Rectangular open magnetic field type electromagnetic vibration table magnetic circuit structure with double-magnetic-circuit two-end symmetric excitation

An electromagnetic vibration, dual magnetic circuit technology, applied in vibration testing, fluid using vibration, testing of machine/structural components, etc., can solve the problems of difficult processing and assembly of permanent magnets, difficult to guarantee assembly accuracy, and limited magnetization effect. , to easily ensure the accuracy of processing and assembly, reduce the difficulty of processing and assembly, and achieve the effect of simple and reliable magnetic circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be described in detail below with reference to the accompanying drawings, and examples will be given.

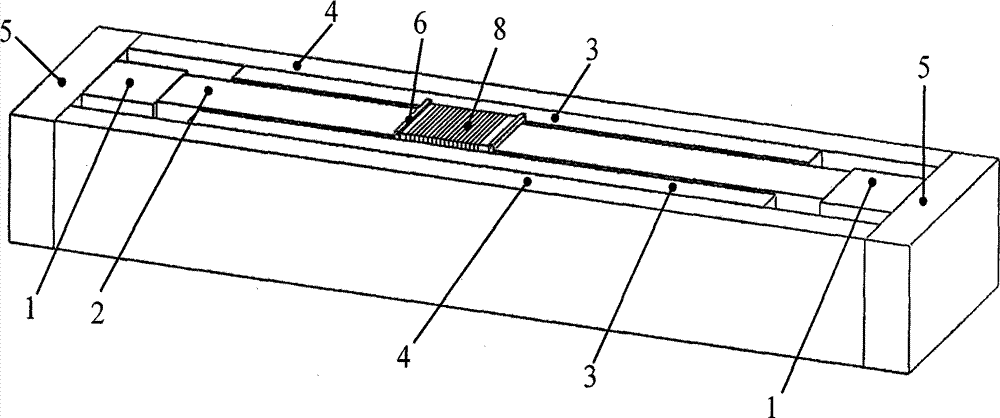

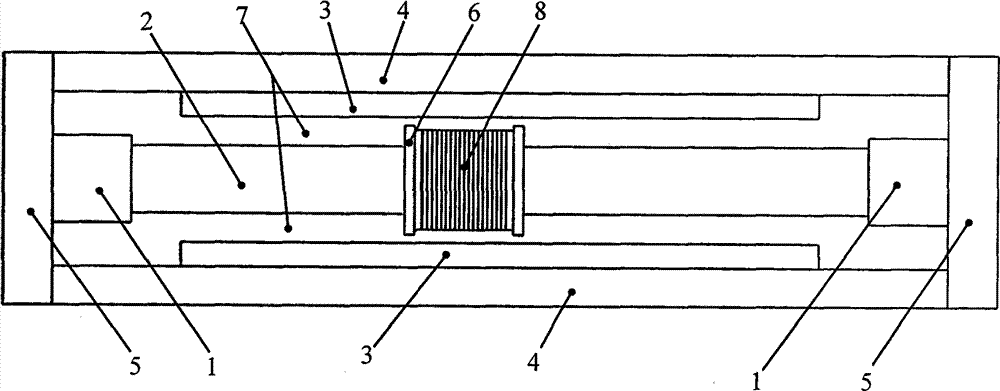

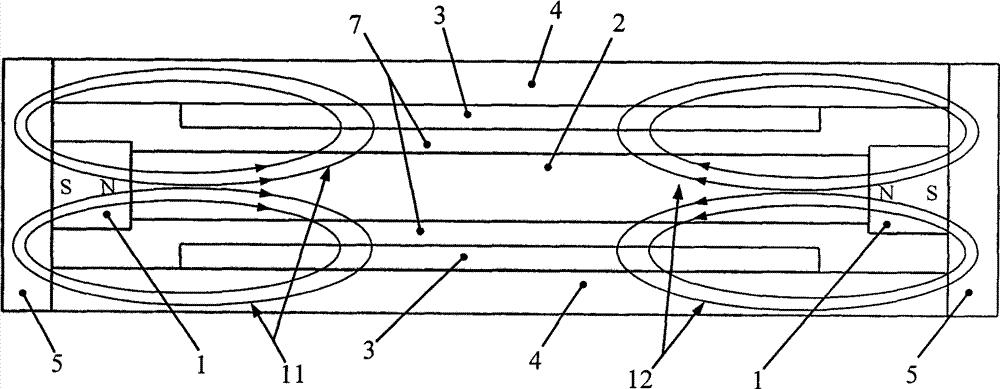

[0041] A rectangular open magnetic field type electromagnetic vibrating table magnetic circuit structure with symmetrical excitation at both ends of the double magnetic circuit, consisting of a permanent magnet 1, a central yoke 2, an inner yoke 3, an outer yoke 4, an end yoke 5, a coil bobbin 6 and The working coil 8 is composed of an axisymmetric structure as a whole. The cross-sections of the permanent magnet 1, the central yoke 2, the inner yoke 3, the outer yoke 4 and the end yoke 5 are all rectangular, and the cross-section of the coil bobbin 6 is square. The two ends of an outer yoke 4 are respectively rigidly connected with two end yokes 5 to form a square-shaped yoke structure. The central yoke 2 is installed on the long axis of the square-shaped yoke structure, and the length of the inner yoke 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com