A hydrostatic test plugging valve

A technology of hydraulic test and valve blocking, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., which can solve the problems of long time-consuming disassembly and assembly of blocked valves, difficulty in disassembly and assembly of blocked valves, and long production cycle. , to achieve the effect of simple and quick disassembly and assembly, difficult assembly, and small installation space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

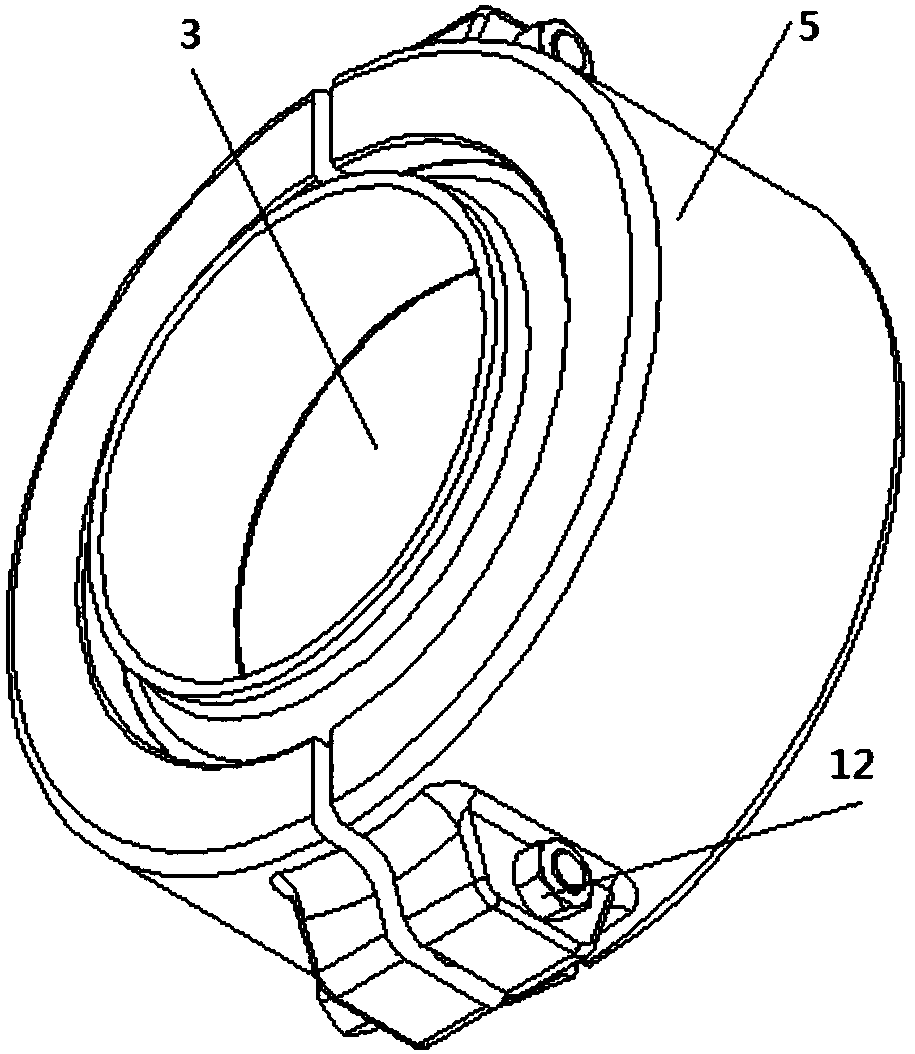

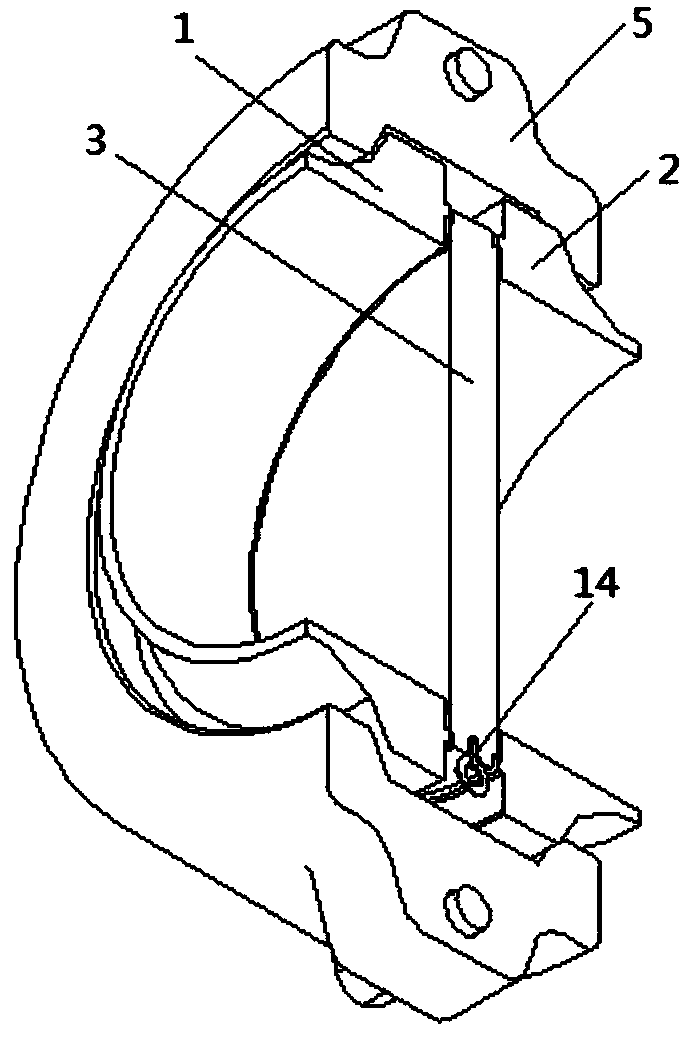

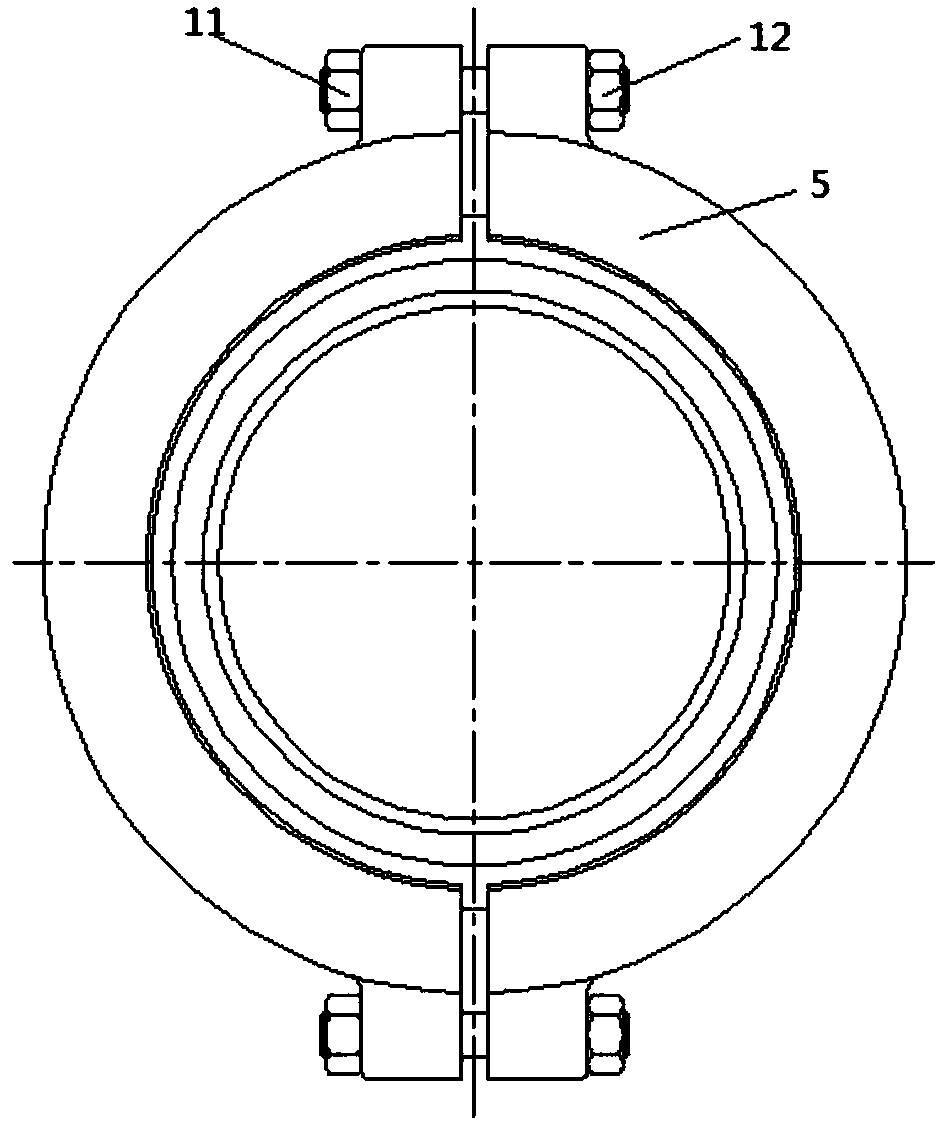

[0036] like Figure 1 to Figure 10 As shown, a plugging valve for a hydraulic test of the present invention includes a left flange 1, a right flange 2, a connecting mechanism and a clamp 5, and the size of the left flange 1 and the right flange 2 and the shape are the same, the connecting mechanism is arranged between the left flange 1 and the right flange 2, and the left flange 1 and the right flange 2 are embedded in the clamp 5 Inside, the connecting mechanism is a blocking plate 3 or a guide tube 4, the left flange 1 is provided with a groove I, and the right flange 2 is provided with a groove II, and the connecting mechanism and the The groove I of the left flange 1 is matched with the groove II of the right flange 2.

[0037] Further, the groove I on the left flange is set as an L-shaped groove I6, and the groove II on the right flange is set as an L-shaped groove II7.

[0038] Further, the connecting mechanism is a blocking plate 3, and the hydraulic test blocking val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com