Patents

Literature

30results about How to "Solve the difficulty of assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

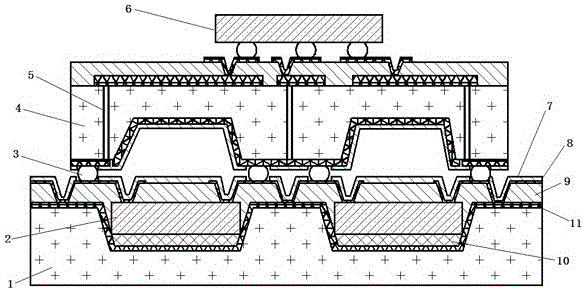

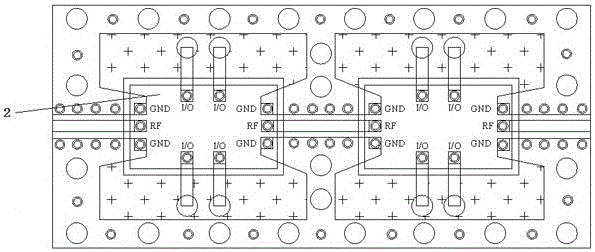

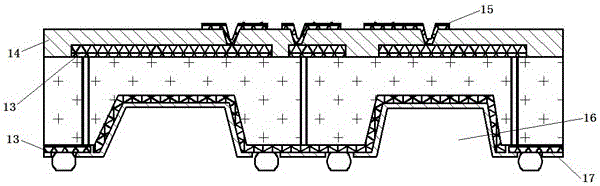

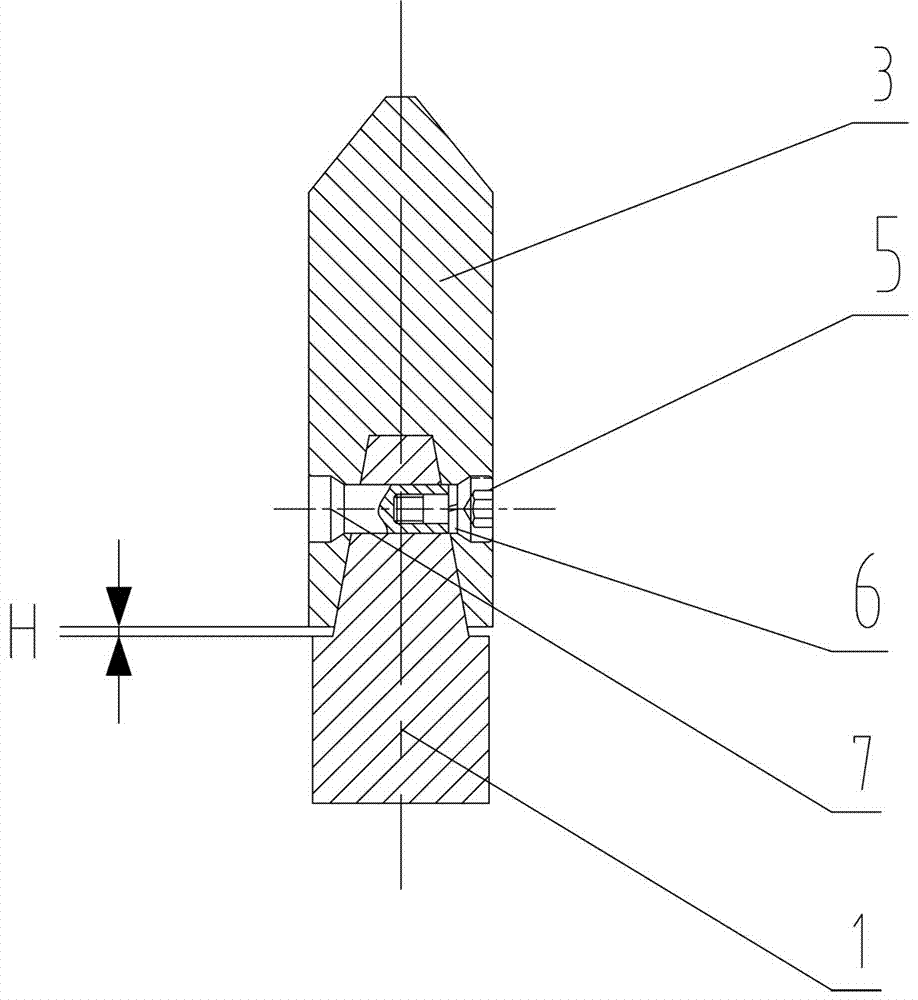

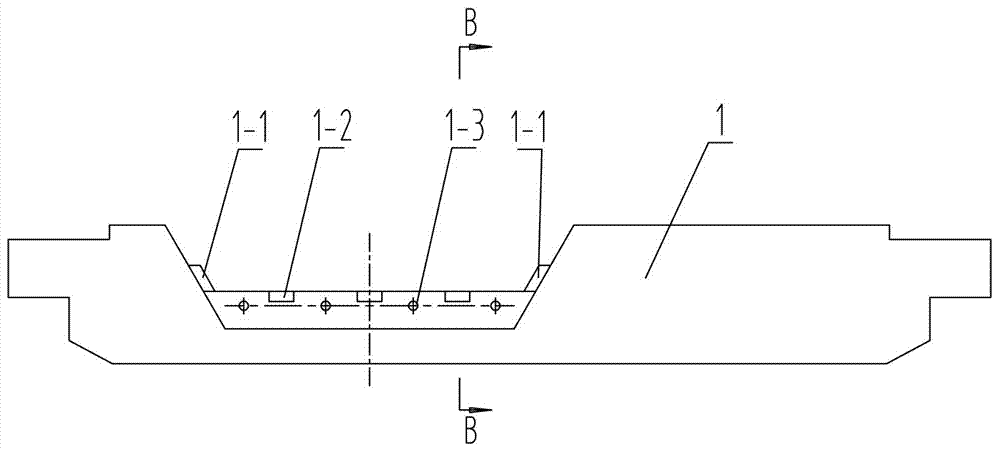

Novel three-dimensional microwave multi-chip module structure

ActiveCN105977235ASolve the difficulty of assemblySolve the sealing problemSemiconductor/solid-state device detailsSolid-state devicesEtchingSolder mask

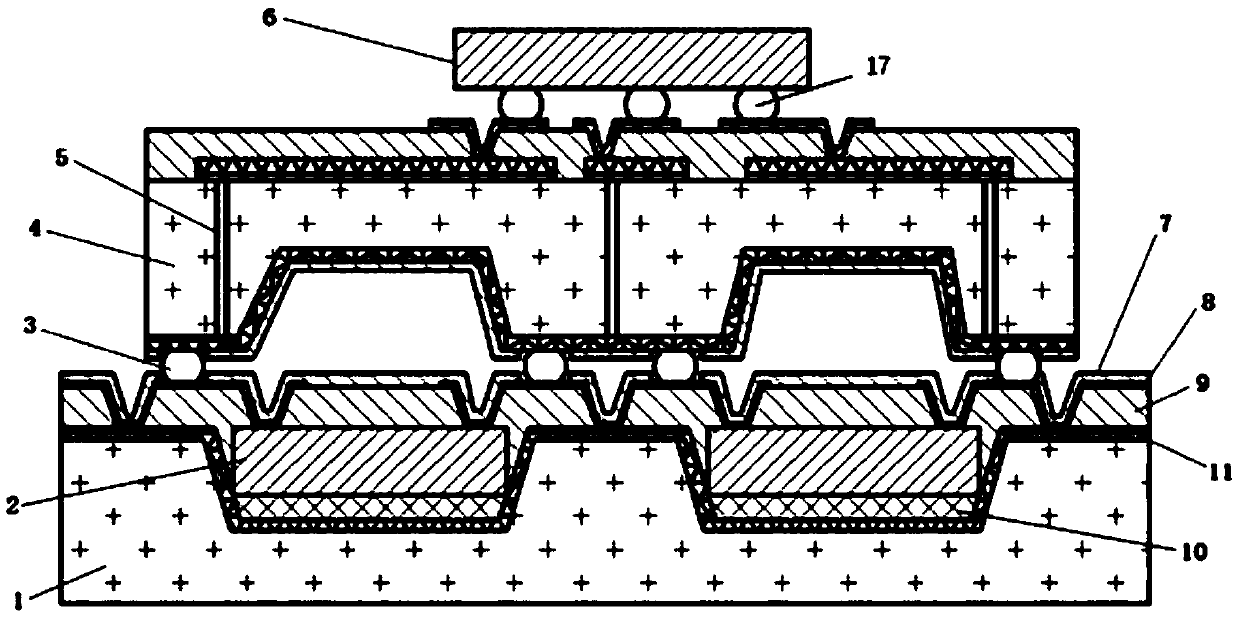

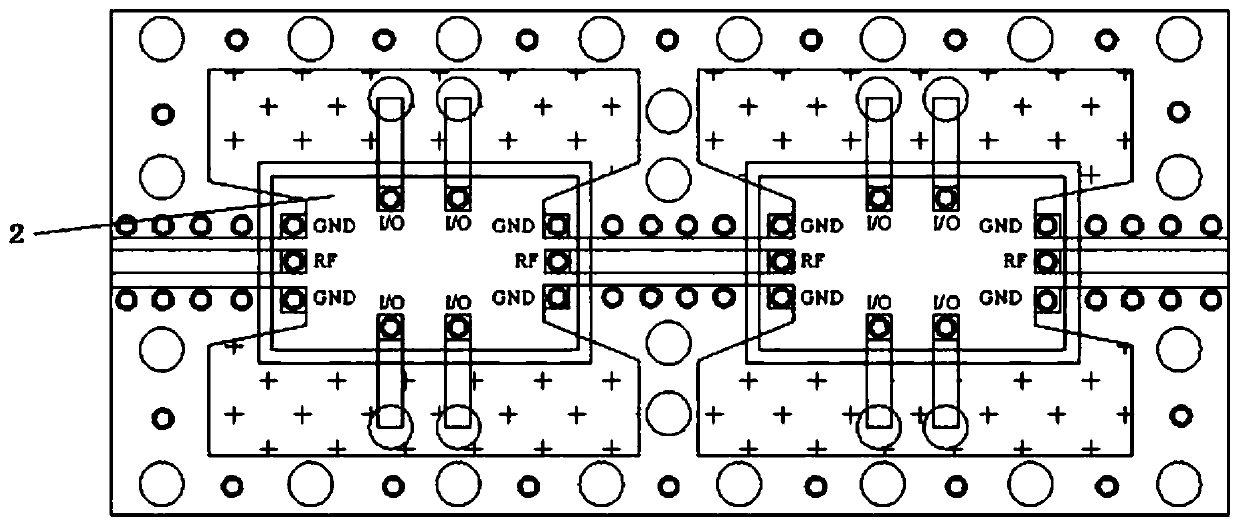

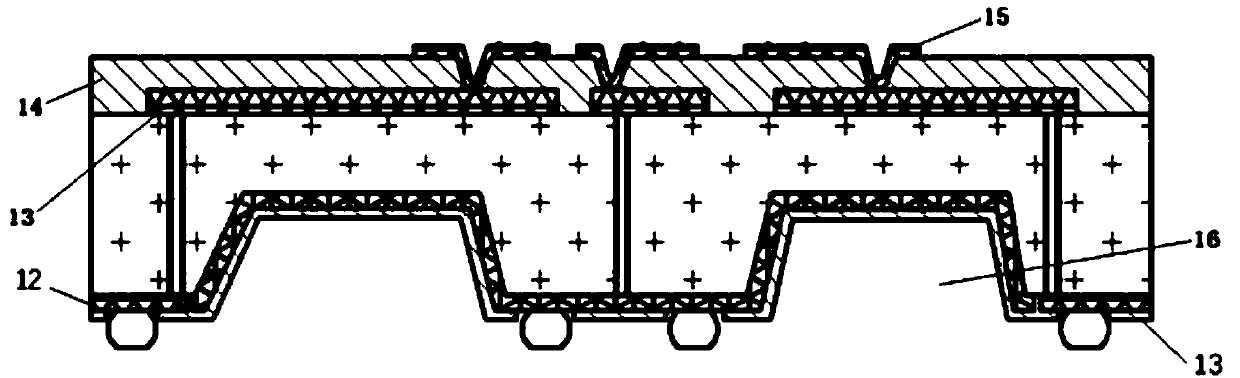

The invention discloses a novel three-dimensional microwave multi-chip module structure, and relates to the field of microwave microelectronic packaging. The structure comprises a bottom silicon chip, an MMIC chip, a top silicon chip and an ASIC chip from the bottom to the top. The bottom silicon chip is provided with a chip installation groove through etching, and the surface of the bottom silicon chip is plated with a first metal layer. The MMIC chip is bound at the bottom of the chip installation groove through a conductive glue layer, and the upper surface of the MMIC chip and the upper surface of the bottom silicon chip are sequentially provided with a sealed protection layer, a second metal layer and a first solder mask layer. A part, corresponding to the chip installation groove of the bottom silicon chip, of the bottom of the top silicon chip is provided with a bottom groove in an etching manner. The corresponding parts of the bottom and top silicon chips are respectively provided with a welding ball convex point pole in an etching manner. A third solder mask layer of the top silicon chip is provided with a metal electrode in an etching manner, and the ASIC chip is welded on the metal electrode of the top silicon chip. The technological production of a three-dimensional microwave multi-chip module is completed in a mode of wafer level through employing a silicon cavity structure and benzocyclobutene secondary wiring, and the production efficiency is improved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

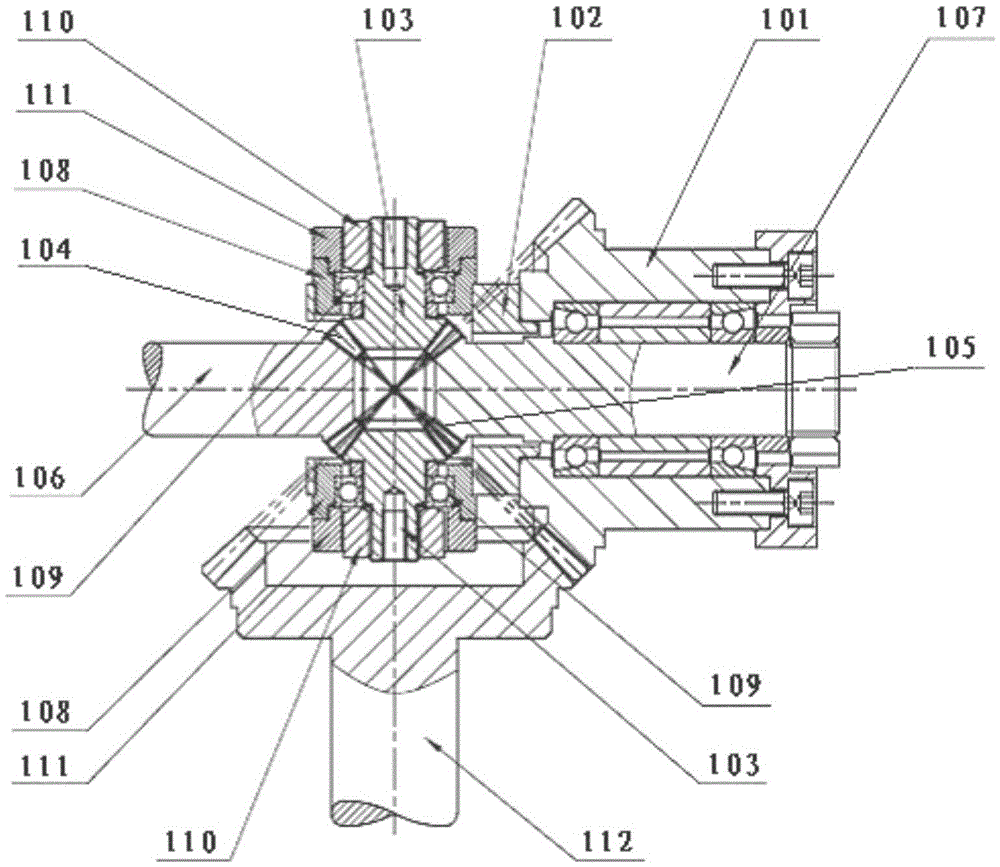

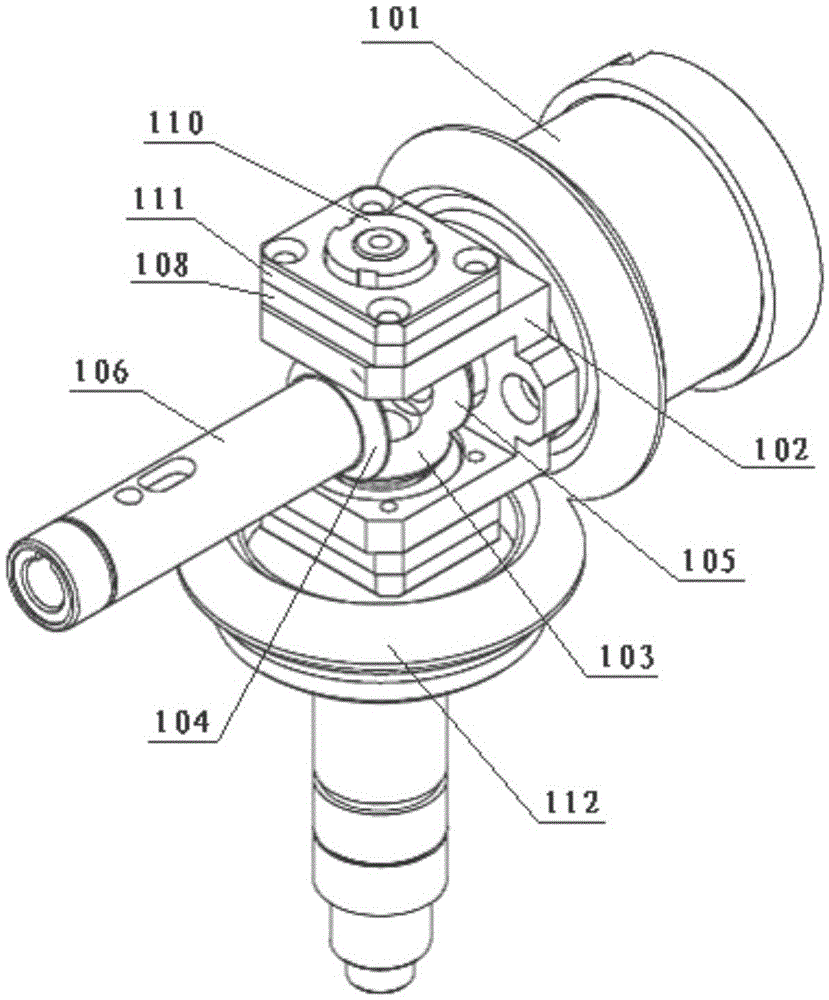

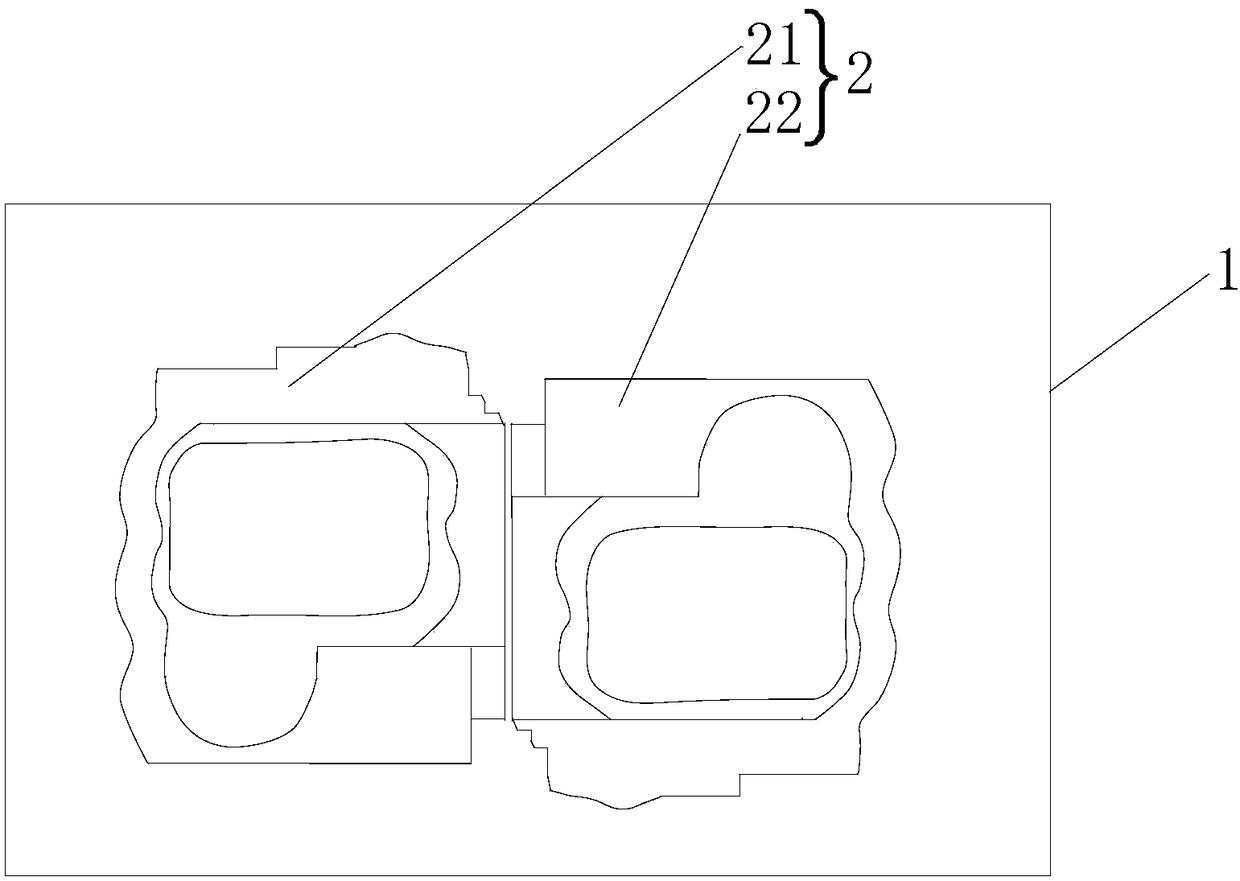

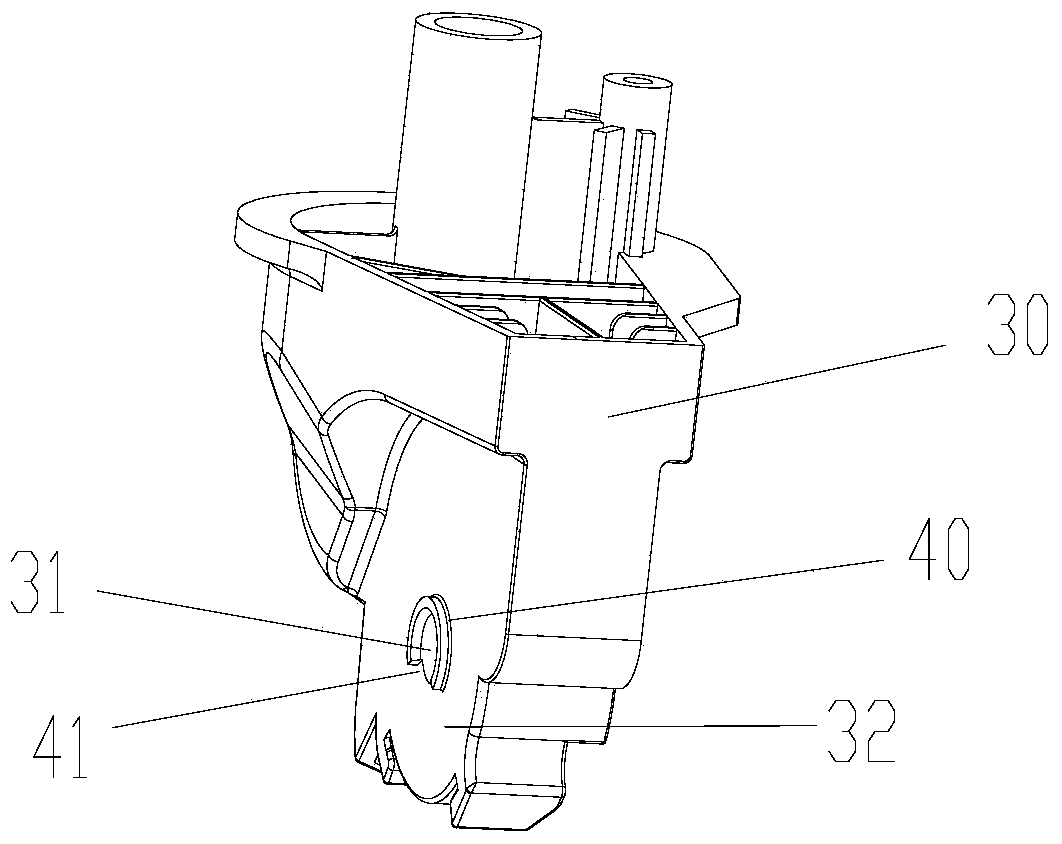

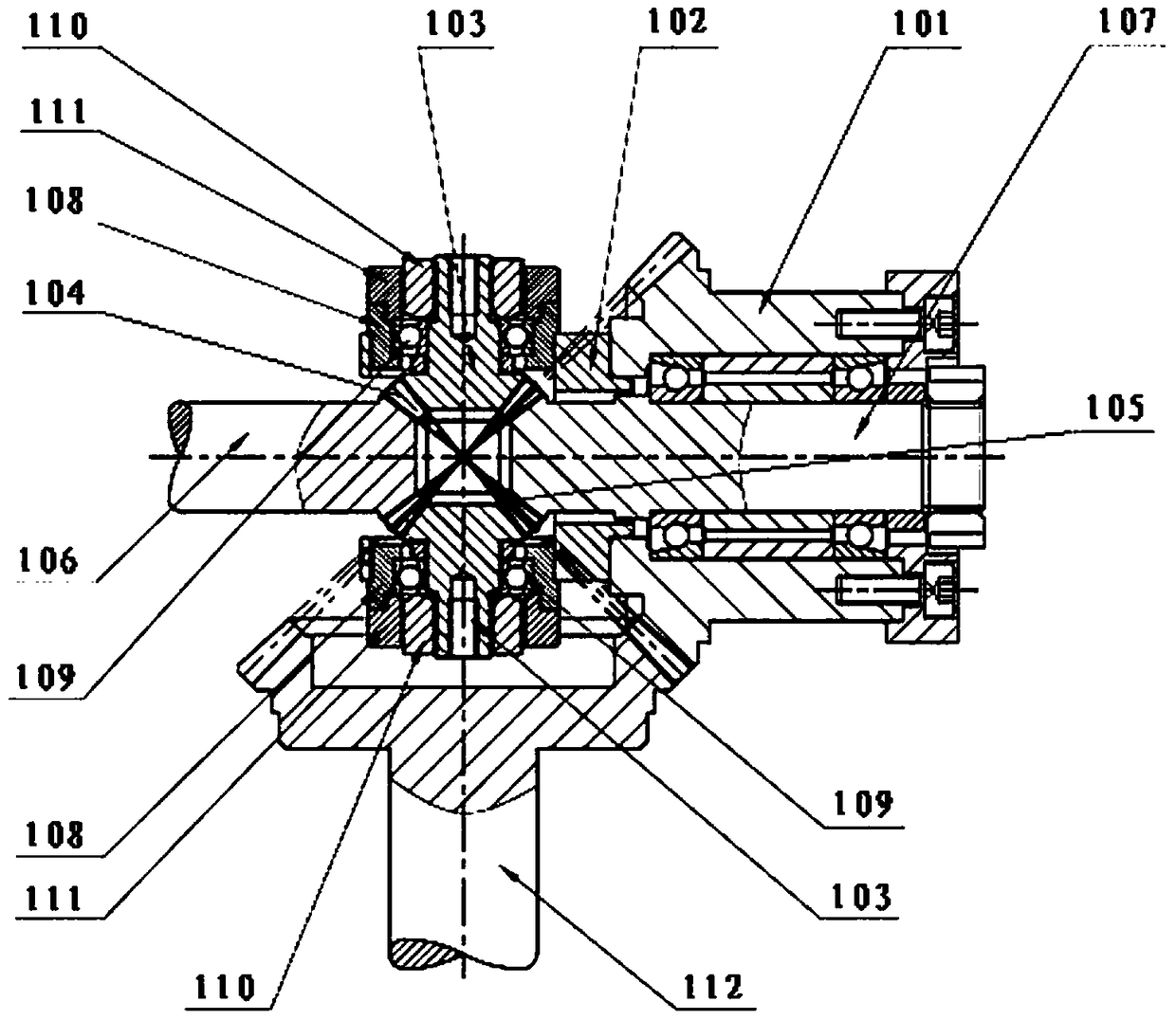

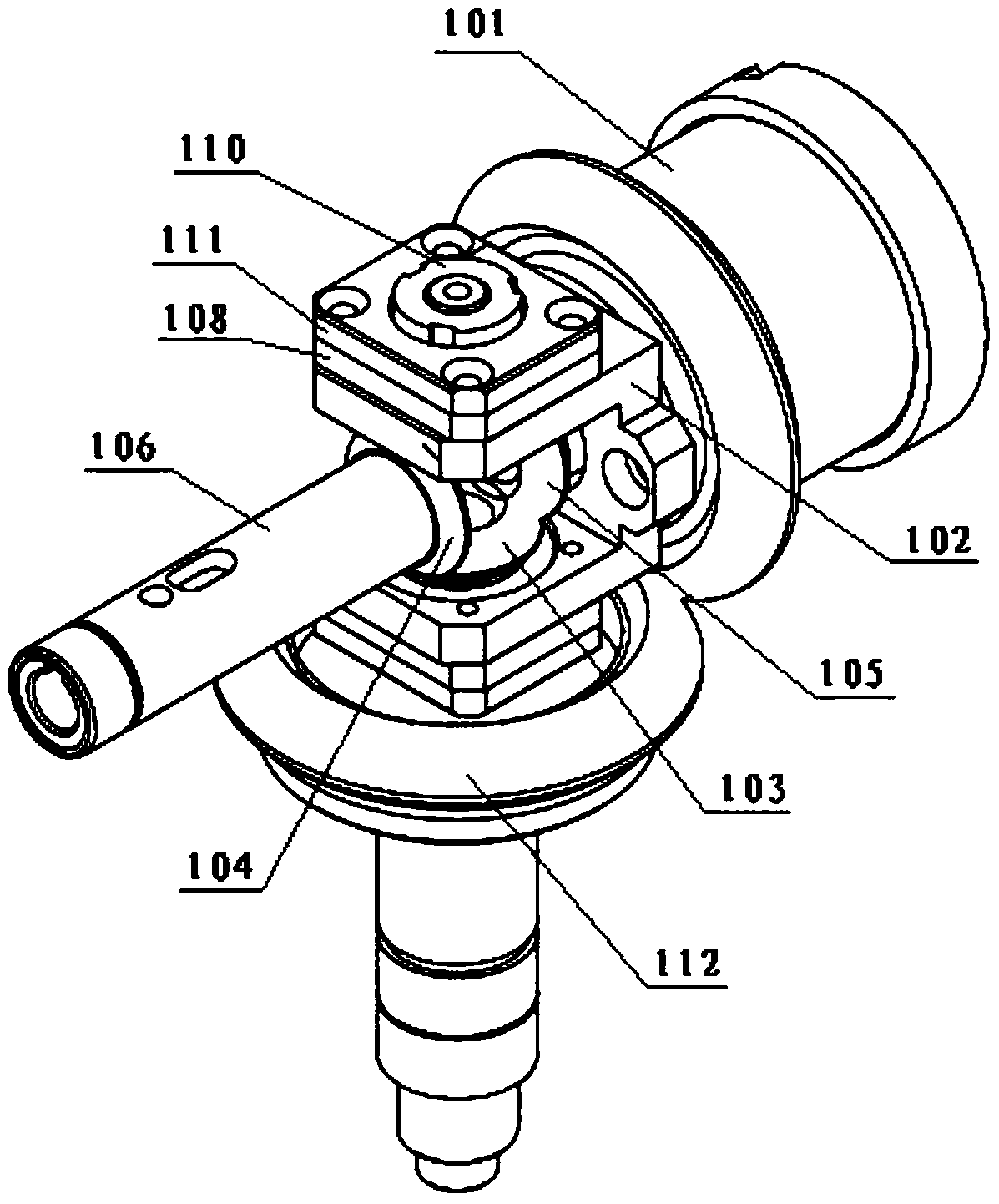

Differential planetary gear structure and vehicle

The invention provides a differential planetary gear structure which comprises a driven gear, a planetary gear carrier, planetary gears, a left half axle gear, a right half axle gear, a left half axle and a right half axle, wherein the left half axle gear is arranged on the left half axle, the right half axle gear is arranged on the right half axle, the left half axle gear and the right half axle gear are meshed with the planetary gears respectively, each planetary gear comprises an axle and a gear fixed at one end of the axle, the axle is rotationally arranged on the planetary gear carrier, the planetary gear carrier is arranged on the driven gear and rotates with the driven gear synchronously, and the driven gear is rotationally arranged on the left half axle or the right half axle in a sleeving manner. The invention further relates to a vehicle. The differential planetary gear structure and the vehicle are simple and compact in structure, omit a straight axle or a cross axle between the two planetary gears compared with a traditional differential, reduce the processing difficulty and the processing and manufacturing costs, are simpler to assemble and have good extendability and universality.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

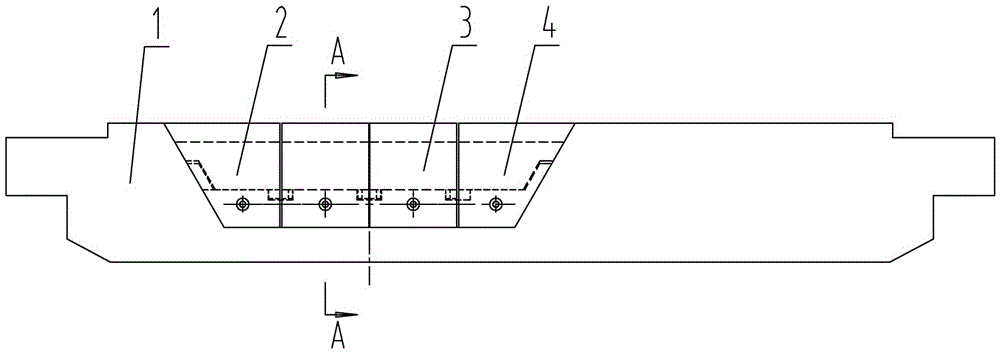

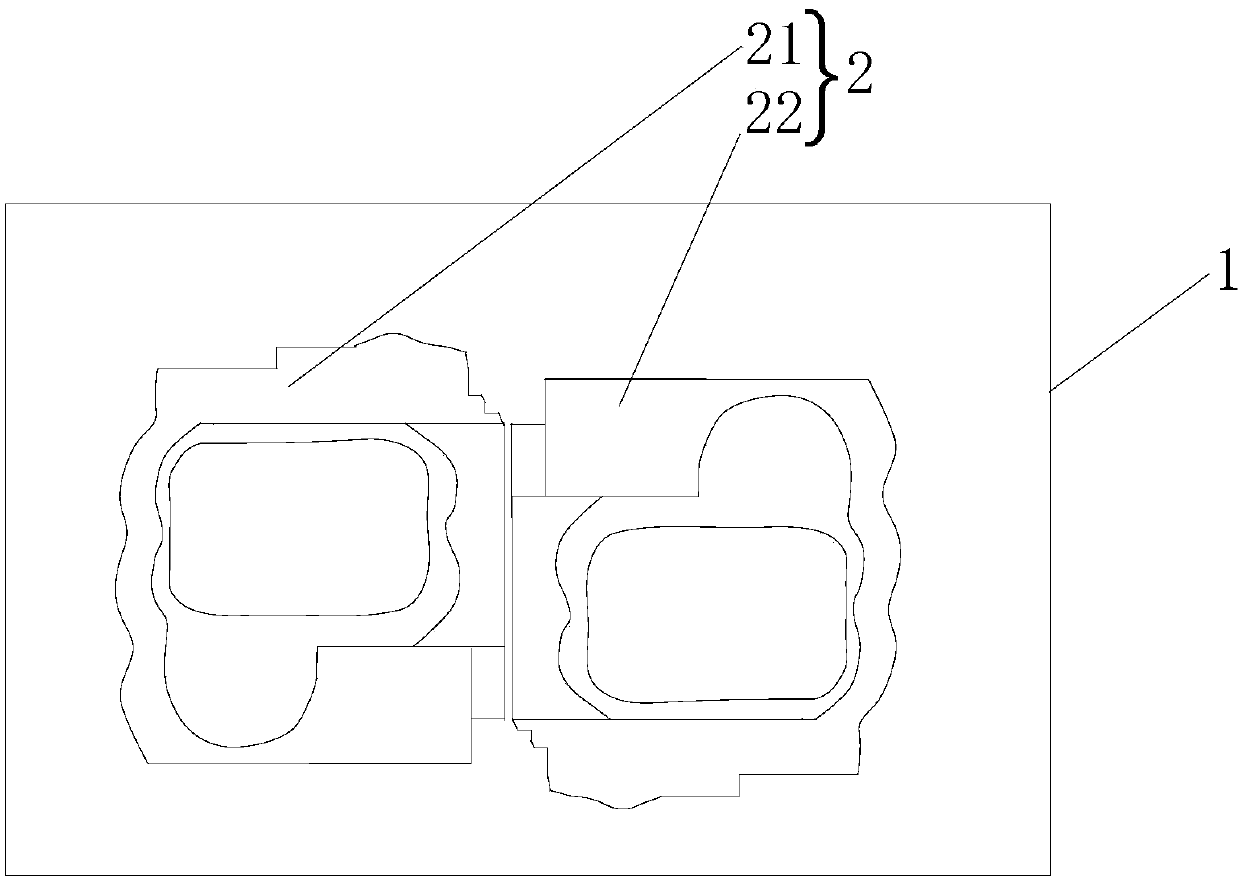

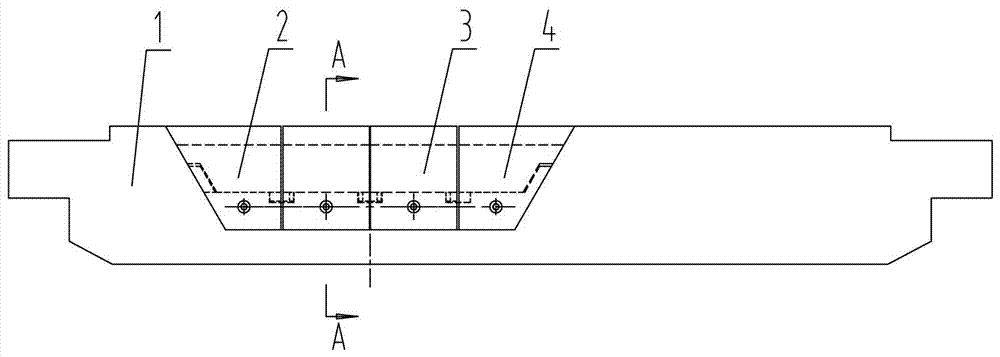

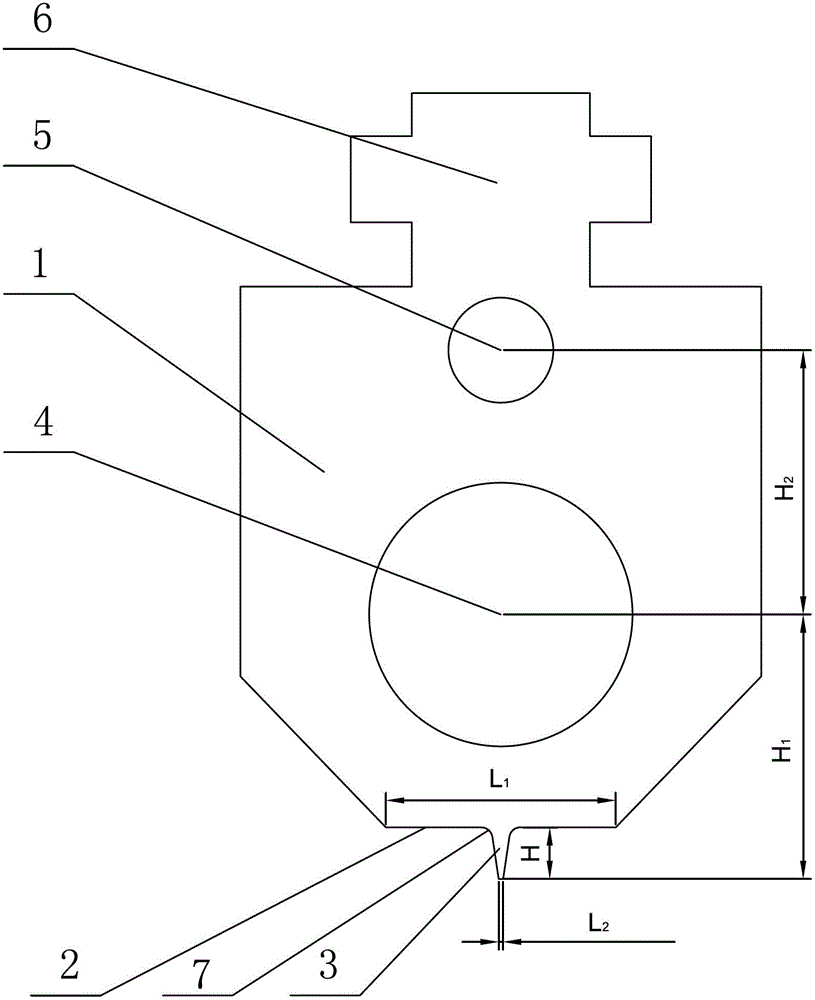

Casting mold for multiple directional control valve

InactiveCN108500206ASolve the difficulty of assemblySolve cleanupFoundry mouldsFoundry coresCasting moldMaterials science

The invention discloses a casting mold for a multiple directional control valve. The casting mold for the multiple directional control valve comprises a sand box, outer shells and a mud core. The mudcore is horizontally arranged in the outer shells, and the outer shells are embedded in the sand box. A cavity for the multiple directional control valve is formed between the outer shells and the mudcore. The number of the outer shells is two, the outer shells refer to the outer shell I and the outer shell II, the outer shell I and the outer shell II are arranged in the sand box side by side, and the two corresponding outer side surfaces of the outer shell I and the outer shell II are attached to each other. The mud core comprises a main core and a plurality of small cores, the main core andthe multiple small cores are assembled into the whole mud core through auxiliary holes, a core rod for forming the multiple directional control valve is arranged in the whole mud core, an air outlethole is formed in the top of the whole mud core, and the air outlet hole is guided out through a steel wire. By means of the casting mold for the multiple directional control valve, assembling difficulty of the mud core can be solved, and the number of defects of castings can be reduced.

Owner:南通曼淇威电气有限公司

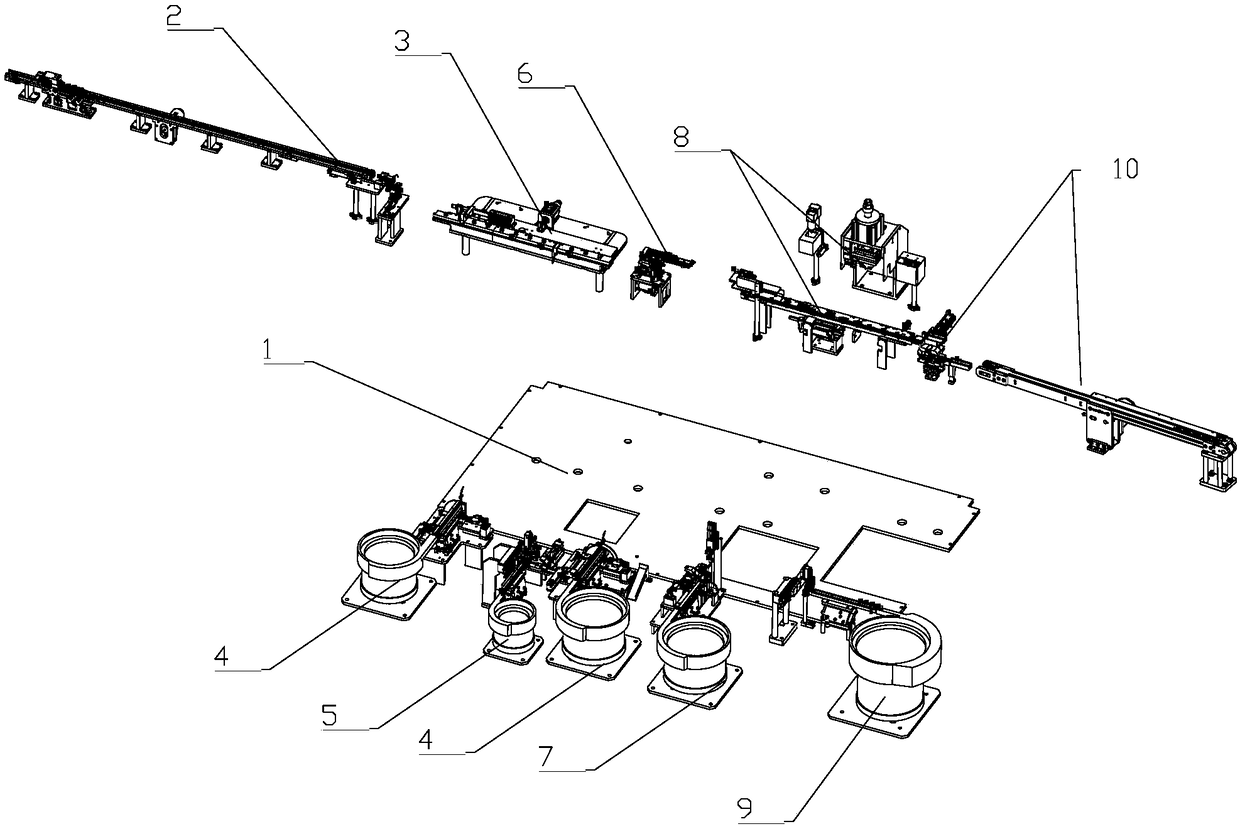

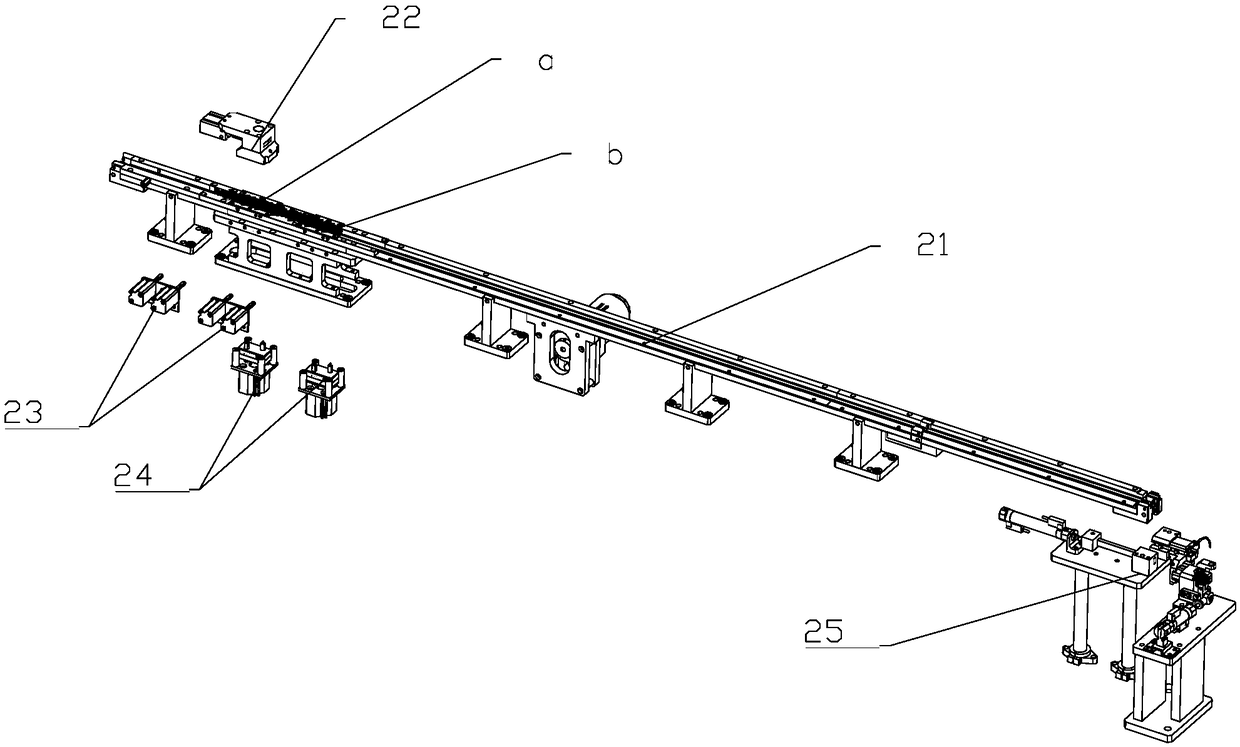

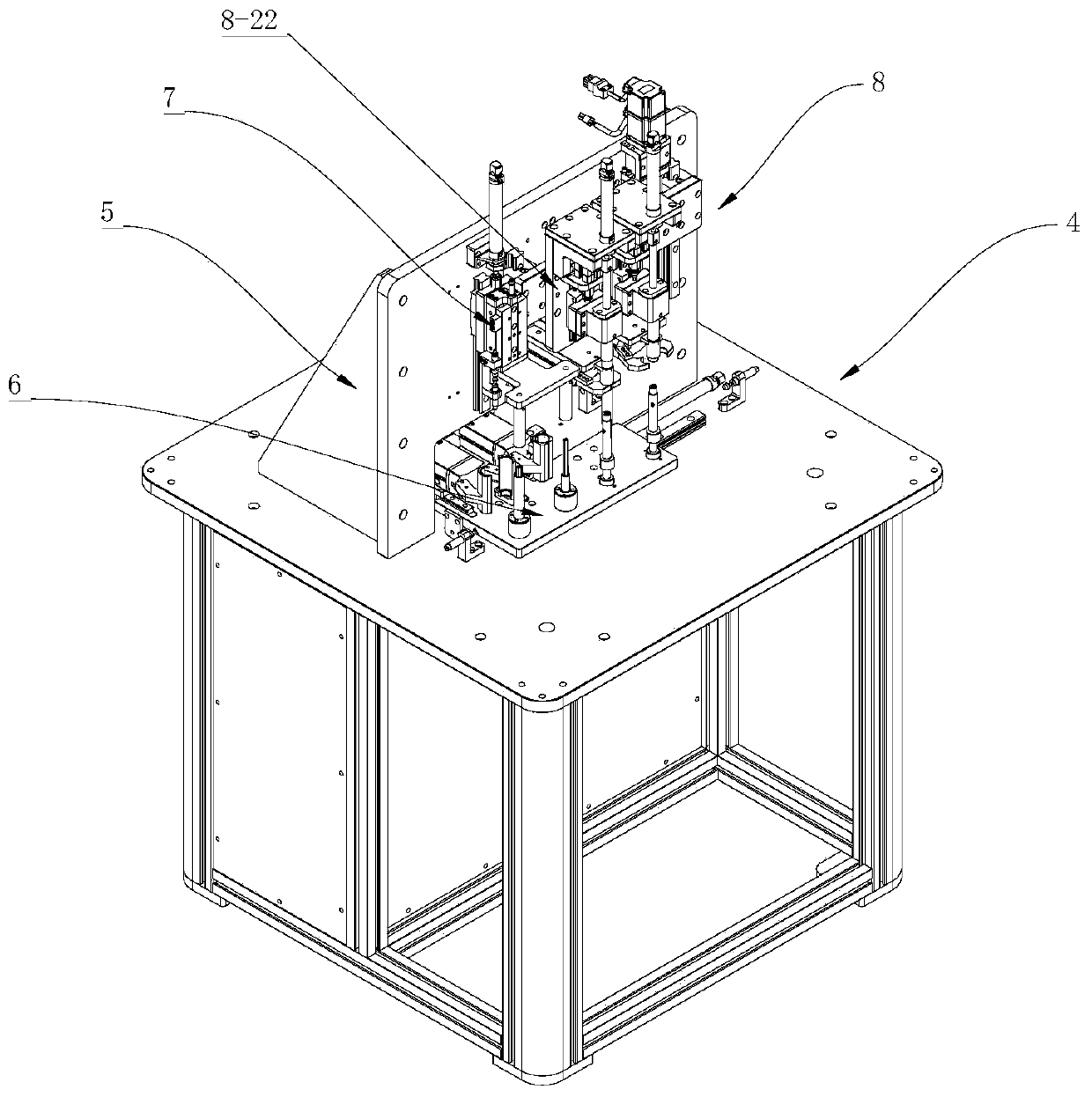

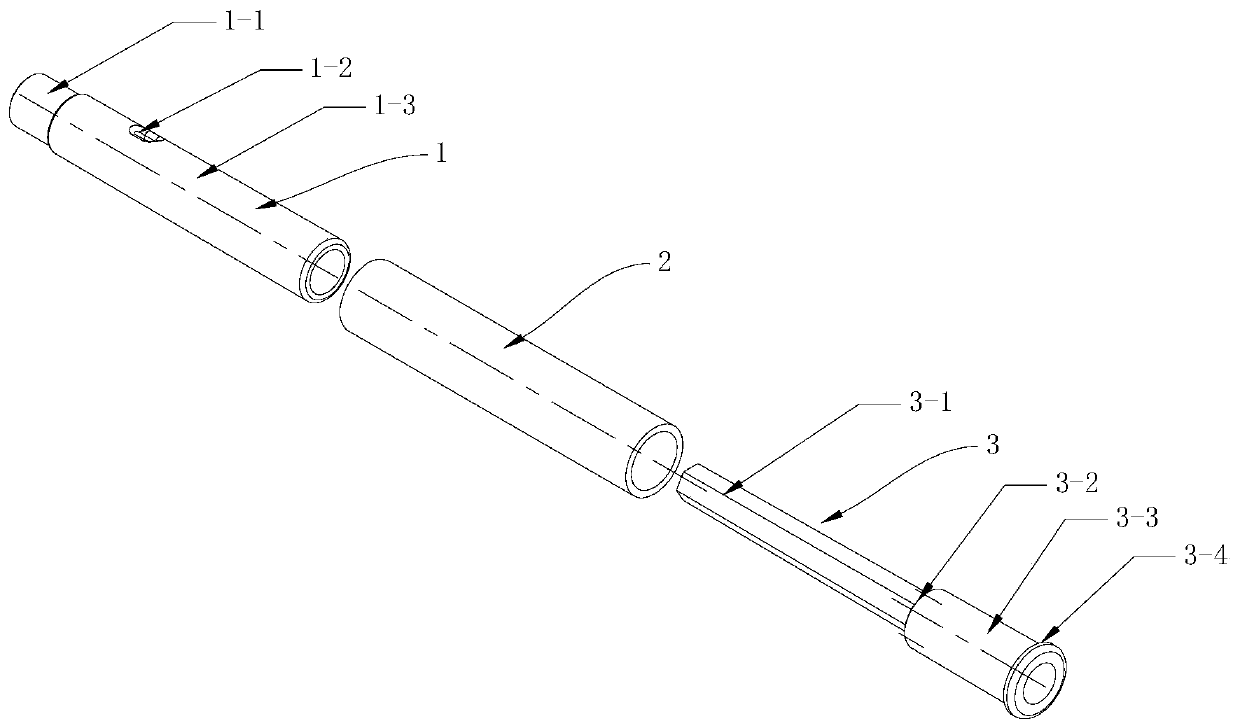

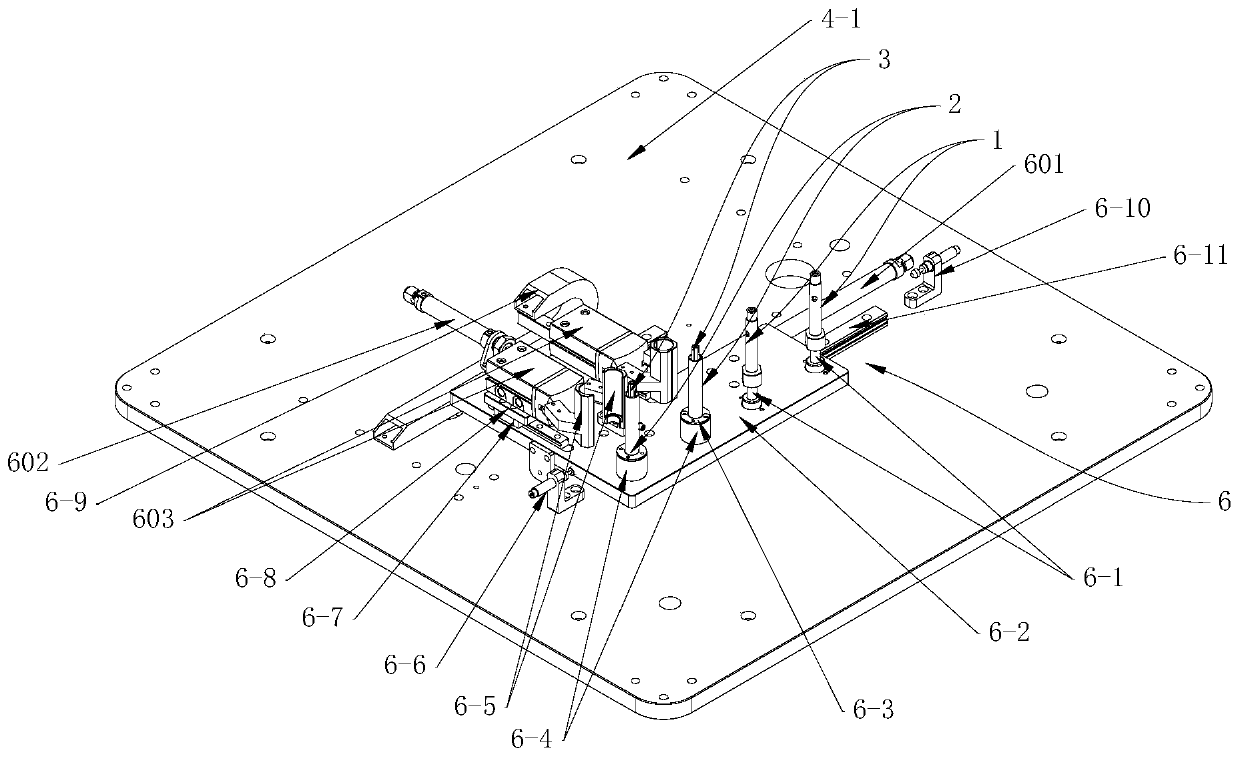

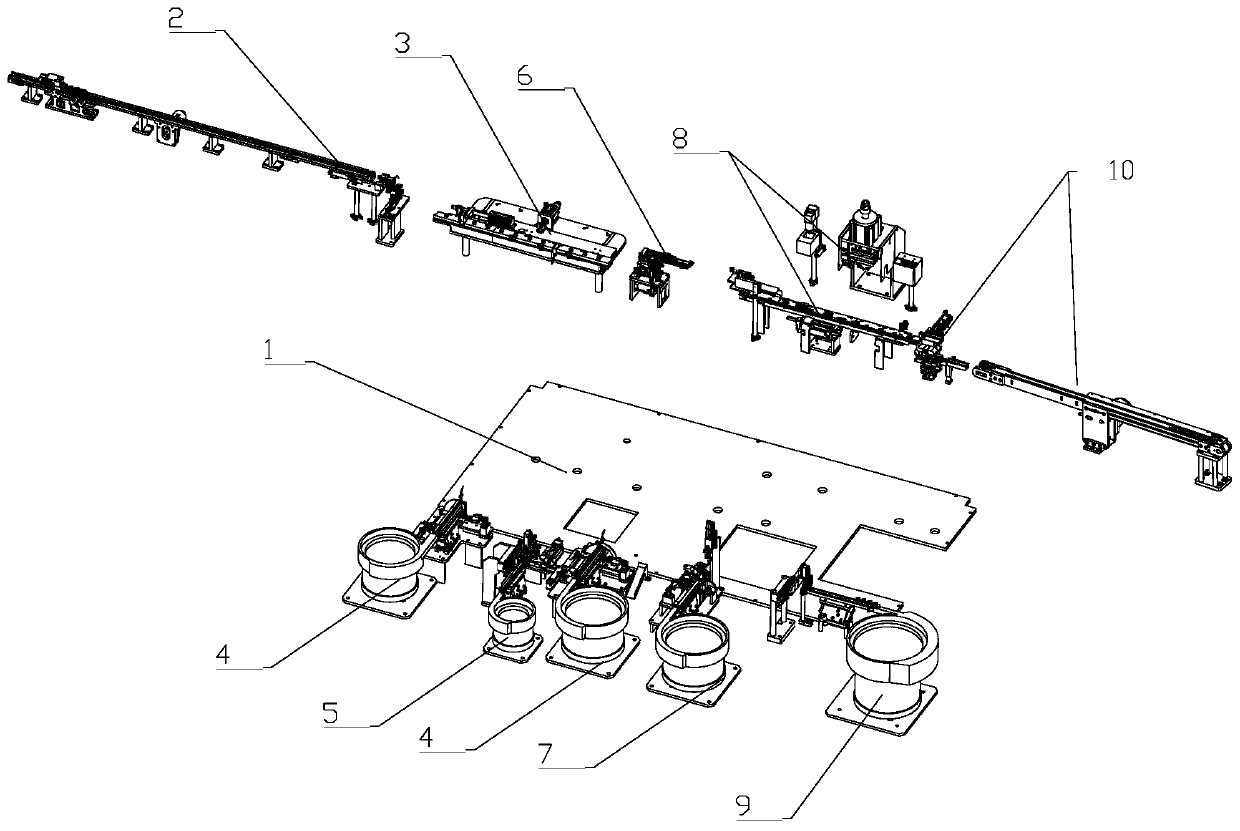

Micro-switch full-automatic assembly production system and pressing, sorting and feeding device

ActiveCN109346348ASolve the difficulty of assemblyImprove pass rateElectric switchesSortingEngineeringDISC assembly

The invention relates to the field of production of electronic elements, in particular to a micro-switch full-automatic assembly production system and a pressing, sorting and feeding device. The pressing, sorting and feeding device for the full-automatic assembling of the micro switch comprises a pressing centrifugal disc assembly, a pressing vibration material rail assembly, a pressing moving-taking block, a slide groove, an eleventh air cylinder, a fifth mounting base, a carrying mechanical arm mechanism, a pressing and tightening mechanism and a third photoelectric sensor assembly. The problem that the assembling difficulty is large in the assembling process, the pressing shape cannot be assembled in one step like a terminal and has to be divided into three parts of sorting, assemblingand tightening are solved, so that the qualified rate of machined finished products is high, and the interference between the mechanisms is small.

Owner:昆山晟欧威自动化科技有限公司

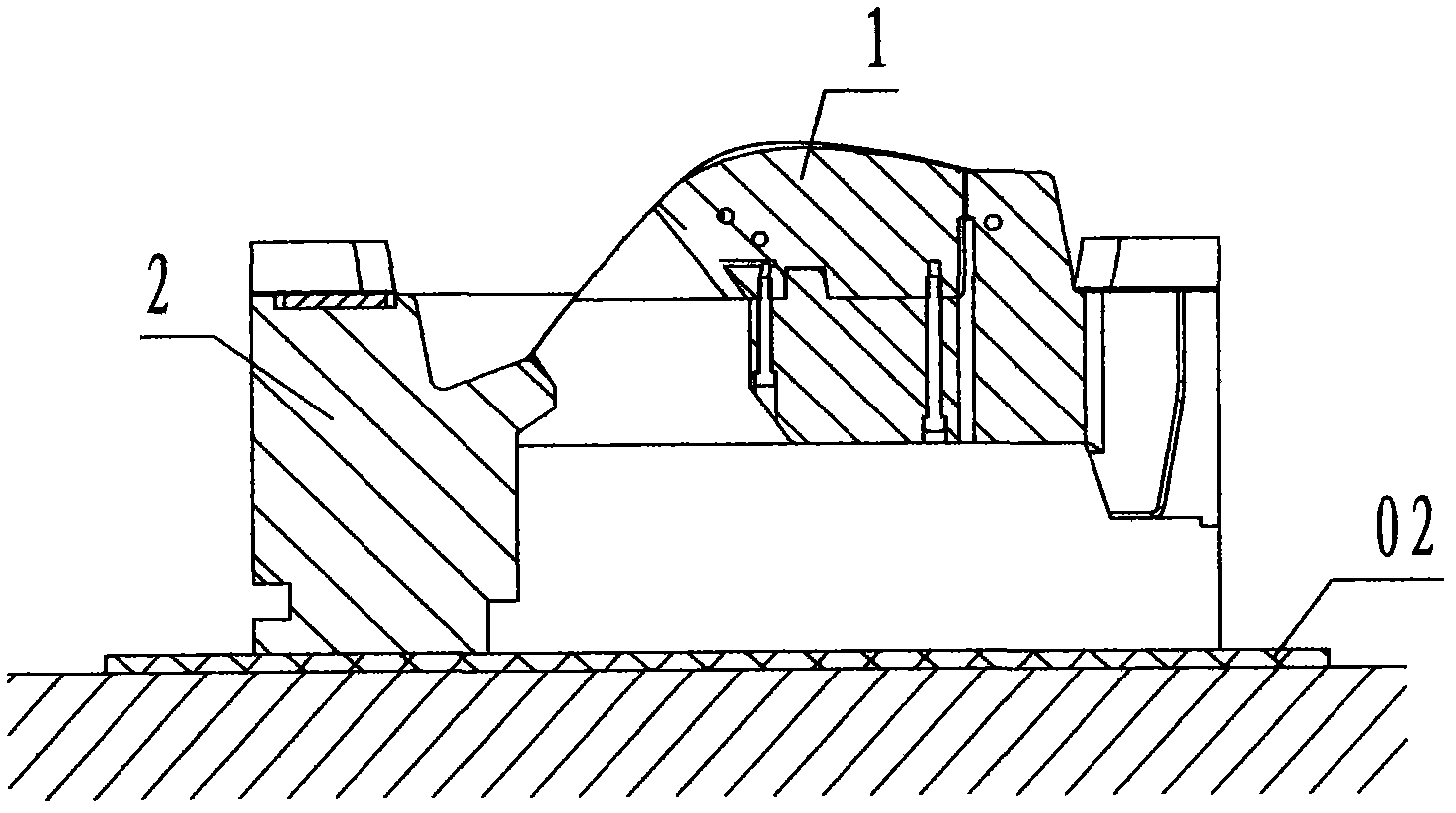

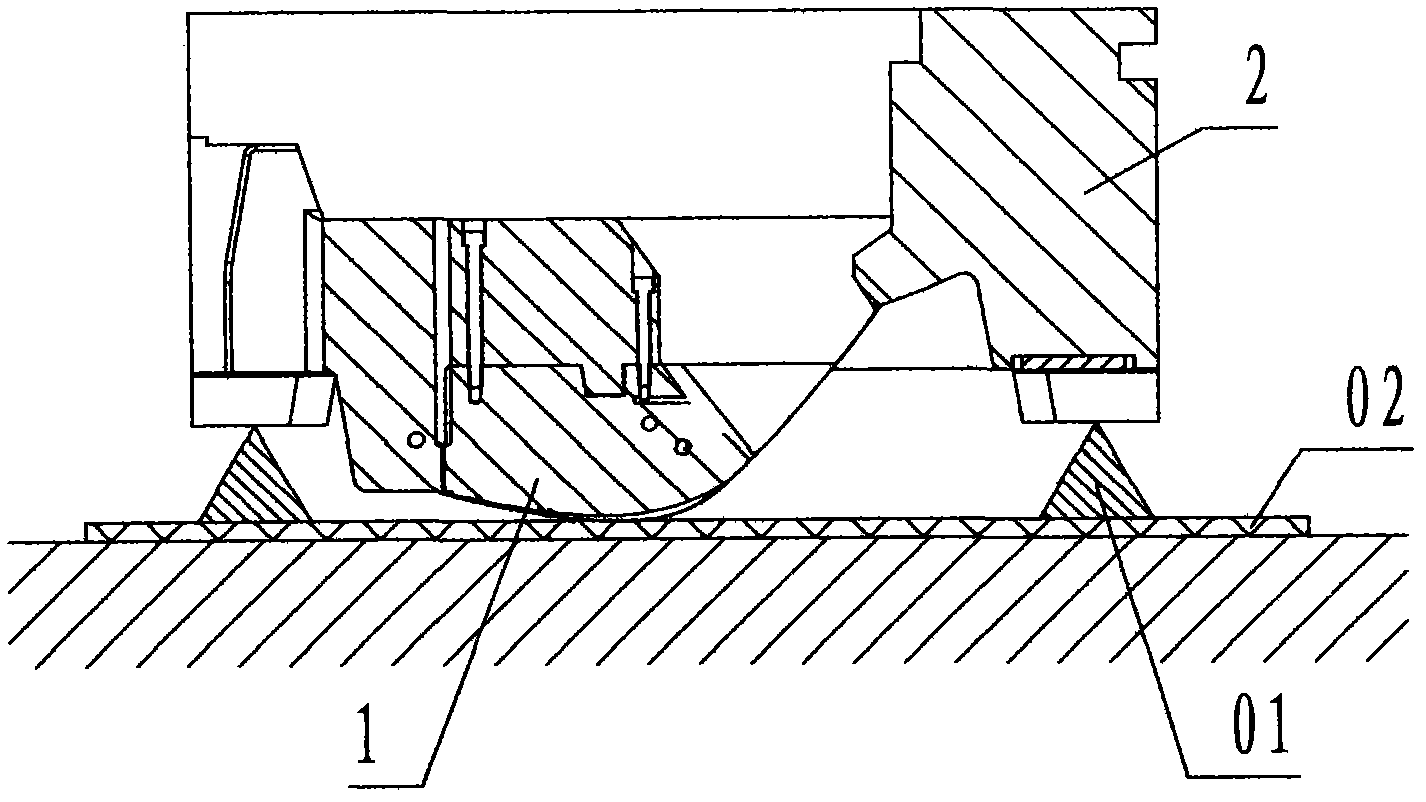

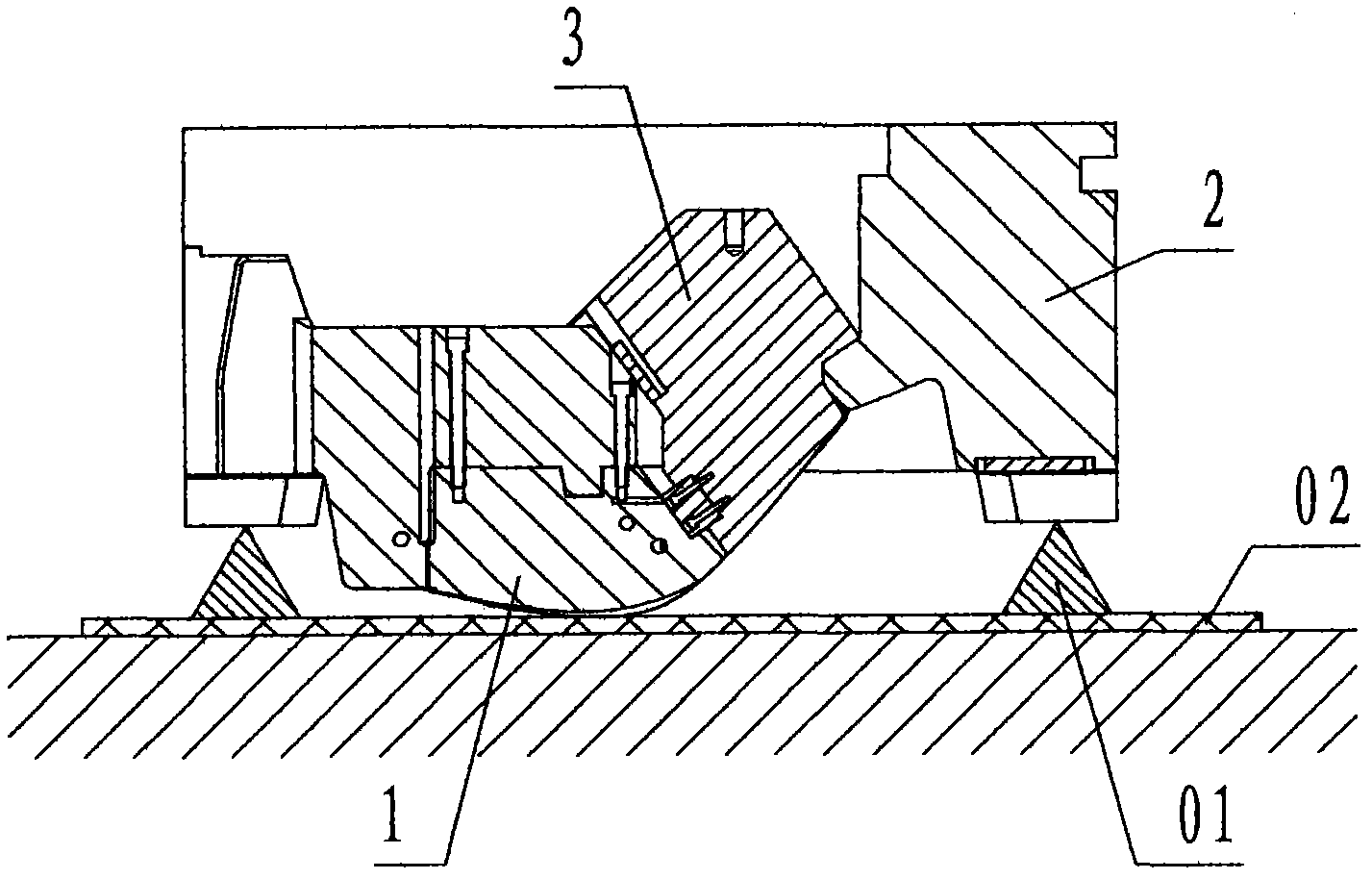

Method for assembling heavy core-pulling mechanism of large injection mould

The invention discloses a method for assembling a heavy core-pulling mechanism of a large injection mould. Firstly, a movable mould core is forwardly mounted in a movable mould carrier plate, and then the movable mould carrier plate is turned by 180 degrees, so that the bottom of the movable mould carrier plate faces up and the movable mould carrier plate is leveled. Secondly, the bottom of a core-pulling slider is lifted by a lifting ring, and the core-pulling slider is vertically lifted along a profile and inserted into core-pulling slots of the movable mould carrier plate and the movable mould core. Thirdly, a core-pulling sliding seat is guided into the movable mould carrier plate in a lifted manner along the direction of a T-shaped groove at the tail of the core-pulling slider. Fourthly, a core-pulling insert is inserted into the space between the movable mould carrier plate and the core-pulling slider in a lifted manner and is fixedly connected with the movable mould carrier plate through screws. Fifthly, a core-pulling cover plate covers the core-pulling sliding seat in a lifted manner and is fixedly connected with the movable mould carrier plate through screws. By the aid of the technical scheme, the method overcomes the shortcomings that the prior art is labor-consuming and time-consuming, and the profile of a core-pulling slider is easily damaged. By means of inverted assembly, assembly of the heavy core-pulling mechanism of the large injection mould is labor-saving and time-saving, and the profile of the core-pulling slider is not damaged.

Owner:宁海胜利模具有限公司

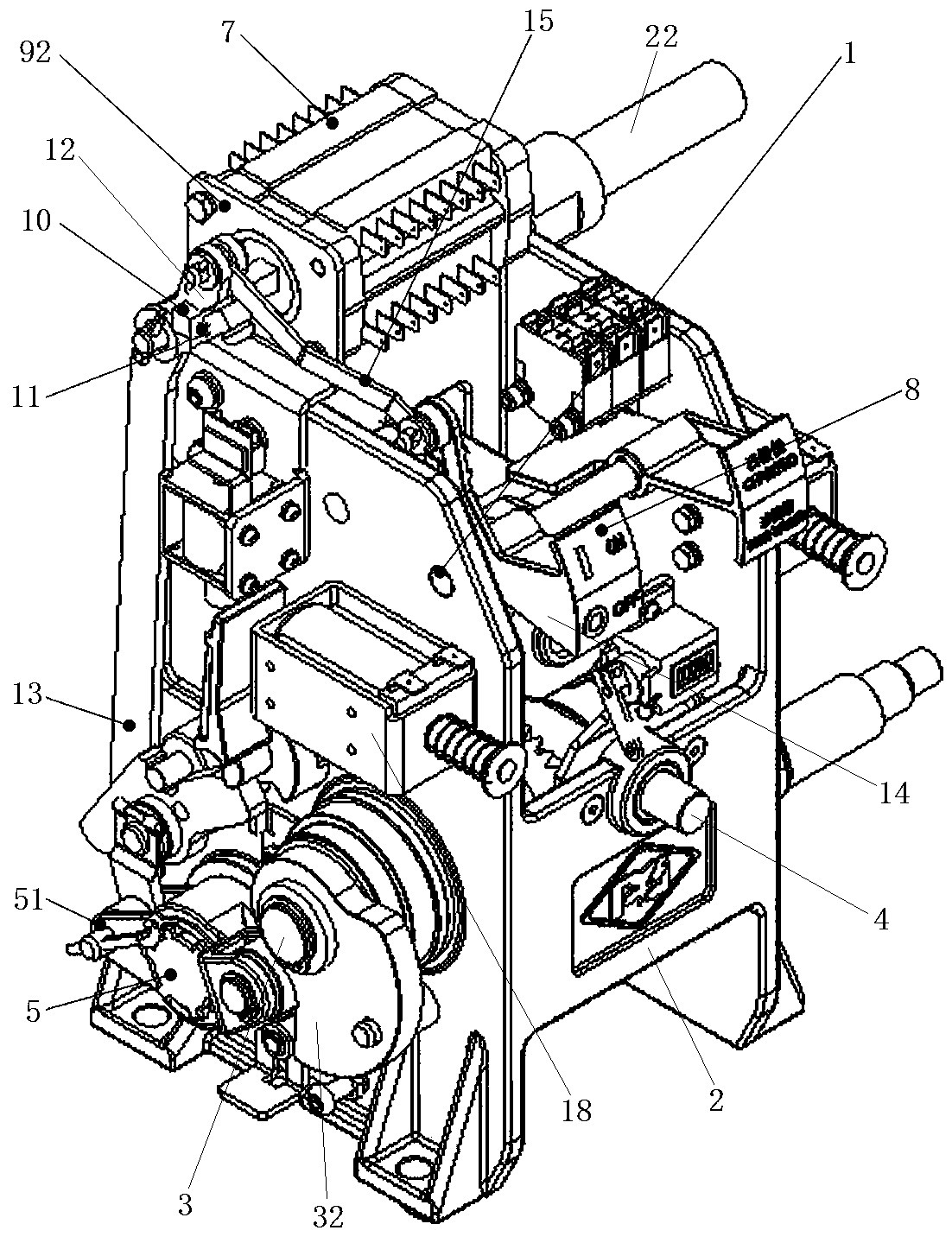

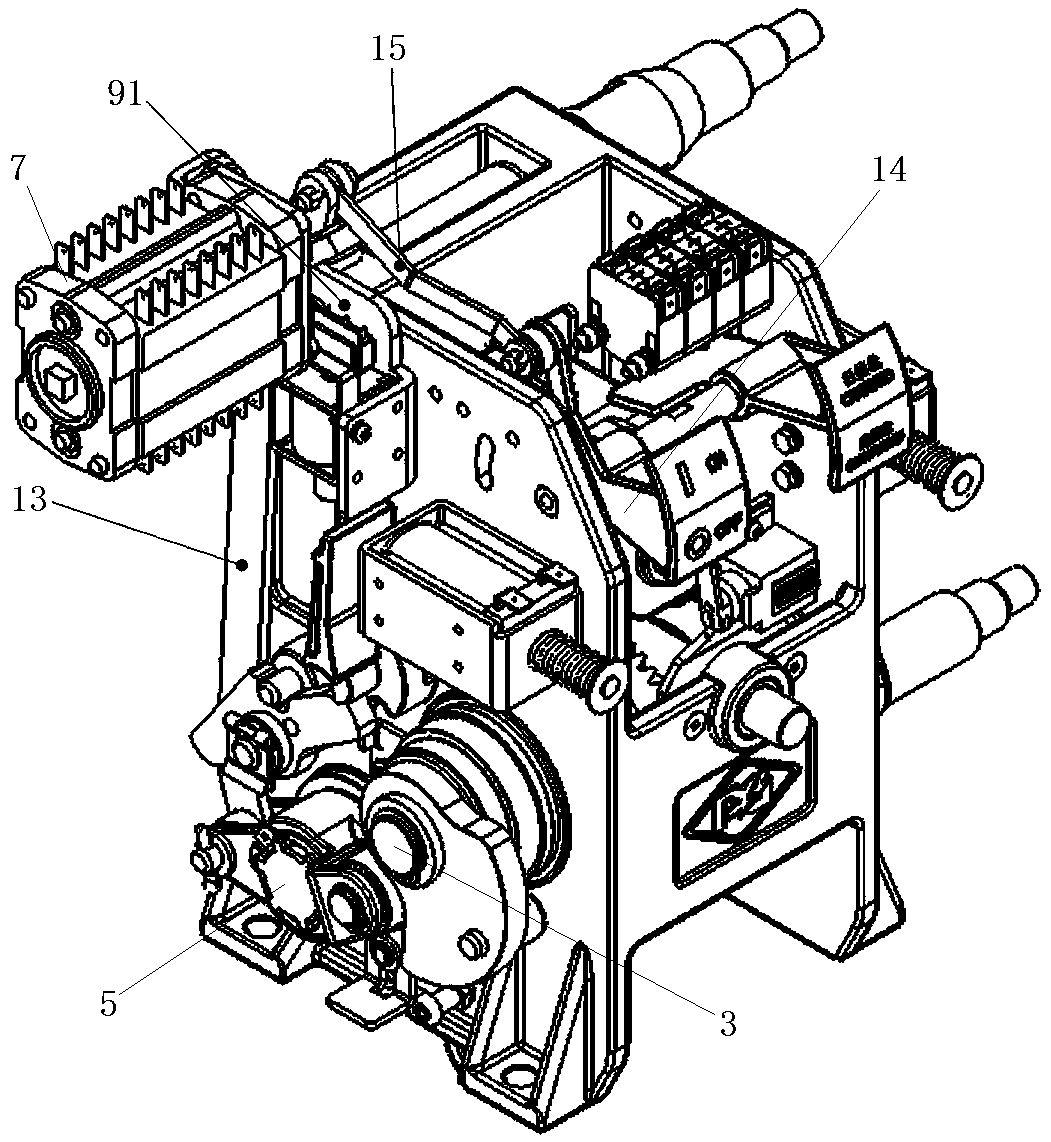

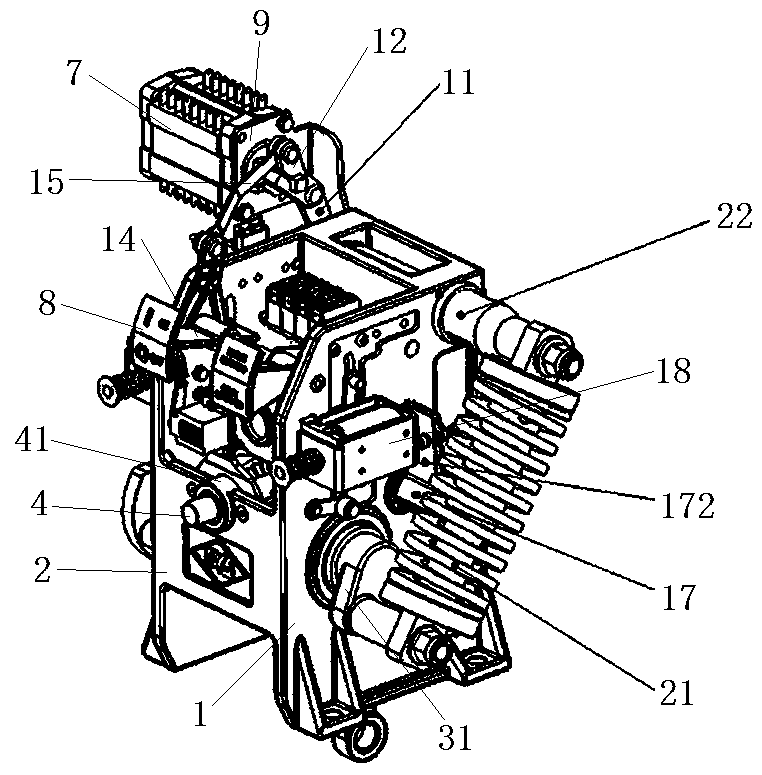

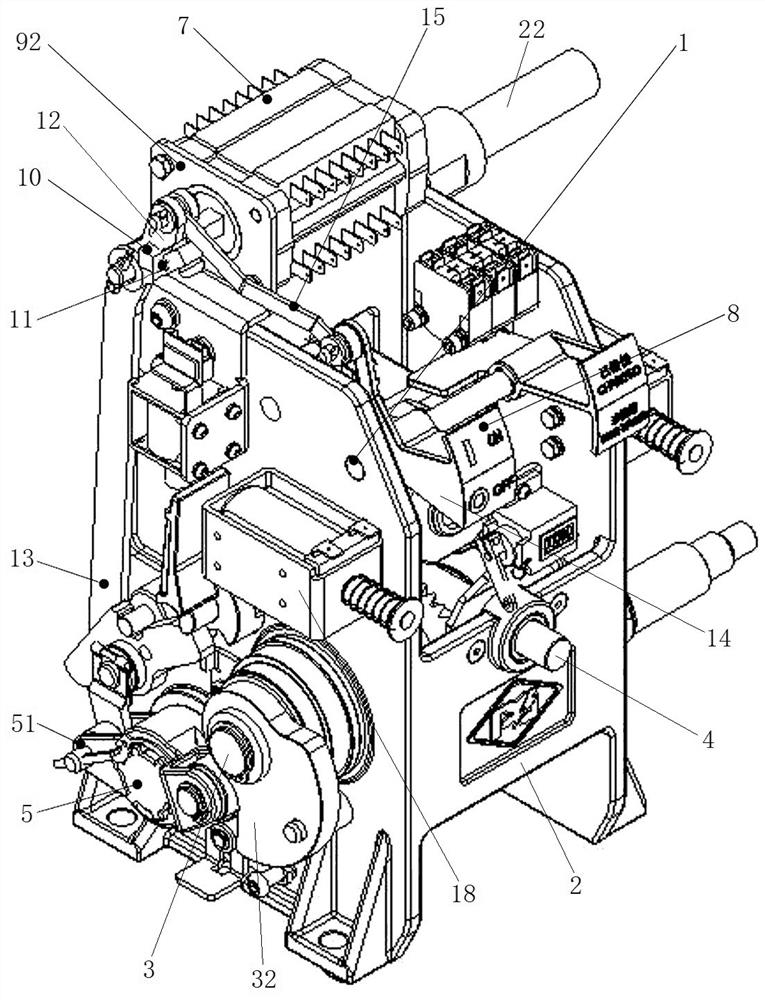

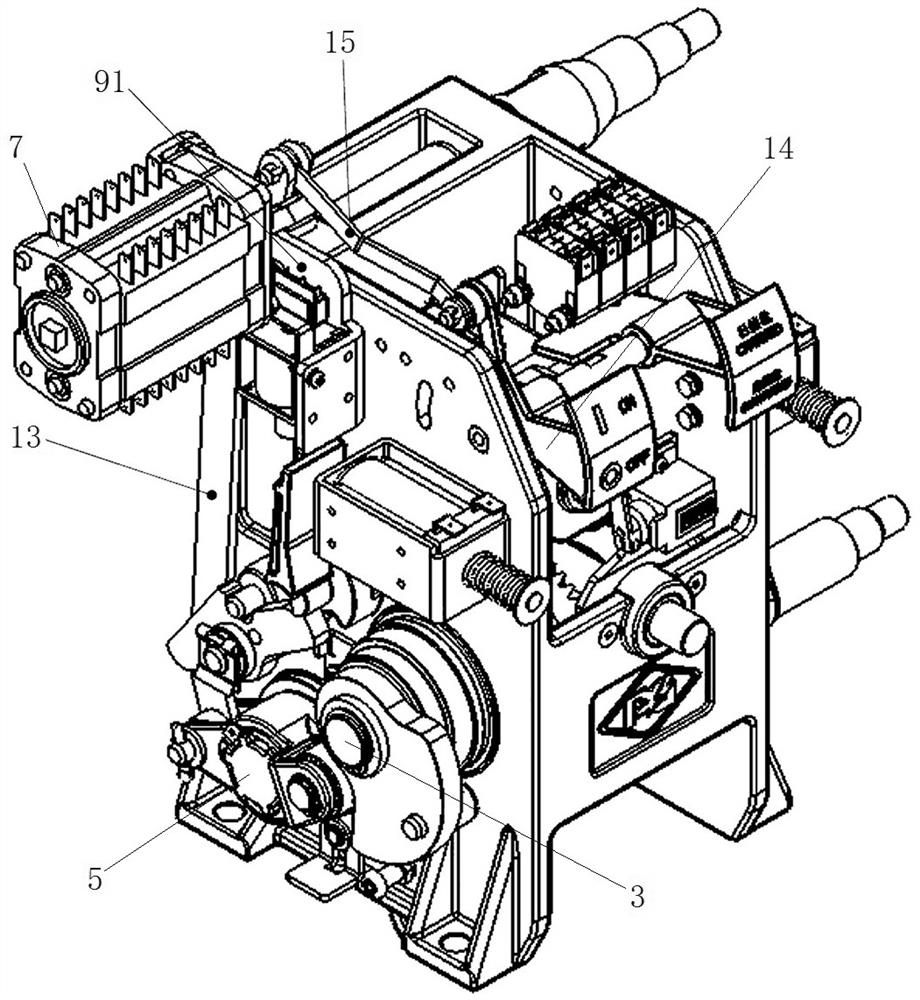

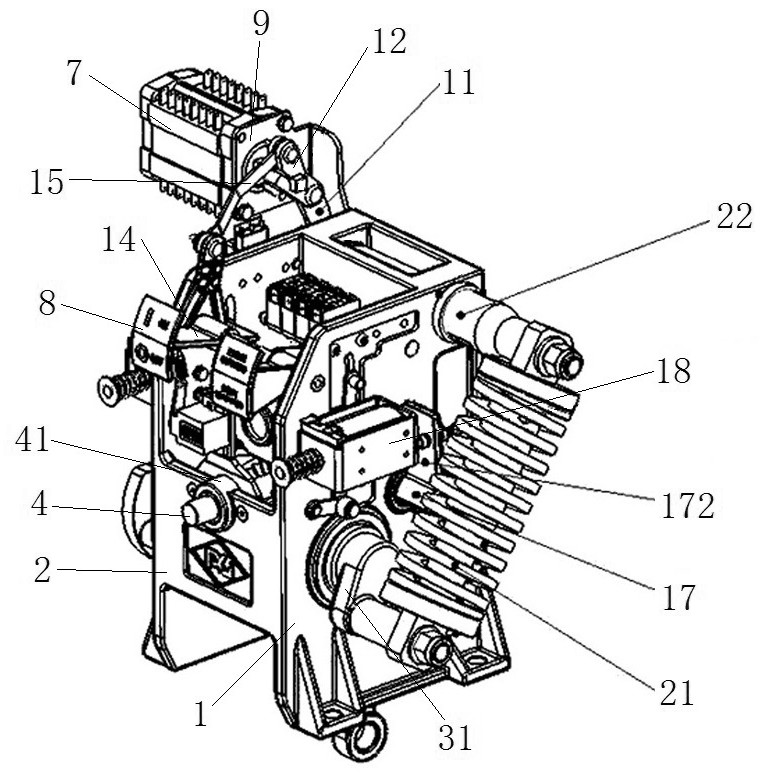

Circuit breaker and operating mechanism thereof

ActiveCN111341607AReduce the number of partsEasy to assembleSwitching device condition indicationProtective switch operating/release mechanismsCrankDrive shaft

The invention relates to a circuit breaker and an operating mechanism thereof. The circuit breaker comprises an arc extinguishing chamber with a moving contact, and an operating mechanism in transmission connection with the moving contact in the arc extinguishing chamber. The operating mechanism comprises a main body frame. An output shaft and an auxiliary switch are arranged on the main body frame; the operating mechanism also comprises an indication board which is assembled on the main body frame in a swinging manner and is used for indicating the working state of the operating mechanism, wherein an output crank arm is arranged on the output shaft, the auxiliary switch is provided with a driving shaft for realizing the action of the auxiliary switch, a first crank arm and a second crankarm are arranged on the driving shaft, and an auxiliary switch driving connecting rod is hinged between the output crank arm and the first crank arm; the indication board is correspondingly provided with a driving connecting lever used for driving the indication board to move, and an indication board driving connecting rod is hinged between the driving connecting lever and the second connecting lever. The state switching between the auxiliary switch and the indication board is achieved through one set of connecting rod mechanism, the number of parts of the operating mechanism is reduced, and assembling is easy.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

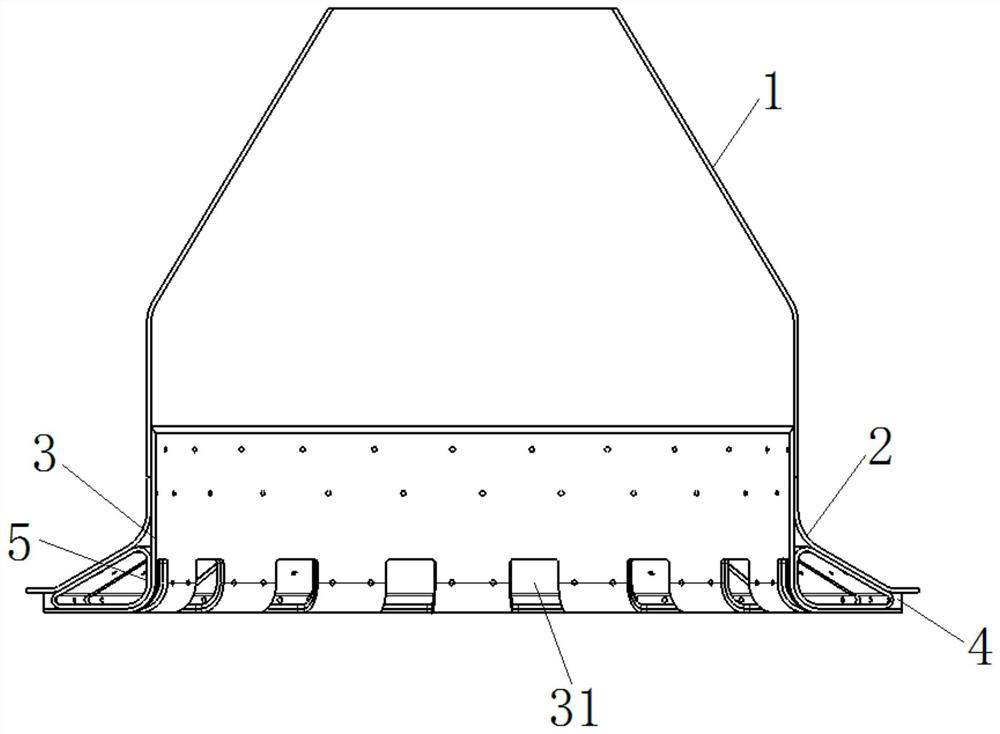

Grate plate protection movable block of single-tooth roller crusher convenient for disassembly and replacement

The invention relates to a grate plate protection movable block of a single-tooth roller crusher convenient for disassembly and replacement. The grate plate protection movable block comprises a grate plate body and a protection movable block connected with the grate plate body, and is characterized in that the protection movable block consists of a left end movable block, a right end movable block and a middle movable block; the normal sections of the left and right end movable blocks and the middle movable block are long structural bodies with triangular upper parts and having regular trapezoidal insertion grooves in the lower parts; bolt holes are formed in the middle lower parts of the left and right end movable blocks and the middle movable block; the grate plate body is a long grate plate having regular trapezoidal bosses, matched with the regular trapezoidal insertion grooves, in the middle parts; bolt holes are also formed in the grate plate body; the regular trapezoidal insertion grooves of the protection movable block and the regular trapezoidal bosses of the grate plate body are inserted, and are fixedly connected through bolts, nuts and spring washers. The grate plate protection movable block has the advantages of simpleness and convenience for replacement, reduction of maintenance workload, shortening of maintenance time and reduction of spare part consumption.

Owner:贾利新

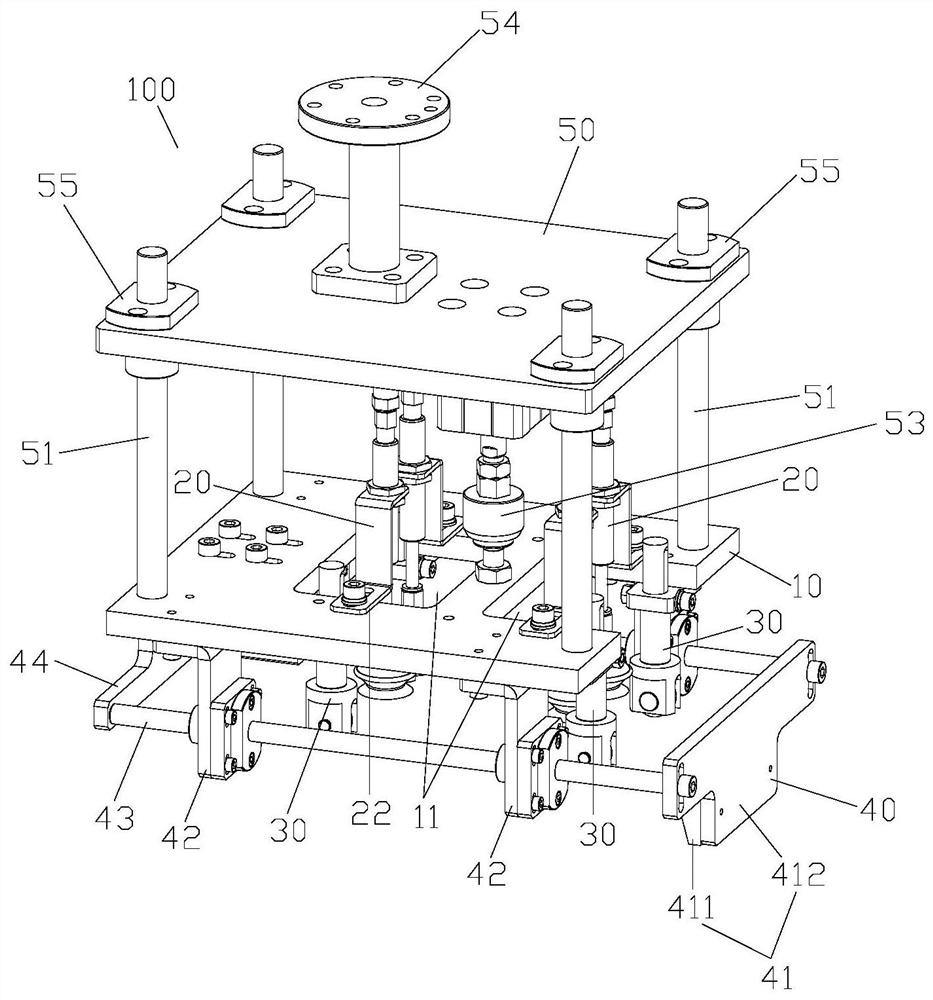

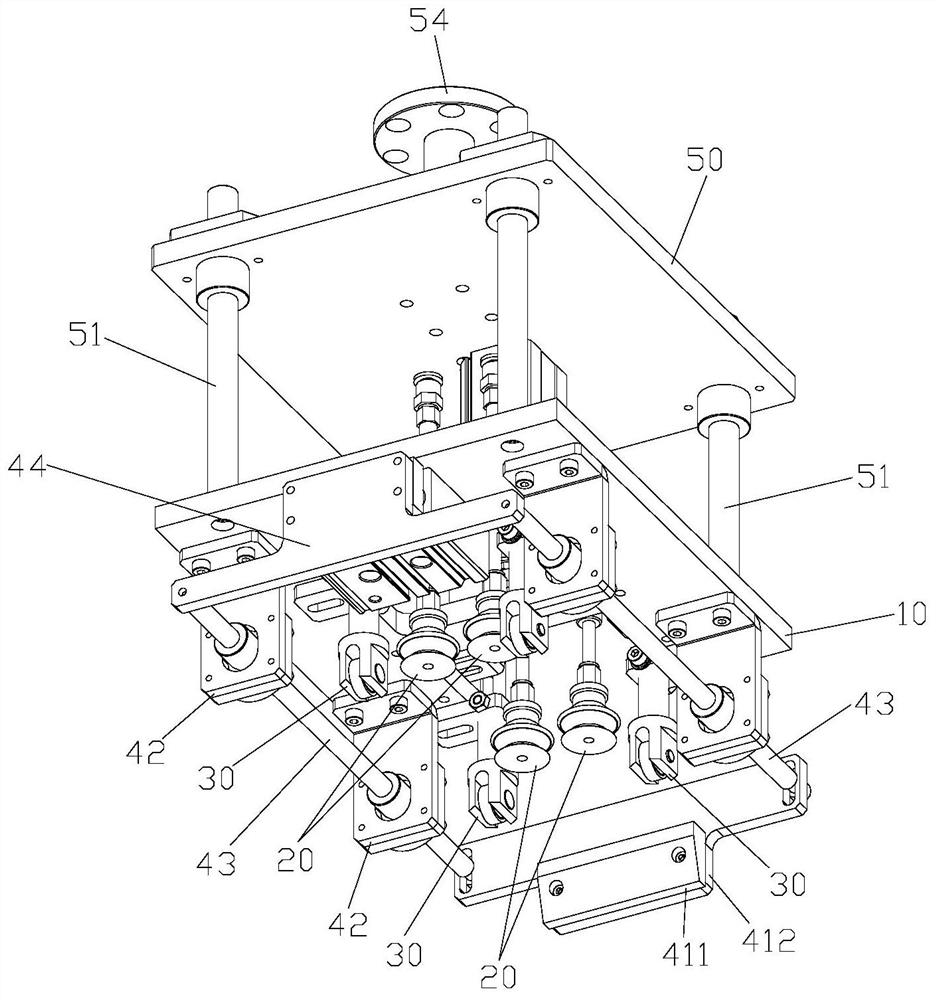

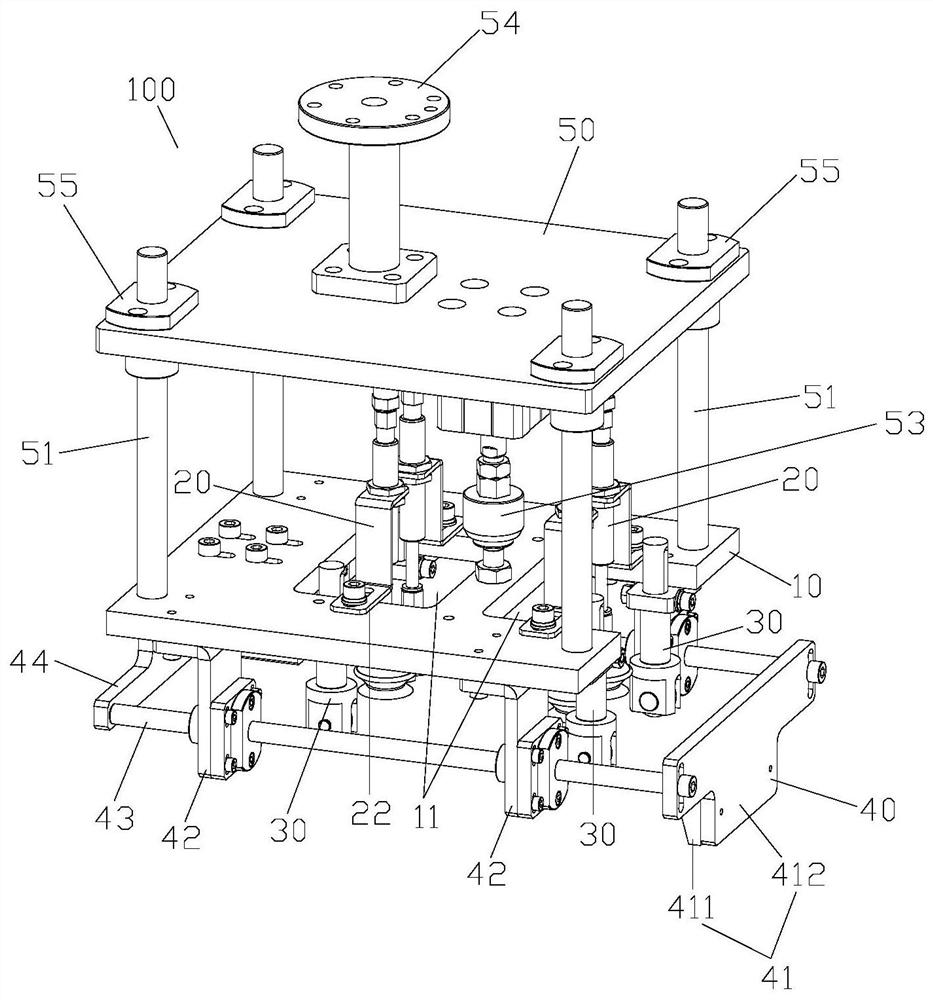

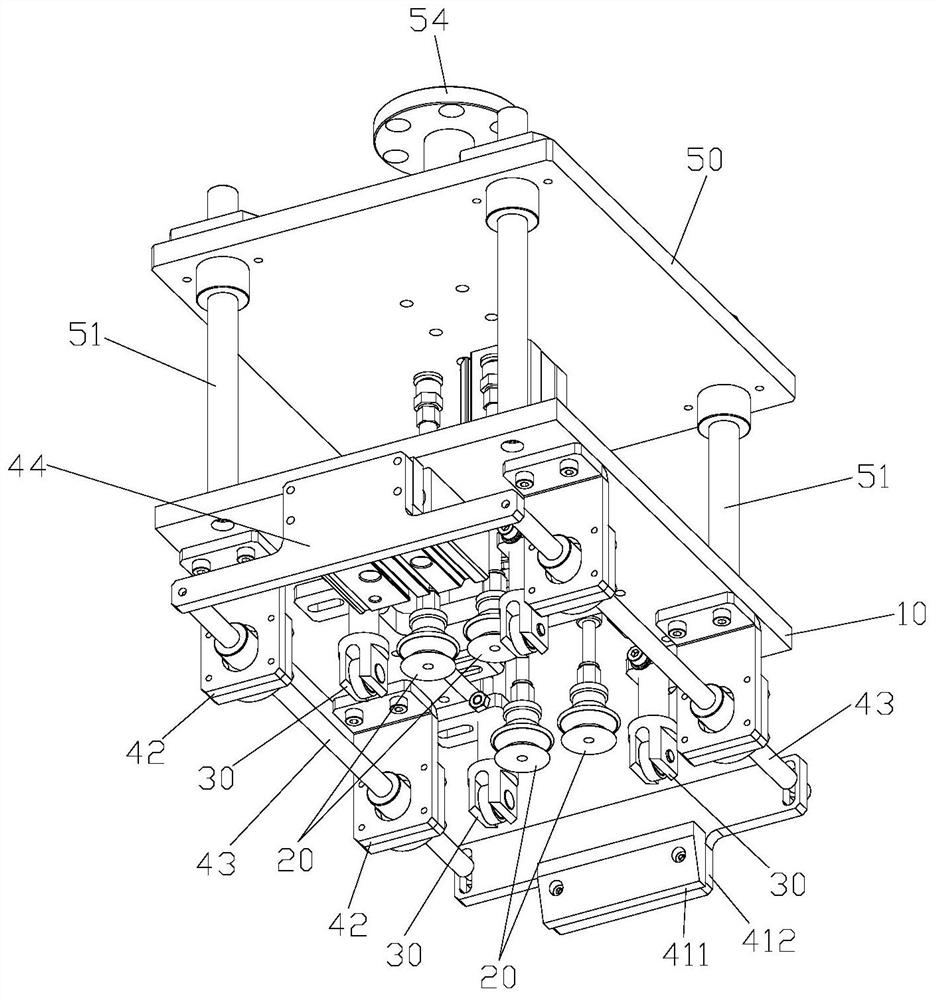

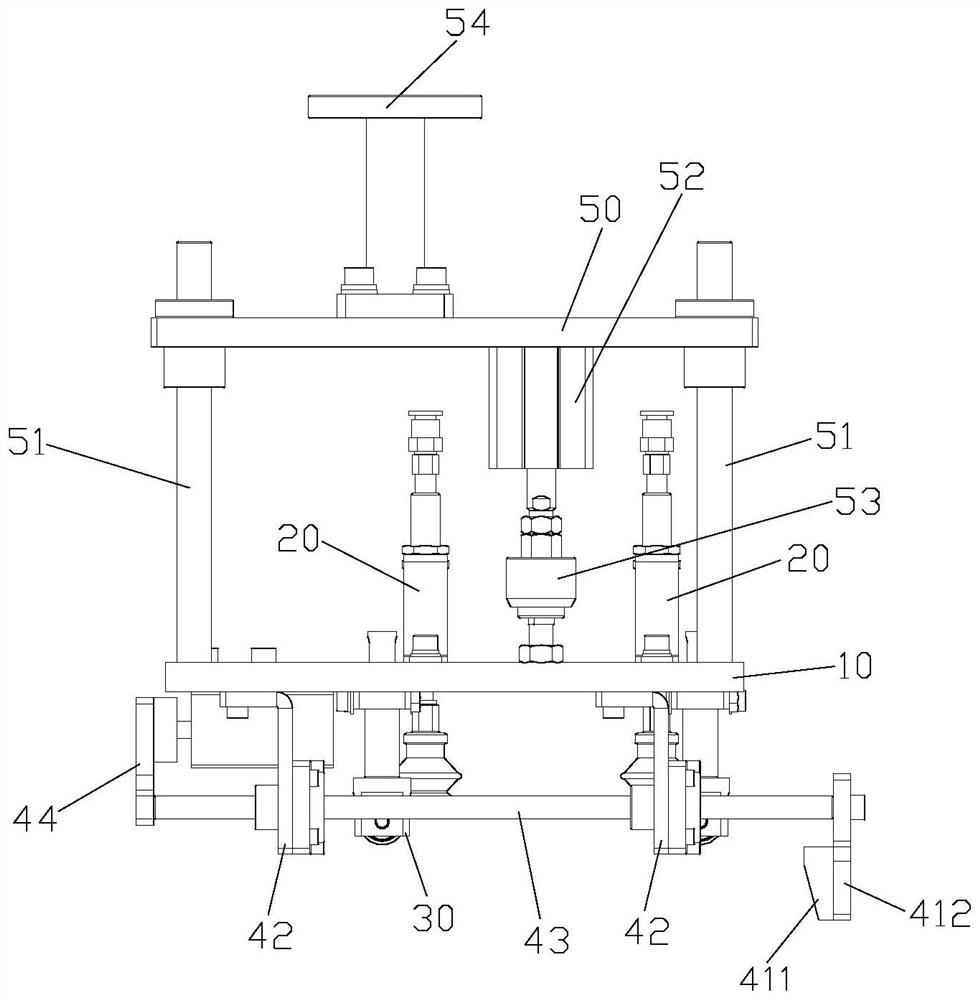

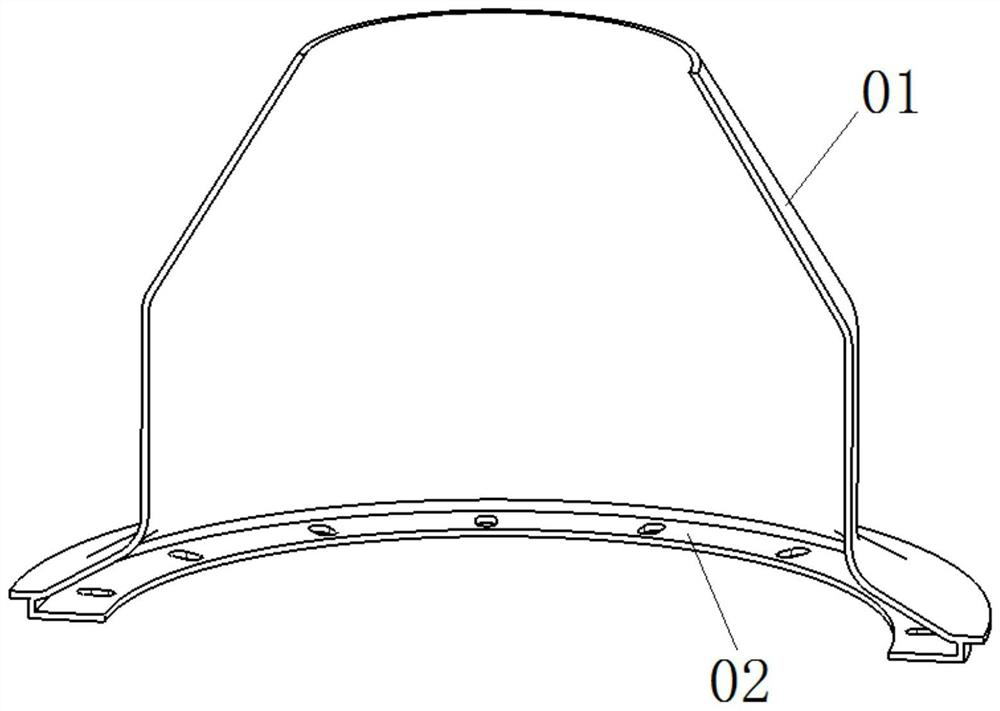

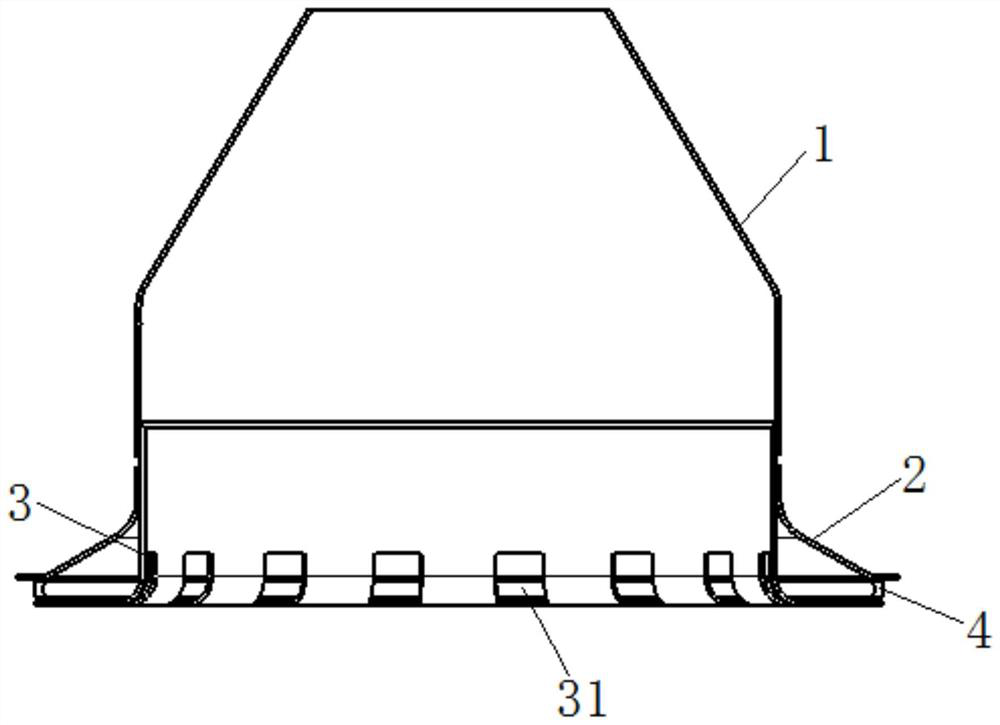

Clamping equipment

ActiveCN112621156AAvoid separationReduce the difficulty of assemblyMetal working apparatusEngineeringVALVE PORT

The invention provides clamping equipment. The clamping equipment comprises a movably-arranged mounting plate; an adsorption assembly fixedly arranged on the mounting plate and used for adsorbing a workpiece; a pressing assembly fixedly arranged on the mounting plate and used for abutting against the workpiece; after the adsorption assembly releases the workpiece, the workpiece is kept in contact with the mounting foundation through the pressing assembly; a pushing assembly mounted on the mounting plate; and the pushing assembly comprises a pushing part, and the pushing part is movably arranged so as to abut against the workpiece and push the workpiece to move to a preset position on a mounting foundation. The clamping equipment integrates the adsorption assembly, the pressing assembly and the pushing assembly, the overall structure is compact, the occupied space is small, a valve cover can be flexibly and accurately installed on an air conditioner outdoor unit through the clamping equipment, the assembling difficulty of the valve cover is reduced, and the problem that in the prior art, due to the installation mode of the valve cover, the assembly difficulty of the valve cover is large is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

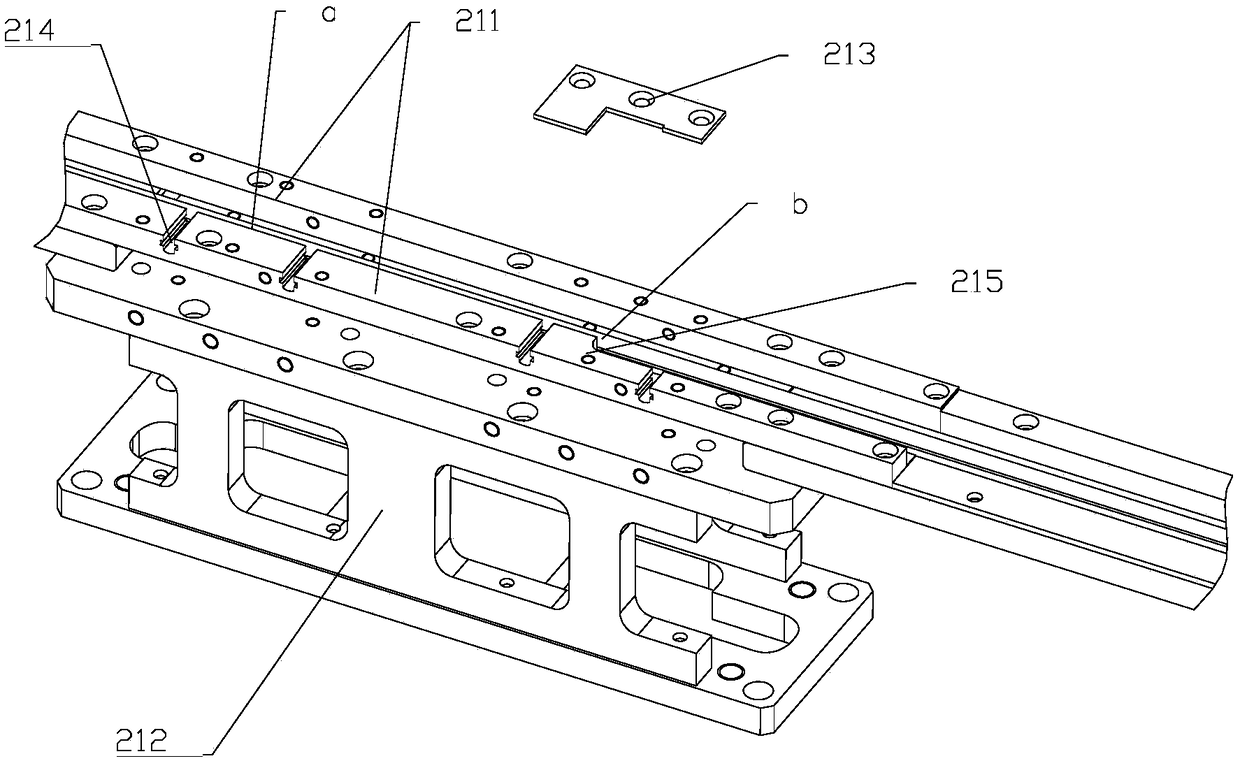

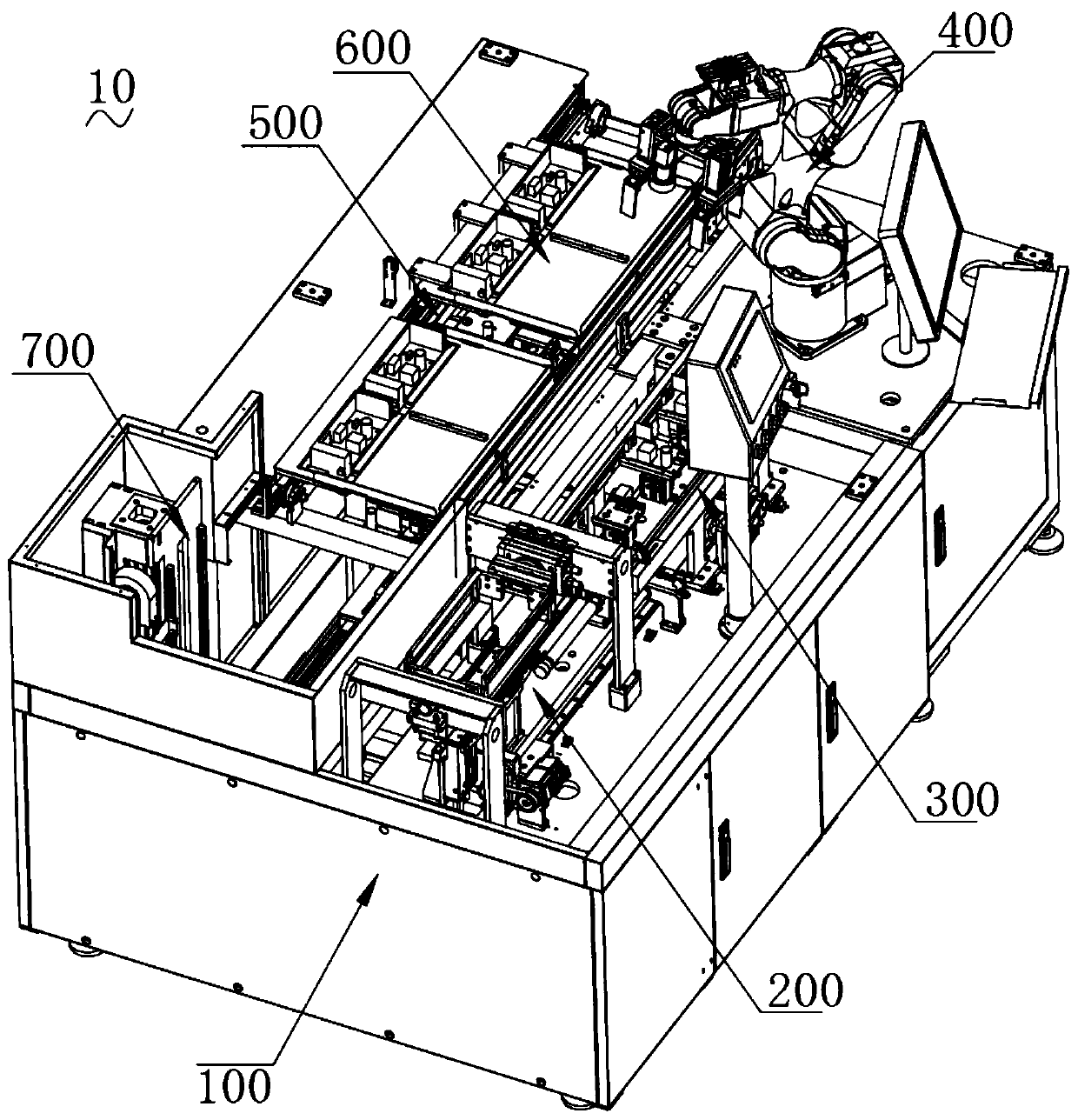

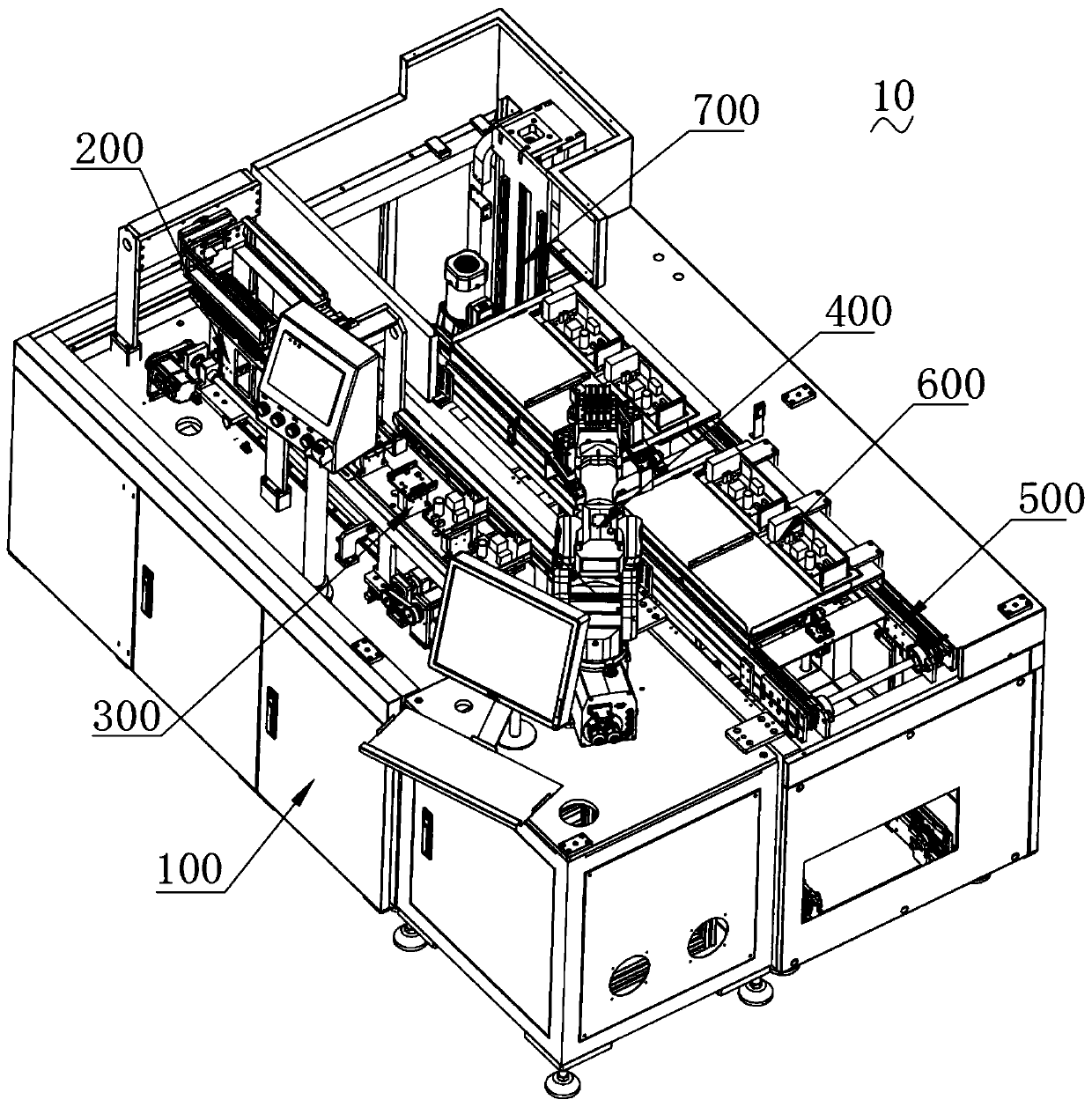

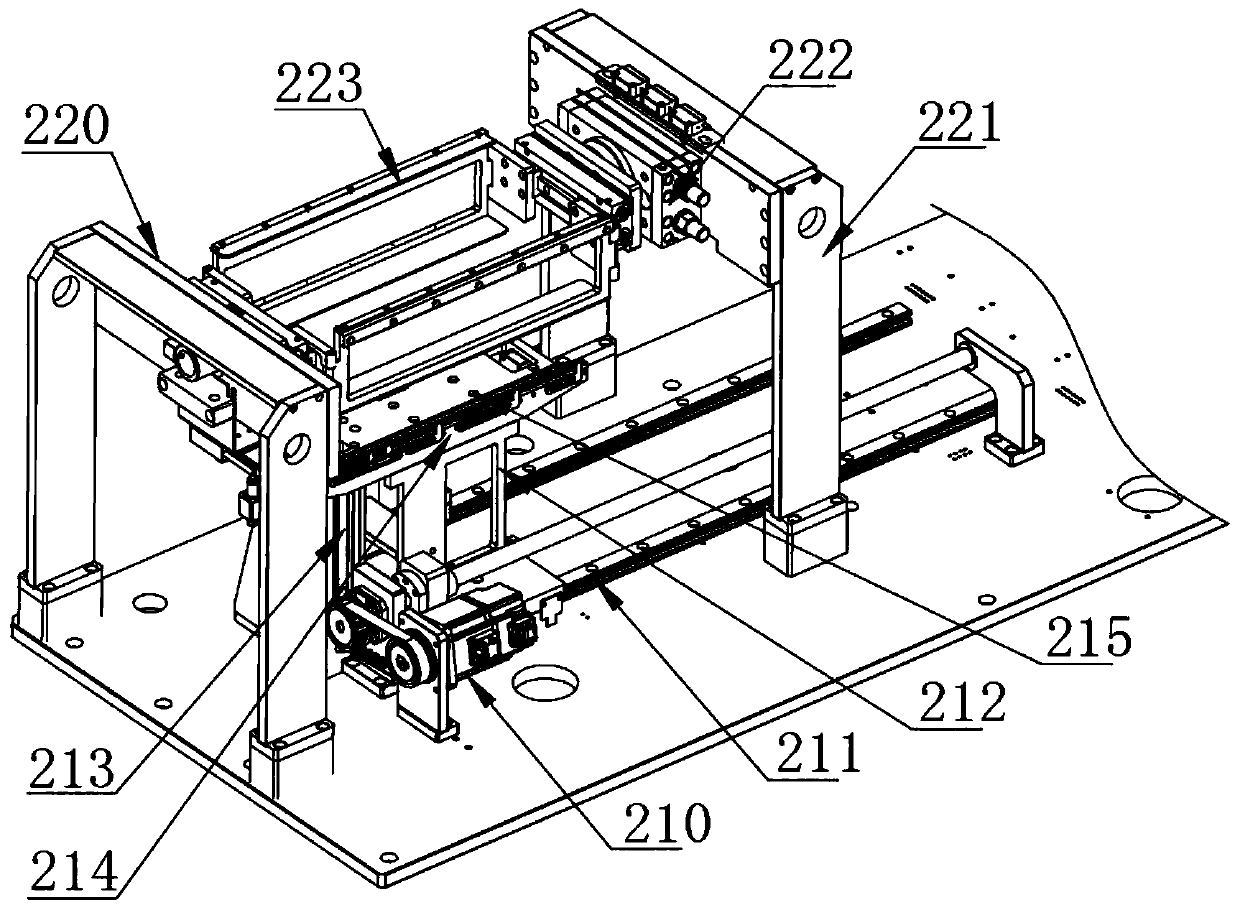

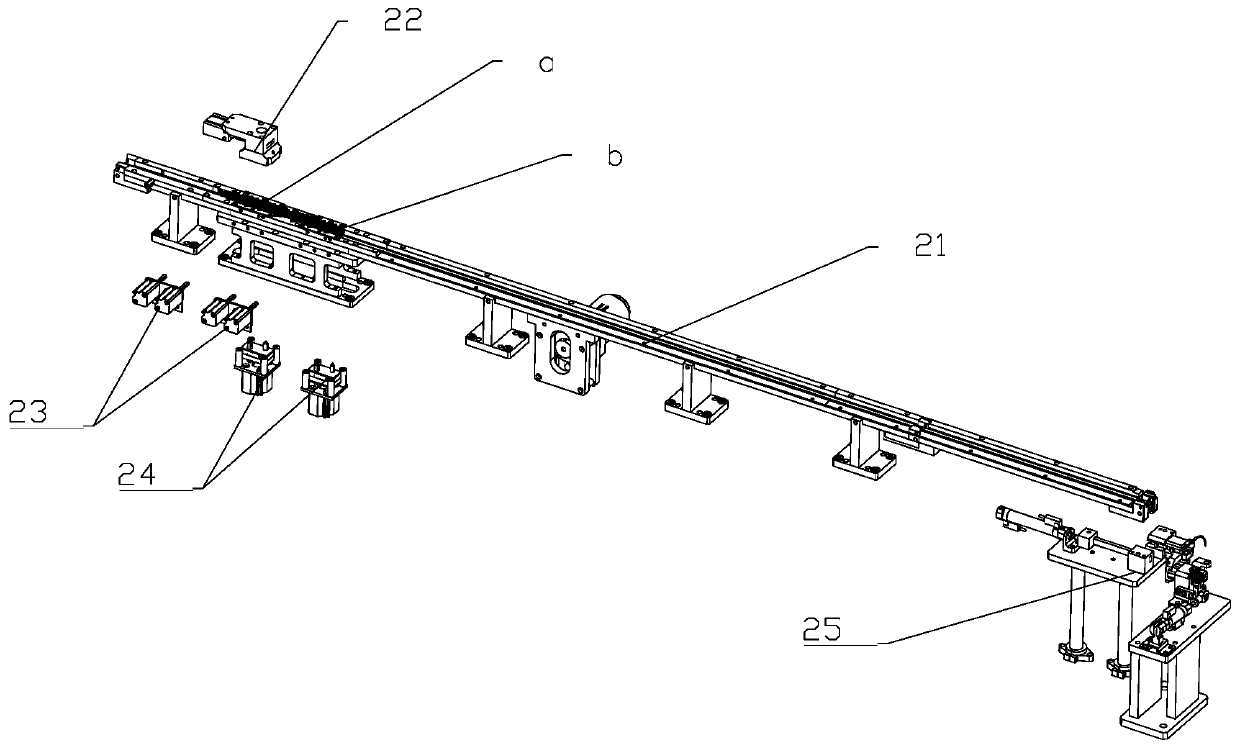

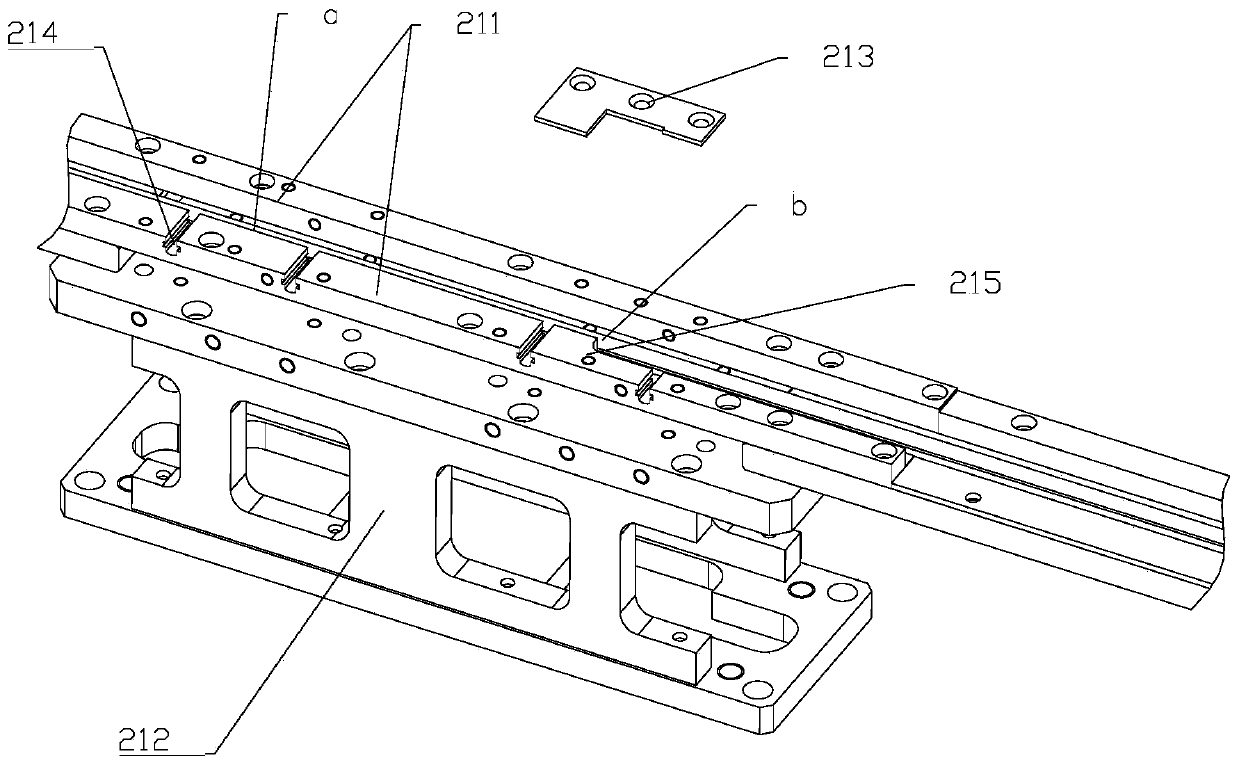

Substrate positioning equipment

PendingCN110561067AHigh positioning accuracyImprove assembly accuracyWork holdersMetal working apparatusPositioning equipmentEngineering

The invention relates to the technical field of automatic positioning and assembly, in particular to substrate positioning equipment. The substrate positioning equipment comprises a rack, a transporting device arranged on one side of the rack and used for transporting substrates, a positioning device connected with the transporting device, a taking device arranged on the rack and used for taking the substrates from the positioning device, a conveying device arranged on the rack and used for assembling and conveying the substrates, an assembly jig conveyed by the conveying device, and a circulating return device connected with the conveying device and used for circular conveying of the assembly jig. The substrate positioning equipment solves the problem of high assembly difficulty of an existing power supply substrate; and with adoption of full-automatic positioning and assembly, assembly is carried out after positioning, and the positioning precision and the assembly precision are high.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

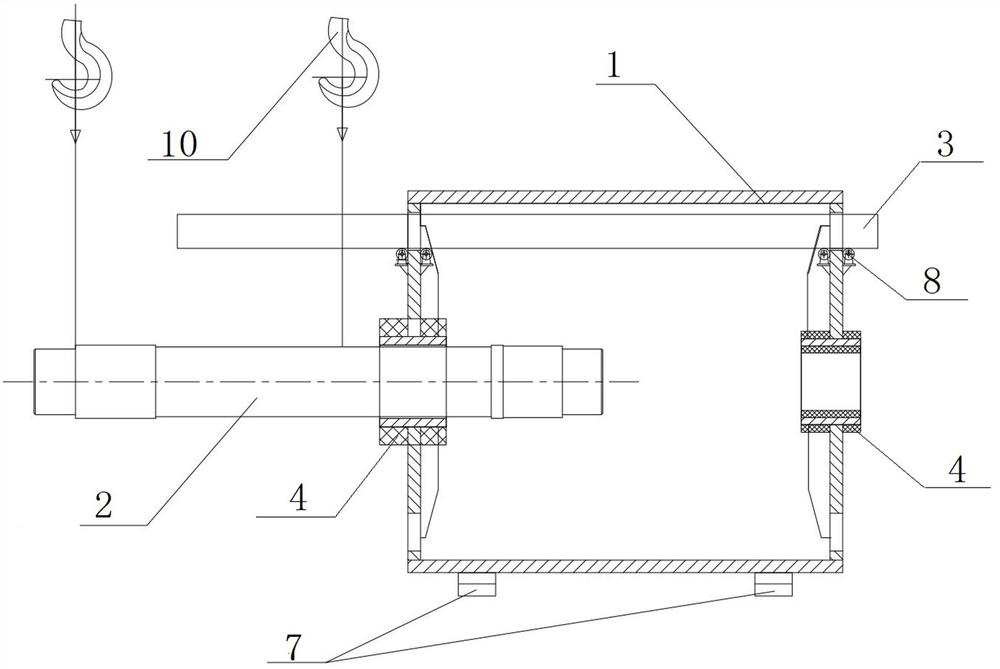

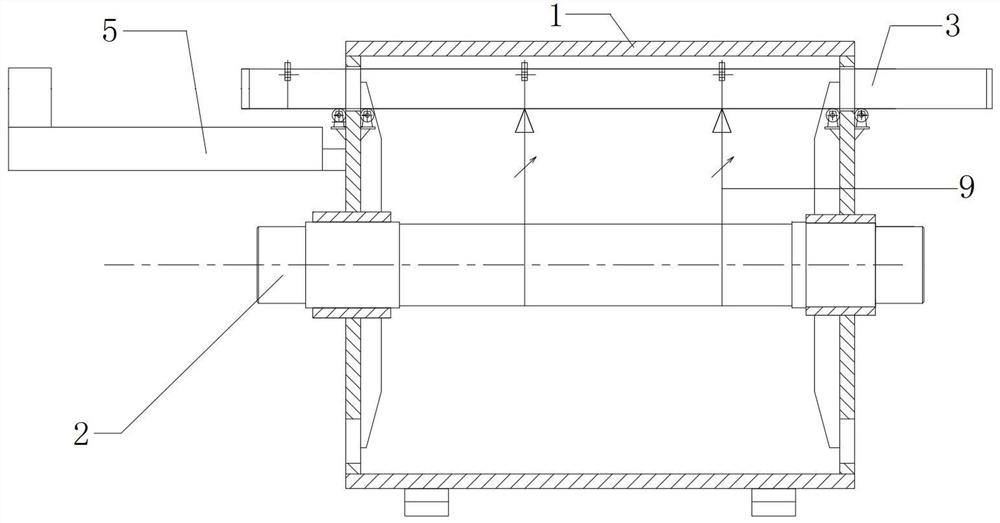

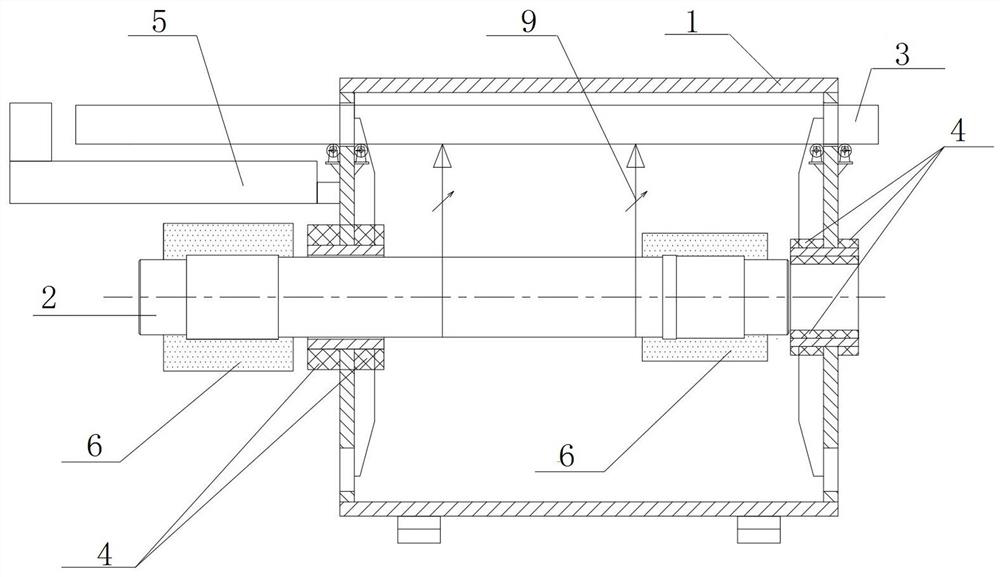

Method for assembling winding drum and winding drum shaft of large ship lift

ActiveCN114850781AReduce the difficulty of assemblySolve the difficulty of assemblyWinding mechanismsMetal working apparatusInterference fitClassical mechanics

The invention relates to the technical field of ship lift engineering, in particular to a method for assembling a winding drum and a winding drum shaft of a large ship lift. Assembling a horizontal displacement hanging beam in the winding drum, and installing two groups of heating devices; first-stage assembly of a drum shaft; mounting a cooling device and a horizontal driving device; the cooling device and the heating device work at the same time, after the preset temperature and time are reached, the cooling device and the heating device are dismantled, and the centering consistency of the winding drum shaft and the winding drum inner hole is checked and rechecked; a horizontal driving device horizontally moves the winding drum shaft, interference fit is converted into clearance fit, and the winding drum shaft is assembled in place; and cooling and inspecting to be qualified to finish the assembly. By means of the assembling method, the problem that in the prior art, hoisting turning-over safety risks exist can be effectively solved.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

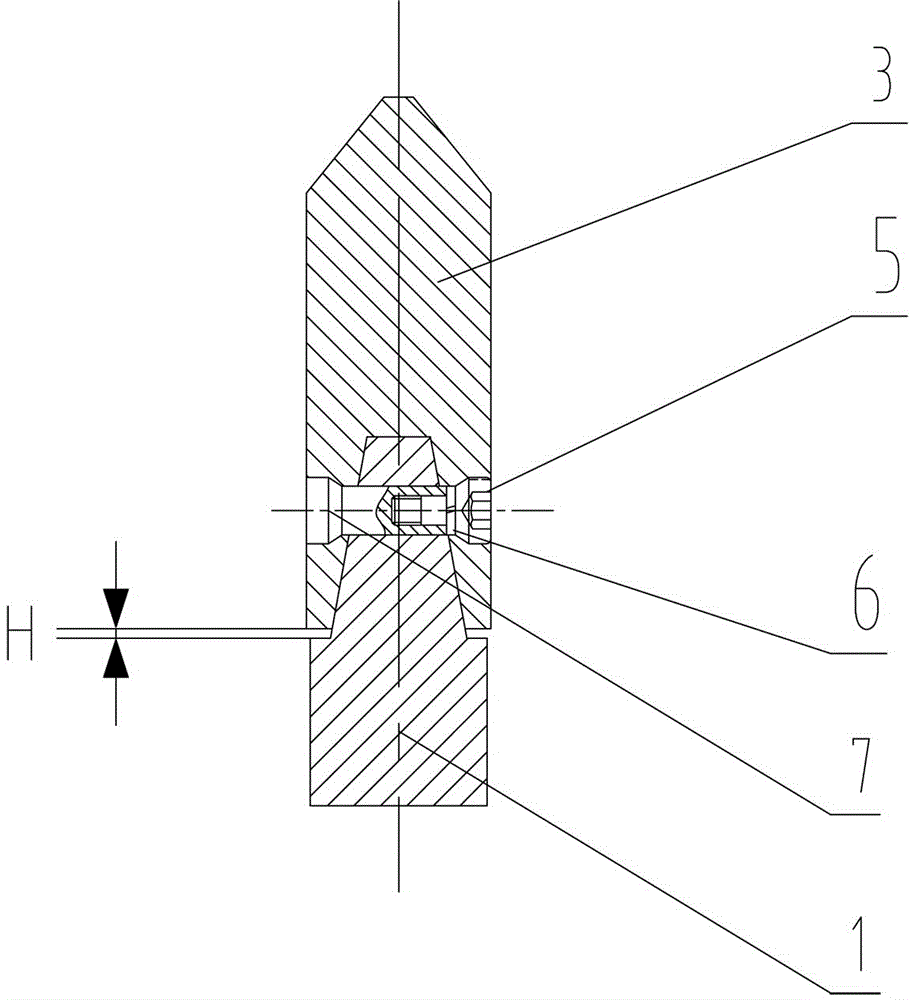

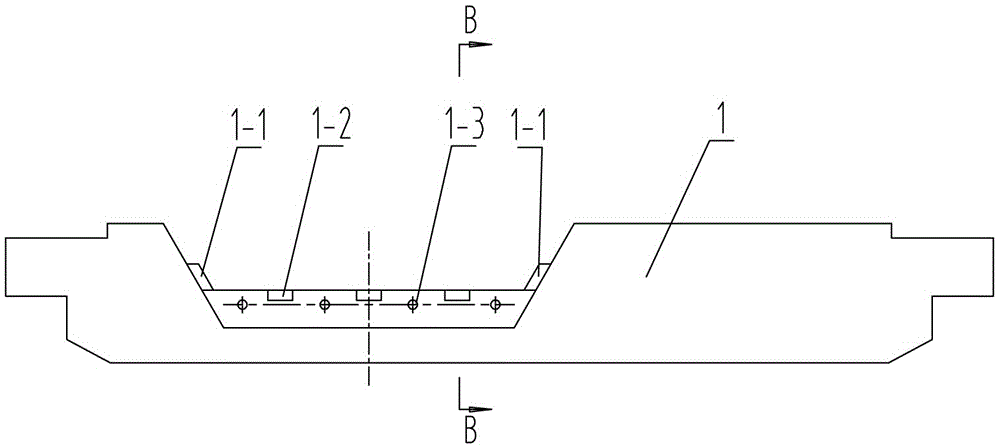

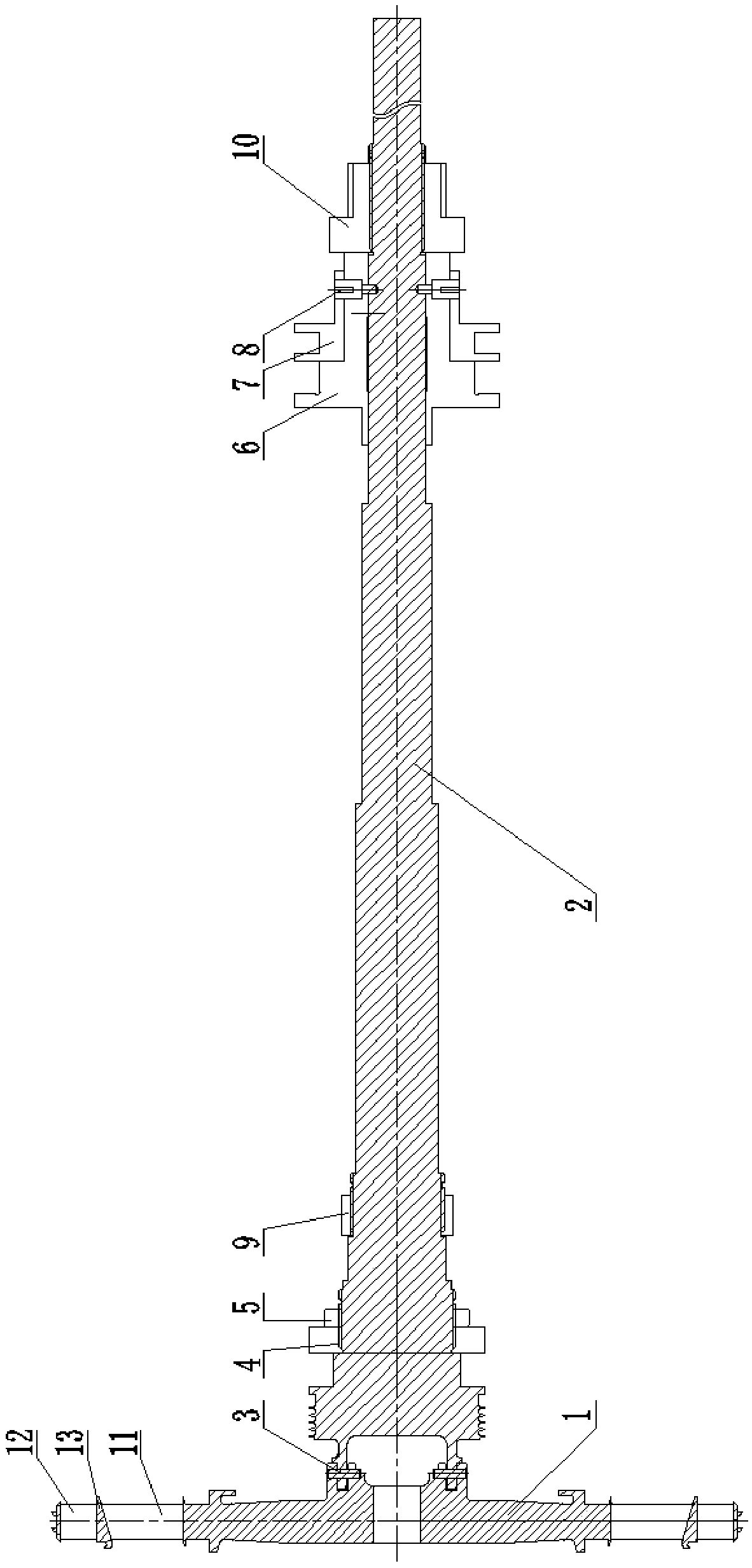

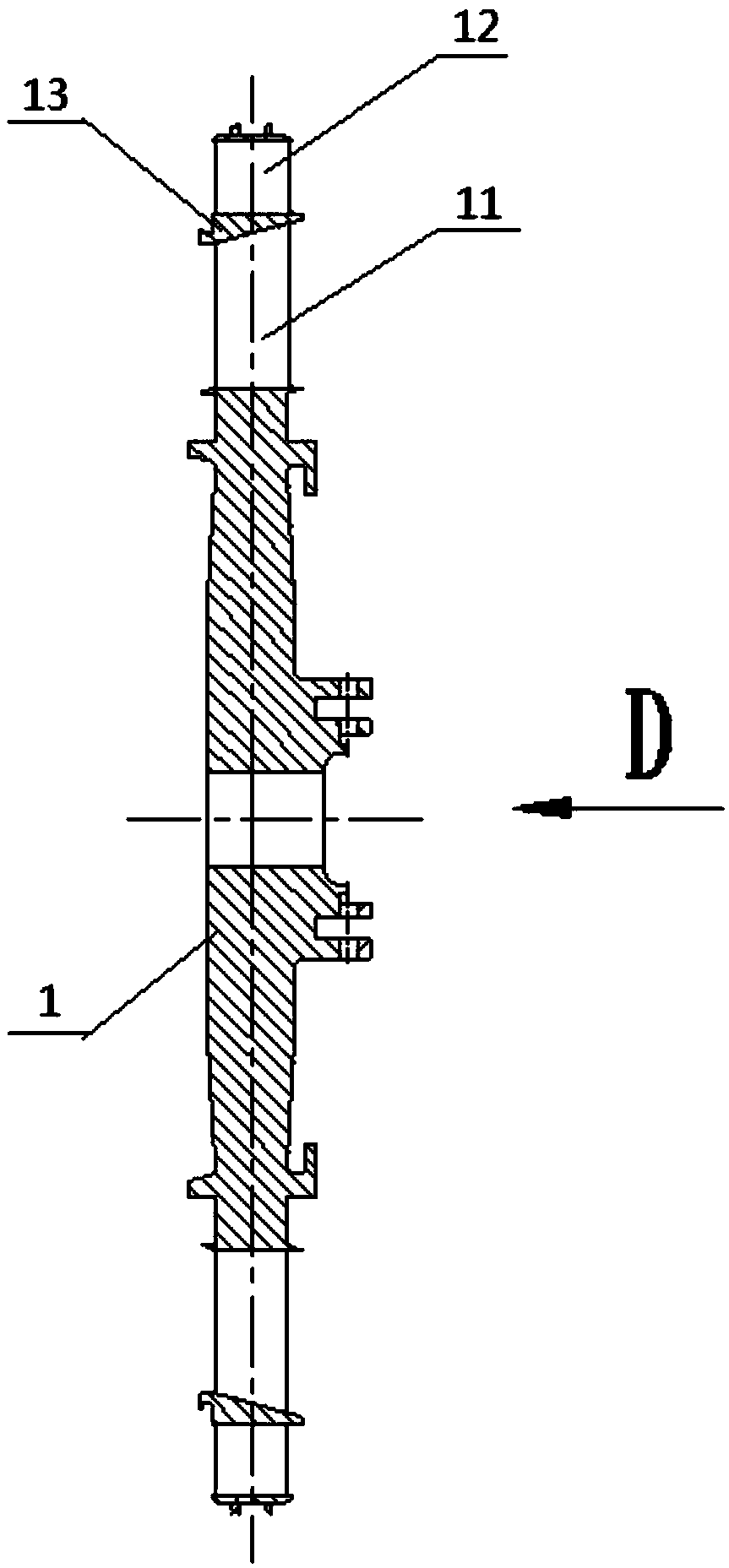

Cantilever type rotor used for backing turbine air blowing loss test

PendingCN109667625ASimple structureMeet the dynamic requirementsBlade accessoriesMachines/enginesSystem structureTurbine blade

The invention discloses a cantilever type rotor used for a backing turbine air blowing loss test and relates to a cantilever type rotor. The cantilever type rotor used for the backing turbine air blowing loss test solves the problems that in a traditional wheel disk and blade rotor test, cost is high, the period is long, and lubricating of bearing system structures at the two ends is relatively complicated. A forward vehicle moving blade (11) is installed on a turbine overall blade disk; a backing turbine blade (12) is installed on the forward vehicle moving blade (11) through a middle ring (13); the turbine overall blade disk, the forward vehicle moving blade (11), the middle ring (13) and the backing turbine blade (12) jointly form a backing turbine double-layer overall blade disk (1); one end of a backing turbine output shaft (2) is connected with the backing turbine double-layer overall blade disk (1) through a disk shaft connection pin (3), and one end of the backing turbine output shaft (2) is suspended; and the backing turbine double-layer overall blade disk (1) is located on the outer sides of two supporting bearing supporting points of a whole rotor. The cantilever type rotor is used for the backing turbine air blowing loss test

Owner:中国船舶重工集团公司第七0三研究所

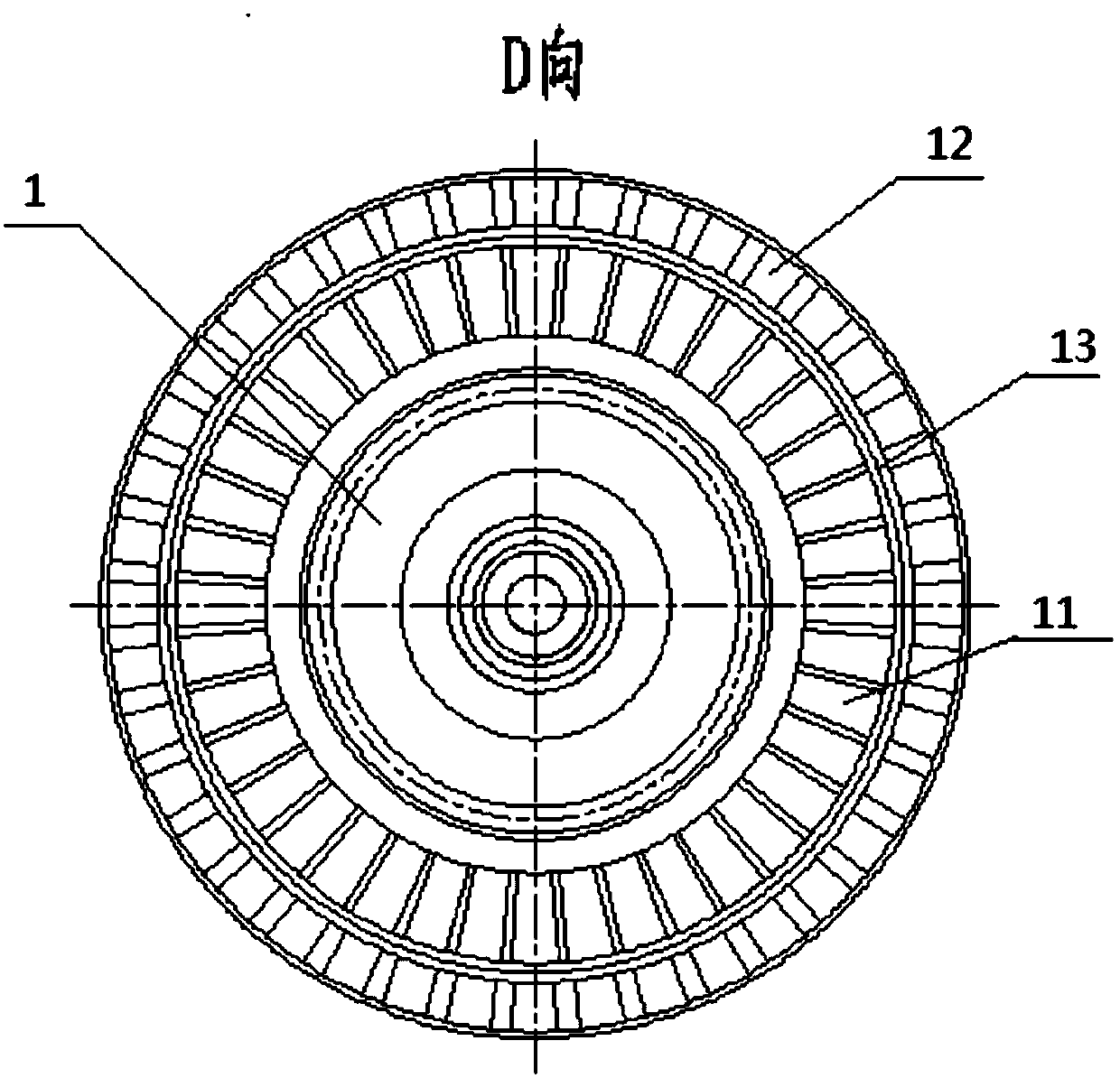

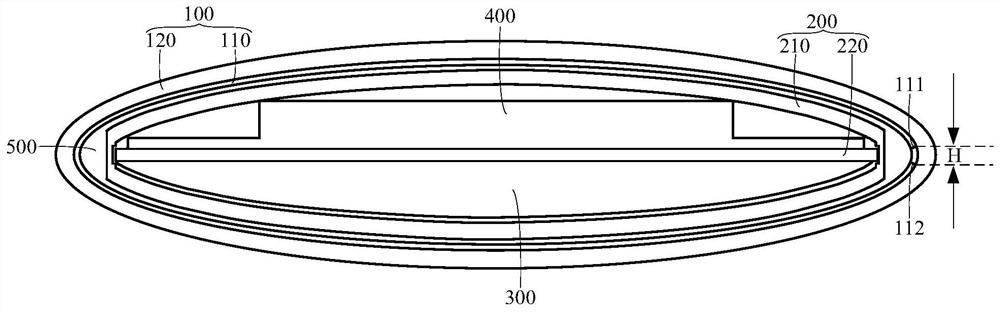

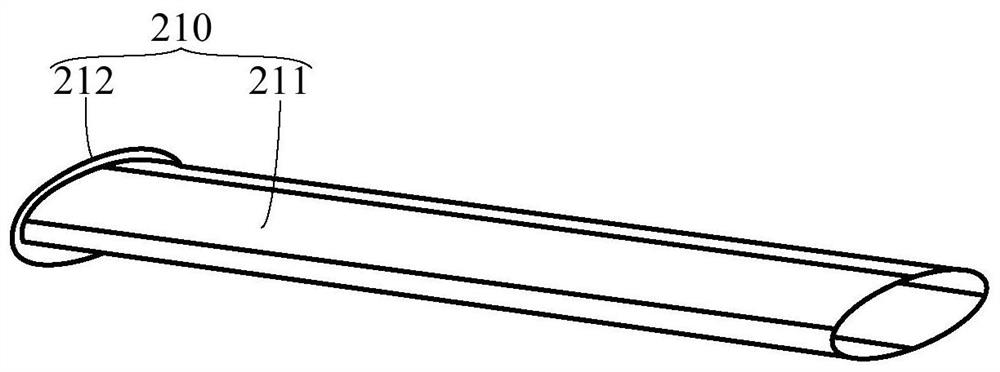

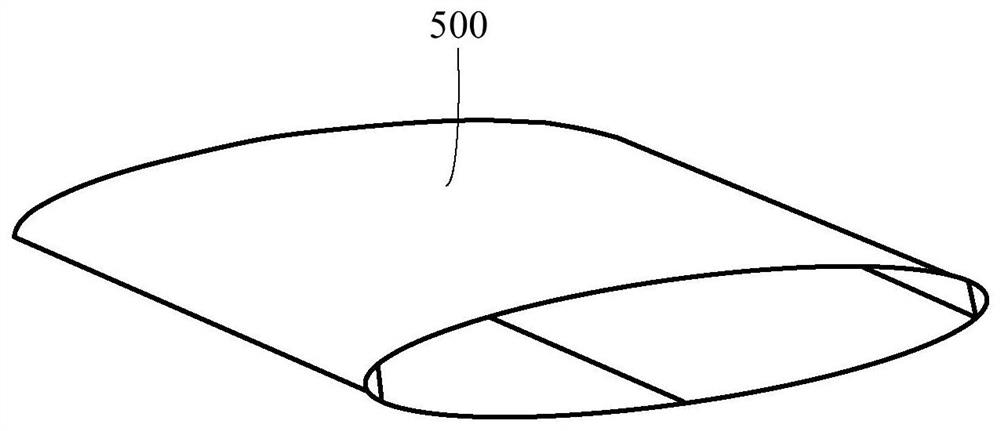

LED (Light-Emitting Diode) T5 split lamp tube with embedded driver

InactiveCN103982801AImprove efficiencyReduce feverLighting heating/cooling arrangementsElectric lightingEngineeringAluminum substrate

The invention discloses an LED (Light-Emitting Diode) T5 split lamp tube with an embedded driver. The LED T5 split lamp tube comprises a tube body, a power supply-bead integral plate and chock plugs, wherein the tube body consists of a heat-dissipating aluminum section, an aluminum substrate and a light-transmitting cover; a slot is formed in the middle of the heat-dissipating aluminum section, and clamping grooves are formed in both sides of the heat-dissipating aluminum section; the aluminum substrate is inserted into the slot of the heat-dissipating aluminum section for fixing; claws are arranged on the light-transmitting cover; the power supply-bead integral plate consists of a bead plate and driving power supplies fixed to the two ends of the bead plate, and is fixed to the aluminum substrate; each chock plug consists of a tubular part and a power plug; the power plugs sleeve into the tubular parts to be fixedly connected with the tubular parts; the tubular parts sleeve both sides of the tube body to block the tube body. Compared with the prior art, the LED T5 split lamp tube has the advantages that the driving power supplies are driven by constant current of a switching power supply, thereby realizing high power supply efficiency, low power supply heat and a wide working voltage range; by adopting embedded driving power supplies, the assembling difficulty is lowered, convenience is brought to installation, the labor cost is reduced, and the stability and cost performance of the LED lamp tube are improved.

Owner:JIANGMEN REPHON OPTOELECTRONICS MFG

Casting mould for multi-way reversing valve

InactiveCN107812885ADifficult to clean upHigh strengthFoundry mouldsFoundry coresCasting defectEngineering

The invention discloses a casting mold for a multi-way reversing valve, which comprises a sand box, a shell and a mud core. The mud core is horizontally arranged in the shell, and the shell is embedded in the sand box; There are two shells, shell I and shell II, and shell I and shell II are arranged side by side in the sand box, and the two outer surfaces corresponding to shell I and shell II are attached to each other; the clay core includes the main core And several small cores, the main core and several small cores are assembled into a whole mud core through the process hole, the inside of the mud core is provided with a core bone for forming the flow channel of the multi-way reversing valve, and the top of the mud core is provided with an air outlet , the air outlet is derived from the steel wire. The invention can solve the difficulty of assembling the core and can reduce the defects of the casting.

Owner:JIANGSU TIANZIGE NEW MATERIAL TECH CO LTD

Ceramic matrix composite inner cone and processing method thereof

ActiveCN112577068ASolve the process problems that are difficult to formEasy to installContinuous combustion chamberButt jointUltimate tensile strength

The invention relates to a ceramic matrix composite inner cone and a processing method thereof so as to solve the problems that a process for preparing an inner cone through a ceramic matrix compositeaccording to a traditional design scheme is difficult to realize, the structural strength can hardly meet requirements, and the assembly difficulty with a mounting seat is high. The inner cone comprises an upper conical face, a lower conical face, an inner conical face and a surrounding component, the upper conical face is in butt joint with the lower conical face, the butt joint position is located on the outer side of the upper end of the inner conical face, the lower end of the inner conical face extends outwards, the outer edge of the lower end of the inner conical face corresponds to theouter edge of the lower end of the lower conical face, the upper side and the lower side of the surrounding component are connected with the outer edge of the lower end of the lower conical face andthe outer edge of the lower end of the inner conical face correspondingly, and multiple bolt mounting holes are circumferentially formed in the lower end of the inner conical face. The processing method of the inner cone comprises the steps that (1) the upper conical face, the lower conical face, the inner conical face and the surrounding component are processed by using the ceramic matrix composite; and (2) the outer side of the inner conical face is sleeved with the upper conical face and the lower conical face, the surrounding component is mounted between the lower conical face and the inner conical face, and fixing is achieved by adopting an online rivet welding technology.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

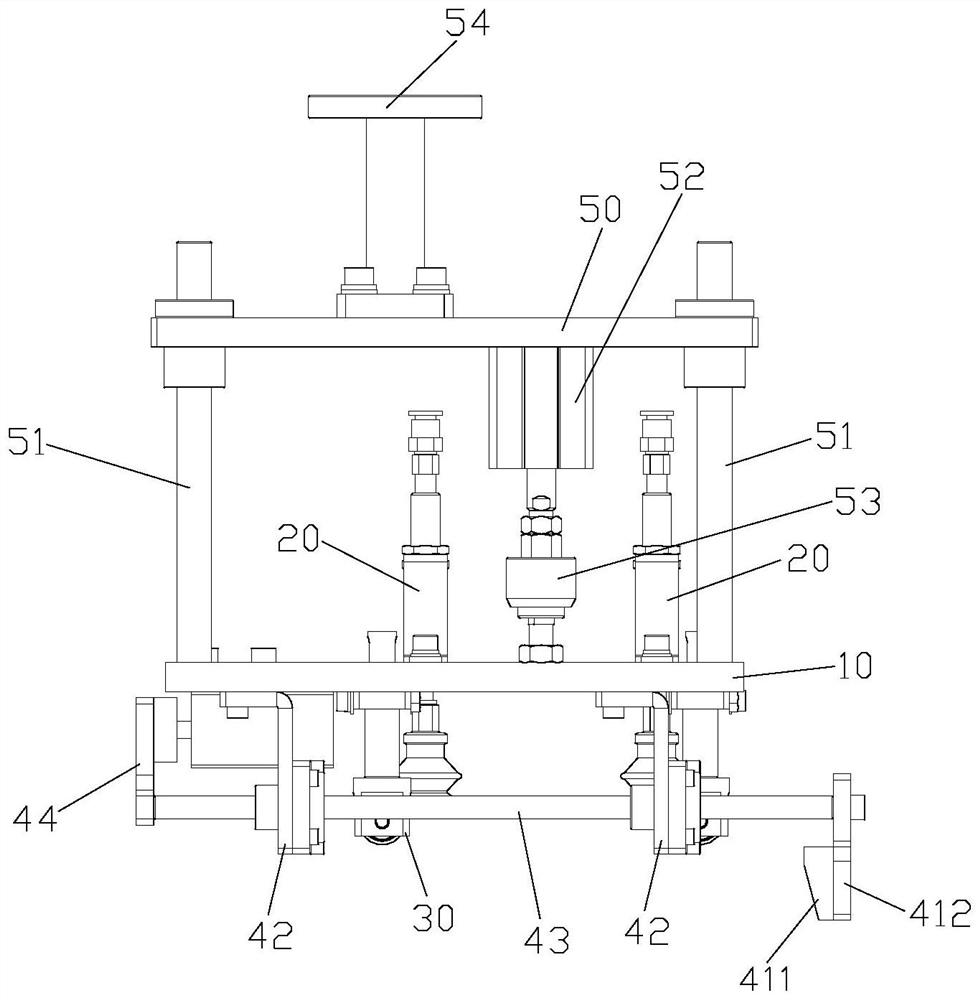

Pump core assembling equipment

PendingCN110815841ASolve the difficulty of assemblyQuick assemblyStructural engineeringSilicon rubber

The invention discloses pump core assembling equipment. The pump core assembling equipment comprises a movable table, a shift driving mechanism, a silicon rubber case assembling mechanism and a guidecolumn assembling mechanism, wherein the movable table is provided with a guide rod installation seat; the shift driving mechanism is used for driving the movable table to move so that the guide rod installation seat located at a first installation station can move to a second installation station; the silicon rubber case assembling mechanism is arranged at the first installation station and comprises a silicon rubber case clamp arranged at the upper end of a silicon rubber case in a covering mode and a silicon rubber case pressing mechanism used for driving the silicon rubber case clamp to move downwards, and a first air guide channel communicating with the silicon rubber case is arranged inside the silicon rubber case clamp; and the guide column assembling mechanism is arranged at the second installation station and comprises a guide column clamp used for fixing a guide column, a guide column lifting mechanism used for driving the guide column clamp to press downwards, and a second air guide channel communicating with the interior of the guide column. The pump core assembling equipment is provided with the silicon rubber case assembling mechanism and the guide column assembling mechanism, pump core assembling is orderly and fast, and by means of the characteristics of the silicon rubber case, two-step assembling is completed through repeated high-pressure gas.

Owner:河南驼人医疗器械研究院有限公司

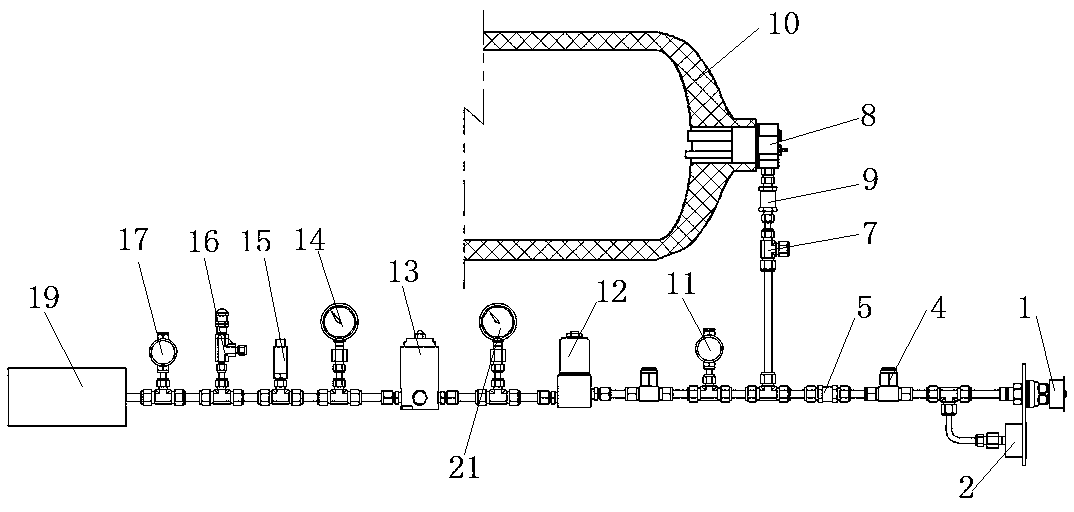

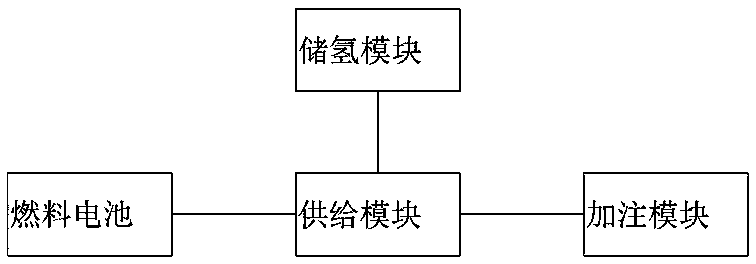

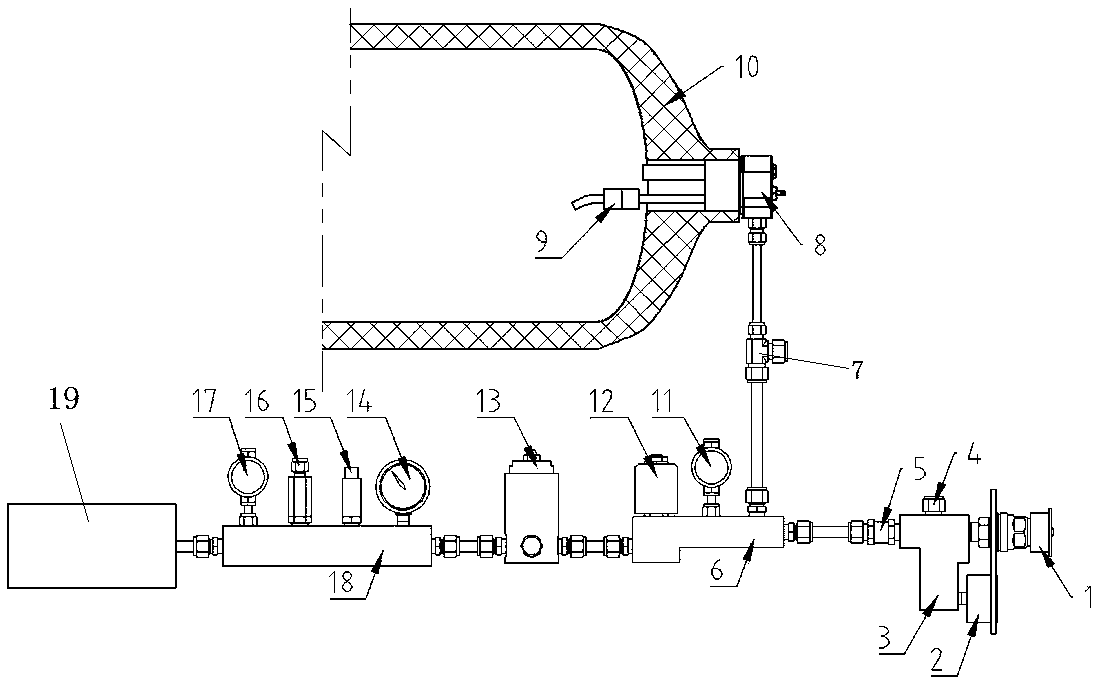

Low-pressure hydrogen supply module of hydrogen filling system and low-pressure hydrogen supply module main body

PendingCN109935861AReduce in quantityShorten development timeFuel cellsProcess engineeringEngineering

The invention relates to a low-pressure hydrogen supply module of a hydrogen filling system and a low-pressure hydrogen supply module main body in the field of duel cell vehicles. The low-pressure hydrogen supply module of the hydrogen filling system comprises at least one of a low-pressure meter, a low-pressure pressure sensor, a safety valve and a low-pressure emptying valve, and further comprises a low-pressure hydrogen supply module main body. The low-pressure hydrogen supply module main body is provided with a low-pressure hydrogen supply inlet, a low-pressure hydrogen supply outlet and at least one element installation port, wherein at least one of the low-pressure meter, the low-pressure pressure sensor, the safety valve and the low-pressure emptying valve is installed on the corresponding element installation port. The filling module main body is further internally provided with a communicating channel used for enabling the low-pressure hydrogen supply inlet, the low-pressure hydrogen outlet and the element installation port to be correspondingly communicated. The scheme of the invention can reduce the number of system components, reduce the connecting points and solve theproblems of excessive potential leakage points, high assembly process and maintenance difficulty and low integration in the existing system.

Owner:ZHENGZHOU YUTONG BUS CO LTD

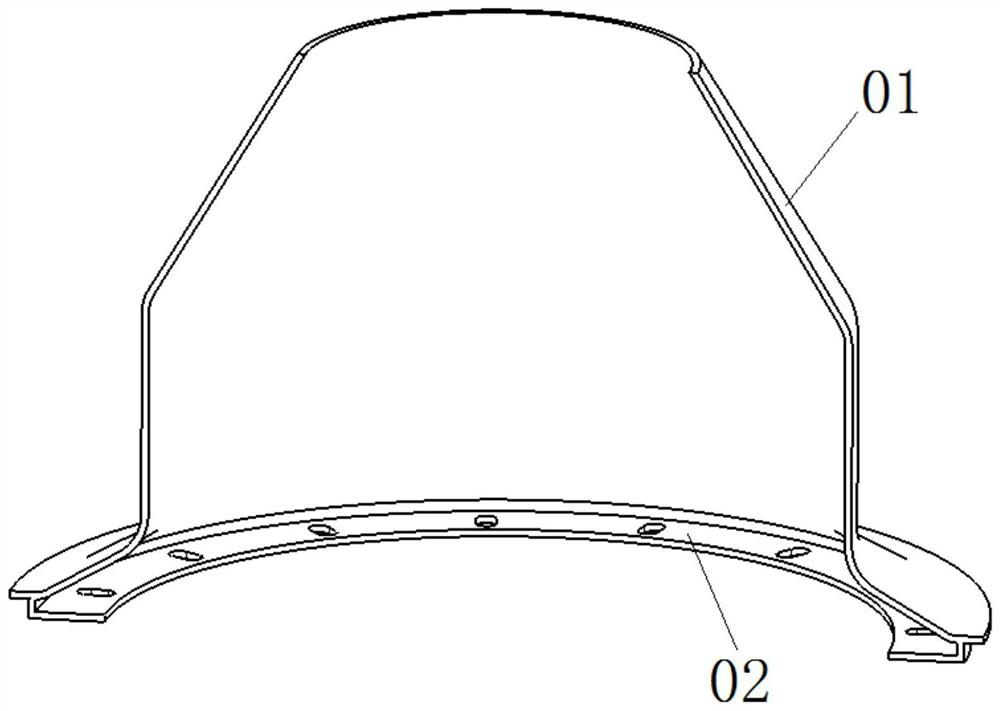

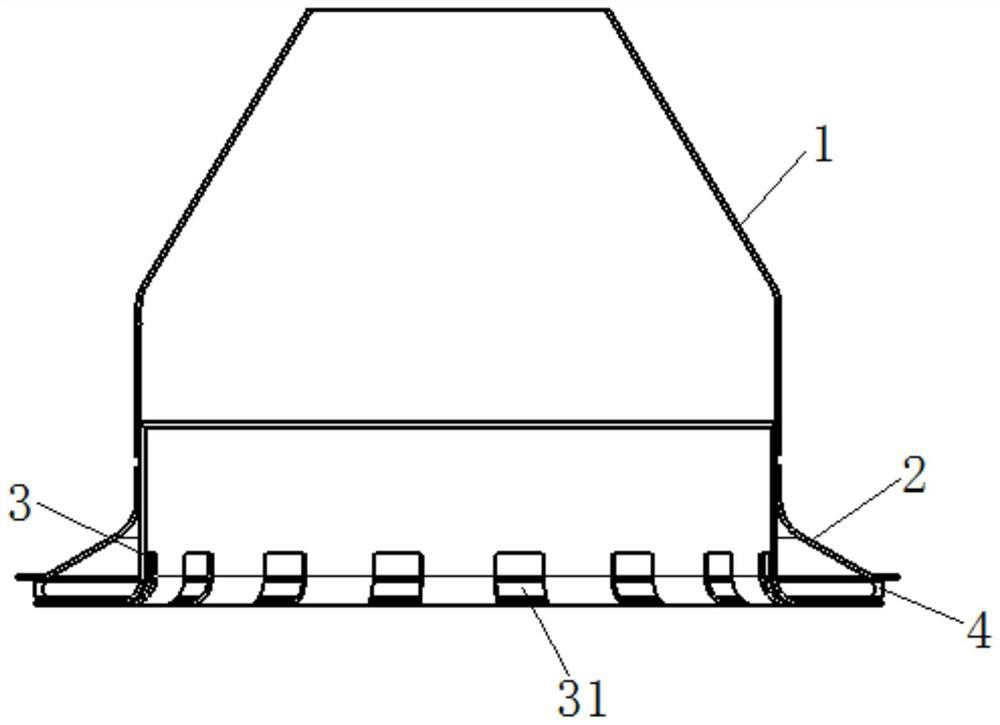

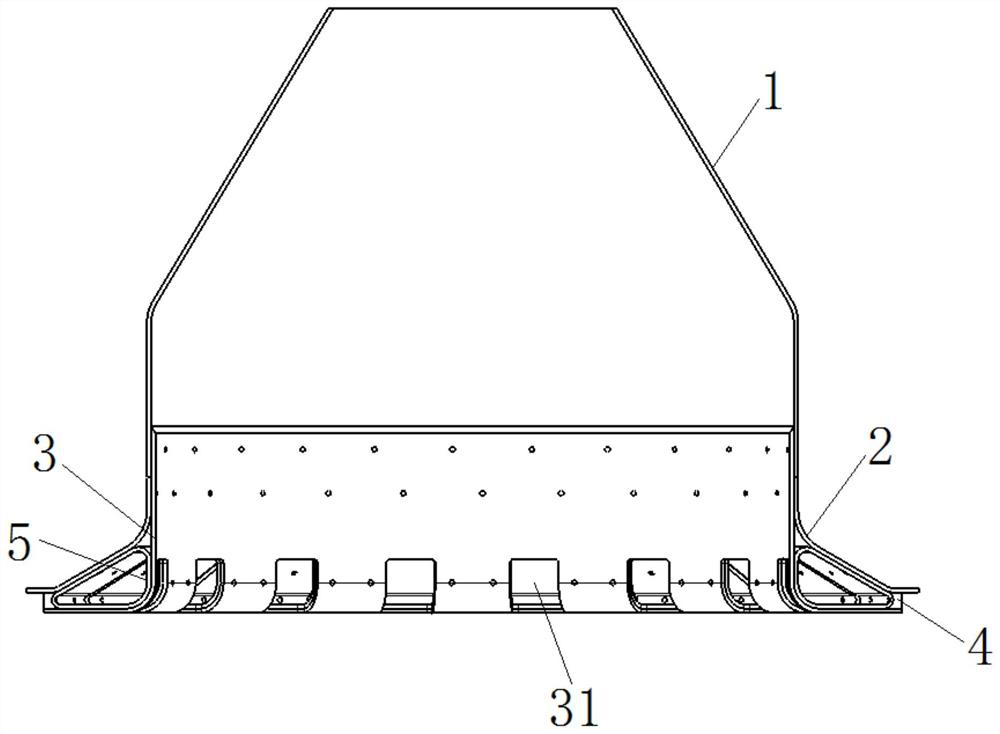

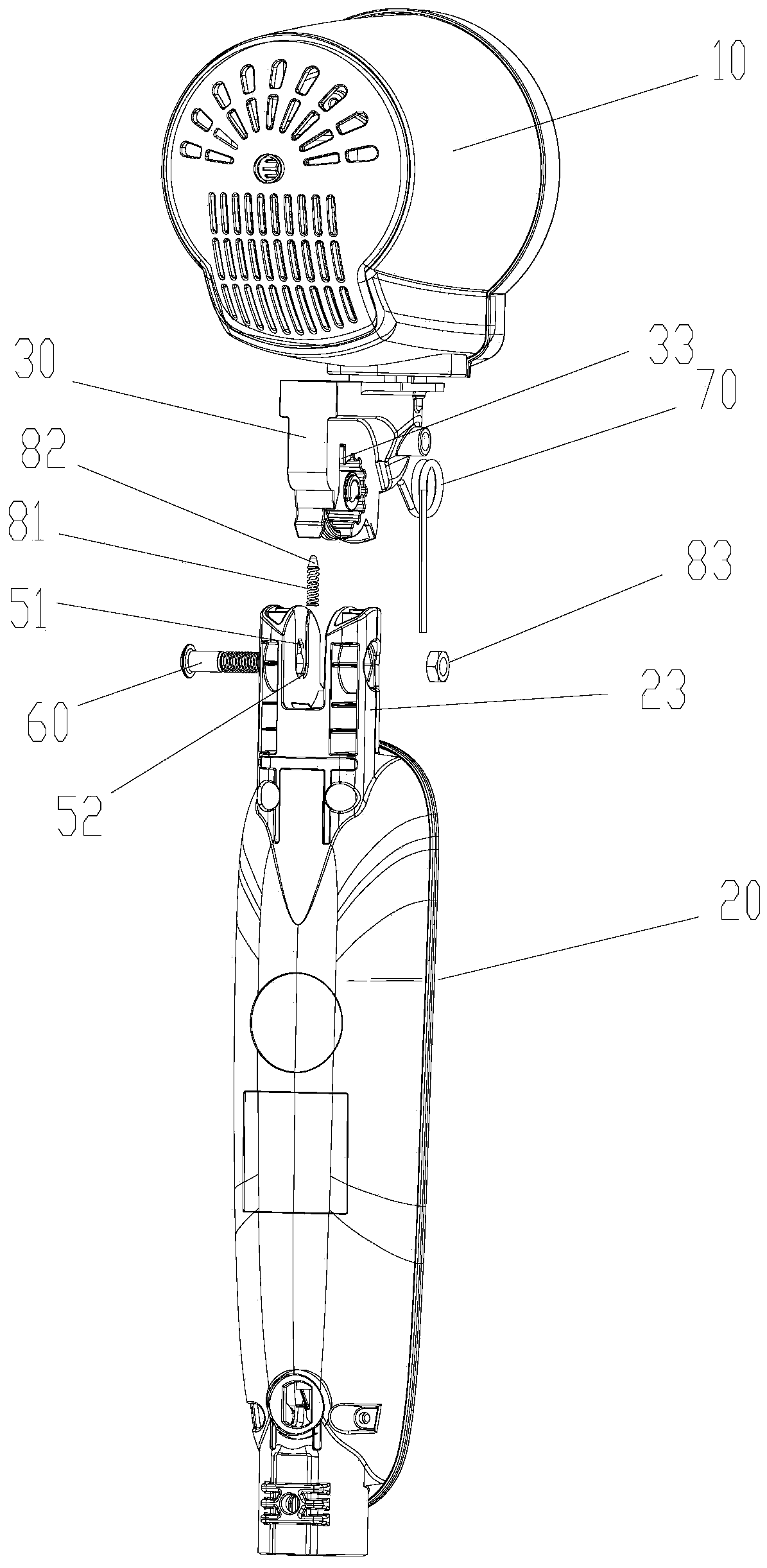

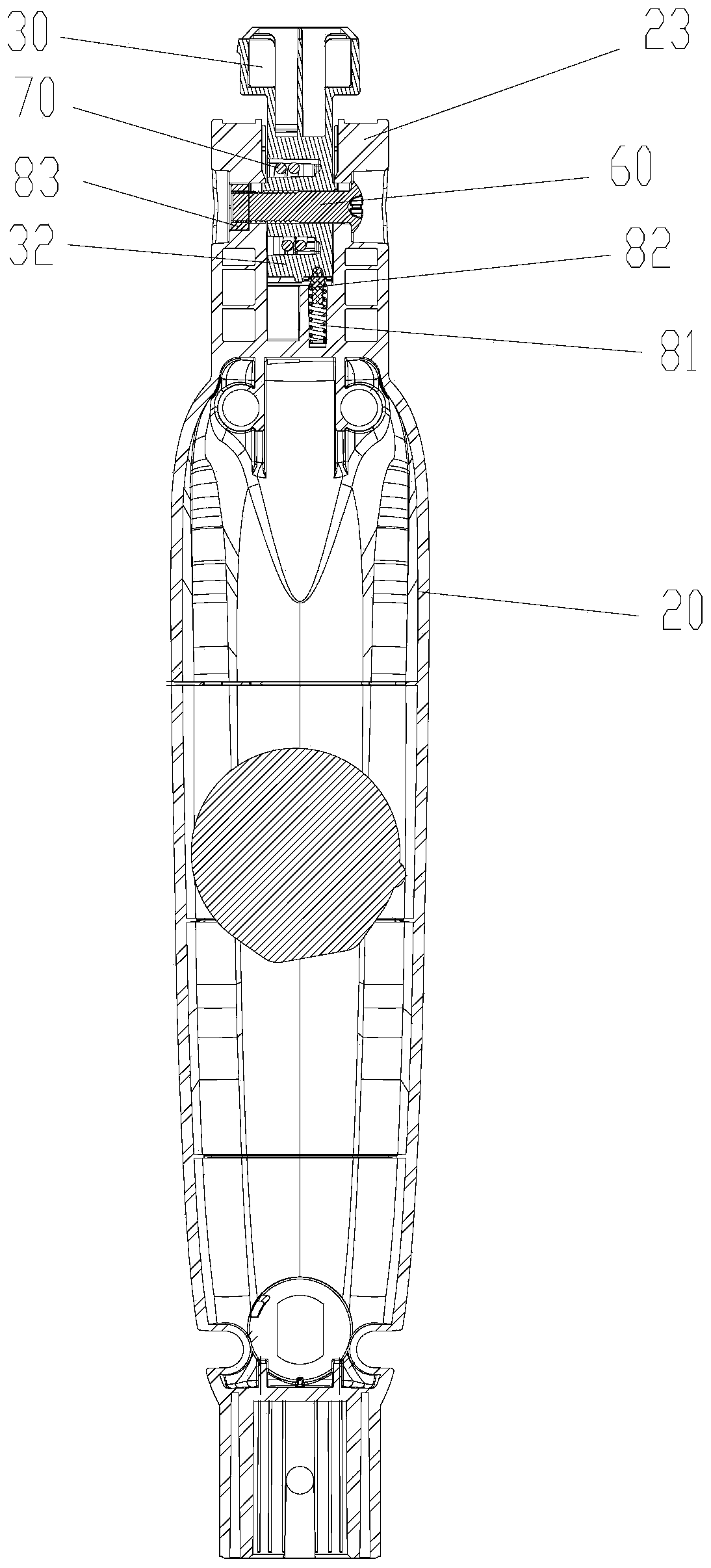

fan

ActiveCN105370628BSolve the difficulty of assemblyImprove fastnessPump componentsPumpsFuselageEngineering

The invention provides a fan. The fan comprises a fan head and a body housing; the fan head is connected with the body housing through a regulating box; a stopping portion is arranged on the body housing; a limiting portion matched with the stopping portion for stopping is arranged on the regulating box so as to weaken or counteract a counter acting force of a torsional spring and / or a positioning spring of the fan on the regulating box. The fan of the present invention is used for solving the problem of great assembly difficulty of a fan in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

gripping equipment

ActiveCN112621156BAvoid separationReduce the difficulty of assemblyMetal working apparatusEngineeringVALVE PORT

The invention provides a clamping device, which comprises: a movably arranged installation; an adsorption component, which is fixedly arranged on the installation plate and used for sucking a workpiece; a pressing component, which is fixedly arranged on the installation plate and used for connecting with the workpiece Abutting; after the adsorption component releases the workpiece, the workpiece is kept in contact with the mounting base through the pressing component; the pushing component is installed on the mounting plate; the pushing component includes a pushing portion, which is movably arranged to meet The workpiece abuts and pushes the workpiece to a preset position on the mounting base. The clamping device integrates adsorption components, pressing components and pushing components. The overall structure is relatively compact and occupies less space. Using this clamping device, the valve cover can be flexibly and accurately installed on the outer unit of the air conditioner, so that the valve cover can be flexibly and accurately installed. The assembly difficulty is reduced, and the problem that the valve cover is difficult to assemble due to the valve cover installation method in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

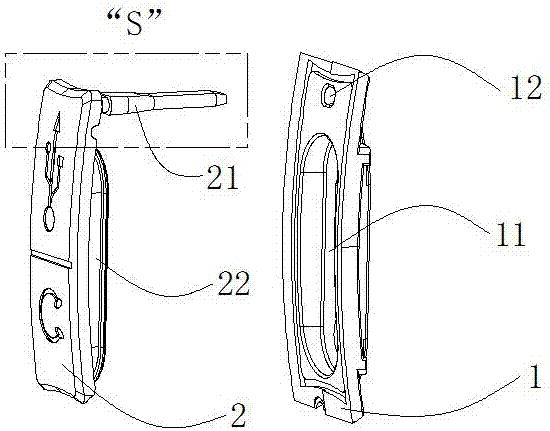

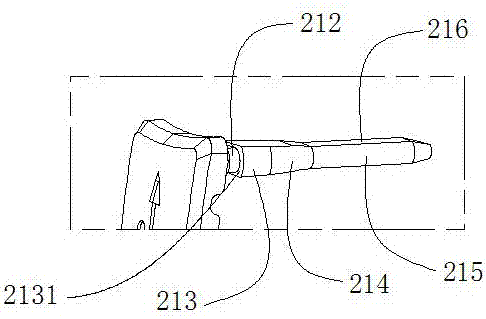

Screw cap rubber plug knob waterproof structure

PendingCN107370857AEasy to assembleSolve the difficulty of assemblyTelephone set constructionsEngineeringMechanical engineering

The invention relates to a screw cap rubber plug knob waterproof structure, comprising a housing and a screw cap rubber plug. The rubber plug comprises a knob. The knob is on the housing. The knob is provided with a convex hull structure in an annular manner. The convex hull structure and the housing are in extrusion interference. Since the waterproof structure is just provided with the convex hull structure and the housing which are in extrusion interference to realize waterproofness, enough interference magnitude can be set to ensure waterproof effect, and assembly is simple and convenient. Since the convex hull structure is just a local bulge protruded on the knob, no matter pulling assembling actions in an assembling process or the waterproof plug is opened and pulled to the knob in a screw cap manner in use by a user, acting forces mainly act on a main part of the knob, and an acting force on the convex hull structure is very low, so as to effectively solve problems in the prior art of waterproofing failure since the knob is pulled repeatedly.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

Single tooth roller crusher grate plate protection live block for easy disassembly and replacement

ActiveCN105413803BEasy to disassembleShaking phenomenon solvedGrain treatmentsPulp and paper industryCrusher

The invention relates to a grate plate protection movable block of a single-tooth roller crusher convenient for disassembly and replacement. The grate plate protection movable block comprises a grate plate body and a protection movable block connected with the grate plate body, and is characterized in that the protection movable block consists of a left end movable block, a right end movable block and a middle movable block; the normal sections of the left and right end movable blocks and the middle movable block are long structural bodies with triangular upper parts and having regular trapezoidal insertion grooves in the lower parts; bolt holes are formed in the middle lower parts of the left and right end movable blocks and the middle movable block; the grate plate body is a long grate plate having regular trapezoidal bosses, matched with the regular trapezoidal insertion grooves, in the middle parts; bolt holes are also formed in the grate plate body; the regular trapezoidal insertion grooves of the protection movable block and the regular trapezoidal bosses of the grate plate body are inserted, and are fixedly connected through bolts, nuts and spring washers. The grate plate protection movable block has the advantages of simpleness and convenience for replacement, reduction of maintenance workload, shortening of maintenance time and reduction of spare part consumption.

Owner:贾利新

Differential planetary gear structure and vehicle

ActiveCN105485291BSimple structureCompact structureDifferential gearingsWheel and axleAutomotive engineering

The invention provides a differential planetary gear structure which comprises a driven gear, a planetary gear carrier, planetary gears, a left half axle gear, a right half axle gear, a left half axle and a right half axle, wherein the left half axle gear is arranged on the left half axle, the right half axle gear is arranged on the right half axle, the left half axle gear and the right half axle gear are meshed with the planetary gears respectively, each planetary gear comprises an axle and a gear fixed at one end of the axle, the axle is rotationally arranged on the planetary gear carrier, the planetary gear carrier is arranged on the driven gear and rotates with the driven gear synchronously, and the driven gear is rotationally arranged on the left half axle or the right half axle in a sleeving manner. The invention further relates to a vehicle. The differential planetary gear structure and the vehicle are simple and compact in structure, omit a straight axle or a cross axle between the two planetary gears compared with a traditional differential, reduce the processing difficulty and the processing and manufacturing costs, are simpler to assemble and have good extendability and universality.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

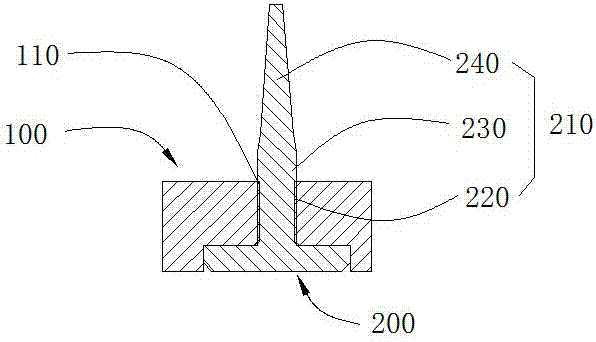

Sealing cutter for thermal shrinkage film yardage roll packaging machine

InactiveCN103158904BSolve the difficulty of assemblyLow costWrapper twisting/gatheringElectricityEngineering

The invention discloses a sealing cutter for a thermal shrinkage film yardage roll packaging machine. The sealing cutter is characterized by comprising a base. The lower end face of the base is a seal face which is a plane. A protruding rib is integrally arranged on the seal face. The protruding rib is equal to the seal face in length and divides the seal face into two parts with the equal width. A heating pipe installation hole and a thermo-electricity coupler installation hole are formed in the base. A connecting line from the center of the heating pipe installation hole to the center of the thermo-electricity coupler installation hole coincides with an axial line of the center of the protruding rib, and the perpendicular distance from the center of the heating pipe installation hole to the top end of the protruding rib is equal to the perpendicular distance from the center of the thermo-electricity coupler installation hole to the top end of the protruding rib. The sealing cutter has the advantages of being simple in structure, easy to assemble, low in cost, and good in sealing-cutting effect.

Owner:YUYAO TEXTILE MACHINERY

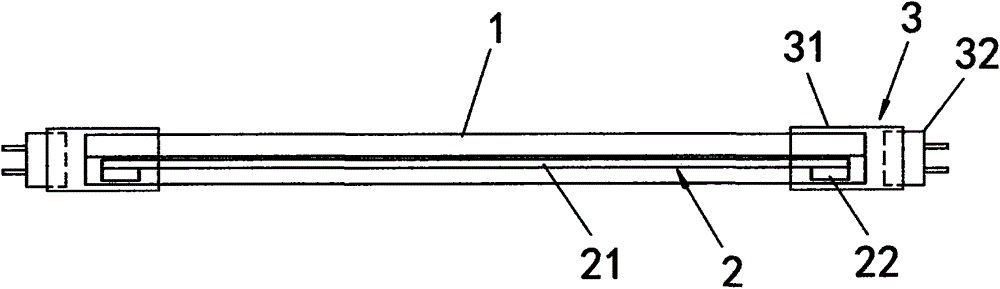

Electronic equipment

ActiveCN112995377ASolve the difficulty of assemblyTelephone set constructionsMechanical engineeringElectrical and Electronics engineering

The invention discloses electronic equipment, and relates to the technical field of communication. The electronic equipment comprises a display screen, wherein the display screen comprises a display screen body and a cover plate, the cover plate is a cylindrical cover plate, the display screen body is covered with the cover plate, and the display screen is provided with a first end and a second end which are opposite to each other; and a support assembly, wherein the support assembly is connected with at least one of the first end and the second end, and at least part of the support assembly is located in the display screen. According to the scheme, the problem that when a display screen of a cylindrical structure is adopted by an existing electronic device, the assembling difficulty is great can be solved.

Owner:VIVO MOBILE COMM CO LTD

A Novel 3D Microwave Multichip Component Structure

ActiveCN105977235BSolve the difficulty of assemblySolve the sealing problemSemiconductor/solid-state device detailsSolid-state devicesMicrowaveEtching

The invention discloses a novel three-dimensional microwave multi-chip module structure, and relates to the field of microwave microelectronic packaging. The structure comprises a bottom silicon chip, an MMIC chip, a top silicon chip and an ASIC chip from the bottom to the top. The bottom silicon chip is provided with a chip installation groove through etching, and the surface of the bottom silicon chip is plated with a first metal layer. The MMIC chip is bound at the bottom of the chip installation groove through a conductive glue layer, and the upper surface of the MMIC chip and the upper surface of the bottom silicon chip are sequentially provided with a sealed protection layer, a second metal layer and a first solder mask layer. A part, corresponding to the chip installation groove of the bottom silicon chip, of the bottom of the top silicon chip is provided with a bottom groove in an etching manner. The corresponding parts of the bottom and top silicon chips are respectively provided with a welding ball convex point pole in an etching manner. A third solder mask layer of the top silicon chip is provided with a metal electrode in an etching manner, and the ASIC chip is welded on the metal electrode of the top silicon chip. The technological production of a three-dimensional microwave multi-chip module is completed in a mode of wafer level through employing a silicon cavity structure and benzocyclobutene secondary wiring, and the production efficiency is improved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

A micro switch automatic assembly production system and a sorting and feeding device

ActiveCN109346348BSolve the difficulty of assemblyImprove pass rateElectric switchesSortingRobot handElectronic component

Owner:昆山晟欧威自动化科技有限公司

A ceramic matrix composite inner cone and its processing method

ActiveCN112577068BSolve the process problems that are difficult to formEasy to installContinuous combustion chamberEngineeringUltimate tensile strength

The invention relates to a ceramic matrix composite material inner cone and a processing method thereof, to solve the problem that the process of preparing the ceramic matrix composite material inner cone according to the traditional design scheme is difficult to realize, the structural strength is difficult to meet the requirements, and the assembly with the mounting seat is difficult. question. The inner cone includes an upper cone surface, a lower cone surface, an inner cone surface, and a surrounding member. The upper cone surface and the lower cone surface are joined, and the butt joint is located outside the end of the inner cone surface, and the lower end of the inner cone surface extends outward. And its outer edge corresponds to the outer edge of the lower end of the lower conical surface, the upper and lower sides of the surrounding member are respectively connected with the outer edge of the lower end of the lower conical surface and the outer edge of the lower end of the inner conical surface, and the lower end of the inner conical surface is circumferentially provided with Multiple bolt mounting holes. The processing method includes: 1) Using ceramic matrix composite materials to process the upper cone surface, lower cone surface, inner cone surface and surrounding member; 2) Set the upper cone surface and the lower cone surface on the outside of the inner cone surface, The shaped member is installed between the lower cone surface and the inner cone surface, and is fixed by online riveting technology.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Circuit breaker and its operating mechanism

ActiveCN111341607BSolve the difficulty of assemblySwitching device condition indicationProtective switch operating/release mechanismsDrive shaftActuator

The invention relates to a circuit breaker and its operating mechanism. The circuit breaker includes an arc extinguishing chamber with a moving contact and an operating mechanism connected with the moving contact in the arc extinguishing chamber. The operating mechanism includes a main body frame, on which an output shaft and an auxiliary switch are arranged. The mechanism also includes an indicator plate that is swingably mounted on the main body frame to indicate the working state of the operating mechanism, the output shaft is provided with an output crank arm, and the auxiliary switch has a drive shaft for realizing the auxiliary switch action. The drive shaft is provided with a first crank arm and a second crank arm, and an auxiliary switch driving link is hinged between the output crank arm and the first crank arm; the indicator board is correspondingly provided with a driving crank arm for driving the indicator board action , there is an indicator drive connecting rod hinged between the driving crank arm and the second crank arm. The state switching of the auxiliary switch and the indicator board is realized through a set of link mechanism, which reduces the number of parts of the operating mechanism and is easy to assemble.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

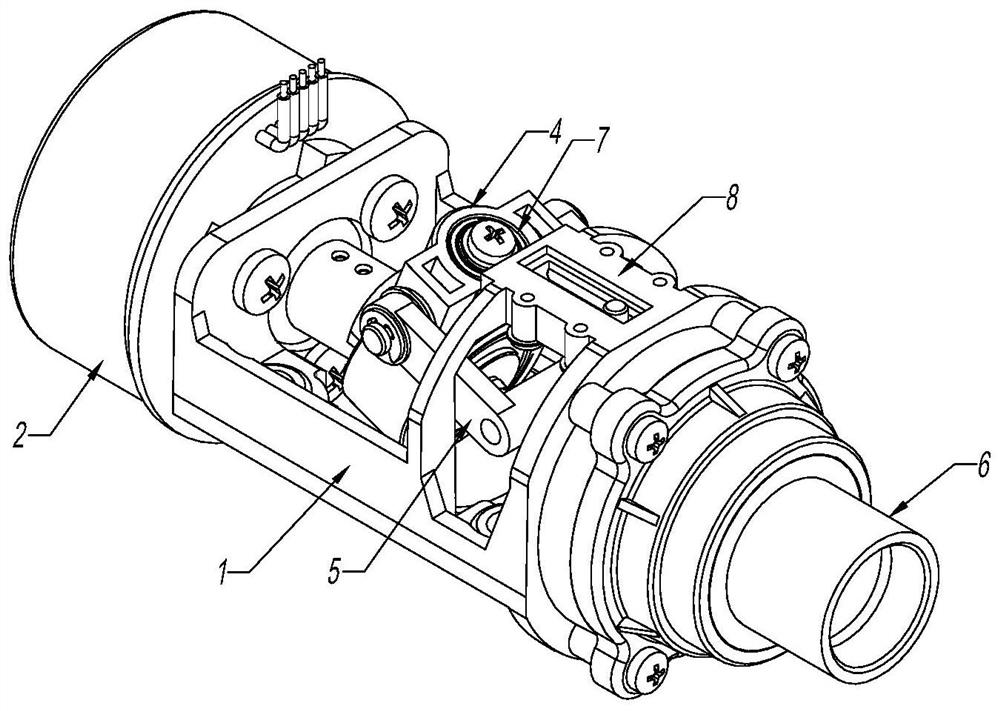

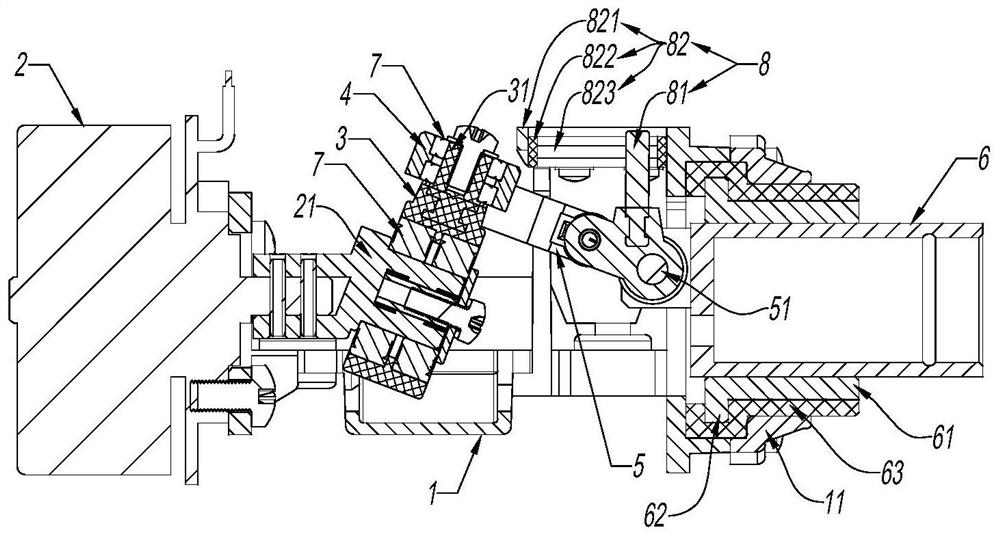

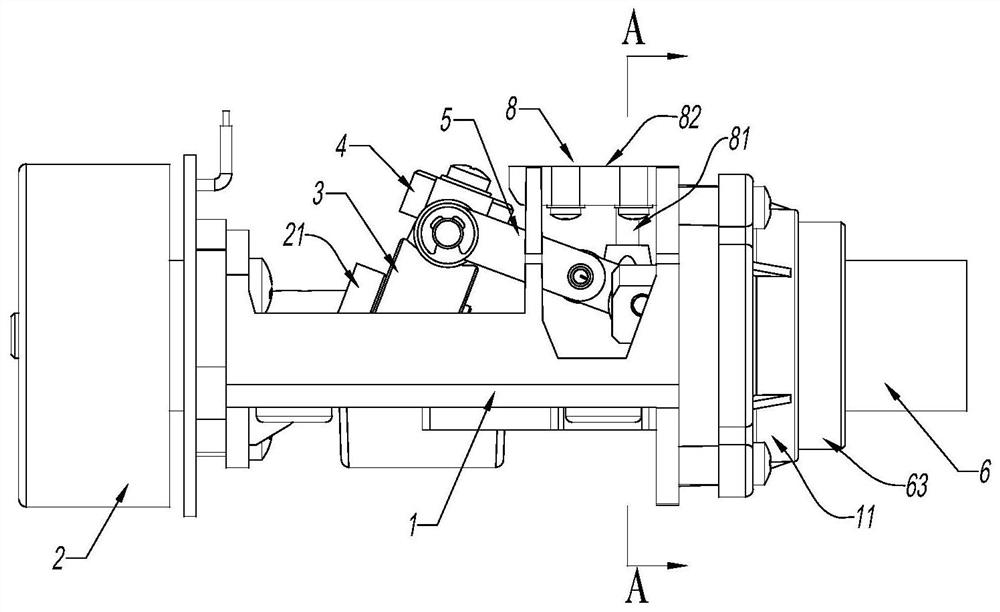

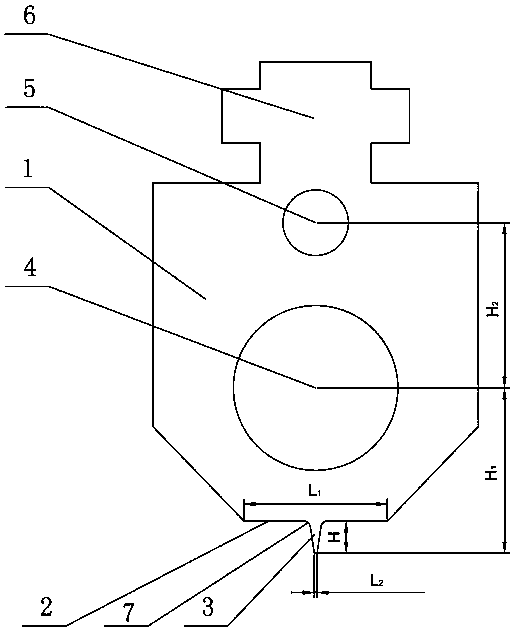

Self-aligning rail type impact massage machine core

PendingCN114306032AGuaranteed flexibilityFlexible movementVibration massageReciprocating motionCoupling

The invention relates to a self-aligning rail type impact massage machine core which comprises a core frame, a motor, an inclined mandrel, a swing block, a universal coupling, a connecting rod, an impact shaft and an impact shaft sleeve. The motor and the impact shaft sleeve are correspondingly fixed to the two ends of the core frame, and the motor drives the inclined mandrel to rotate and drives the impact shaft to do reciprocating rectilinear motion along the impact shaft sleeve through the swing block, the universal shaft joint and the connecting rod. Wherein a guide mechanism is further arranged, and the guide mechanism comprises a self-aligning rod and a track groove; the aligning rod is locked on a non-rotating moving part in the impact shaft transmission chain; the rail groove is formed in the core frame and restrains the movement direction of the aligning rod. According to the invention, the self-aligning rod is matched with the track groove, so that the reciprocating motion of the impact shaft is restrained, the motion flexibility of each part is ensured, unnecessary wear is reduced, and the difficulty of processing and assembling is solved. The whole device has the advantages of being compact in structure, flexible in movement matching, low in noise and free of twisting.

Owner:厦门岱锐斯智能科技有限公司

Manufacturing process of sealing cutter for heat shrinkage film cloth roll packaging machine

InactiveCN107867451ASolve the difficulty of assemblyPrevent adhesionPackagingEngineeringVertical distance

The invention discloses a sealing cutter for a heat shrinkage film cloth roll packaging machine. The cutter is characterized by comprising a base, the lower end face of the base is a sealing face, thesealing face is a plane, a convex rib is integrally arranged on the sealing face, the convex rib is equal to the sealing face in length, the sealing face is divided into two parts with the same width, a heating pipe mounting hole and a thermocouple mounting hole are formed in the base, the connecting line of the centre of the heating pipe mounting hole and the center of the thermocouple mountinghole coincides with the central axis of the convex rib, and the vertical distance between the center of the heating pipe mounting hole and the top end of the convex rib is equal to the vertical distance between the center of the thermocouple mounting hole and the top end of the convex rib. The sealing cutter has the beneficial effects of being simple in structure, easy to assemble, low in cost andgood in sealing cutting effect.

Owner:合肥果成科技有限公司

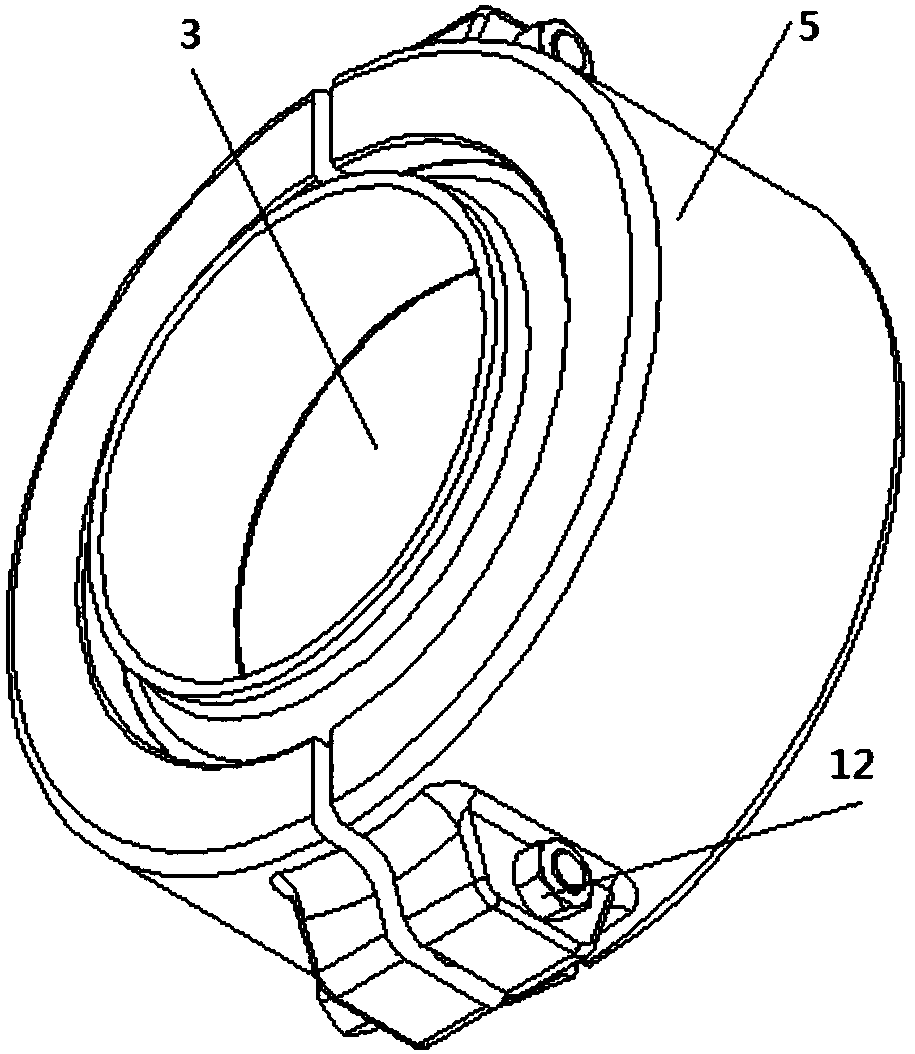

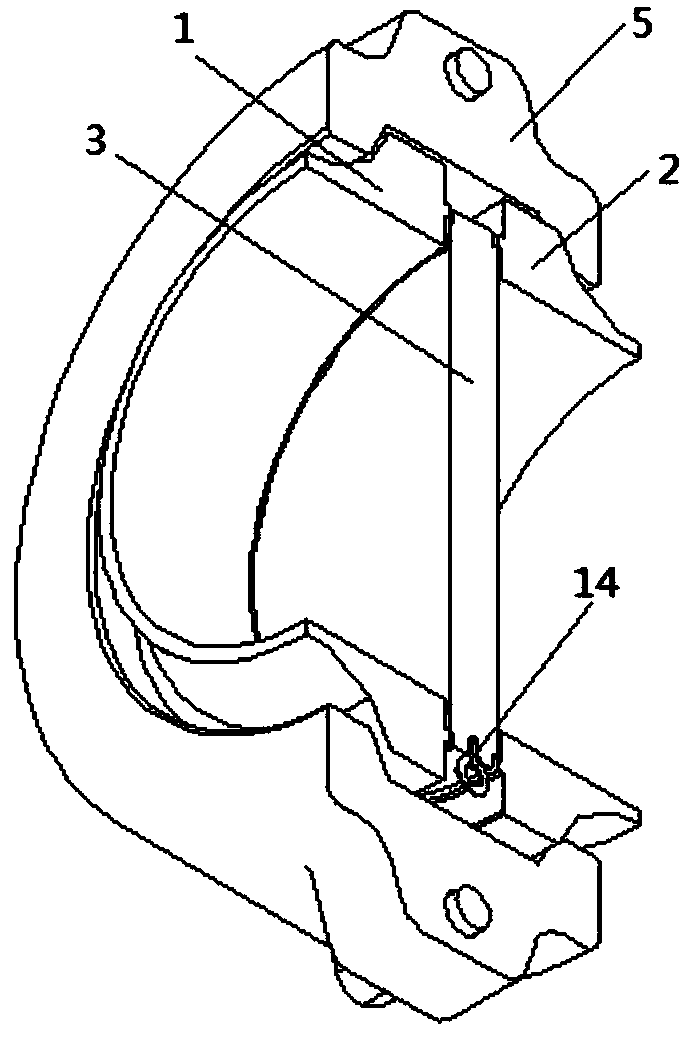

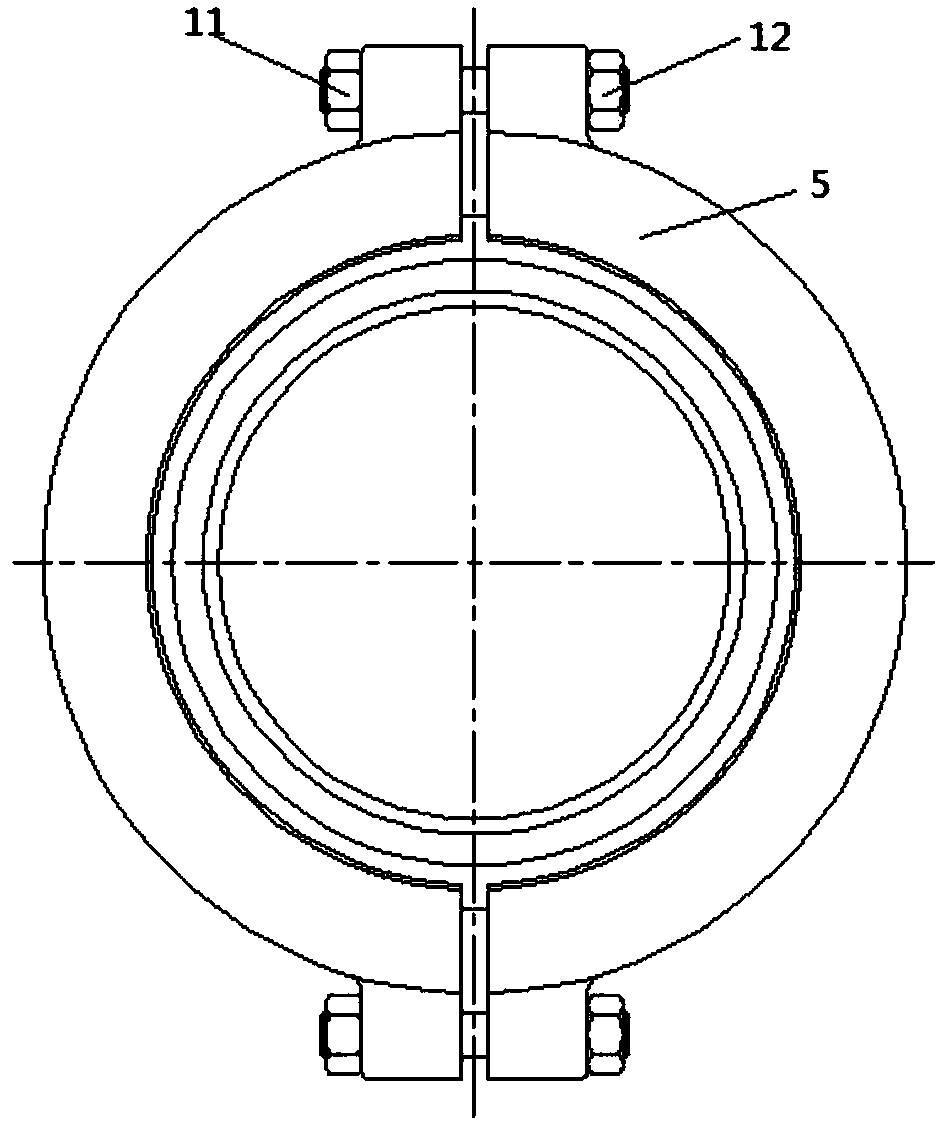

A hydrostatic test plugging valve

ActiveCN106090526BSimple structureEasy to processPipe elementsFluid-tightness measurement using fluid/vacuumVALVE PORTHydraulic test

Owner:NANTONG POWER STATION VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com