Power-driven gas compressor of novel structure

A new type of structure, compressor technology, applied in the direction of machine/engine, liquid fuel engine, mechanical equipment, etc., can solve the problems that the electric compressor cannot meet the electric environmental control system, the reliability of the ball bearing is poor, and the structure is complicated, and the structure is simple. , high reliability, the effect of increasing the critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

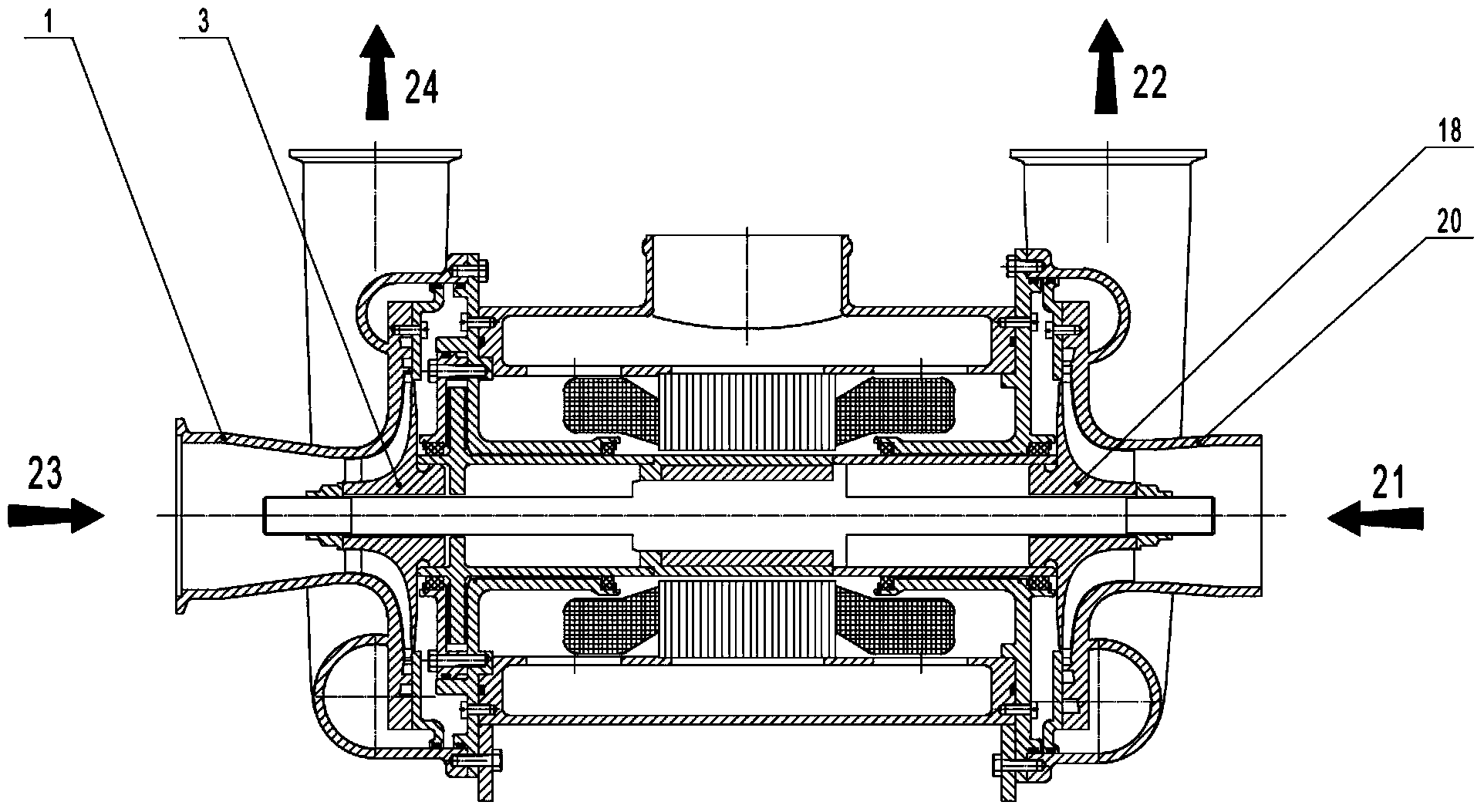

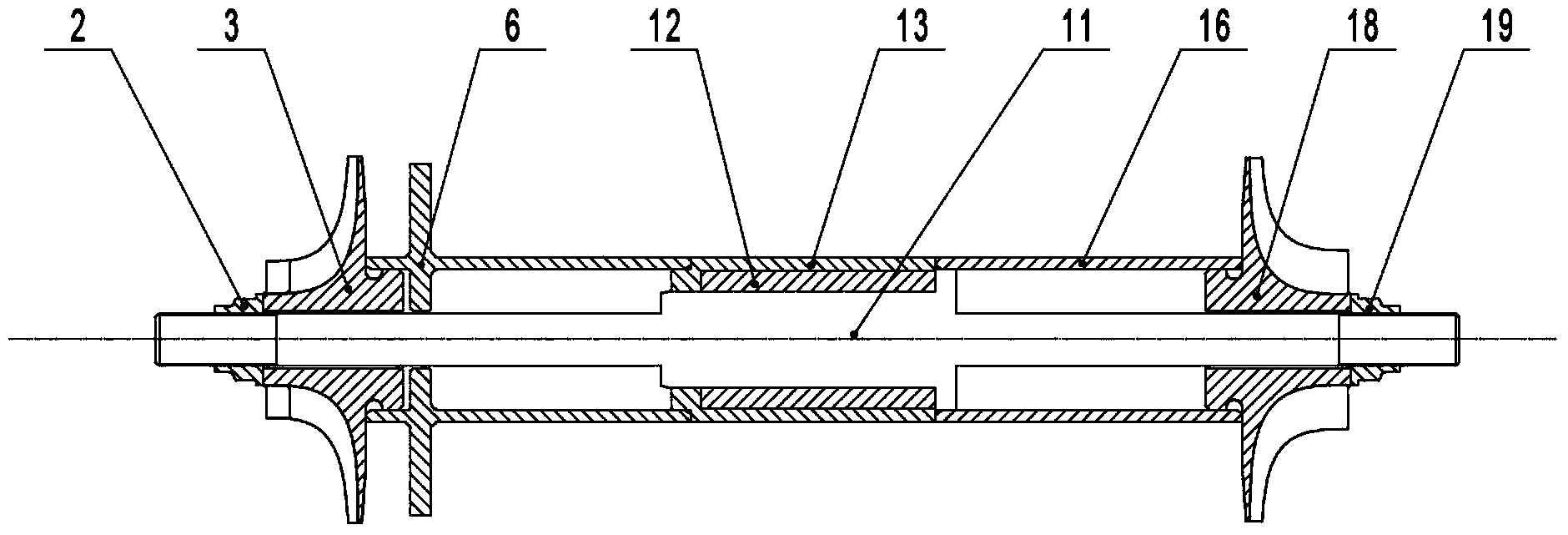

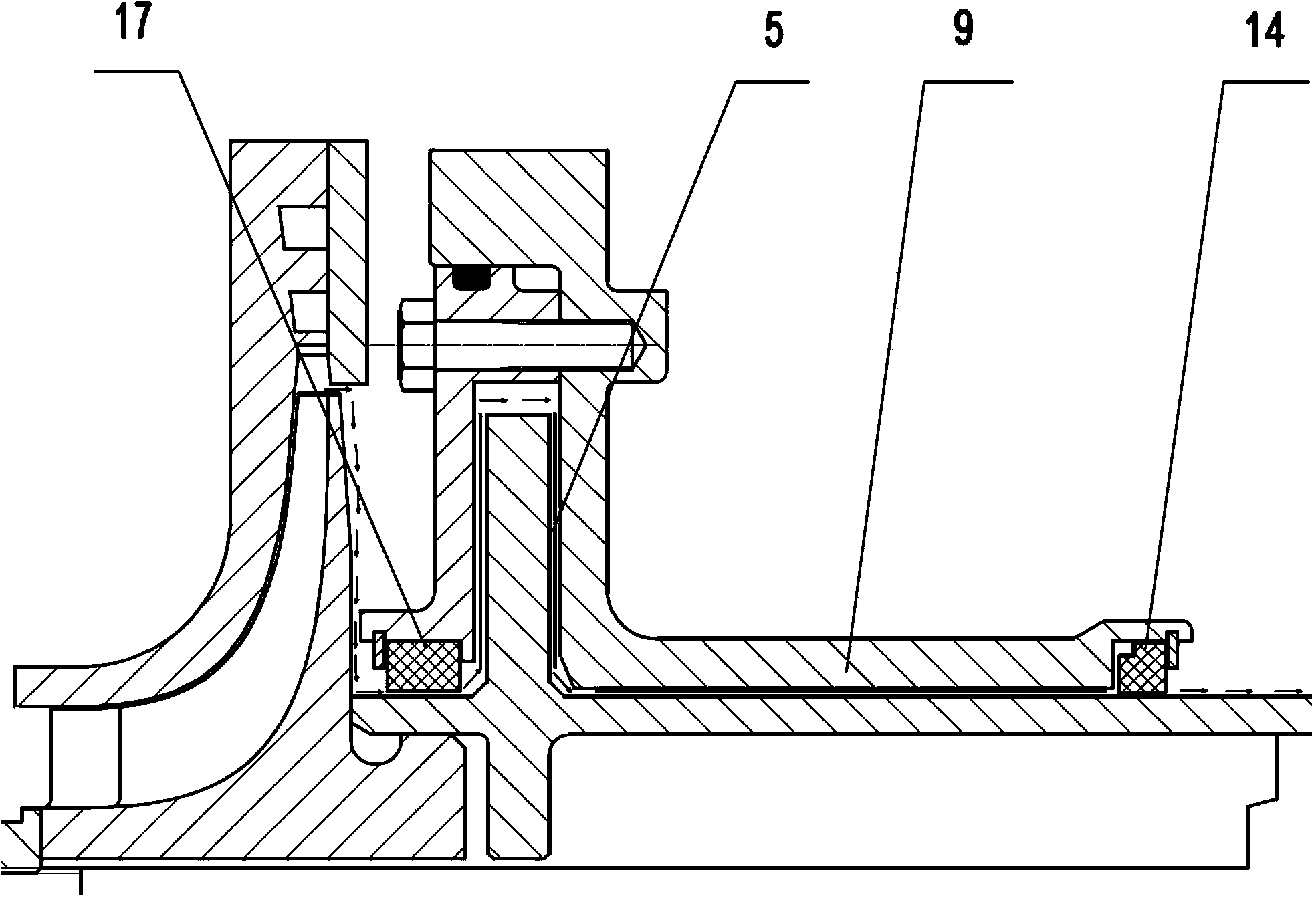

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings of the specification. Please refer to the instruction manual Figure 1~3 .

[0020] The electric compressor designed by the present invention adopts a two-stage compression structure, and its structure diagram is shown in figure 1 The ram air first enters the first-stage compression process. The air gets more pressure energy through the first-stage impeller 18, the first-stage diffuser and the first-stage volute 20, and its temperature and pressure are increased; from the first-stage volute 20 After the high temperature and high pressure air is cooled by the radiator, it enters the secondary compression process. Through the secondary impeller 3, the secondary diffuser and the secondary volute 1, the pressure of the gas is further increased to reach the environmental control system The desired state. According to the characteristics of the current fighter aircraft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com