Method and system for sequencing and scheduling

An optimization method, algorithm technology, applied in the direction of instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

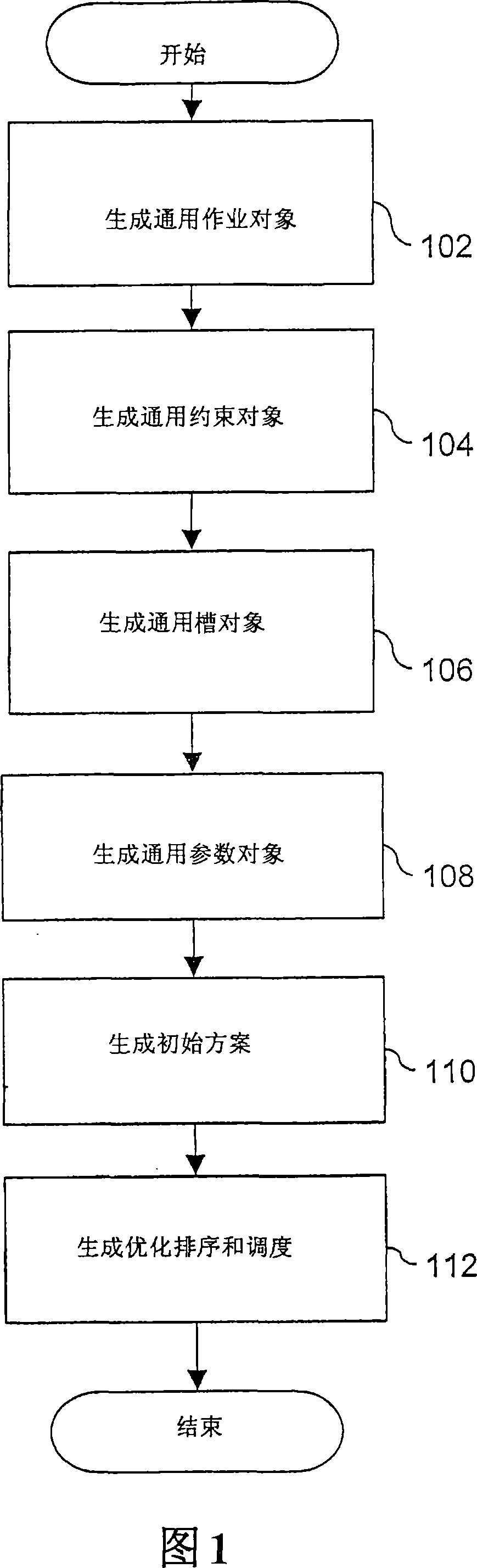

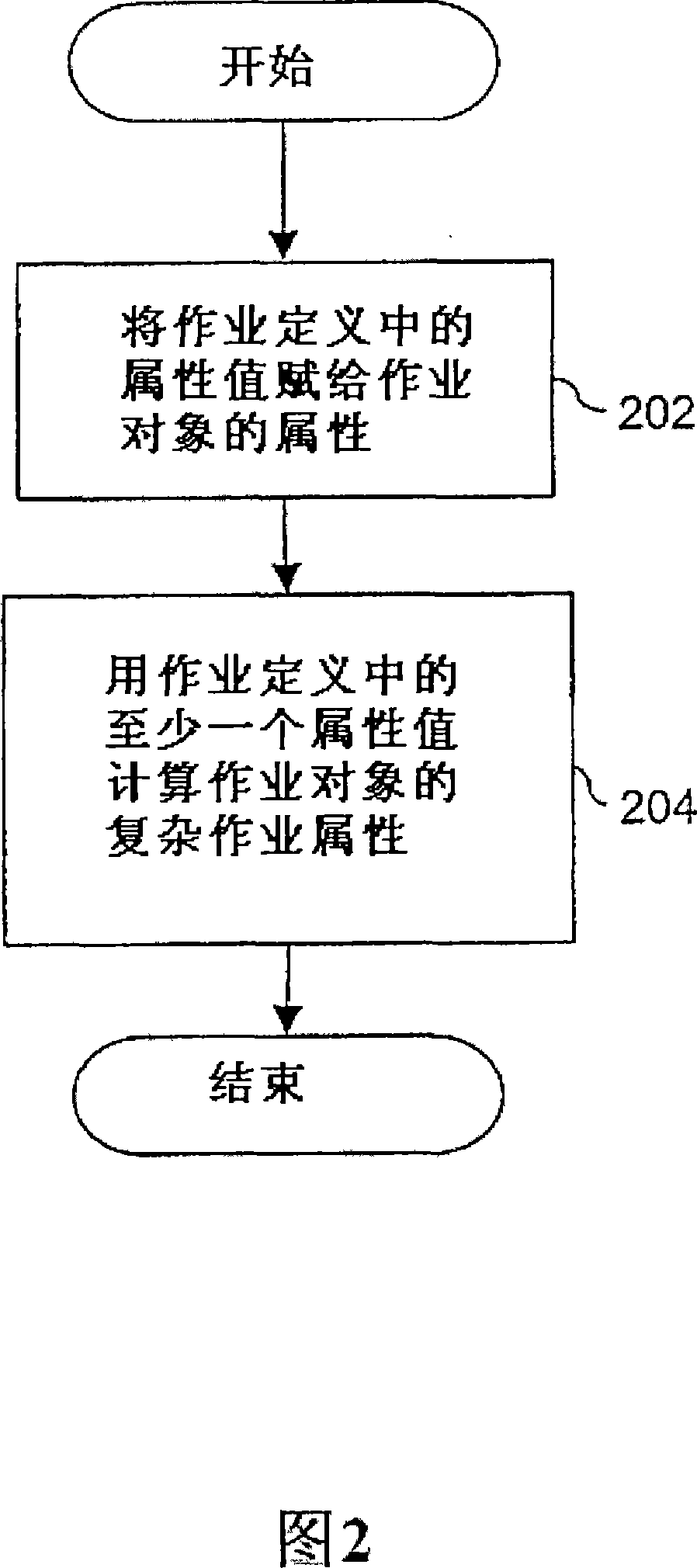

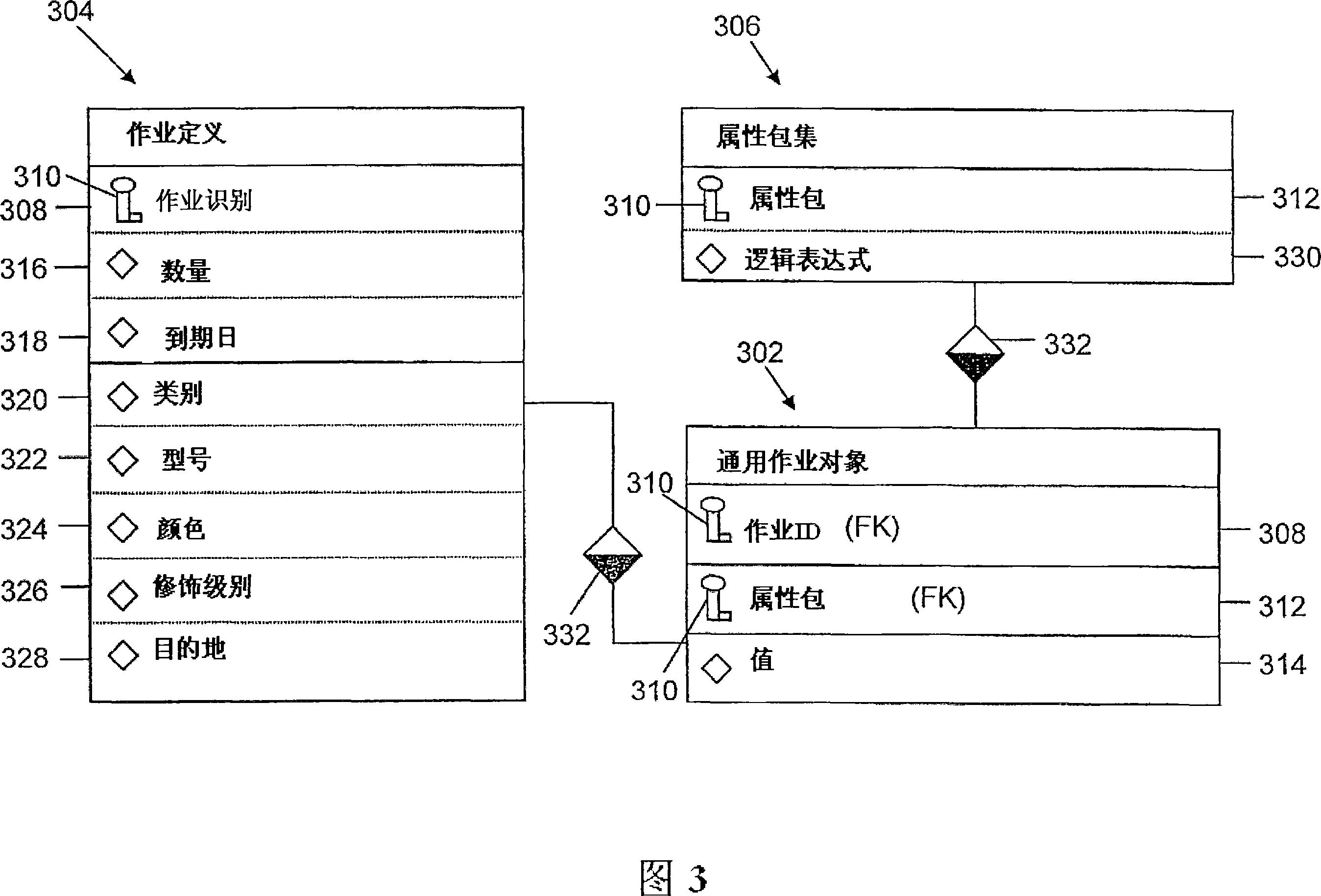

Method used

Image

Examples

example 1

[0067] Example 1: Converting Constraint Types

[0068] Example 1 is an exemplary conversion constraint type. The constraint is named COLOR-BW (color—black / white), and this term serves as a constraint identifier. The attribute package EXTERIOR-COLOR (external color) is applied to the attribute value BLACK (black) and the attribute value WHITE (white). The user-defined logic specifies that if a black car is produced, it cannot be followed by a white car. Assign a priority of 10 to this constraint. Priority can be used to imply that this constraint is more important than other constraints based on a user-defined size. A transition constraint is violated when black cars are produced immediately after white cars in sequencing or scheduling. Furthermore, it is contemplated that a flag is used to indicate that a constraint is active rather than disabled. Also, assign a value of 0 to the changeover time between cars in the production line.

example 2

[0069] Example 2: Types of Feature Capacity Constraints

[0070]Example 2 is an exemplary feature capacity constraint type. Applies the attribute package EXTERIOR-COLOR (external color) to the attribute value RED (red). Also, specify a minimum production volume of 0 and a maximum production volume of 1000. In this example, the position is for one week. Additionally, the constraint is assigned a priority of 5, indicating that the constraint has medium priority based on the user-defined size. The quantity type JOB-QUANTITY specifies the logic to use. Here, the logic specifies that a maximum of 1000 red cars can be produced in a week. Additionally, a penalty factor of 2 is assigned, which means that the larger the violation, the more severe the penalty.

example 3

[0071] Example 3: Allocation Constraint Types

[0072] Example 3 is an exemplary distribution constraint type. Given a constraint name DISTRIBUTE-MODEL (distribution - model), and apply the attribute package MODEL to all jobs, regardless of job attributes. This is indicated by marking the field "attribute value" blank. The quantity type JOB-QUANTITY specifies the user-defined logic to use. This logic specifies that jobs of all models should be evenly distributed. The fields "tolerance plus quantity" and "tolerance minus quantity" indicate that the job production must combine all specified tolerances and ensure high quality. The preprocess value specifies that a target value must be calculated. For certain constraint types (such as distributional constraint types), the occurrence and extent of constraint violations are determined by comparing observed values in ordering and scheduling with target values. Preprocessing is the process of automatically calculating target va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com