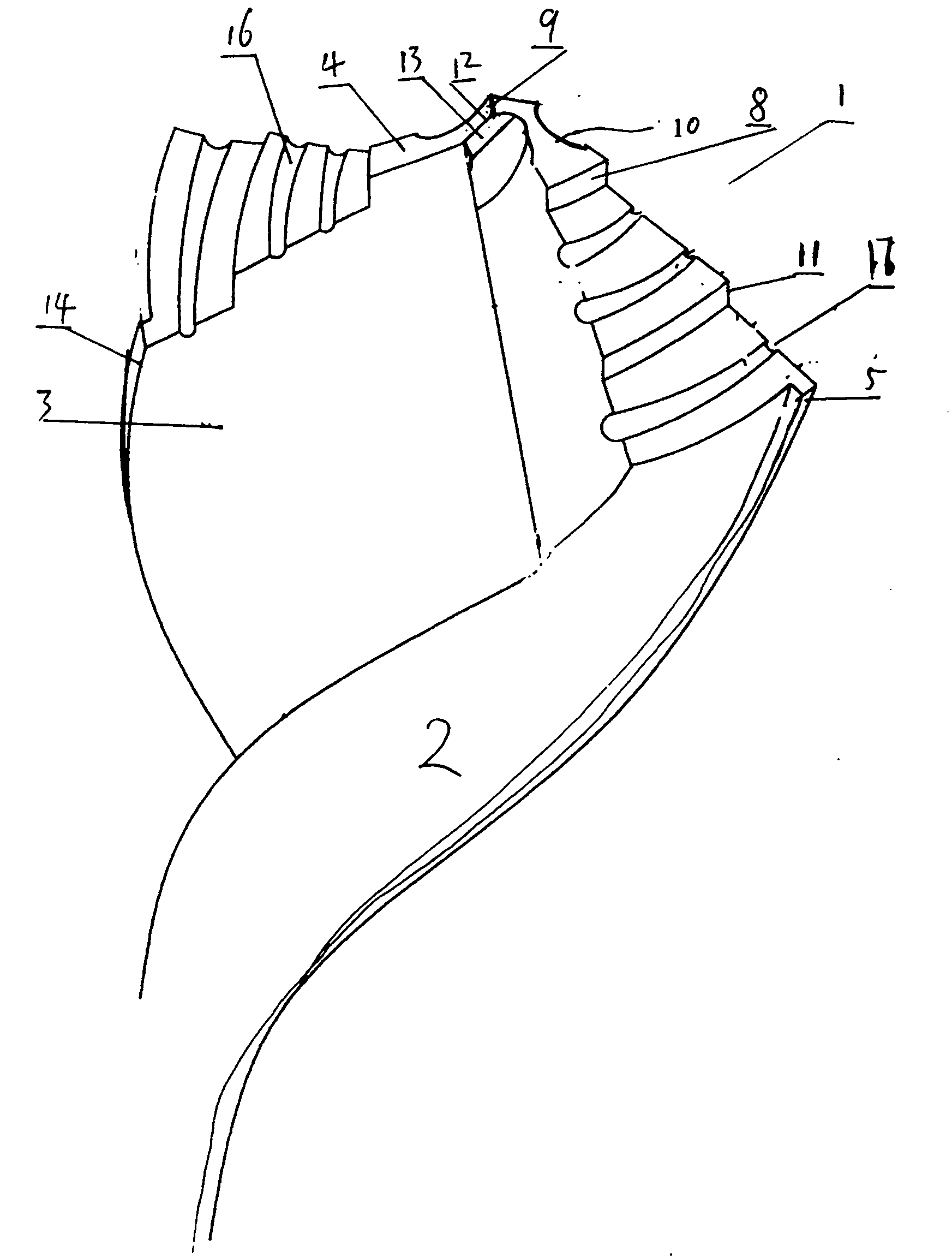

Embodiment approach 3

[0040] Such as image 3 As shown, the spiral tool for composite positioning cutting according to the third embodiment of the present invention includes a tool head 1. The tool head 1 is integrally provided with two spiral strips 2, and the surface of the spiral strip 2 facing the cutting direction is the cutting surface 3. The top and back side of the cutting surface 3 is the rear cutting surface 4, and the outermost surface of the spiral 2 is the secondary cutting surface 5. The cutting surface 3 and the secondary cutting surface 5 intersect to form a secondary cutting edge 14, and the inner tip of the rear cutting surface 4 The chisel edge 9 begins to form one or more steps 6 in a manner of gradually decreasing its height to the outside. At least one stepped edge 11 is formed at the intersection of the stepped rear cutting surface 4 and the cutting surface 3, and on the stepped cutting edge 10 At least one notch edge 17 is provided with grooves 16 with an opening extending tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com