Convenience-for-transportation disorganized transportation transformer and transport case thereof

A transport box and box cover technology, applied in the field of transformers, can solve the problems of huge engineering construction funds, inability to meet transportation requirements, and non-compliance with environmental protection requirements, and achieve reasonable heat dissipation and insulation structure, transportation weight reduction, and good product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

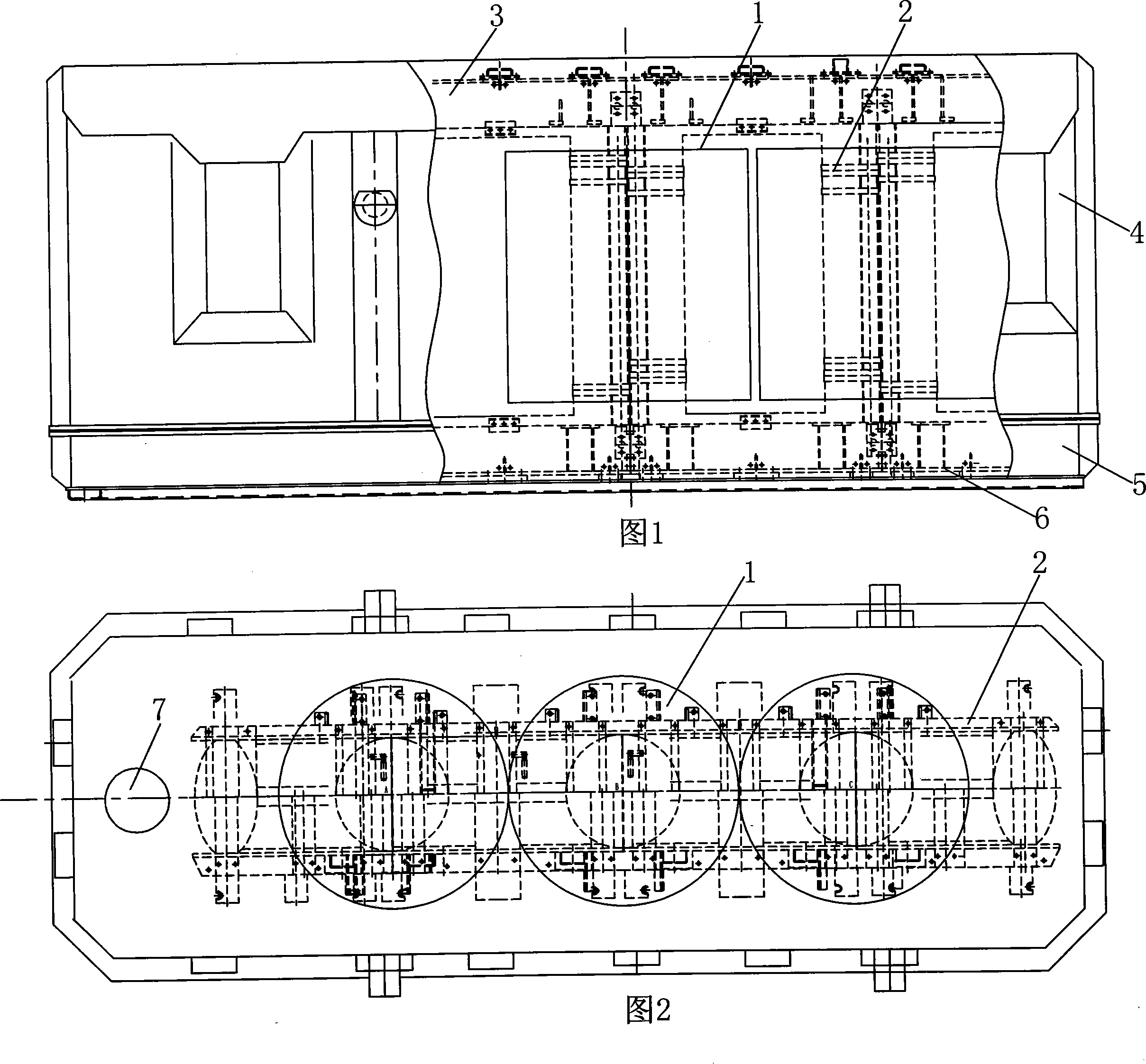

[0033] Embodiment: Taking a three-phase 360MVA / 330kV transformer as an example, as shown in Figure 1 and Figure 2, this example includes 4 single-frame double-column iron cores, an upper fuel tank 4, a lower fuel tank 5, a coil 1, and an iron core The overall product upper clamp 3, the product overall lower clamp 4, two layers of insulating cardboard are arranged between the adjacent single-frame double-column iron cores, fixed by adhesive tape 17, and the coil 1 is placed on the adjacent single-frame double-column iron cores On the top, steel gaskets are placed between the lower running clamps 4 of the adjacent single-frame double-column iron core, and the upper running clamp 3 of the iron core is placed above the assembled single-frame double-column iron core. Fixed, the upper fuel tank 4 and the lower fuel tank 5 are combined and placed at one end of the iron core.

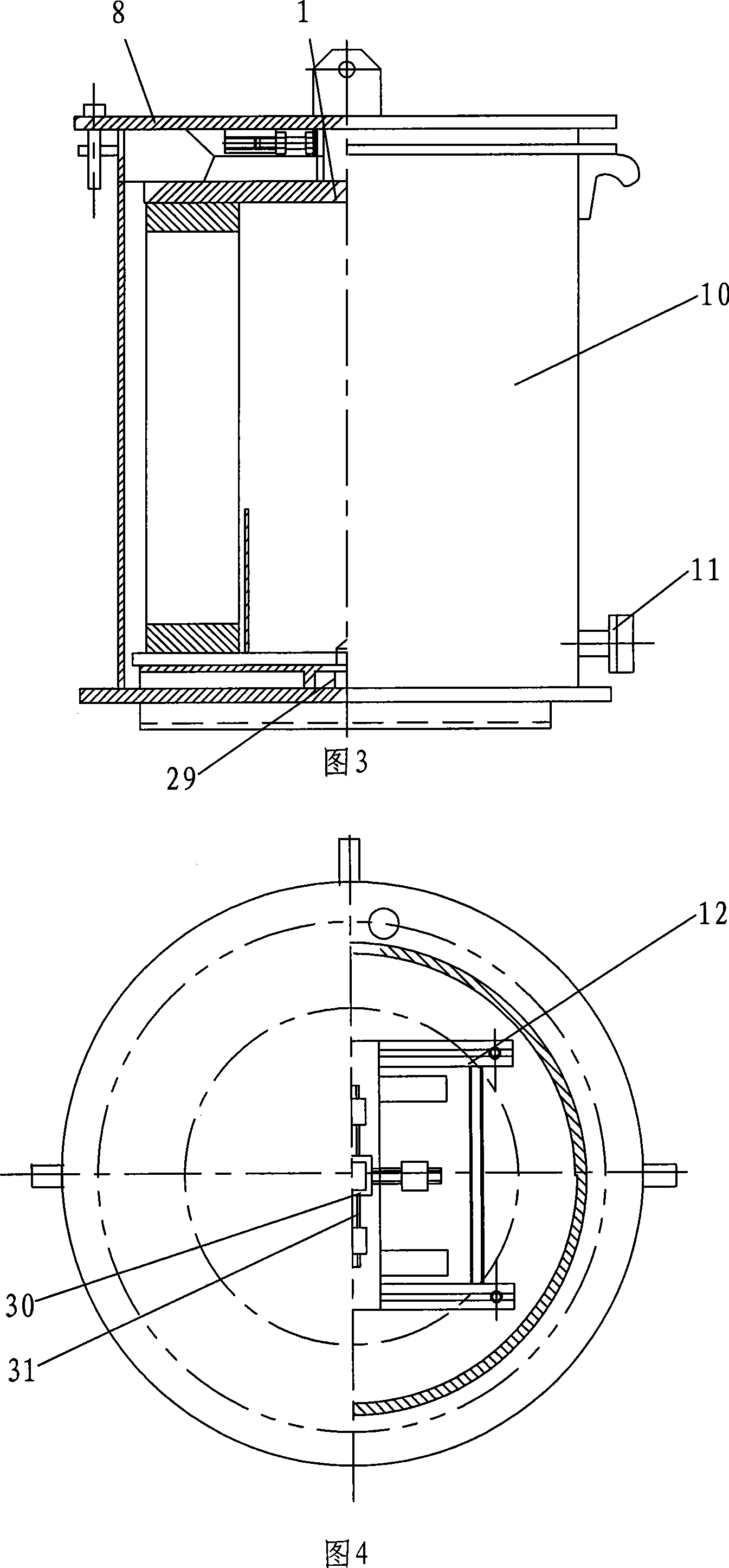

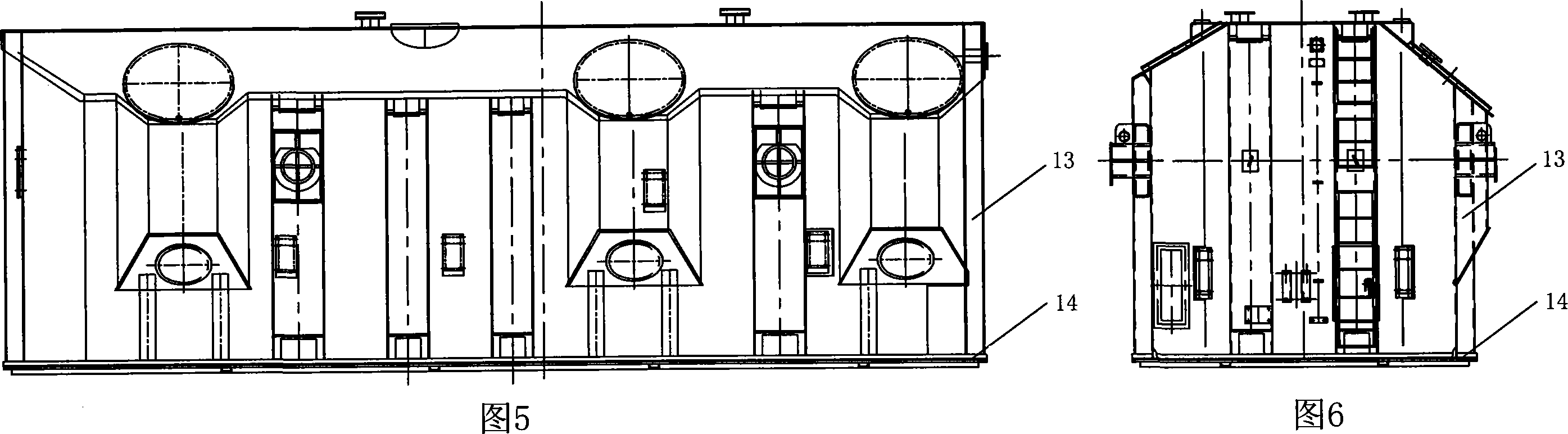

[0034] The transport clip used in the present invention includes iron core transport box, coil transport box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com