Preparation method of high temperature stable titanium dioxide nanotube powder

A titanium dioxide, high temperature stable technology, applied in the field of new energy materials and catalytic materials, can solve problems such as fracture, sintering, collapse, etc., and achieve the effects of simple steps, convenient operation and excellent catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

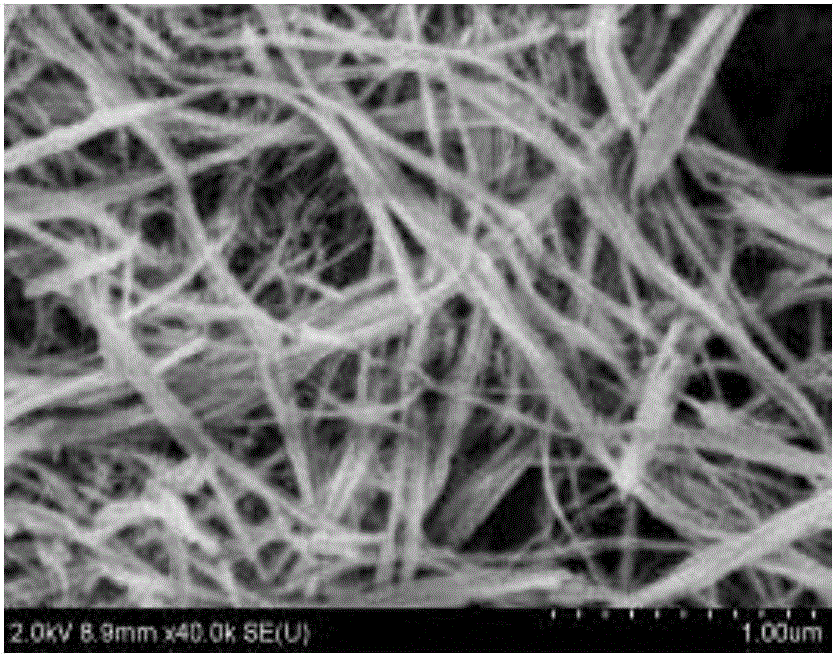

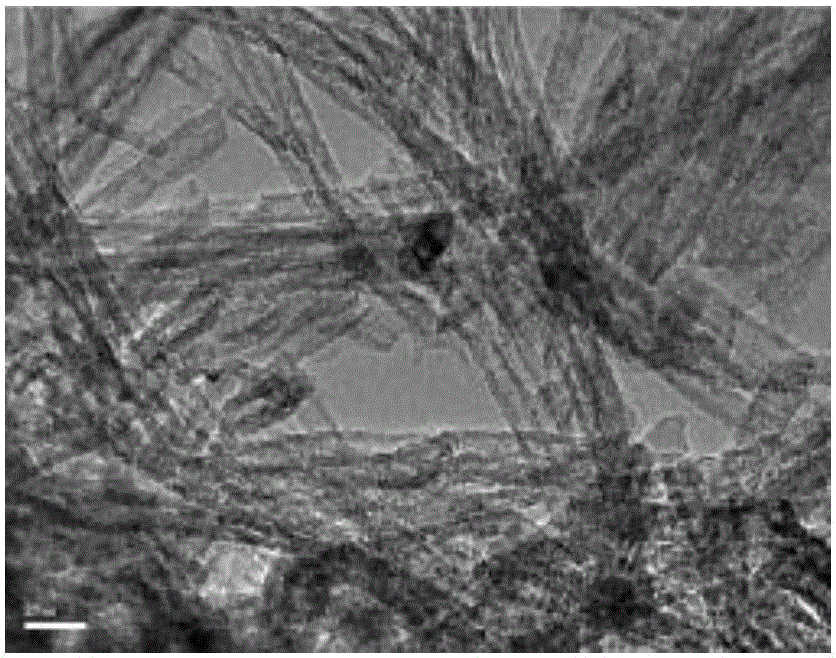

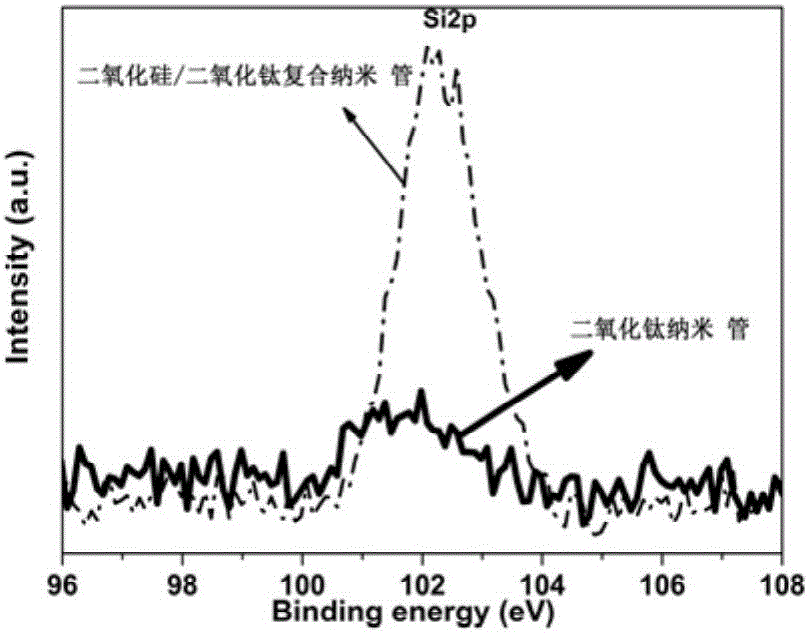

[0032] Add 6g of anatase titanium dioxide nanopowder into 150mL of sodium hydroxide solution with a concentration of 10moL / L, stir and transfer to a reaction kettle, the hydrothermal reaction temperature is 115°C, the reaction time is 24-36h, and naturally cool to room temperature . Filter and wash with deionized water several times until the pH of the washing solution is ≈7. Pour off the supernatant, add 0.15moL / L hydrochloric acid solution to the above powder, stir or sonicate for 2 hours, wash the acid-treated sample with deionized water several times again until the pH of the washing solution is ≈7, filter, and finally Dry the obtained powder at 50° C., and the product is titanate nanotube powder.

[0033] Disperse 2g titanate nanotubes in 50mL deionized water solution, stir and add glacial acetic acid with a volume fraction of 5% to the solution dropwise until the pH of the solution is ≈ 3, stir at room temperature for 1-2 hours, then add 100mL silane coupling agent KH5...

Embodiment 2

[0035]Add 7g of anatase titanium dioxide nanopowder into 175mL of sodium hydroxide solution with a concentration of 10moL / L, stir and transfer to a reaction kettle, the hydrothermal reaction temperature is 115°C, the reaction time is 20-30h, and naturally cool to room temperature . Filter and wash with deionized water several times until the pH of the washing solution is ≈7. Pour off the supernatant, add 0.1moL / L hydrochloric acid solution to the above powder, stir or sonicate for 2-3 hours, wash the acid-treated sample with deionized water several times until the pH of the washing solution is ≈7, filter , and finally dry the obtained powder at 55° C., and the product is titanate nanotube powder.

[0036] Disperse 1.5g titanate nanotubes in 50-80mL deionized aqueous solution, stir and add glacial acetic acid with a volume fraction of 6-8% dropwise to the solution until the pH value of the solution is 3-4, and stir at room temperature for 1-2h Then add 150mL silane coupling a...

Embodiment 3

[0038] Add 8g of anatase titanium dioxide nanopowder into 180mL of sodium hydroxide solution with a concentration of 10moL / L, stir and transfer to a reaction kettle, the hydrothermal reaction temperature is 120°C, the reaction time is 18-24h, and naturally cool to room temperature . Filter and wash with deionized water several times until the pH of the washing solution is ≈7. Pour off the supernatant, add 0.1-0.5moL / L hydrochloric acid solution to the above powder, stir or sonicate for 2-3 hours, and wash the acid-treated sample with deionized water several times until the pH of the washing solution is ≈7 , filter, and finally dry the obtained powder at 50-60° C., and the product is titanic acid nanotube powder.

[0039] 2g titanate nanotubes were ultrasonically stirred and dispersed in 80mL deionized aqueous solution to form solution A, 1g hexadecyltrimethylammonium bromide was dissolved in 15mL deionized aqueous solution to form solution B, 0.6mL orthosilicate ethyl Dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com