Single tooth roller crusher grate plate protection live block for easy disassembly and replacement

A technology of convenient disassembly and grate plate, applied in the direction of grain processing, etc., can solve the problems of inability to disassemble the movable block, breakage of the movable protective cap, and accelerated wear of the movable block, so as to reduce the maintenance workload, shorten the maintenance time, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

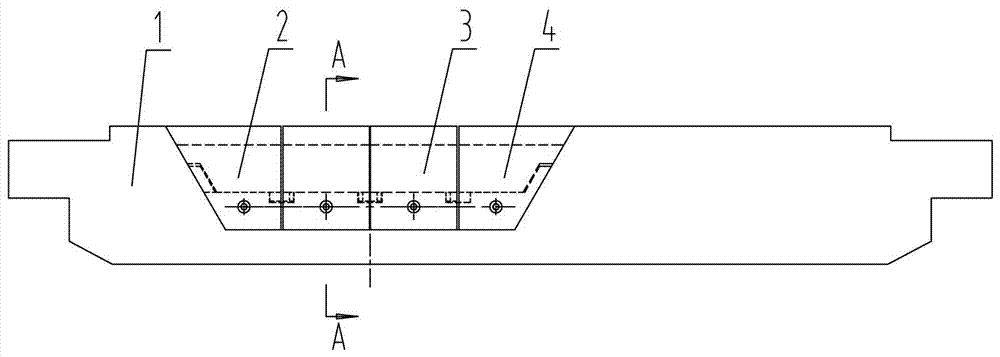

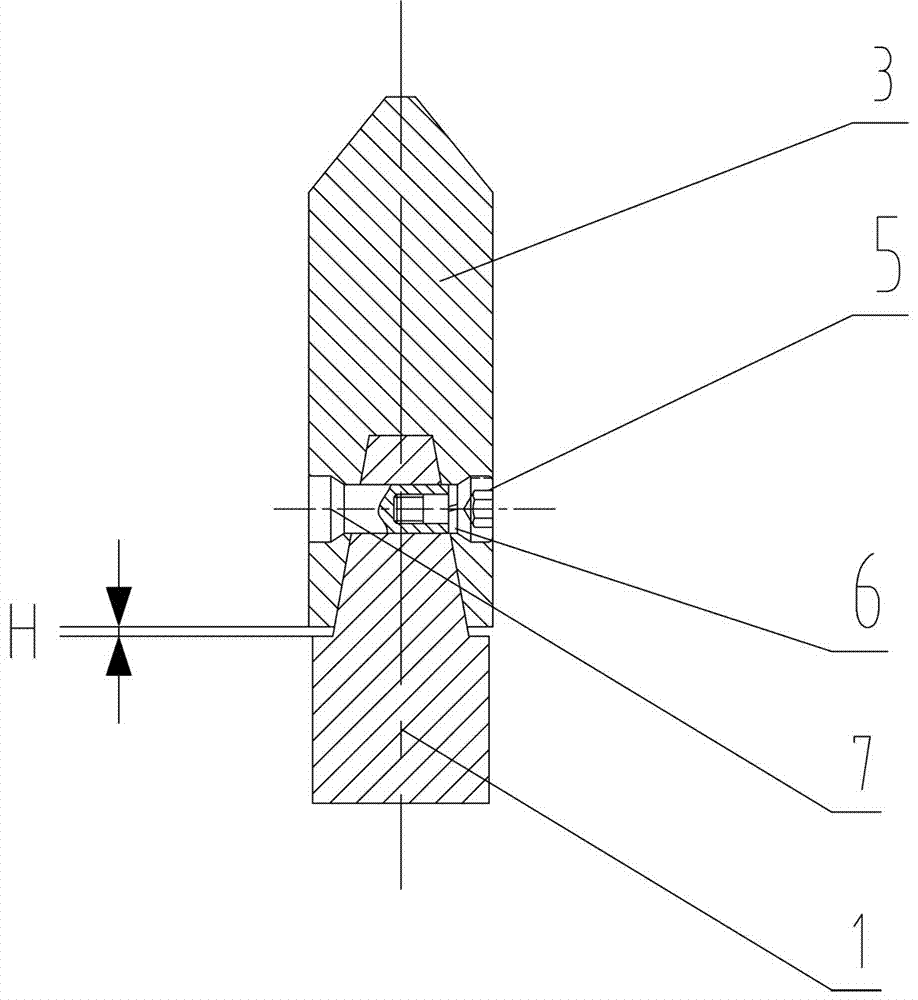

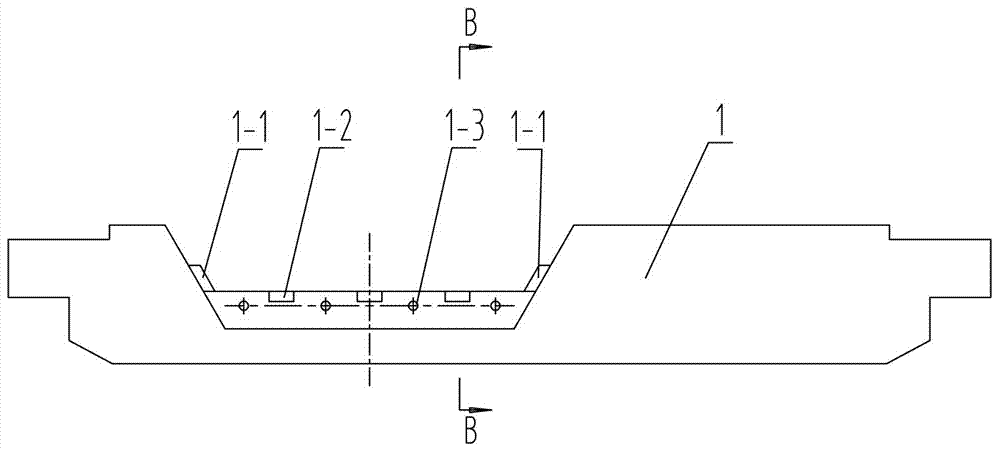

[0033] Such as Figure 1-8 As shown, a kind of single-toothed roller crusher grate plate protection block of the present invention which is convenient to disassemble and replace includes a grate plate body 1 and a protection block connected with the grate plate body 1, which is characterized in that the protection block It is composed of the left end movable block 2, the right end movable block 4 and the middle movable block 3. The connecting surface of the left end movable block 2, the right end movable block 4 and the grate plate body 1 is a slope with a large upper part and a smaller lower part, and is connected with the central part. The surface is straight, and the front section of the left end movable block 2 and the right end movable block 4 is a triangular upper part, and an elongated structure with a positive trapezoidal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com