Processing method of valve core of multiway valve

A processing method and multi-way valve technology, which is applied in metal processing, manufacturing tools, heat treatment equipment, etc., can solve problems such as multi-way valve core deformation and cracking, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The application of the present invention in processing the valve core of a multi-way valve is described in detail.

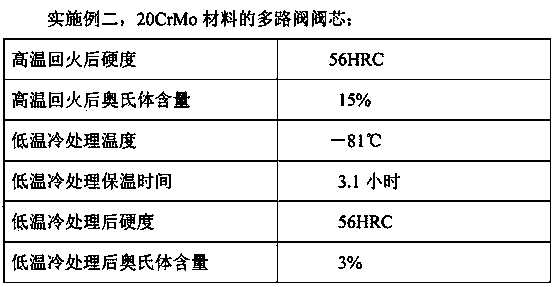

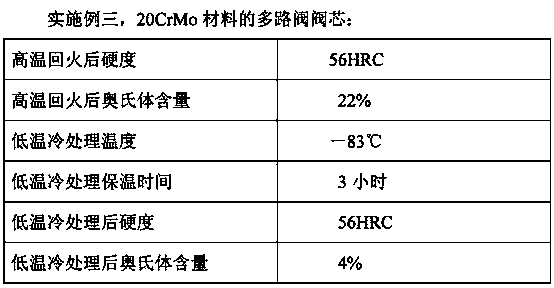

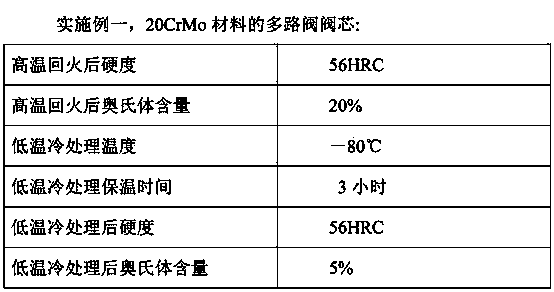

[0020] In the processing of the multi-way valve core, the material to be processed is prepared first, and the material to be processed is 20CrMo, and the material to be processed is subjected to quenching and tempering treatment to make the internal structure of the material uniform and improve the machining performance. The semi-finished valve core is reserved for 0.25~ With a machining allowance of 0.35mm, the semi-finished valve core is carburized, quenched and high-temperature tempered, and then cooled to room temperature for low-temperature cold treatment, so that the surface hardness of the semi-finished valve core reaches HRC 58~62; the cold treatment medium is liquid nitrogen, The temperature of low-temperature cold treatment is -80~-83℃, and the holding time is 3~3.1 hours. During the process of low-temperature cold treatment, the residual austeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com